Preparation method of lithocarpus litseifolius sweet tea

A production method and technology of wood ginger, applied in directions such as tea substitutes, can solve the problems of high brittleness, inability to process wood ginger leaves, and inability to maintain good color, taste and aroma, and achieve good color, improved taste, and sweet aroma. lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

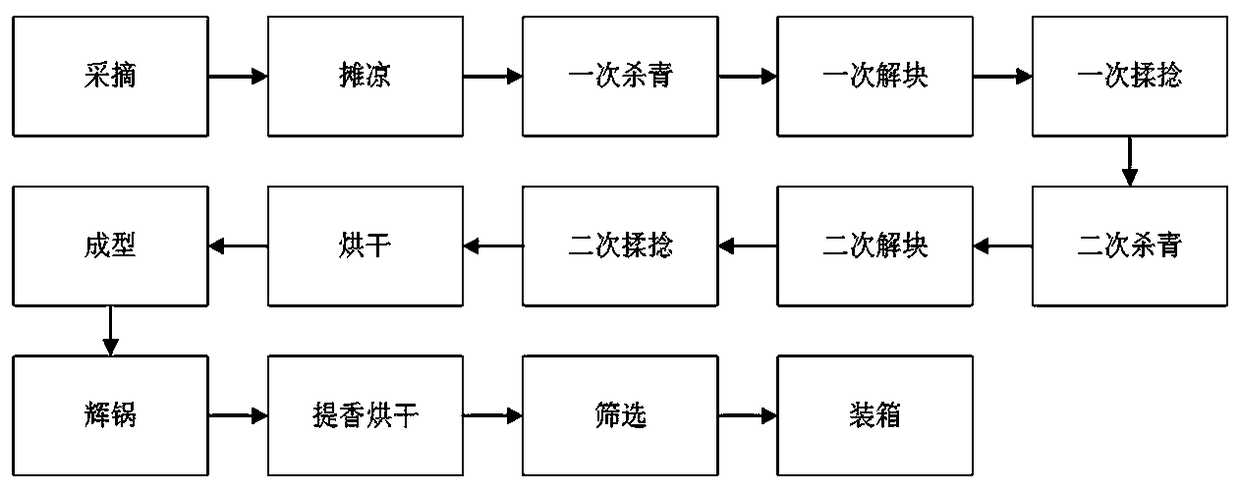

[0032] Such as figure 1 Shown, the preparation method of a kind of wood ginger leaf ke sweet tea of the present invention comprises the following steps:

[0033] S1: Harvesting the young leaves of Mujiang Ye Ke as tea raw materials, and cooling them;

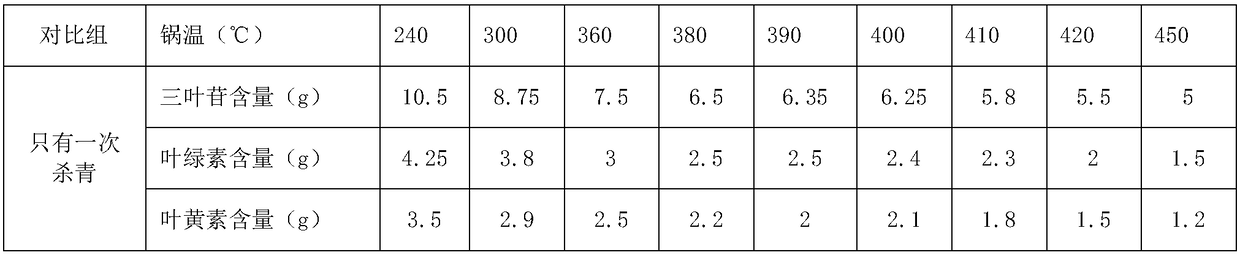

[0034] S2: Treat the cooled tea leaves at one time, the temperature of the pot at one time is 380°C-400°C, let the tea leaves be greened for 6-8 minutes, and then spread to cool down;

[0035] S3: performing a rolling treatment after deblocking and dispersing the above-mentioned completely cooled tea leaves;

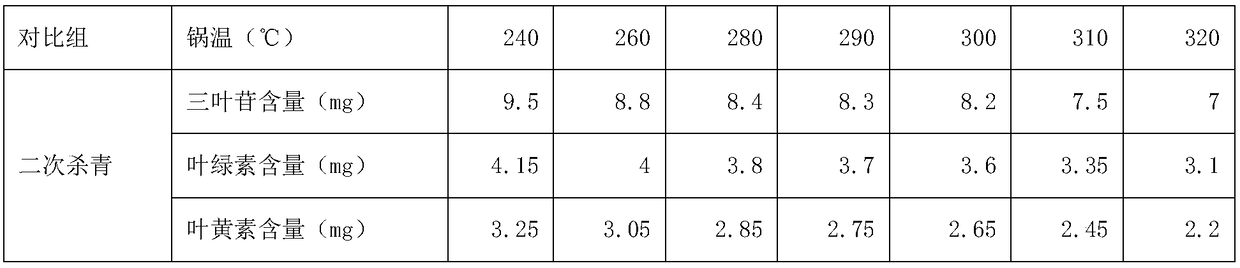

[0036] S4: Carry out secondary de-enzyming, secondary unblocking, and secondary kneading treatments on the tea leaves after the first rolling, the temperature of the secondary de-enzyming pot is 280°C-300°C, and the de-enzyming is performed for 5-6 minutes;

[0037] S5: The tea after the second rolling is sequentially dried, shaped, potted, dried, screened, and boxed.

[0038] The specific steps of harvesting in the s...

Embodiment 2

[0058] Such as figure 1 As shown, on the basis of embodiment 1, a specific embodiment is provided, and the specific implementation steps are as follows:

[0059] Harvesting: In cloudy and sunny days, choose silky and unhardened young leaves for manual picking. When picking fashion tea leaves, you must use a ventilated bamboo weaving tool. Do not pressurize when packing. Fresh leaves should be sent to the tea factory for cooling after they are full. , Avoid fever.

[0060] Cooling: spread the fresh leaves evenly on a ventilation grid with a thickness of 3-5 cm, and spread them for 4 hours. When the temperature is high in summer, use a fan to cool them to avoid heat generation. Turn the leaves 2-3 times in the middle.

[0061] One-time finishing: Use a combustion-heating small-sized drum finishing machine, the pot temperature is 390°C, and the greening is done for 7 minutes. In principle, it smells no raw smell. When the sweet smell appears, take it out of the pot, and then spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com