Method for manufacturing powder coating material, coated article and method for manufacturing same, and method for manufacturing carboxyl-group-containing fluororesin

A technology of powder coating and manufacturing method, which is applied in the direction of powder coating, polyester coating, epoxy resin coating, etc., can solve the problem of poor weather resistance of cured film, and achieve the effect of excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

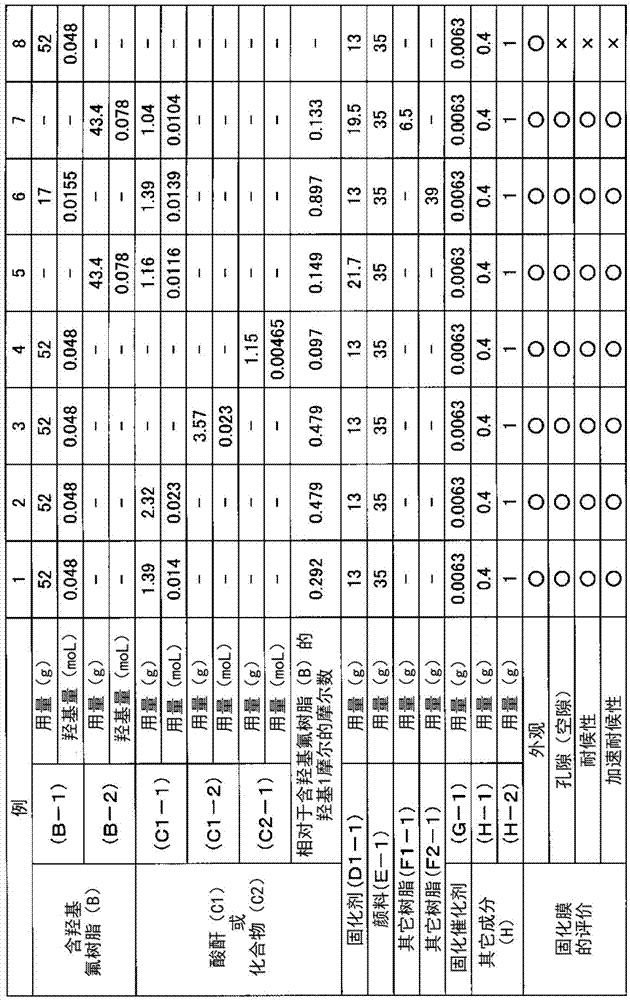

[0330] Hereinafter, examples and comparative examples are shown to describe the present invention in detail. However, the present invention is not limited to these. Examples 1-7 are examples, and Example 8 is a comparative example.

[0331] [measurement method, evaluation method]

[0332] (glass transition temperature)

[0333] Glass transition temperature is the midpoint glass transition temperature determined by differential scanning calorimetry (DSC) method.

[0334] (molecular weight)

[0335] The number average molecular weight and the mass average molecular weight are values obtained in terms of polystyrene by gel permeation chromatography (GPC) method.

[0336] (The average particle size)

[0337] The average particle size of the powder is measured using a laser diffraction particle size distribution analyzer (manufactured by Sympatec, Helos-Rodos) and obtained from the 50% average volume particle size distribution.

[0338] (Appearance of cured film)

[0339] ...

example 1~8

[0379](manufacturing of powder coatings)

[0380] The components described in Table 1 were mixed for about 10 to 30 minutes with a high-speed mixer (manufactured by Yuzaki Co., Ltd.) to obtain a powdery mixture. Using a twin-screw extruder (manufactured by ThermoPRISM, 16 mm extruder), this mixture was melt-kneaded at a cylinder set temperature of 120° C. for 2 minutes to obtain pellets. The pellets were pulverized at room temperature using a pulverizer (manufactured by FRITSCH Corporation, device name: Rotor-SpeedMill P14), and classified with a 150-mesh sieve to obtain a powder coating having an average particle diameter of about 40 μm.

[0381] In addition, for powder coatings, the infrared absorption spectrum is obtained by infrared spectroscopy. In the powder coating materials of Examples 1 to 3 and Examples 5 to 7, peaks of ester bonds and peaks of carboxyl groups accompanying the reaction of the hydroxyl group in the hydroxyl group-containing fluororesin (B) with the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com