Glass plate manufacturing method

A manufacturing method and glass plate technology, applied to the photoplate-making process of the patterned surface, instruments, and originals for photomechanical processing, etc., can solve the problems of adverse effects on the optical properties of the glass plate, and achieve excellent visibility and operability. Ease of use and reduced man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0121] Hereinafter, the present invention will be further described by way of examples.

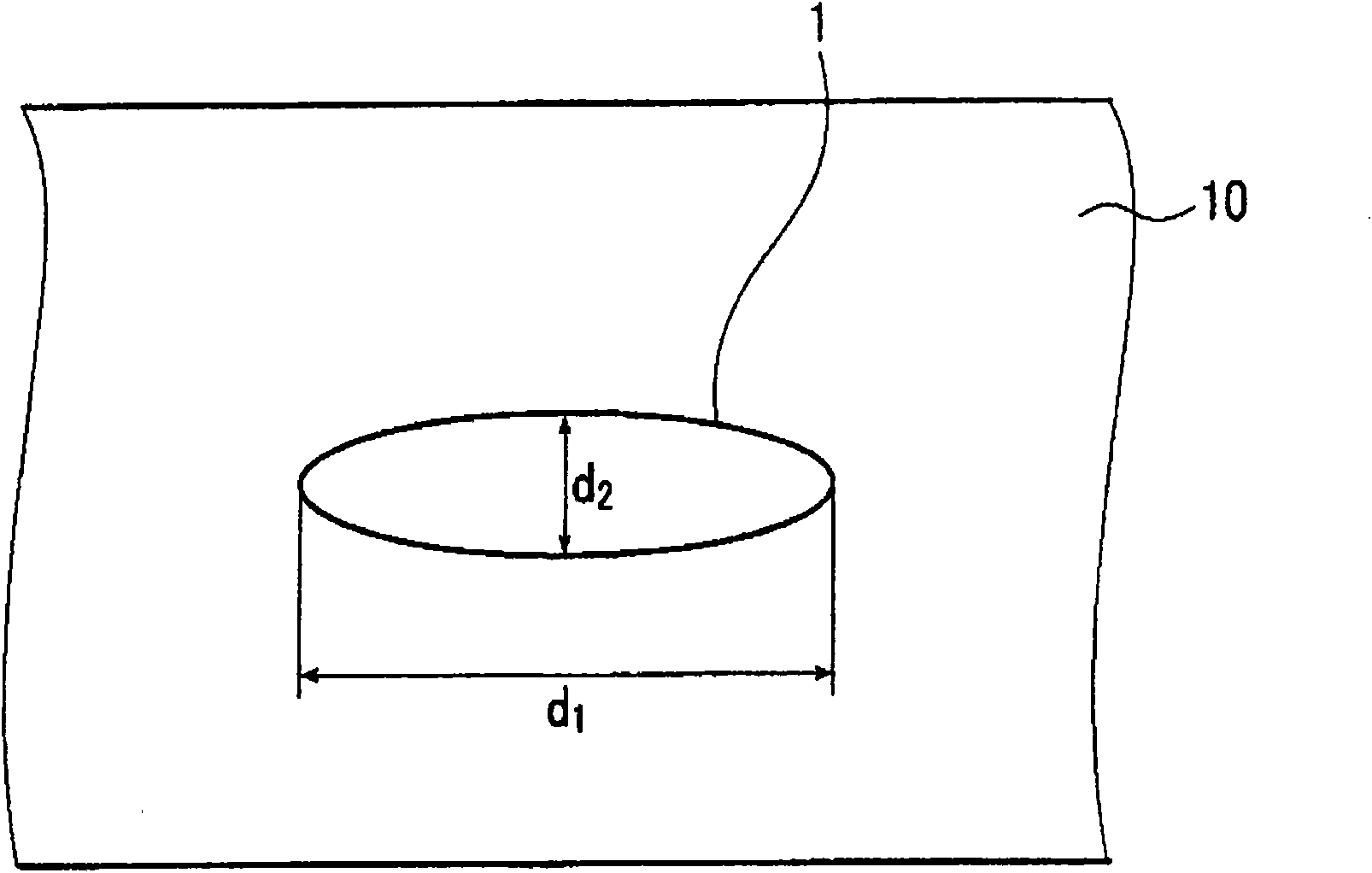

[0122] Prepare glass plates with air bubbles inside. The glass plate was a 3 cm×3 cm glass substrate for a liquid crystal display (trade name AN100, manufactured by Asahi Glass Co., Ltd., strain point 670° C., softening point 950° C.), and a thickness of 0.7 mm. The bubbles present in this glass plate had an approximately elliptical shape and a maximum diameter of 400 μm. Put the glass plate into the heating furnace, after the temperature of the glass plate is 800°C, from CO 2 The laser light source irradiated the bubbles in the glass plate under the following conditions.

[0123] Light form: continuous excitation light (CW light)

[0124] The maximum diameter of light on the surface of the glass plate: 1.4mm

[0125] Average output: 5W

[0126] Irradiation time: 10 seconds

[0127] After irradiation, the maximum diameter of bubbles shrinks from the initial 400 μm to about 200 μm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com