Manufacturing method of heat-shrinkable auto-adhesive vacuum plating protective film

A protective film and manufacturing method technology, applied in the direction of flat products, applications, household appliances, etc., can solve the problems of the user's material loss of brand image, inability to play a protective role, damage to the surface quality of the product, etc., to achieve good re-peeling performance, Excellent barrier and mechanical properties, solve the effect of easy warping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

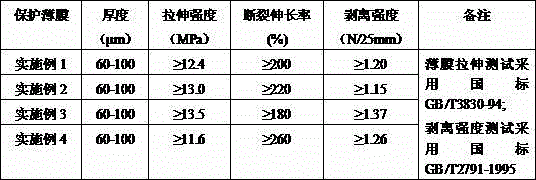

Examples

Embodiment 1

[0022] A kind of manufacture method of heat-shrinkable self-adhesive vacuum plating protection film, comprises the following steps:

[0023] (1) First synthesize polyvinyl polyacrylate: dissolve 5 kg of glycidyl acrylate, 30 kg of methyl methacrylate, 10 kg of ethyl acrylate, 50 kg of butyl acrylate, and 5 kg of hydroxyethyl methacrylate in 200 mL of ethyl acetate The comonomer solution was obtained in the ester, and 1 / 2 of the comonomer solution was taken out, and 0.5kg of azobisisoheptanonitrile initiator was added to polymerize at 80°C for 1 h, and then the remaining 1 / 2 of the comonomer solution and the remaining 0.5 kg of azobisisoheptanonitrile initiator, after the dropwise addition is completed, continue to react for 3 hours, then, keep the reaction temperature constant, slowly add 0.2kg of triethylamine catalyst and 5kg of acrylic acid functional monomer dropwise, after the dropwise addition, continue to React for 3 hours, and finally, use a rotary evaporator to concen...

Embodiment 2

[0026] A kind of manufacture method of heat-shrinkable self-adhesive vacuum plating protection film, comprises the following steps:

[0027] (1) Synthesize polyvinyl polyacrylate first: dissolve 10 kg allyl glycidyl ester, 32 kg methyl methacrylate, 40 kg butyl acrylate, 10 kg isooctyl acrylate, and 8 kg hydroxyethyl methacrylate Obtain a comonomer solution in 200L toluene, take out 1 / 2 of the comonomer solution, add 0.6kg of azobisisobutyronitrile initiator to polymerize at 85°C for 1 h, then add the remaining 1 / 2 of the comonomer solution dropwise With the remaining 0.4 kg azobisisobutyronitrile initiator, after the dropwise addition, continue to react for 3h, then, keep the reaction temperature constant, slowly add dropwise 0.2kg cetyltrimethylammonium bromide catalyst and 5kg coating After the dropwise addition of the functional monomer of aconic acid, continue to react for 3 hours, and finally, use a rotary evaporator to concentrate the solution, let the solvent evaporate...

Embodiment 3

[0030] A kind of manufacture method of heat-shrinkable self-adhesive vacuum plating protection film, comprises the following steps:

[0031](1) First synthesize polyvinyl polyacrylate: dissolve 5 kg of glycidyl acrylate, 30 kg of methyl methacrylate, 10 kg of ethyl acrylate, 50 kg of butyl acrylate, and 5 kg of hydroxyethyl methacrylate in 200 mL of ethyl acetate The comonomer solution was obtained in the ester, and 1 / 2 of the comonomer solution was taken out, and 0.5kg of azobisisoheptanonitrile initiator was added to polymerize at 80°C for 1 h, and then the remaining 1 / 2 of the comonomer solution and the remaining 0.5 kg of azobisisoheptanonitrile initiator, after the dropwise addition is completed, continue to react for 3 hours, then, keep the reaction temperature constant, slowly add 0.2kg of triethylamine catalyst and 5kg of acrylic acid functional monomer dropwise, after the dropwise addition, continue to React for 3 hours, and finally, use a rotary evaporator to concent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com