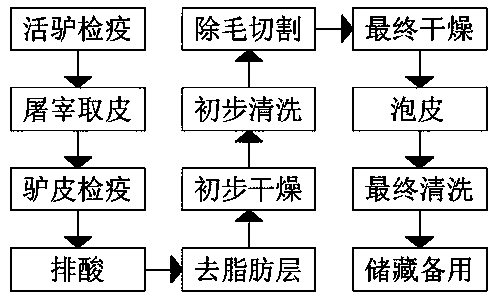

Donkey hide treatment method before donkey-hide gelatin decoction and process flow

A treatment method and process technology, applied in fur cutting, leather drying, shearing, etc., can solve the problems of donkey hide deterioration, affecting the quality of gelatin and donkey-hide gelatin, and protein loss, so as to reduce air pollution, reduce the retention of spoiled blood, The effect of ensuring freshness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: a kind of donkey hide treatment method and technical process before boiling donkey-hide gelatin, comprising the following steps:

[0039] S1. After the live donkeys are quarantined, they are sent to large slaughterhouses for slaughter. After the live donkeys are slaughtered, they enter a food-grade production and processing environment, and the donkey skins are removed for quarantine;

[0040] S2. Send the donkey skin in S1 to the acid discharge room. First, control the temperature of the acid discharge room at 0-12°C, the wind speed at 1-2m / s, and after the cooling time of 10-16h, adjust the temperature of the acid discharge room to 15-16 ℃, after the suspension time is 30-40h, adjust the temperature of the acid discharge room at 0-5°C, control the relative humidity at 80%-98%, and let the air flow naturally for 30-40h to complete the acid discharge step;

[0041] S3. Put the donkey skin that has completed the acid removal step in S2 on the donkey skin me...

Embodiment 2

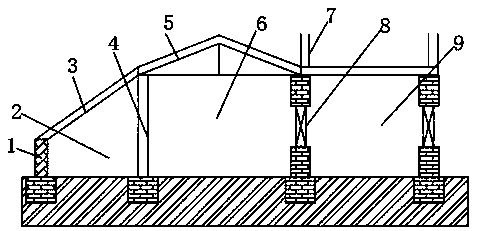

[0051] Embodiment 2: Based on Embodiment 1, the difference is that the drying room includes a lighting room A2, a lighting room B6 and a ventilation drying room 9, and the drying room is sequentially provided with a lighting room A2, a lighting room B6 and a ventilation drying room from left to right. Room 9, the left side of lighting room A2 is provided with vent A1, the upper end of lighting room A2 is provided with glass lighting wall 3, the middle of lighting room A2 and lighting room B6 is provided with support column 4, and the top left side of lighting room B6 is provided with glass lighting wall B5, ventilation openings C8 are arranged on the left and right sides of the ventilation drying chamber 9, and six exhaust outlets 7 are uniformly arranged on the top of the ventilation drying chamber 9.

[0052] Air velocity entering vent C8 by temperature difference :

[0053]

[0054] In the above formula: - the specific gravity of the outside air, - the difference b...

Embodiment 3

[0065] Example 3: Based on Example 1, the difference is that after the live donkey is slaughtered, the donkey skin enters a food-grade production and processing environment and then undergoes acid discharge. The temperature of the acid discharge room is controlled at 8°C, and the wind speed is controlled at 2m / s. After 12 hours, adjust the temperature of the acid discharge room to 15°C. After the suspension time of 30, adjust the temperature of the acid discharge room to 3°C, and control the relative humidity at 88%. After 30 hours of natural air convection, the acid discharge is completed and the next step is to remove the flesh from the fresh skin. It is easier to remove meat and oil from salt-dried skin, and the cleanliness of the treatment is greatly improved, and the use of automatic equipment to remove the fat layer improves work efficiency, and then enters the automatic shaving line to remove the hair on the donkey skin and then enters the automatic cutting line. Cut the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com