Method of preparing functional monascus powder based on spraying drying method and effectively maintaining total content of MK and stability of acid MK

A functional monascus powder, spray drying technology, applied in microorganism-based methods, biochemical equipment and methods, fungi and other directions, can solve the problems of large decline rate of total MK content and high conversion rate, and reduce drying time. , The effect of high fermentation titer and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

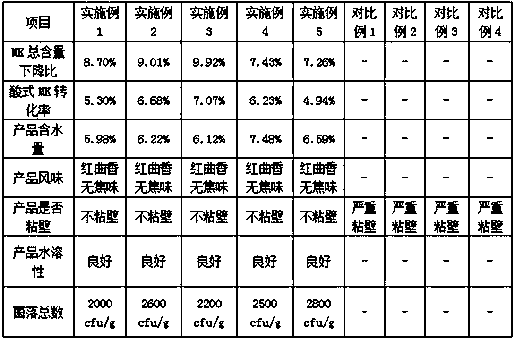

Examples

Embodiment 1

[0026] In this embodiment, a spray-drying method is used to prepare functional red yeast rice powder and a method for effectively maintaining the total content of MK and the stability of acidic MK, including the following steps:

[0027] Step A. Design medium with tartary buckwheat powder as carbon source, the formula is: tartary buckwheat powder 6.0%, 10% soybean hydrolyzate 5.0%, sugar alcohol 2.2%, corn steep liquor 0.12%, NaNO 3 0.15% , MgSO 4 ·7H 2 O 0.12%, k 2 HPO 4 ·3H 2 O0.14%, ZnSO 4 ·7H 2 O 0.15%, MnSO 4 ·7H 2 O 0.14%, (NH 4 ) 2 SO 4 0.16%, pH4.53. Combining Monascus purple with liquid submerged fermentation in a 1500L fermenter to produce a functional red yeast fermentation broth with MK as the main target product, the fermentation process is controlled as follows: inoculum size: 6%; temperature: 0-96h 28.5°C, 97h- End 22.6°C; Stirring speed: 75rpm; Ventilation volume: 70m 3 / h; tank pressure: 0.035MPa; cultivated for 18 days.

[0028] Step B. Use a p...

Embodiment 2

[0032]In this embodiment, a spray-drying method is used to prepare functional red yeast rice powder and a method for effectively maintaining the total content of MK and the stability of acidic MK, including the following steps:

[0033] Step A. Design medium with tartary buckwheat flour as carbon source, the formula is: tartary buckwheat flour 7.0%, 10% soybean hydrolyzate 6.5%, sugar alcohol 3.0%, corn steep liquor 0.10%, NaNO 3 0.12% , MgSO 4 ·7H 2 O 0.13%, K 2 HPO 4 ·3H 2 O 0.12%, ZnSO 4 ·7H 2 O 0.18%, MnSO 4 ·7H 2 O 0.18%, (NH 4 ) 2 SO 4 0.20%, pH4.35. Combining Monascus purple with liquid submerged fermentation in a 1500L fermenter to produce a functional red yeast fermentation broth with MK as the main target product, the fermentation process is controlled as inoculum size: 3.5%; temperature: 0-96h 32.5°C, 97h-end 25.3℃; Stirring speed: 100rpm; Ventilation volume: 80m 3 / h; tank pressure: 0.045MPa; cultivated for 19 days.

[0034] Step B. Use a pressurized...

Embodiment 3

[0038] In this embodiment, a spray-drying method is used to prepare functional red yeast rice powder and a method for effectively maintaining the total content of MK and the stability of acidic MK, including the following steps:

[0039] Step A. Tartary buckwheat powder and tartary buckwheat powder are used as the carbon source design medium, the formula is: tartary buckwheat powder and tartary buckwheat powder (1:1) 7.5%, 10% soybean hydrolyzate 6.2%, sugar alcohol: 5.0% , corn steep liquor 0.14%, NaNO 3 0.20% , MgSO 4 ·7H 2 O0.20%, K 2 HPO 4 ·3H 2 O 0.16%, ZnSO 4 ·7H 2 O 0.12%, MnSO 4 ·7H 2 O 0.10%, (NH 4 ) 2 SO 4 0.12%, pH4.68. Combining Monascus purple with liquid submerged fermentation in a 1500L fermenter to produce a functional red yeast fermentation broth with MK as the main target product, the fermentation process is controlled as follows: inoculum size: 10%; temperature: 0-96h 33.5°C, 97h- End 23.6°C; Stirring speed: 60rpm; Ventilation volume: 110m 3 / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com