Carbon fiber base fabric composite material and preparation method and application thereof

A carbon fiber cloth and composite material technology, which is applied to carbon fiber cloth-based composite materials and their preparation and application fields, can solve problems such as affecting CCL production operations, carbon fiber cloth base weft skew or warp and weft dispersal, fiber breakage, etc., and achieves thermal conductivity. And the effect of enhancing the system is good, the probability of white spots and white spots is reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

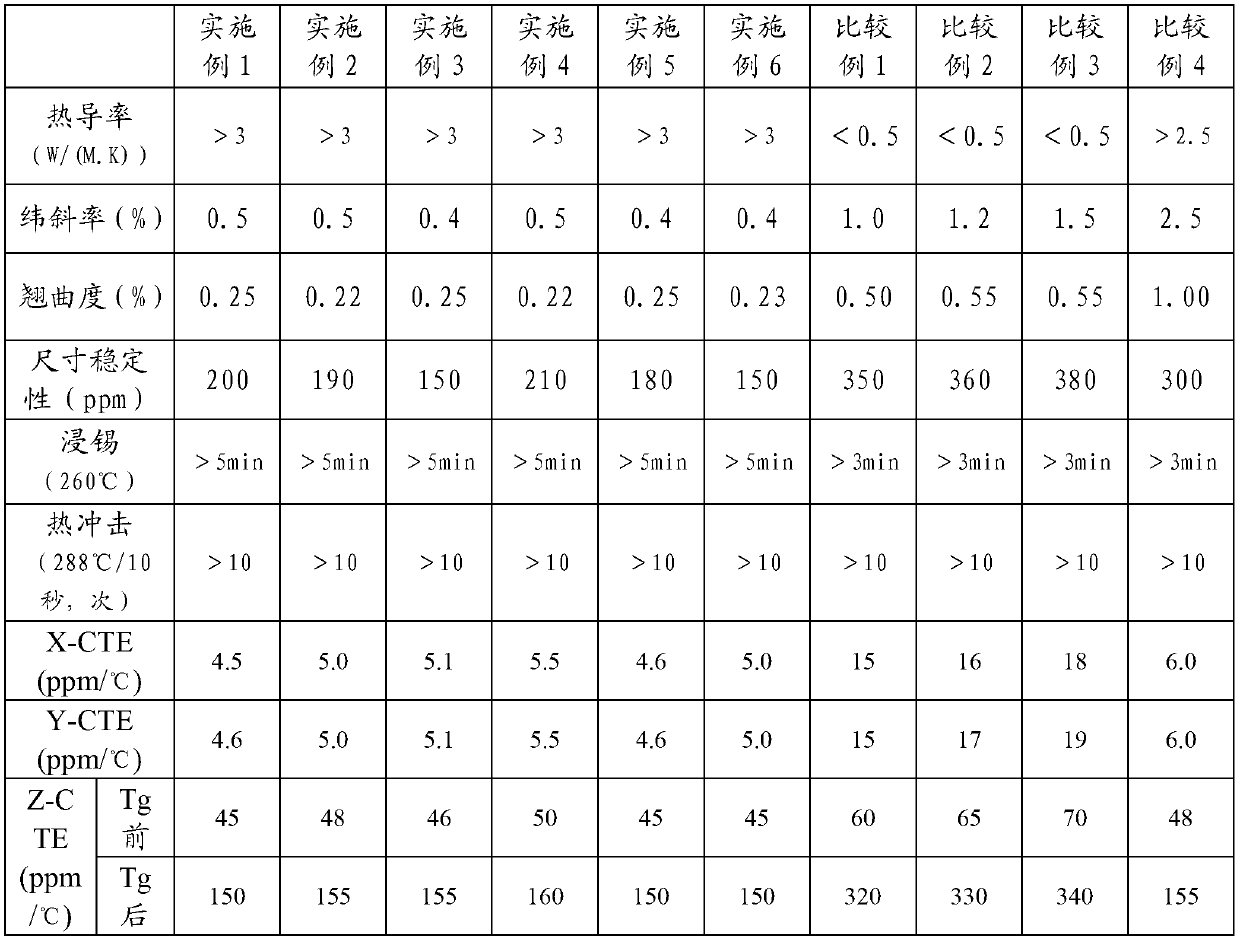

Examples

Embodiment 1

[0022] A carbon fiber cloth base composite material, including carbon fiber cloth base, epoxy resin layer and release film, the unit weight of carbon fiber cloth base is 125g / m 2 , the thickness of the epoxy resin layer is 50 μm.

[0023] The preparation steps of this kind of carbon fiber cloth-based composite material are as follows:

[0024] Step A: Prepare the glue, mix the epoxy resin and dicyandiamide in an equivalent ratio of 1:0.95, stir for more than 4 hours, control the gelation time index of the epoxy resin mixture within 300 seconds, and prepare the glue Dispersions;

[0025] Step B: Coat the above adhesive dispersion on the release film, put the release film coated with the adhesive dispersion in an oven, and bake at 80-160°C for 3 minutes to remove the solvent , to obtain a rubberized film layer;

[0026] Step C: Alternately stack the glued film layer and carbon fiber cloth prepared in step B, and the stacking sequence is as follows: glued film layer, carbon f...

Embodiment 2

[0029] A carbon fiber cloth base epoxy resin copper clad laminate, including carbon fiber cloth base, epoxy resin layer and copper foil, the unit weight of carbon fiber cloth base is 195g / m 2 , the thickness of the epoxy resin layer is 100 μm.

[0030] The preparation steps of this carbon fiber cloth-based epoxy resin copper-clad laminate are as follows:

[0031] Step A: Prepare the glue, mix epoxy resin and dicyandiamide in an equivalent ratio of 1:1, stir for more than 4 hours, control the gelation time index of the epoxy resin mixture within 300 seconds, and prepare the glue Dispersions;

[0032] Step B: Coat the above glued dispersion on the copper foil, put the release film coated with the glued dispersion into an oven, bake at 80-160°C for 4 minutes to remove the solvent, Prepare the glued copper foil layer;

[0033] Step C: Alternately laminate the rubberized film layer and carbon fiber cloth prepared in step B, and the stacking sequence is as follows: rubberized co...

Embodiment 3

[0036] A carbon fiber cloth base composite material, including carbon fiber cloth base, epoxy resin layer and aluminum foil, the unit weight of carbon fiber cloth base is 255g / m 2 , the thickness of the epoxy resin layer is 150 μm.

[0037] The preparation steps of this kind of carbon fiber cloth-based composite material are as follows:

[0038] Step A: Prepare the glue, mix the epoxy resin and the phenolic resin in an equivalent ratio of 1:1.05, stir for more than 4 hours, control the gelation time index of the epoxy resin mixture to more than 200 seconds, and prepare the glue dispersion body;

[0039] Step B: Coat the above-mentioned glue-coated dispersion on aluminum foil, put the release film coated with glue-coated dispersion in an oven, bake at 80-160°C for 5 minutes to remove the solvent, and prepare Glue-coated aluminum foil layer;

[0040] Step C: Alternately laminate the glued film layer and carbon fiber cloth prepared in step B, and the lamination sequence is as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com