Temporarily water-soluble disperse dye and preparation method and application thereof

A disperse dye, soluble technology, applied in the field of dyes, can solve the problem of insufficient variety of designs and colors, and achieve the effects of fine printing patterns, convenient waste water treatment, and good exhaustion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

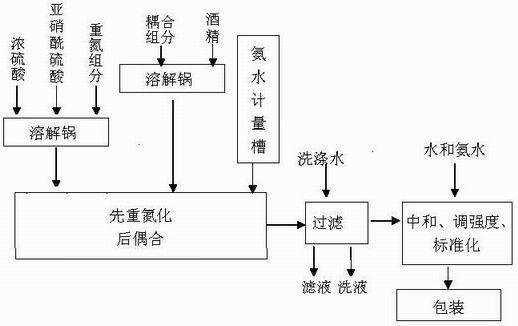

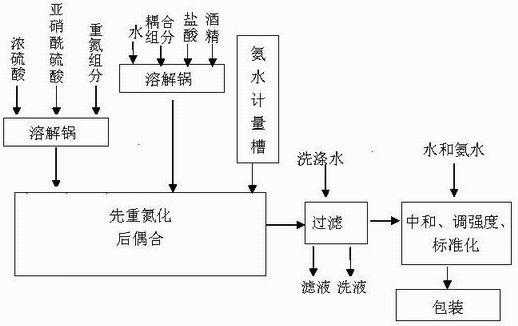

Image

Examples

Embodiment 1

[0036] Synthetic target compound: Huang 22#

[0037]

[0038] The synthesis principle is

[0039] Diazo reaction:

[0040]

[0041] coupling reaction

[0042]

[0043] Add 90g of water, 23.75g of cyanoethylbenzylaniline with a purity of 99.5%, 35ml of alcohol, and 80ml of hydrochloric acid with a concentration of 36.5% in the coupling component dissolving pot to obtain a coupling component solution after dissolution.

[0044] Add 30g of 98% sulfuric acid and 29.54g of salt-free nitrosylsulfuric acid with a content of 42% to the diazonium reaction kettle in sequence, and add 2,6-dibromo-4-carboxymethanesulfonylaniline within 1 hour at a temperature of 1°C. 38.16g. After the addition, the diazotization reaction was carried out at 40°C under normal pressure. After 7 hours of reaction, a diazonium salt solution was obtained, which was then added to the coupling reaction kettle.

[0045] Add the measured coupling component solution and ammonia water into the diazonium s...

Embodiment 2

[0049] Use the 3% liquid water-soluble disperse dye that embodiment 1 prepares as the inkjet printer ink, after printing, handwriting is even, after separating out dyestuff on printing paper, dyestuff can not be dissolved again. Drops of water are added to the printed paper without ink spreading.

Embodiment 3

[0051] Use the 3% liquid water-soluble disperse dye that embodiment 1 prepares, add the ammoniacal liquor of 0.5% of ink gross mass, the ethylene glycol dimethyl ether of ink gross mass 1%, the JFC dispersant of ink gross mass 0.1%, stir and mix After uniformity, as an inkjet printer ink, after printing, the handwriting is uniform, and the dye will not be dissolved again after the dye is precipitated on the printing paper. Drops of water are added to the printed paper without ink spreading.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum absorption wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com