Press prepared peanut oil pretreatment method

A technology of peanut oil and pressing method, which is applied in the direction of fat production, edible oil/fat, fat oil/fat production, etc. It can solve the problems of high cost, burnt smell, and destruction of peanut oil nutrients, so as to achieve low initial investment and operation cost , reduce the content of aflatoxin, beneficial to human health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

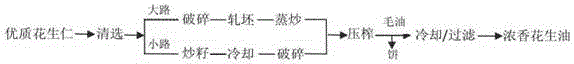

[0046] Embodiment 1: the preparation technology of Rou Yaxiang peanut oil

[0047] Prepare Rou Ya Xiang Peanut Oil as follows

[0048] (1) Get 25kg of peanut kernels, and use the TQLZ60*100 screening machine to select;

[0049] (2) Add the screened peanuts to a short-medium wave infrared heating machine for processing by vacuum suction (temperature 120-140°C, processing distance 20cm, material thickness 5cm, wavelength 2.5μm), and the processed peanuts are heated at room temperature Cool for 5 hours, and use LXT-1 to remove the red coat;

[0050] (3) Utilize coarse crushing machine to pulverize to about 40 orders;

[0051] (4) Squeeze for 40min under a pressure of 60Mpa (three-column hydraulic oil press);

[0052] (5) Utilize BAJ1 / 310-U plate-and-frame filter to filter (filter pressure 2bar) to obtain peanut oil.

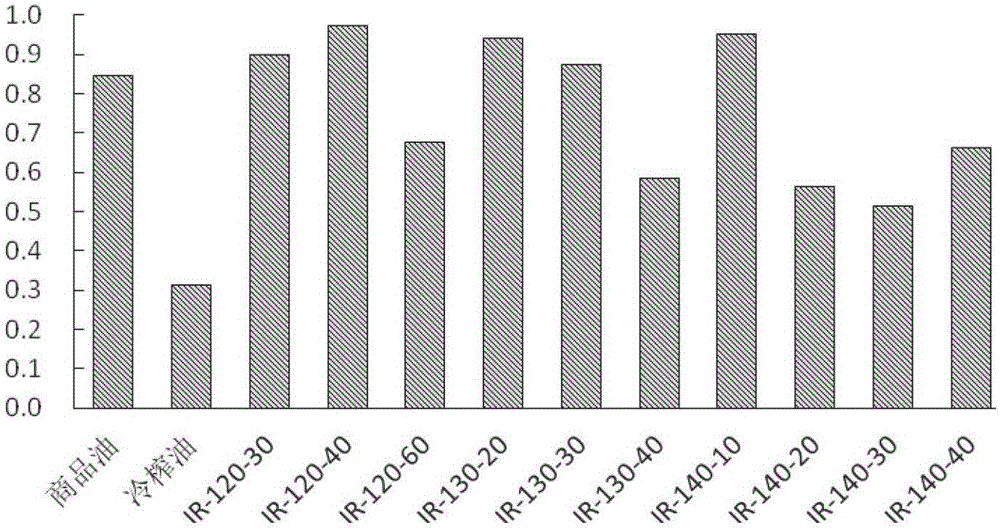

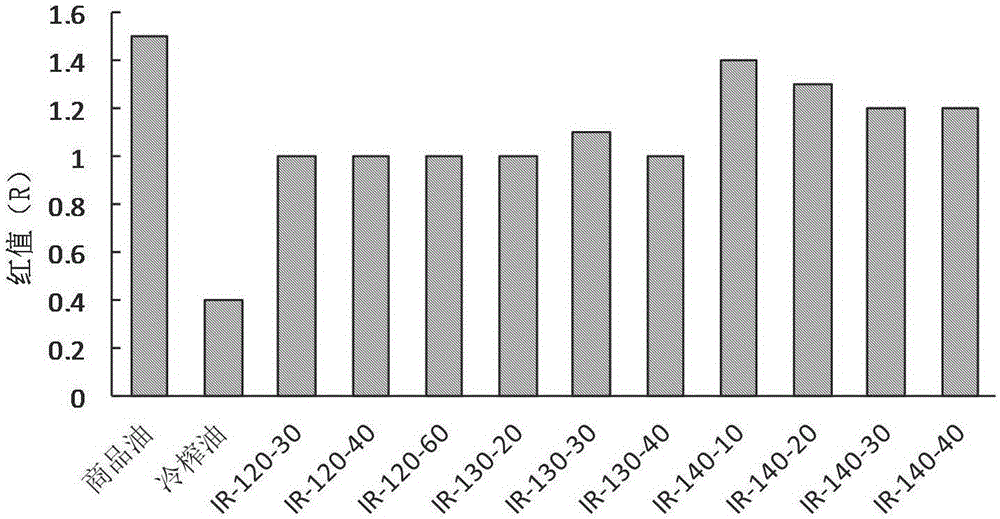

[0053] At the same time, the influence of different infrared heating temperatures and times on peanut oil was investigated, such as Figure 1-4 shown.

[0054...

Embodiment 2

[0060] Embodiment 2: the preparation technology of Rou Yaxiang peanut oil

[0061] Prepare Rou Ya Xiang Peanut Oil as follows:

[0062] (1) Get 25kg of peanut kernels, and use the TQLZ60*100 screening machine to select;

[0063] (2) Put the screened peanuts into a short-medium-wave infrared heating machine for processing by vacuum suction. The processing temperature is 140°C, the processing distance is 22cm, the material thickness is 6.6cm, the wavelength is about 4μm, and the processing time is 20min). The peanuts were cooled at room temperature for 5 hours, and the red coat was removed by LXT-1;

[0064] (3) Utilize coarse crushing machine to pulverize to about 40 orders;

[0065] (4) Squeeze for 40min under a pressure of 60Mpa;

[0066] (5) Use a BAJ1 / 310-U plate-and-frame filter to filter at a filtration pressure of 2 bar to obtain soft and fragrant peanut oil.

[0067] The oil yield of peanut oil obtained according to the method is 85%. The color is light, the acid v...

Embodiment 3

[0072] Embodiment 3: the preparation technology of Rou Yaxiang peanut oil

[0073] Prepare Rou Ya Xiang Peanut Oil as follows:

[0074] (1) Get 25kg of peanut kernels, and use the TQLZ60*100 screening machine to select;

[0075] (2) Put the screened peanuts into a short-medium wave infrared heating machine for processing by vacuum suction (temperature 120°C, processing distance 15cm, material thickness 3.5cm, wavelength 0.8μm, processing time 60min), processed Peanuts are cooled at room temperature, and the red coat is removed by LXT-1;

[0076] (3) Utilize coarse crushing machine to pulverize to about 40 orders;

[0077] (4) Squeeze for 40min under a pressure of 60Mpa;

[0078] (5) Use a BAJ1 / 310-U plate-and-frame filter to filter at a filtration pressure of 2 bar to obtain soft and fragrant peanut oil.

[0079] The yield of peanut oil obtained according to the method is 86%. The color is light, the acid value is 0.62mgKOH / g, the aflatoxin content is only 0.8ppb, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com