Silicone acrylate emulsion and graphene oxide-modified inorganic paint and preparation method thereof

A silicone-acrylic emulsion, inorganic coating technology, applied in anti-corrosion coatings, conductive coatings, coatings, etc., can solve problems such as health effects

Inactive Publication Date: 2017-05-10

CHANGZHOU UNIV

View PDF6 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

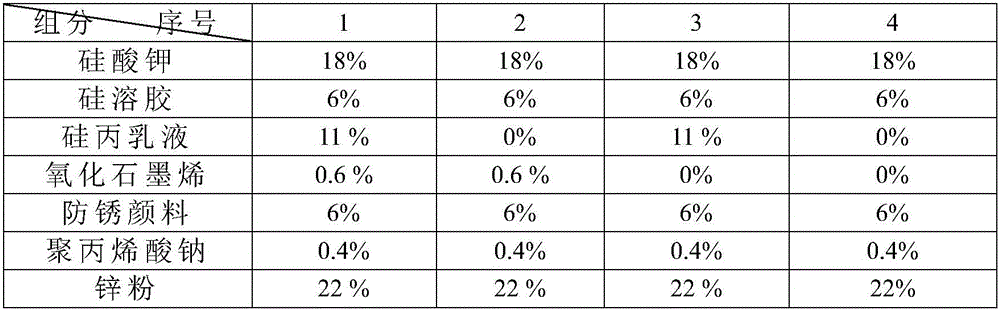

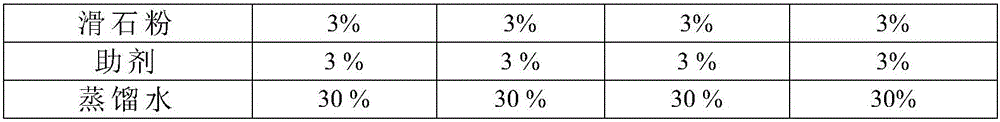

[0051] The concrete formula of embodiment 1 and comparative example 2,3,4 is shown in table 1.

[0052] Table 1 Example Concrete Proportion

[0053]

[0054]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides a silicone acrylate emulsion and graphene oxide-modified inorganic paint and a preparation method thereof. The paint is an anticorrosion priming paint which takes an alkali metal aqueous solution as a film forming substance, takes graphene oxide and zinc dust as a main filling material, and takes the silicone acrylate emulsion as a modifier. The silicone acrylate emulsion is obtained by the processes that an appropriate auxiliary agent is added in an organosilicon monomer containing an unsaturated bond as well as an acrylic acids monomer, and the materials are polymerized through a core-shell coating polymerization technology; flexibility of a film is improved when the emulsion is added in the inorganic paint, and Van der Waals force of a coating on a base material is increased. and the graphene oxide has excellent conductive performance and mechanical property. The experiment proves that flexibility, salt fog resistance, adhesive force and conductivity of the paint are obviously increased.

Description

technical field [0001] The present invention relates to a coating and a preparation method thereof, more specifically to an anti-corrosion primer for steel structures such as pipelines, bridges, storage tanks, and ships, specifically silicon-acrylic emulsion and graphene oxide modified inorganic coatings and their preparation method. Background technique [0002] The anti-corrosion mechanism of inorganic zinc-rich primer is mainly to sacrifice the anode zinc powder to protect the metal as the cathode in the corrosive environment. Therefore, in order to make the coating conductive and play the role of a sacrificial anode, the coating requires a large amount of zinc powder to ensure sufficient contact between the zinc powder and the steel. However, if the content of zinc powder in the coating is too high, the surface of the coating will be uneven after curing, and pores will easily occur, which will affect the corrosion resistance of the coating. At the same time, the film-f...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D133/04C09D7/12C09D5/10C09D5/24

CPCC09D143/04C08K2201/001C09D5/106C09D5/24C09D7/61C09D7/65C08L33/02C08K13/02C08K3/34C08K3/36C08K2003/0893C08K3/04

Inventor 王树立陈玉赵书华饶永超陈宏季廷伟代文杰

Owner CHANGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com