Method for processing color matching design of fur garment facing material

A fur and pattern technology, which is applied to the processing method and product field of fur fabric color matching patterns, can solve the problems of environmental pollution, natural color and pattern monotony, irregular shape, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

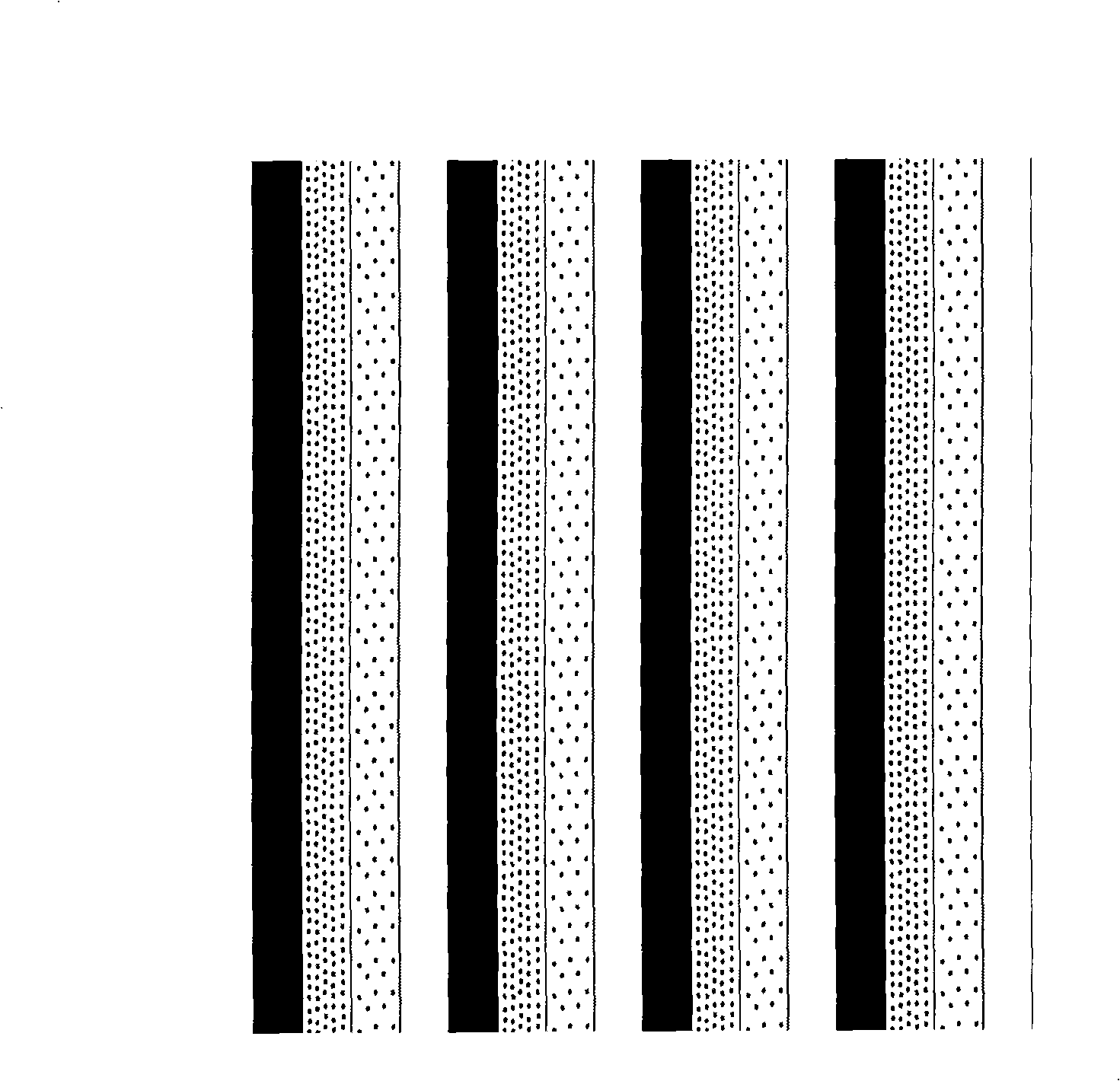

[0015] Refer to Figure 1. According to the length and color of the fur on the fur raw materials, choose the same fur raw materials as much as possible, and do the necessary trimming of the adjacent edges that need to be spliced. The shape of the interface is not necessarily a straight line, and the shape is consistent. Prepare for splicing into long strips. The strip fur raw materials or small pieces of fur raw materials with the same color and luster classified by step one are spliced longitudinally into longitudinal fur strips whose length is significantly longer than the width, and the longitudinal strips of different luster are arranged at intervals and spliced horizontally to form a surface fur Materials are spare.

