A kind of thermite welding flux and its application

A technology of thermite and aluminum powder, which is applied in the field of flux, can solve the problems of not disclosing the hardness transition of the weld, and achieve the effects of reducing the possibility of white spots and microcracks, small hardness difference, and good transition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Example 1 Use of bainitic steel in homogeneous rail welding.

[0045] Bainitic steel welded joints are bainite at both ends.

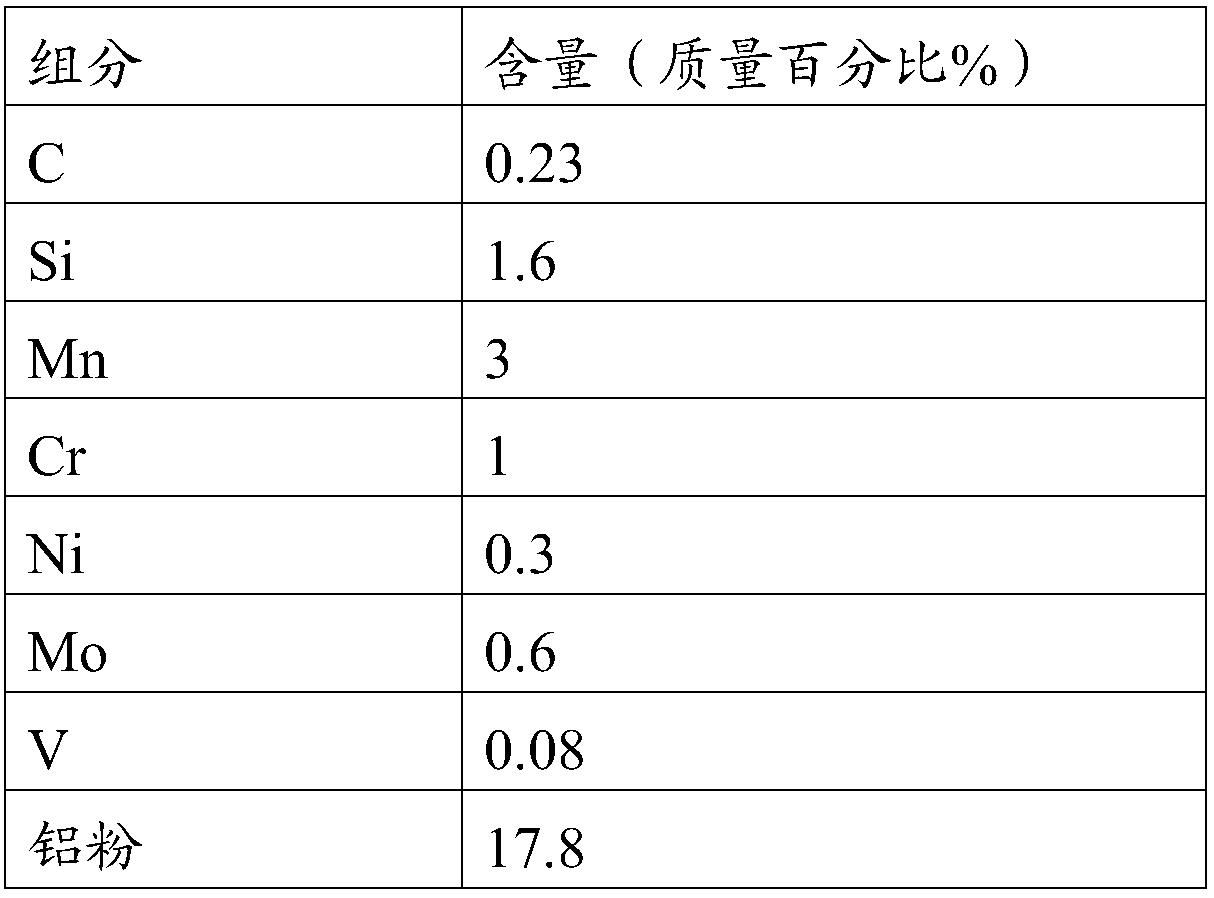

[0046] The thermite flux provided in this embodiment, the mass percentages of each component are as follows:

[0047] Table 1. Embodiment 1 thermite soldering flux formula

[0048] components

Content (mass percent %)

C

0.10

Si

1.0

mn

2.3

Cr

0.7

Ni

1.2

Mo

0.2

V

0.03

Aluminum powder

18.2

60

margin

[0049] The particle size of each component is 10-80 mesh.

[0050] The thermite flux provided in this embodiment is used to weld two bainitic steel welded joints.

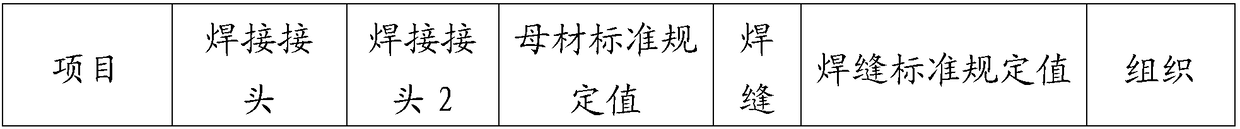

[0051]The welding process and weldment requirements in this embodiment are implemented in accordance with the standards TBT1632.3-2005 and TBT1632.1-2005. Unless otherwise specified, the following data are all obtained from the 75kg / m rail test.

Embodiment 2

[0052] Example 2 The use of bainitic steel and pearlitic steel in welding heterogeneous rails

[0053] The two ends of the welded joint are respectively bainite steel and pearlitic steel.

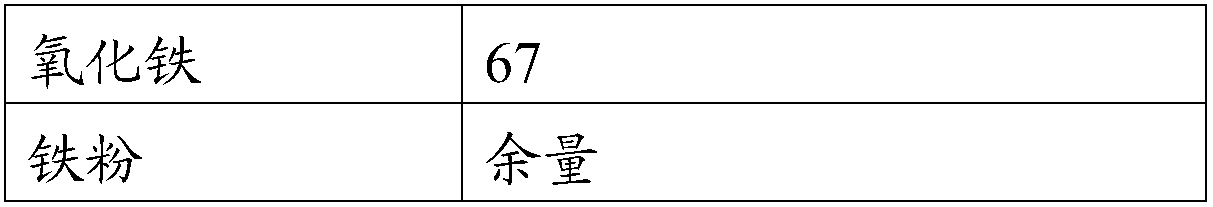

[0054] Table 2. Embodiment 2 thermite soldering flux formula

[0055]

[0056]

[0057] The particle size of each component is 10-80 mesh.

[0058] Use the thermite flux provided in this example to weld the two welded joints. One of them is a welded joint of bainitic steel (denoted as welded joint 1), and the other is a welded joint of pearlitic steel (denoted as welded joint 2).

[0059] The welding process and weldment requirements in this embodiment are implemented in accordance with the standards TBT1632.3-2005 and TBT1632.1-2005. Unless otherwise specified, the following data are all obtained from the 75kg / m rail test.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com