Manufacturing method of bicolor wax-texture crack split leather

A production method and technology of two-layer leather, which are applied in the directions of leather softening, leather drying, leather surface treatment, etc., can solve the problems of high price and poor waterproofness, and achieve the effect of simple and easy production method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

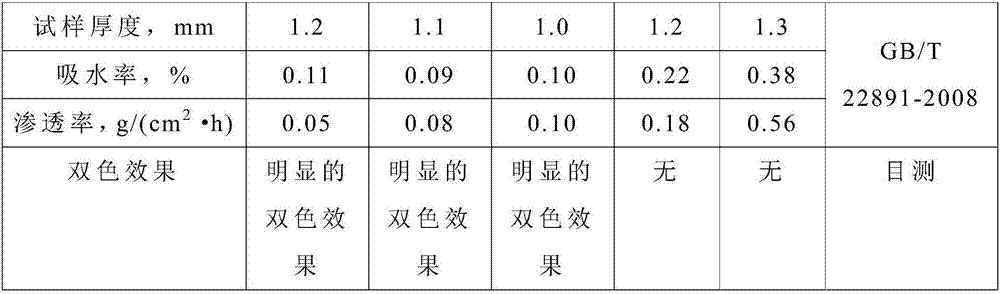

Examples

Embodiment 1

[0033] The manufacturing method of the two-layer two-color waxy crackle skin comprises the following steps:

[0034] Step 1, drying: take the two-layer cowhide material that has been processed and dyed, and dry it at 40°C for 26 hours to obtain the dried leather material;

[0035] Step 2, leather grinding: After grinding the bottom and surface of the dried leather material obtained in Step 1 in sequence, sweeping dust is carried out to obtain the leather material for grinding. Grinding the bottom and grinding the surface, the bottom grinding is: use 180 # 、220 # Grind the bottom with sandpaper, and remove the long and thick fibers on the bottom surface; the grinding surface is: use 180 # 、280 # Sandpaper grinding, in which, the belly of the leather is finely ground until the fibers on the surface of the leather are uniform;

[0036] Step 3, softening: use an octagonal drum to soften the buffed leather obtained in Step 2 at 45°C for 3 hours to obtain softened leather;

[0...

Embodiment 2

[0044] The manufacturing method of the two-layer two-color waxy crackle skin comprises the following steps:

[0045] Step 1, drying: take the two-layer cowhide material that has been processed and dyed, and dry it for 30 hours at 30°C to obtain the dried leather material;

[0046] Step 2, leather grinding: After grinding the bottom and surface of the dried leather material obtained in Step 1 in sequence, sweeping dust is carried out to obtain the leather material for grinding. Grinding the bottom and grinding the surface, the bottom grinding is: use 180 # 、220 # Grind the bottom with sandpaper, and remove the long and thick fibers on the bottom surface; the grinding surface is: use 180 # 、280# Sandpaper grinding, in which, the belly of the leather is finely ground until the fibers on the surface of the leather are uniform;

[0047] Step 3, softening: Use an octagonal drum to soften the buffed leather obtained in Step 2 at 40°C for 3.5 hours to obtain softened leather;

[0...

Embodiment 3

[0055] The manufacturing method of the two-layer two-color waxy crackle skin comprises the following steps:

[0056] Step 1, drying: take the two-layer cowhide material that has been processed and dyed, and dry it at 50°C for 24 hours to obtain the dried leather material;

[0057] Step 2, leather grinding: After grinding the bottom and surface of the dried leather material obtained in Step 1 in sequence, sweeping dust is carried out to obtain the leather material for grinding. Grinding the bottom and grinding the surface, the bottom grinding is: use 180 # 、220 # Grind the bottom with sandpaper, and remove the long and thick fibers on the bottom surface; the grinding surface is: use 180 # 、280 # Sandpaper grinding, in which, the belly of the leather is finely ground until the fibers on the surface of the leather are uniform;

[0058] Step 3, softening: Use an octagonal drum to soften the buffed leather obtained in Step 2 at 50°C for 2.5 hours to obtain softened leather;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com