Red temporary water-soluble disperse dye and manufacturing method and use thereof

A disperse dye, soluble technology, applied in the field of dyes, can solve the problems of insufficient variety of colors and can not meet actual use, etc., and achieve the effect of being beneficial to the reuse of wastewater, bright colors, and protection of technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

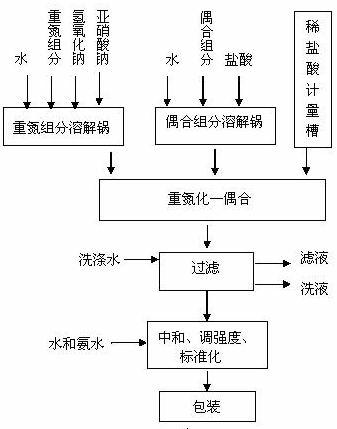

Method used

Image

Examples

Embodiment 1

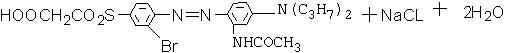

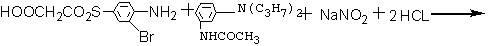

[0038]Add 190g of water, 75.11g of 2-bromo-4-carboxymethanesulfonylaniline with a purity of 97.5%, and sodium hydroxide with a purity of 96% to the diazo component dissolving pot in order to neutralize and dissolve until fully dissolved. The amount of sodium hydroxide added makes the solution pH = 7~7.5, then add 58.51ml of sodium nitrite with a concentration of 29.48g / 100ml, add ice and cool to 0~1°C to obtain the diazo component liquid, and transport the diazo component liquid to the high level of the diazo liquid Groove; Add water 125g, purity 99% m-acetamido N, N dipropylaniline 58.92g, concentration 36.5% hydrochloric acid 25ml successively in the coupling component dissolving pot, wait for m-acetamido N, N dipropylaniline to dissolve Finally, the coupling component liquid is obtained, and the coupling component liquid is transported to the coupling reaction kettle; another part of 36.5% hydrochloric acid 20.3ml is diluted to 20% and transported to the dilute hydrochloric ...

Embodiment 2

[0042] Use the 3% liquid water-soluble disperse dye that embodiment 1 prepares as the inkjet printer ink, after printing, handwriting is even, after separating out dyestuff on printing paper, dyestuff can not be dissolved again. Drops of water are added to the printed paper without ink spreading.

Embodiment 3

[0044] Use the 3% liquid water-soluble disperse dye of embodiment 1 preparation, add the ammoniacal liquor of 0.5% of ink gross mass, the ethylene glycol dimethyl ether of ink gross mass 1%, the JFC dispersant of ink gross mass 0.1%, stir and mix After uniformity, as an inkjet printer ink, after printing, the handwriting is uniform, and the dye will not be dissolved again after the dye is precipitated on the printing paper. Drops of water are added to the printed paper without ink spreading.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum absorption wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com