Nut paste processing method of food processer

A processing method and technology of nut butter, which can be applied in household utensils, roasters/barbecue grids, applications, etc., can solve the problems of no guarantee of sanitation and health, less production steps, and harmful effects on the body, and achieve the goal of making nut butter. The process is easy and pleasant, the production steps are few, and the effect of strong fragrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

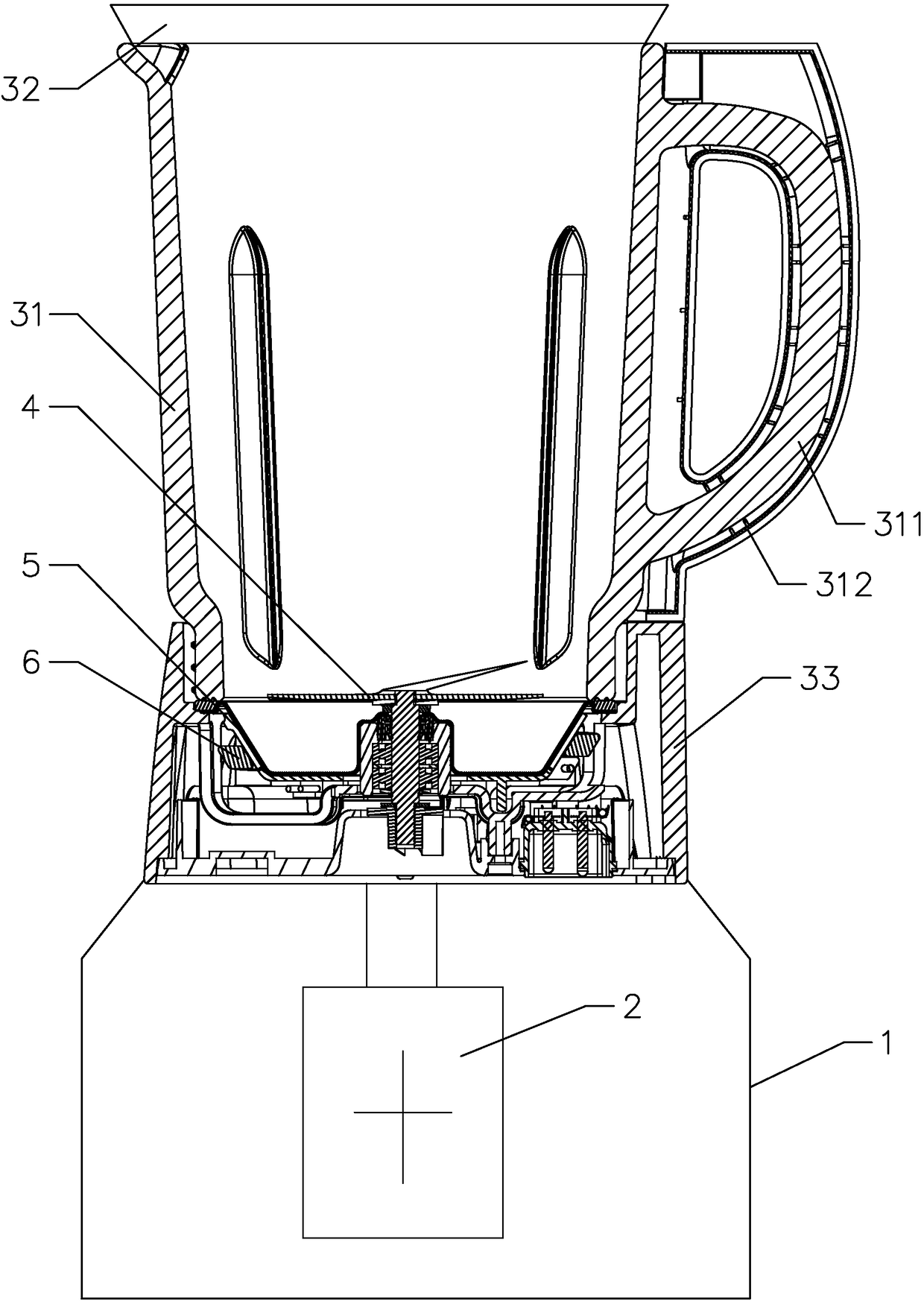

Image

Examples

Embodiment 1

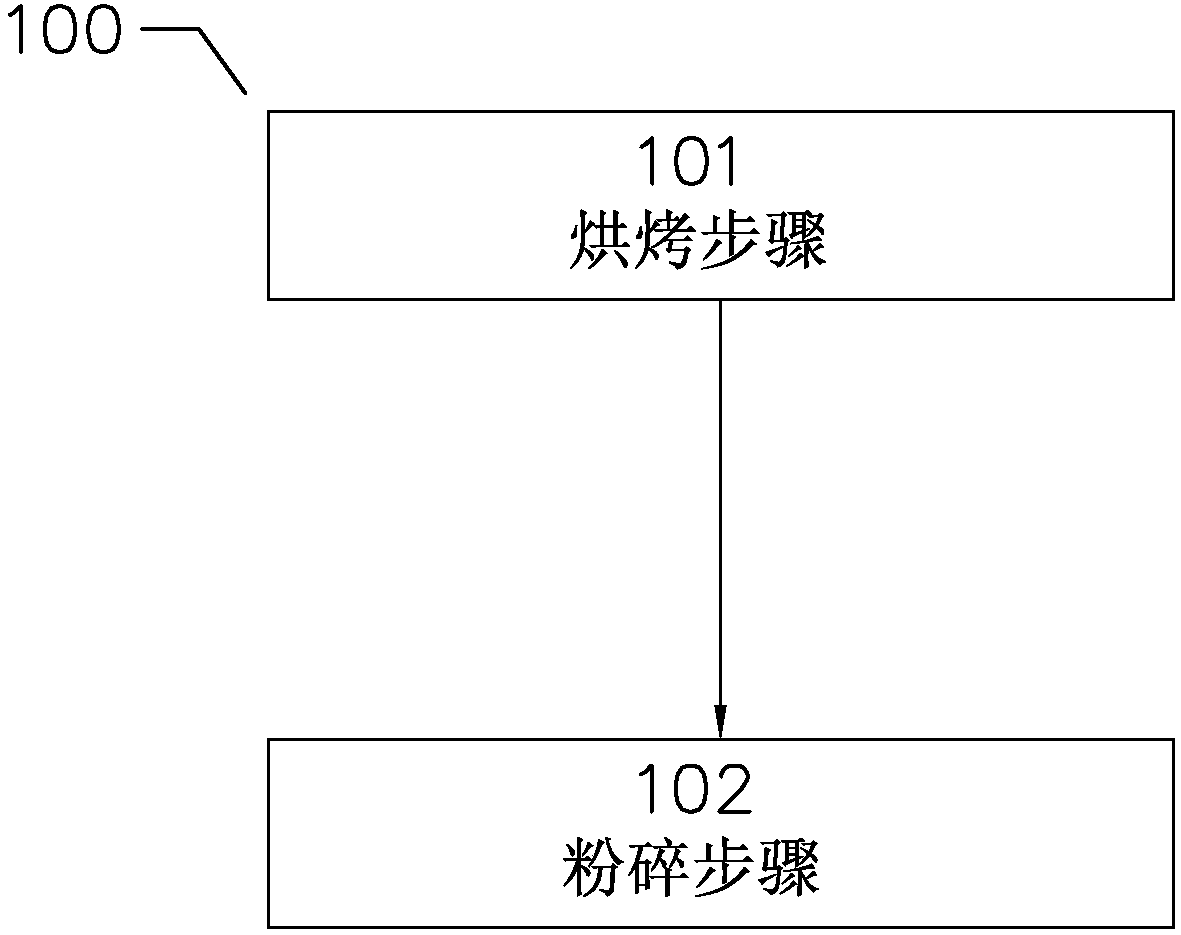

[0038] like figure 2 As shown, the present invention provides a nut butter processing method 100 for a cooking machine, the method includes the following steps:

[0039] Baking step 101: After adding the ingredients, the control board receives the user's instruction to start the cooking machine, and the heating plate heats the nuts in the cup until they are cooked; baking refers to directly baking the nuts without adding water or other liquids bake.

[0040] Pulverizing step 102: After the nuts are roasted, the motor drives the pulverizer to rotate to pulverize the nuts in the cup.

[0041] Specifically, the volume of heated nuts is V1, the capacity of the cup is V2, 1 / 4≤V1 / V2≤1, in this embodiment, V1 / V2 is 3 / 5, which can ensure that the amount of nuts is sufficient , during the roasting step, a good heat transfer effect can be formed between the nuts, so that the nuts are evenly heated during roasting, and a better roasting effect can be achieved, that is, the roasted nut...

