Laminate and filter of display using the same laminate

A laminated body and display technology, applied in the direction of optical filters, optics, instruments, etc., can solve the problems of lower pass rate, lower commodity value, lower durability, etc., and achieve less occurrence of white spots, high infrared reflectivity, The effect of high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0141] (1) Formation of transparent conductive filter laminate film

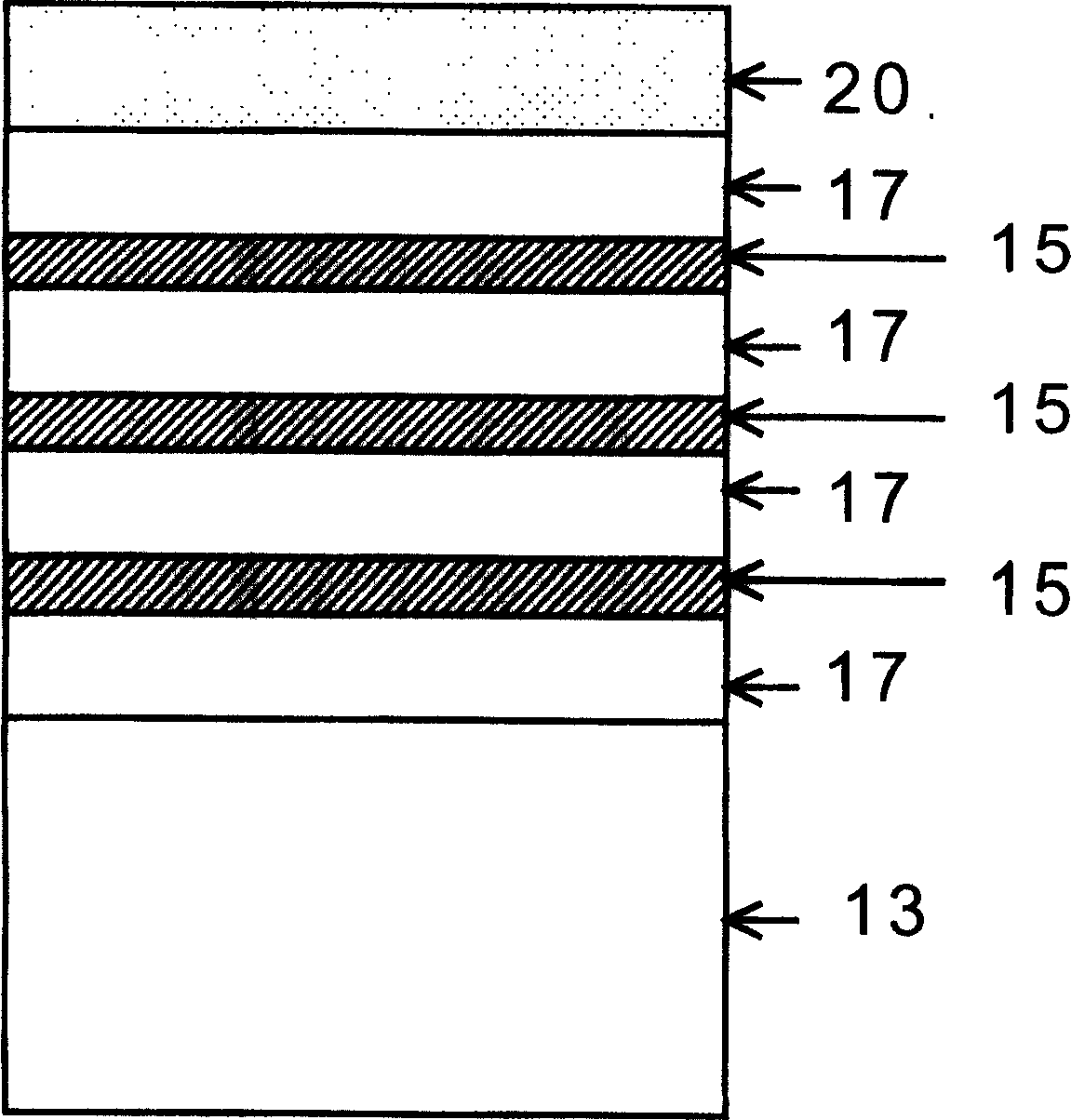

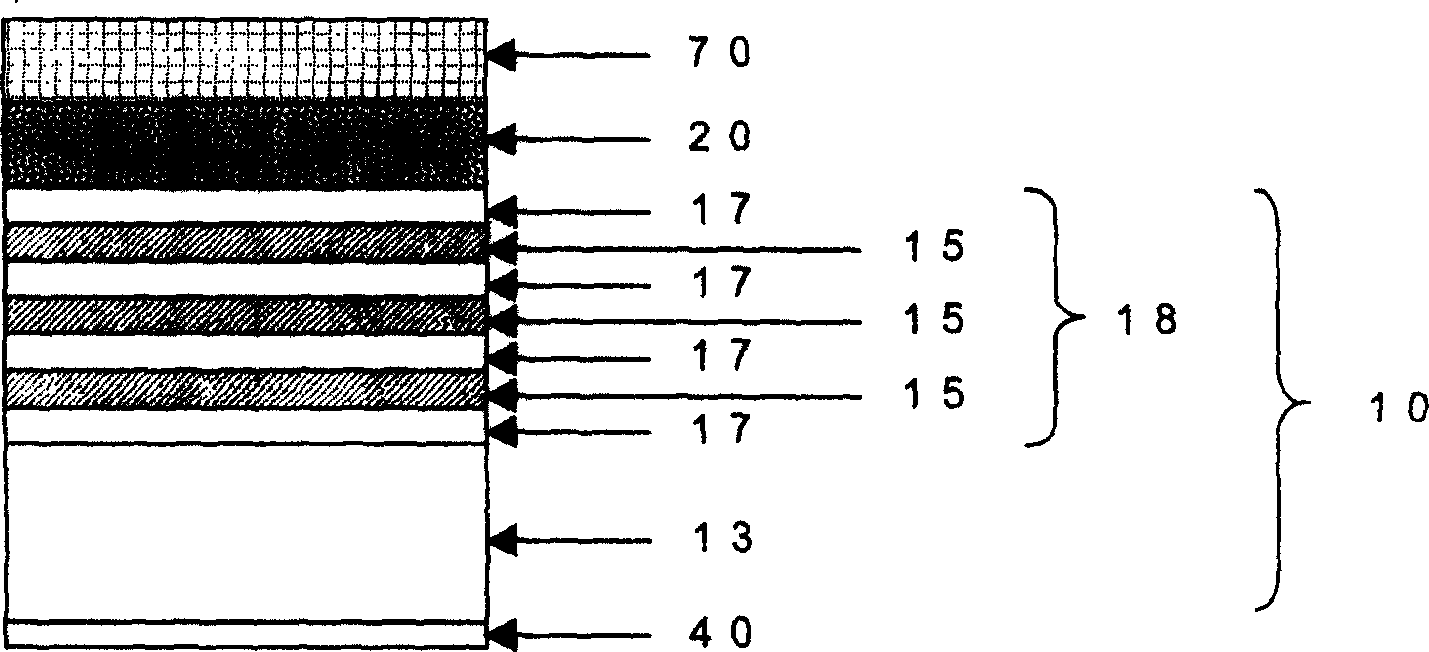

[0142] made and figure 1 The shown transparent conductive thin-film laminated film has the same configuration. That is, a polyethylene terephthalate film (thickness 75 μm) was used as a transparent substrate, and ITO made of oxides of indium and tin was sequentially laminated on one of its main surfaces using DC magnetron sputtering. filter layer (transparent high refractive index thin film layer) and silver thin film layer (transparent metal thin film layer) to obtain a transparent conductive thin film laminate film. The composition of the transparent conductive thin film laminate film is transparent film substrate (75μm) / ITO(40nm) / Ag(15nm) / ITO(80nm) / Ag(20nm) / ITO(80nm) / Ag(15nm) / ITO( 80nm).

[0143] Here, in the formation of ITO, an indium oxide-tin oxide sintered body (In 2 o 3 :SnO 2 =90:10 (mass ratio)), and an argon-oxygen mixed gas (total pressure 266 mPa, oxygen partial pressure 5 mPa) was used a...

Embodiment 2

[0155] Except that the thickness after coating and drying of the protective layer was 1 μm, it was produced in the same manner as in Example 1 to produce an optical filter for a display, and the results of the accelerated corrosion resistance test for this filter were shown in Table 1. middle.

Embodiment 3

[0157] In addition to using a coating liquid composed of polyester resin as a binder material and zinc oxide / antimony oxide as inorganic fine particles (trade name: Sumitomo Osaka Sementos Misefin) as the coating liquid, the thickness of the protective layer is 0.1 Except for μm, an optical filter for a display was fabricated in the same manner as in Example 1, and the results of the accelerated corrosion resistance test performed on the optical filter in the same manner are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com