Production of suede leather from low quality leathers

A technology of suede and second leather, applied in fur finishing and other directions, can solve the problems of inapplicability and inability to disperse fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

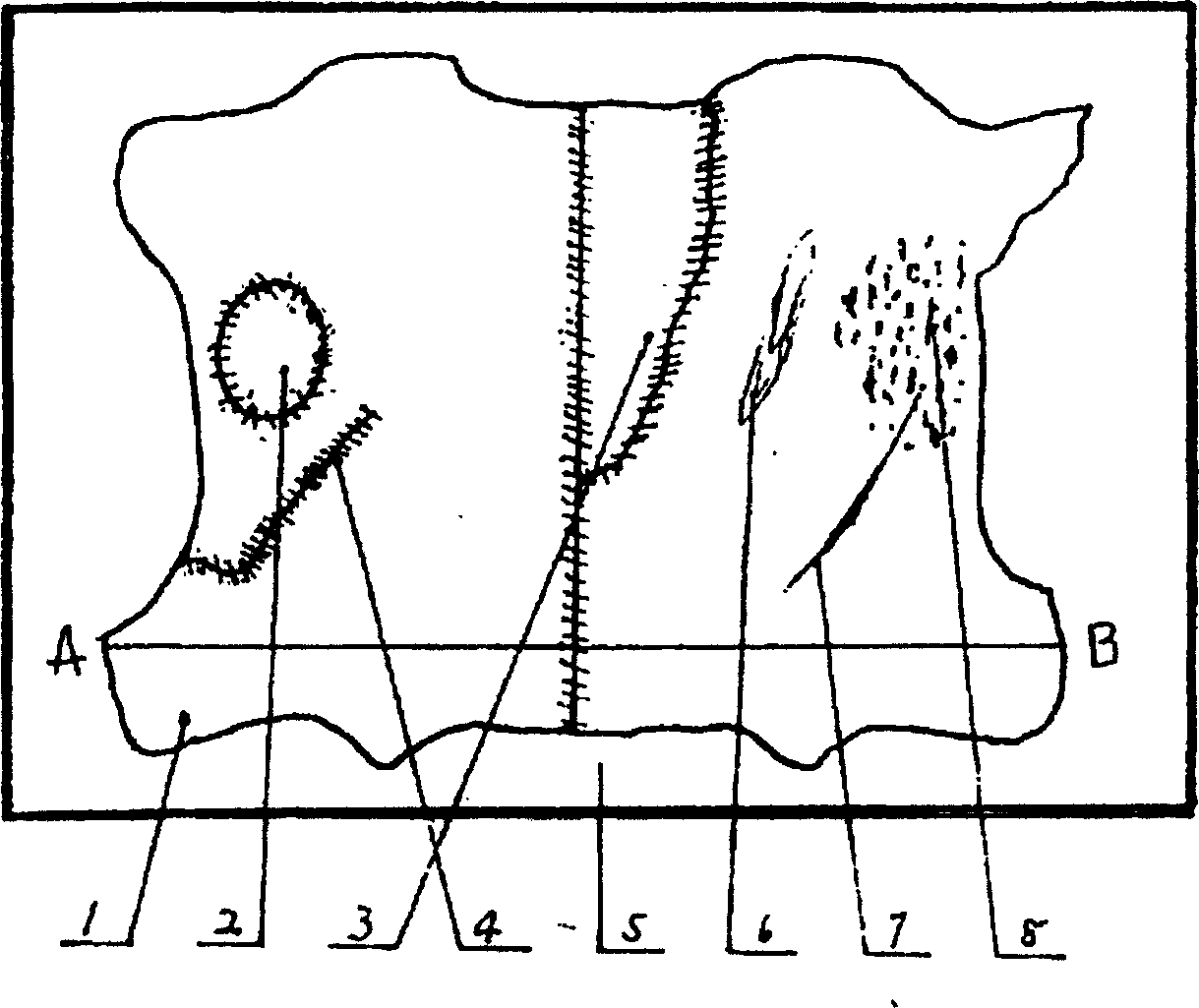

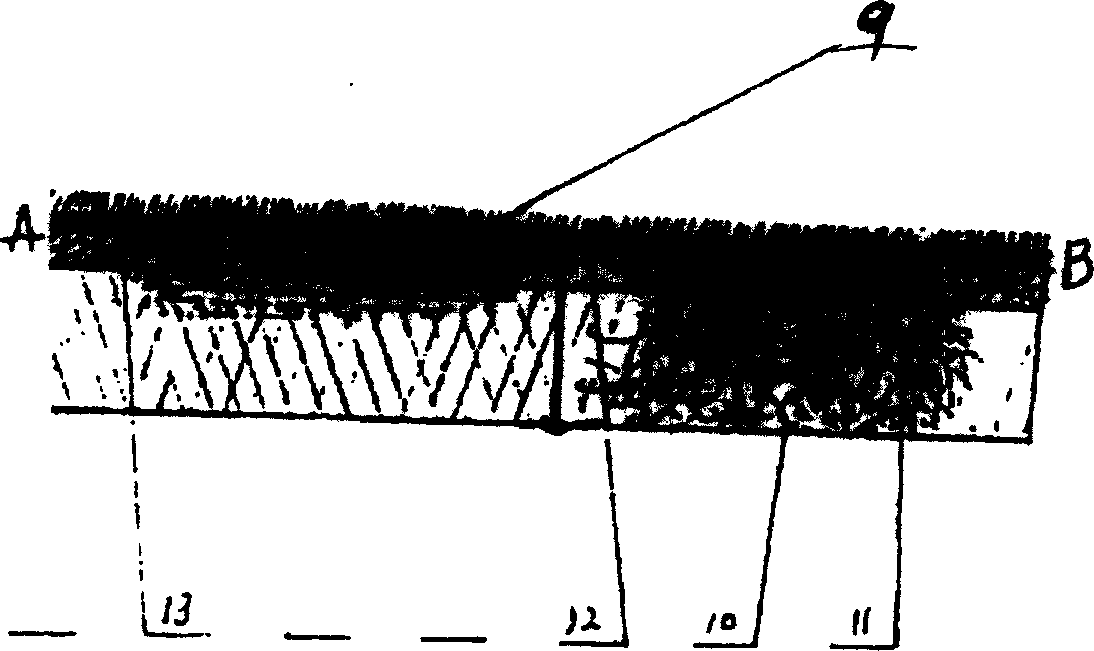

[0007] The method according to the present invention will be described in detail below in conjunction with the accompanying drawings, and its implementation details and working conditions will be further described. The damaged secondary leather involved in this method includes: small-sized or small pieces of secondary leather 1, damaged leather with holes of different sizes in the leather plate 2, damaged leather with missing pieces 3 on the edge, and machinery on the edge or in the middle. Wounded leather with torn cracks 4, mechanical scratches on the leather surface 6, damaged leather with tracer hook marks 7, damaged leather with chemically corroded depressions and pits 8, chemical agent damage network inside the leather board The residual leather of the bran board 9 caused by the layer, the residual leather of the leather fiber caused by the microbial erosion of the bad board 10, and the second and third layers of leather; The wooden board 5 used for the nail show has a k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com