Embodiment 2

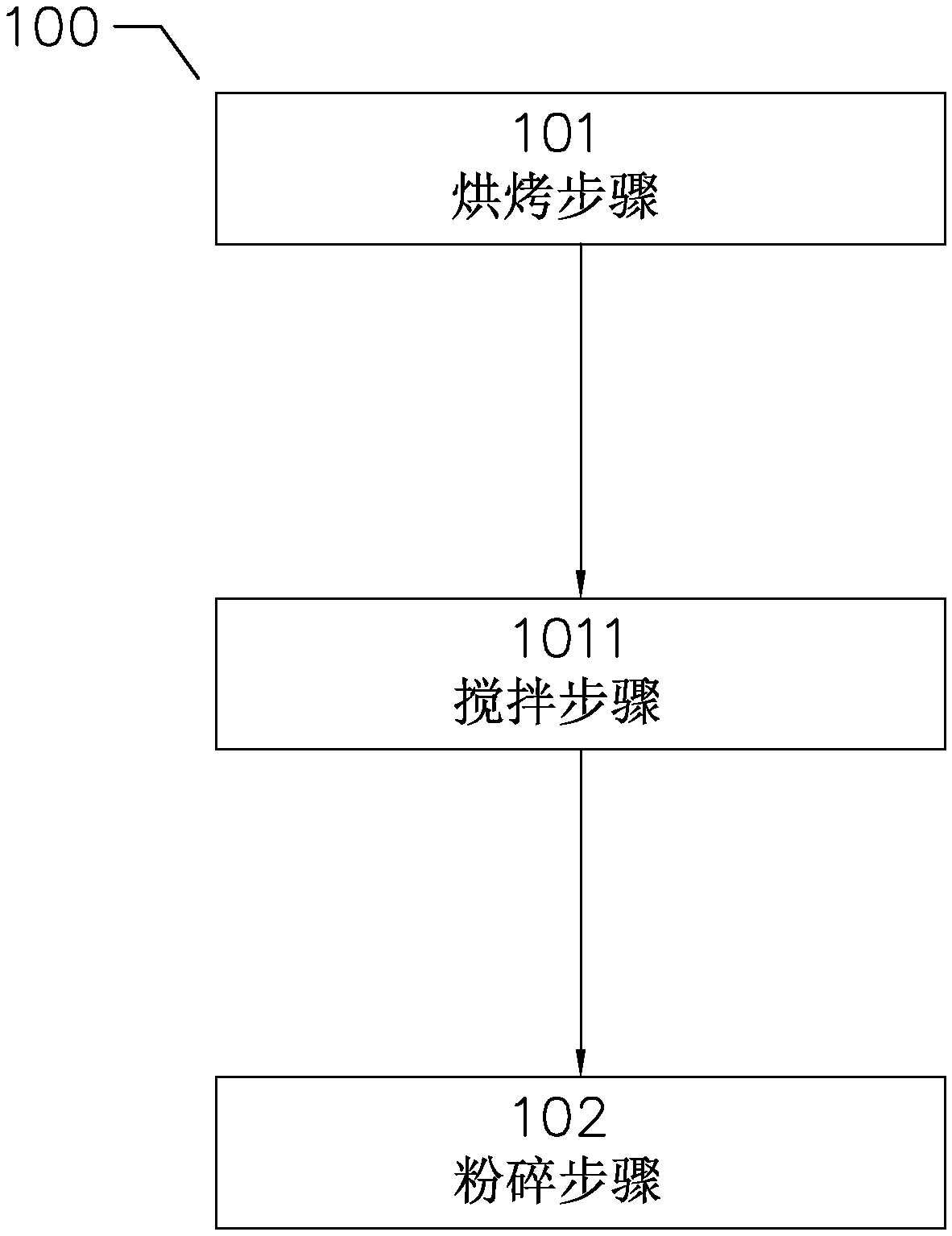

[0050] The difference between this embodiment and Embodiment 1 is that the nut butter processing method also includes a stirring step.

[0051] In this example, if image 3 As shown, the nut butter processing method 100 comprises the following steps:

[0052] Baking step 101: After adding the ingredients, the control board receives the user's instruction to start the cooking machine, and the heating plate heats the nuts in the cup until they are matured;

[0053] Stirring step 1011: the motor drives the pulverizer to stir the nuts in the cup at a speed of S1;

[0054] Pulverizing step 102: After the nuts are roasted, the motor drives the pulverizer to rotate to pulverize the nuts in the cup.

[0055] In this embodiment, by setting the stirring step, when the nuts are roasted, the nuts can be turned over very well, so that the nuts are heated evenly, so that the roasting effect of the nuts is well guaranteed, so that the produced nut butter not only tastes Good, and strong f...

Embodiment 3

[0060] The difference between this embodiment and Embodiment 2 is that the stirring step includes an intermittent stirring step.

[0061] In this example, if Figure 4 As shown, the nut butter processing method 100 comprises the following steps:

[0062] Baking step 101: After adding the ingredients, the control board receives the user's instruction to start the cooking machine, and the heating plate heats the nuts in the cup until they are matured;

[0063] Stirring step 1011: the motor drives the pulverizer to stir the nuts in the cup at a speed of S1;

[0064] Intermittent stirring step 1012: the motor drives the pulverizer to stir the nuts in the cup for a period of time t 2 , and then the motor stops working for a period of time t 3 ;

[0065] Pulverizing step 102: After the nuts are roasted, the motor drives the pulverizer to rotate to pulverize the nuts in the cup.

[0066] In this embodiment, by setting the intermittent stirring step in the stirring step, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com