The production method of two-color printing oil leather

A production method and printing technology, which are used in leather hammering, leather impregnation, fur finishing, etc., can solve the problems of poor friction and fading, easy peeling of the printing layer, poor waterproofness, etc. The effect of using the range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

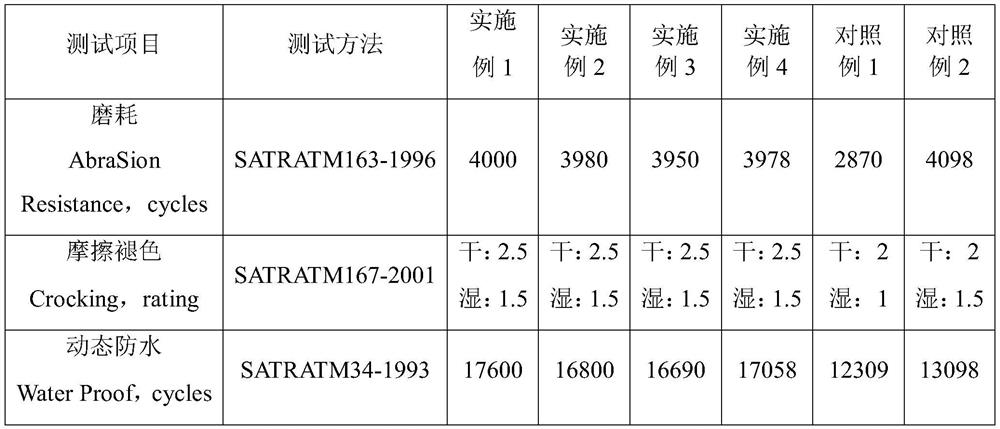

Examples

Embodiment 1

[0026] The method for making two-color printed oil leather includes the following steps: Grinding: take dry cow split leather, use 180# and 220# sandpaper to grind the bottom in sequence, and use 180# and 280# sandpaper to grind the surface in sequence;

[0027] A soft fall: the time for falling soft is 4h;

[0028] Roller grease: Roller coat water-based nitrocellulose varnish MelioEW-348.B (the mass ratio of water and grease is 1:3) diluted with water on the surface of the leather embryo that has been softened once, and the amount of roller coating is 12g / square foot ;

[0029] stand overnight;

[0030] Printing: Apply printing chemical to the leather surface, add water-based cotton acetate varnish Melio EW-629.B, 2-ethoxyethanol and Supronil HK dye (color: Black W, the quality of dye water added is water-based cotton acetate 2% of varnish) mixed with water and stirred evenly, and the mass ratio of the water-based cotton acetate varnish Melio EW-629.B to 2-ethoxyethanol was...

Embodiment 2

[0034] The method for making two-color printed oil leather includes the following steps: Grinding: take dry cow split leather, use 180# and 220# sandpaper to grind the bottom in sequence, and use 180# and 280# sandpaper to grind the surface in sequence;

[0035] A soft fall: the time to fall soft is 3.5h;

[0036] Roller grease: Roller coat the water-based nitrocellulose varnish Melio EW-348.B (the mass ratio of water, ethanol and grease is 1:1:3) diluted with water and ethanol on the surface of the skin that has been softened once. The amount of roller coating is 10g / square foot;

[0037] stand overnight;

[0038] Printing: Roll the printing chemical onto the surface of the leather, add water-based cotton varnish Melio EW-629.B, 2-ethoxyethanol and Supronil HK dye water (color: Dark Brown 01, the quality of dye water added is water-based 0.9% of cotton varnish acetate) mixed and stirred evenly, the mass ratio of the water-based cotton varnish acetate Melio EW-629.B and 2-et...

Embodiment 3

[0042] The method for making two-color printed oil leather includes the following steps: Grinding: take dry cow split leather, use 180# and 220# sandpaper to grind the bottom in sequence, and use 180# and 280# sandpaper to grind the surface in sequence;

[0043] A soft fall: the time to fall soft is 4.5h;

[0044] Roller grease: Roller coat water-based nitrocellulose varnish MelioEW-348.B (the mass ratio of water and grease is 1:3) diluted with water on the surface of leather embryo that has been softened once, and the amount of roller coating is 15g / square foot ;

[0045] stand overnight;

[0046] Printing: Roll the printing chemical onto the surface of the leather, add water-based cotton varnish Melio EW-629.B, 2-ethoxyethanol and Supronil HK dye water (color: Red Brown.B, the weight of the dye water is 0.5% of water-based cotton acetate varnish) mixing and stirring evenly, the mass ratio of described water-based cotton acetate varnish Melio EW-629.B and 2-ethoxyethanol is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com