Fur fulling and shaping rotary pan

A technology of wool milling and pot turning, which is applied in raw hide/leather/fur manufacturing equipment, small raw hide/large raw hide/leather/fur treatment, small raw hide/large raw hide/leather/fur mechanical treatment, etc. Various problems such as fur milling and shaping, difficult wood bran treatment, more manpower and physics, etc., to reduce manpower input, keep clean, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

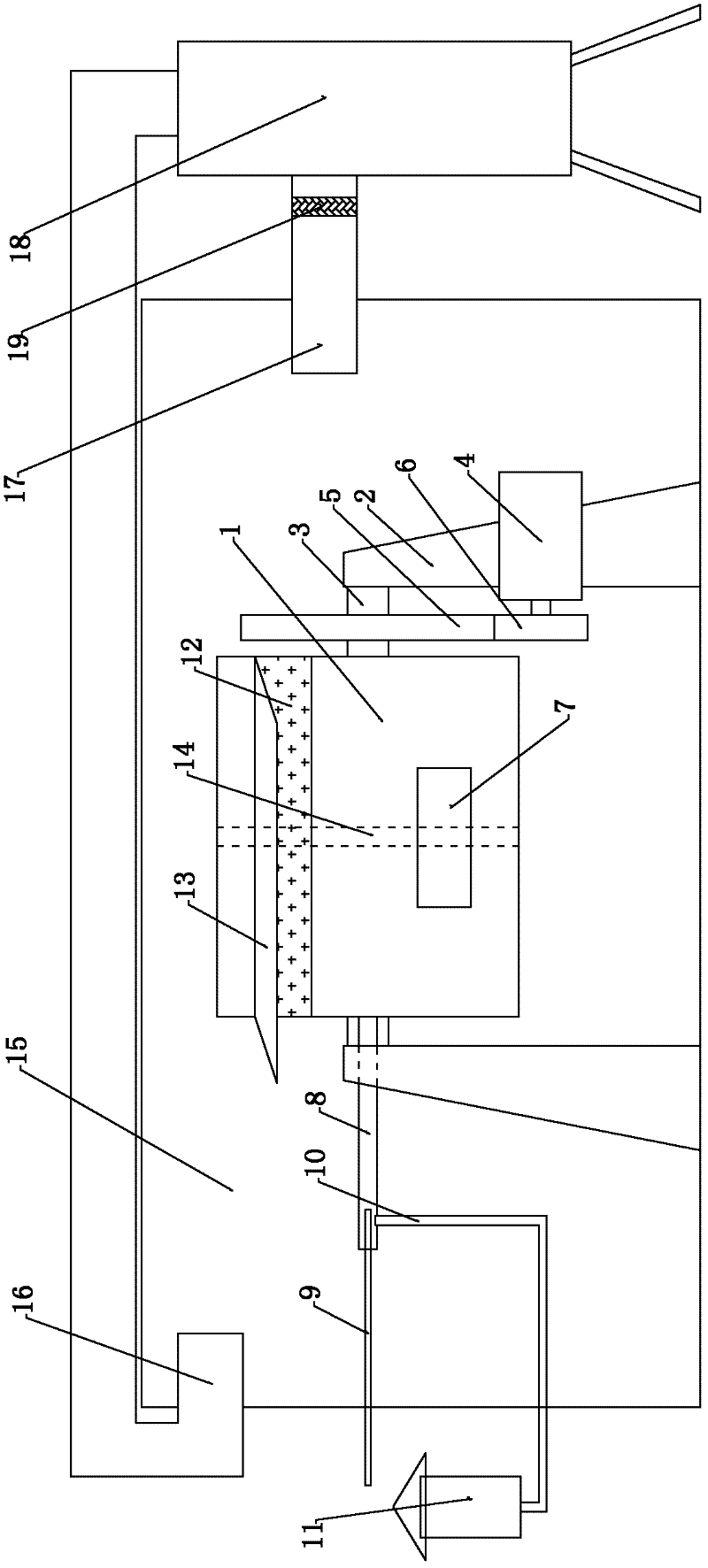

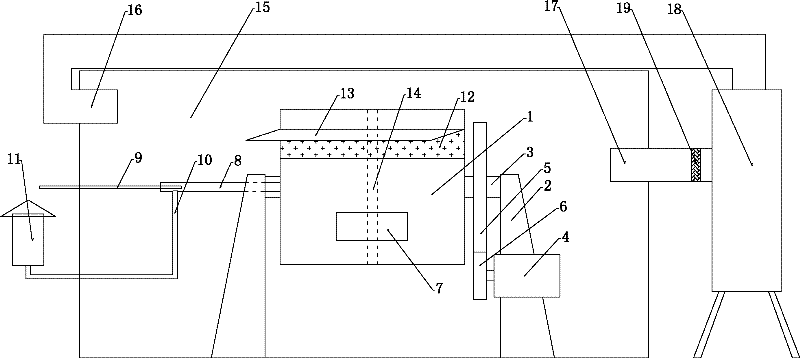

[0012] Such as figure 1 As shown, the fur milling and shaping rotary pot described in this embodiment mainly includes a rotary pot 1, a rotating shaft 3, a bracket 2 and a motor 4, and the rotary pot 1 is fixed on the bracket 2 through the rotating shaft 3, and the The rotating shaft 3 is provided with a large gear 5, the large gear 5 meshes with the pinion 6 on the motor 4 for transmission, and the rotary pot 1 is provided with a feeding door 7, and the rotating shaft 3 on the other side of the large gear 5 is hollow. structure, the same side of the rotating shaft 3 is provided with a vent pipe 8, one end of the vent pipe 8 passes through the rotating shaft 3 and is connected to the rotating pot 1, and the other end of the vent pipe 8 extends into a steam nozzle 9 at a certain distance, and the end of the vent pipe 8 is connected to the Seal between the outer walls of the steam nozzle 9, a liquid medicine inlet pipe 10 is provided between the closed port of the steam nozzle 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com