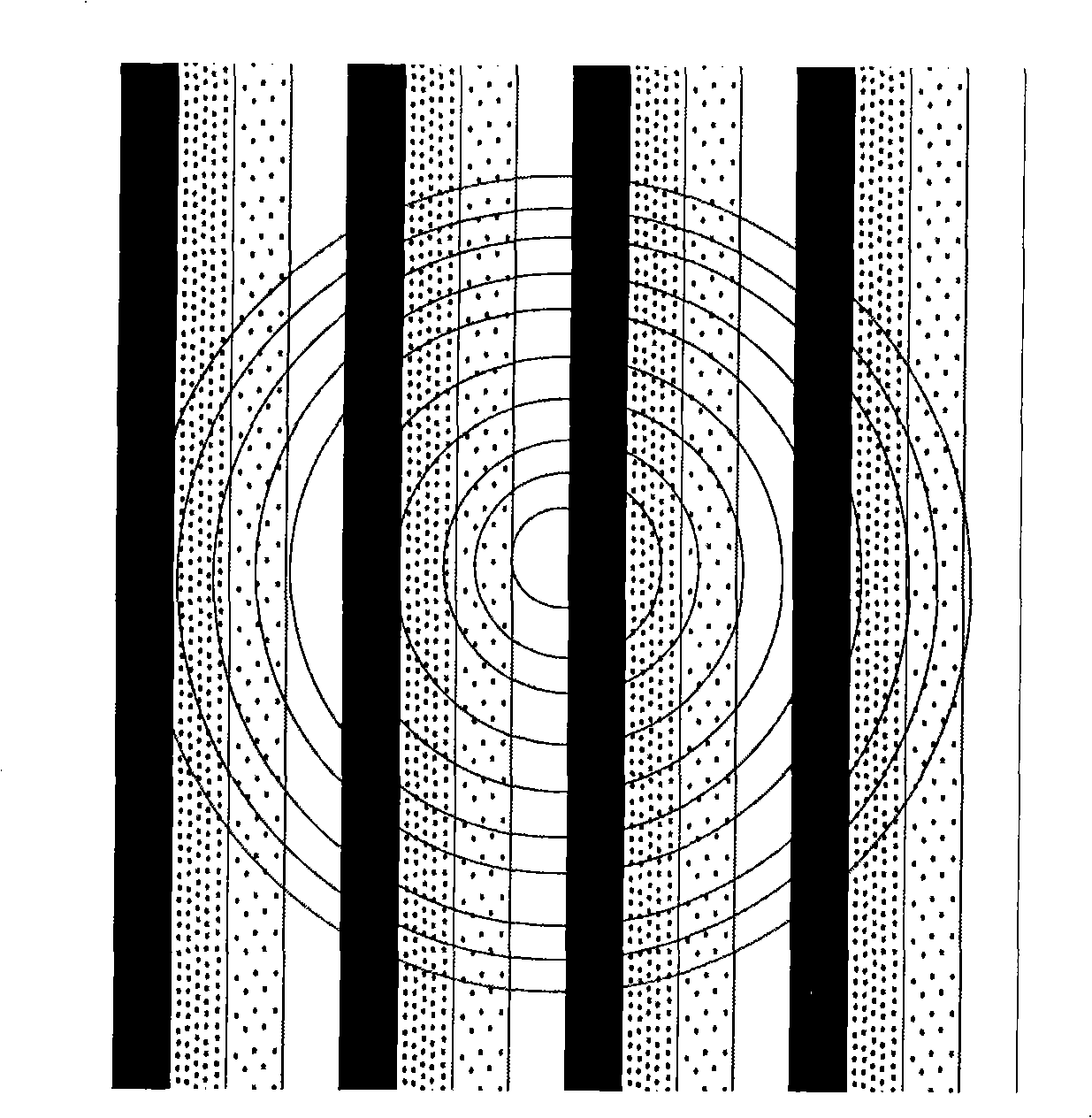

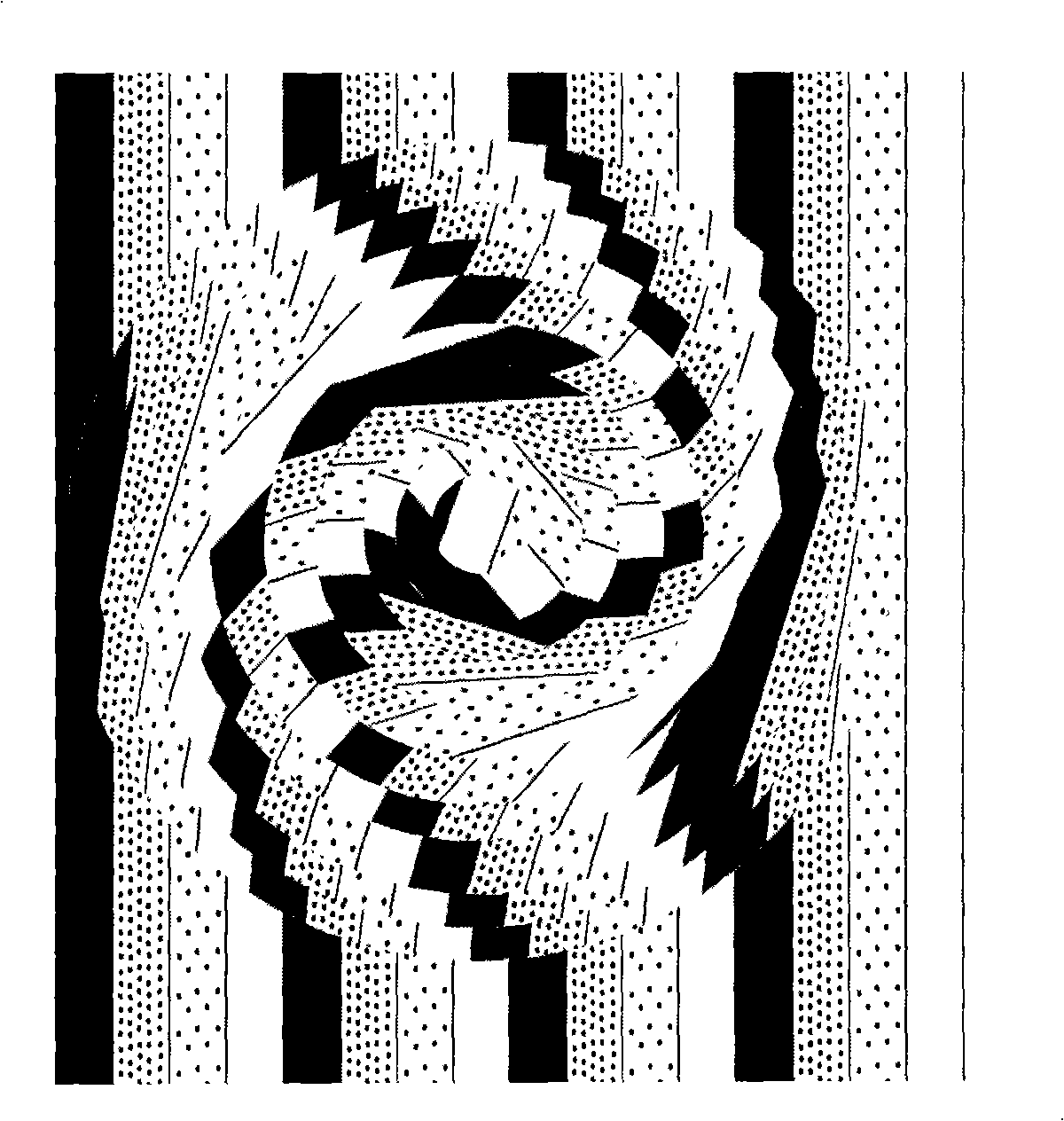

[0016] Referring to Figure 2, the pattern outline is drawn on the reverse side of the planar fur material that has been spliced in steps one and two. The pattern has the characteristics of center symmetry and concentrically enlarged inner and outer layers. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com