Preparation method of egg rice crackers

A technology for eggs and rice crackers, which is applied in baking, baked food, food science, etc. It can solve the problems of single variety of glutinous rice products and low production efficiency, and achieve the effect of uniform color without variegation, low cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] Egg rice cracker, its preparation method comprises the following steps:

[0037] (1) Puffing step: Weigh 5kg of glutinous rice on an electronic scale, put the glutinous rice in the puffing tank, heat the puffing tank to a temperature of 150°C, control the puffing pressure at 0.5MPa, keep it for 3-5min, open the puffing tank mouth to proceed Expanded to obtain 4.8kg of expanded glutinous rice flower, and the bulk density of the expanded glutinous rice flower granule is 76g / L. The moisture content of the glutinous rice flower particles was determined to be 4.52%.

[0038] (2) Beating step

[0039] Weigh 1 kg of eggs on an electronic scale, and after breaking the shell, prepare 0.82 kg of whole egg liquid, take 0.8 kg of whole egg liquid, add 0.4 kg of glucose powder to the whole egg liquid, stir evenly, and obtain 1.2 kg of egg slurry.

[0040] (3) Mixing step

[0041] Put 1.2 kg of egg slurry obtained in step (2) and 4.8 kg of glutinous rice flower obtained in step (1...

Embodiment 1

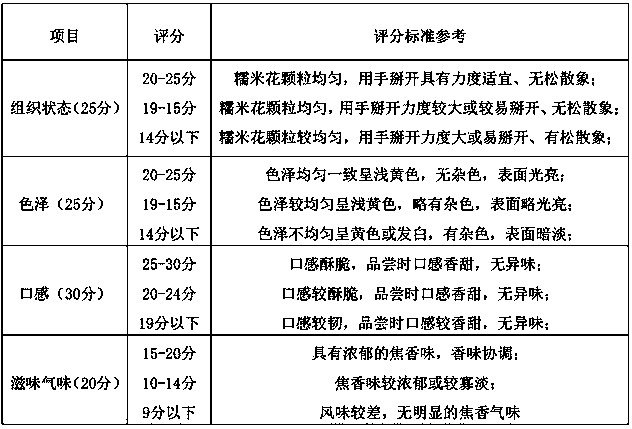

[0050] The test results of the egg rice crackers obtained in Example 1 are: the upper and lower sides of the fruit body have the same color, the appearance is plump, the mouthfeel is crisp, there is no burnt smell, and the fruit body is firm and not fragile. When tasting, the taste is sweet and crisp, soft and easy to melt, without peculiar smell, and the score is 91 points. Its water content was determined to be 4.23%.

Embodiment 2

[0052] Egg rice cracker, its preparation method comprises the following steps:

[0053] (1) Puffing step: Weigh 5kg of glutinous rice on an electronic scale, put the glutinous rice in the puffing tank, heat the puffing tank to a temperature of 160°C, control the puffing pressure at 0.6MPa, keep it for 3-5min, open the puffing tank mouth and proceed Expanded to obtain 4.45kg of expanded glutinous rice flower, and the bulk density of the expanded glutinous rice flower granule is at 80g / L. The water content of glutinous rice flower particles was determined to be 4.31%.

[0054] (2) Beating step

[0055] Weigh 1 kg of eggs on an electronic scale, break the shell, prepare 0.85 kg of whole egg liquid, take 0.7 kg of whole egg liquid, add 0.42 kg of glucose powder to the whole egg liquid, stir evenly, and obtain 1.12 kg of egg slurry.

[0056] (3) Mixing step

[0057] Put 1.12 kg of egg slurry obtained in step (2) and glutinous rice flower obtained in step (2) into a mixer and mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com