Tubular pelt board inner bag

A rawhide, tubular technology, applied in the field of tubular rawhide inner bag, can solve the problems of insufficient scraping of rawhide, backside creep of rawhide, insignificant pressure of support bag, etc., to achieve the effect of reducing drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

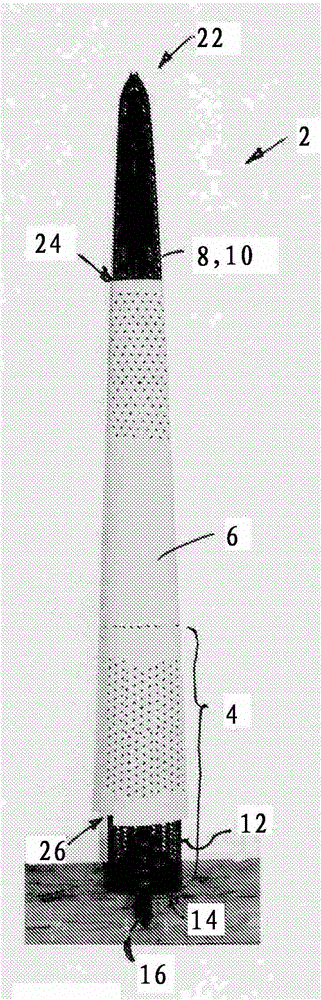

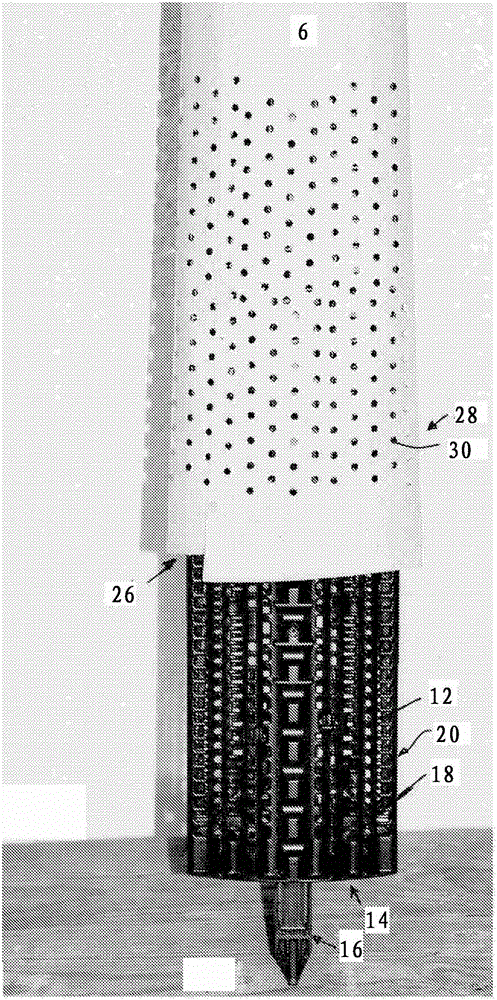

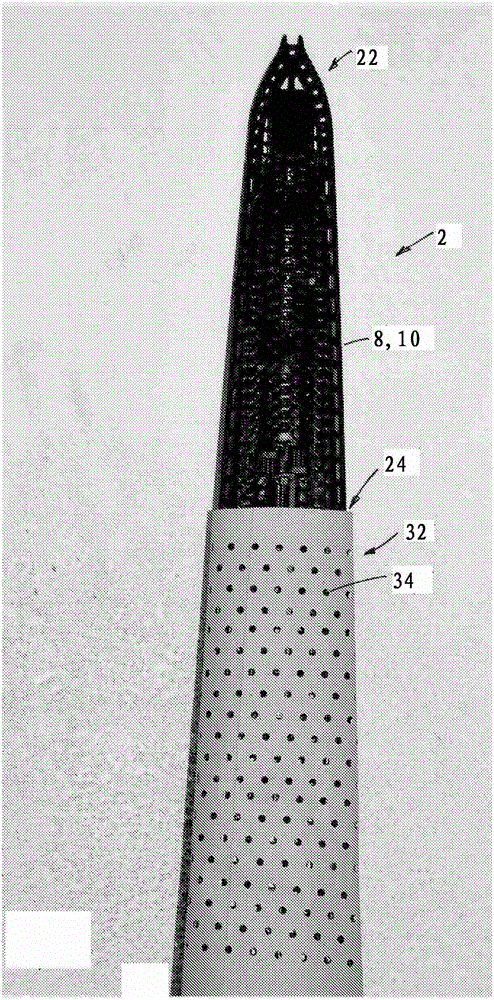

[0033] figure 1 A modern rawhide board 2 is shown comprising a support area 4 partly covered with a tubular rawhide inner pocket 6 according to the invention. The modern rawhide board 2 comprises in the illustrated embodiment two assembled arcuate half-shells 8 whose surfaces 10 have a very open structure in the shape of holes 12 . The half-shells 8 together delimit a cavity open at the foot end 14 of the rawhide board 2, wherein it comprises a blunt projection 16 from the foot end 14, which cooperates with a displaceable expansion element 18 (cf. Figure 6 ) connection, the element can be displaced between a retracted position and a forward position located between the sides 20 of the half shells 8, in the retracted position, the half shells 8 are combined with each other along the sides 20. The rawhide board 2 further comprises a pointed nose 22 .

[0034] The tubular rawhide inner bag 6 made in the illustrated embodiment of a moisture and fat absorbent paper material has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com