Automatic leather drying device

A drying device and leather technology, applied in leather drying, raw hide/leather/fur manufacturing equipment, small raw hide/large raw hide/leather/fur treatment, etc., to achieve strong practicability, reduce manual operations, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

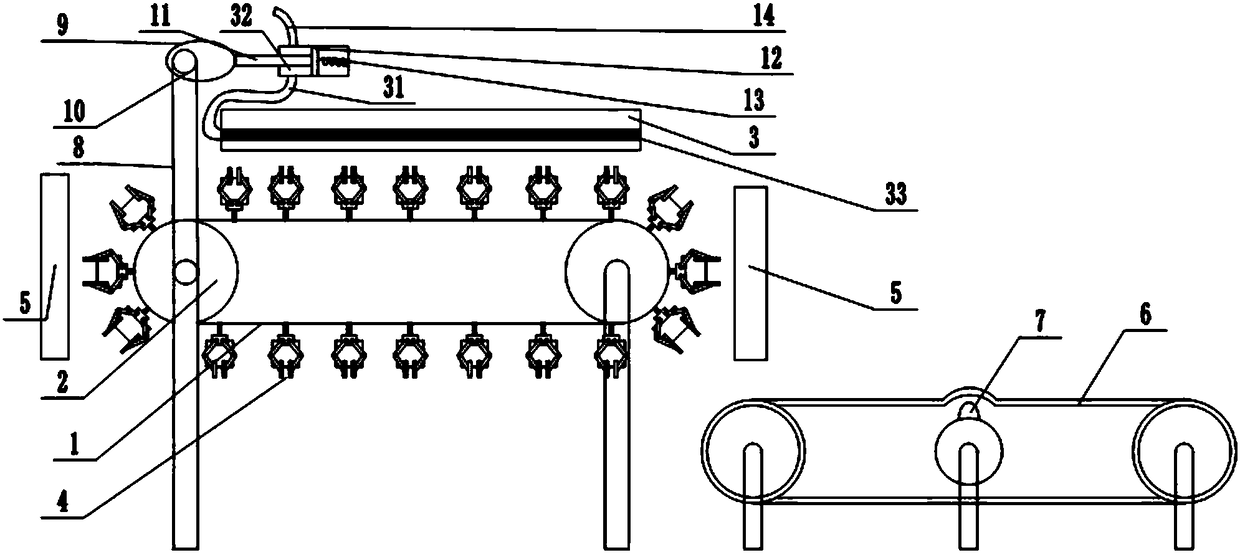

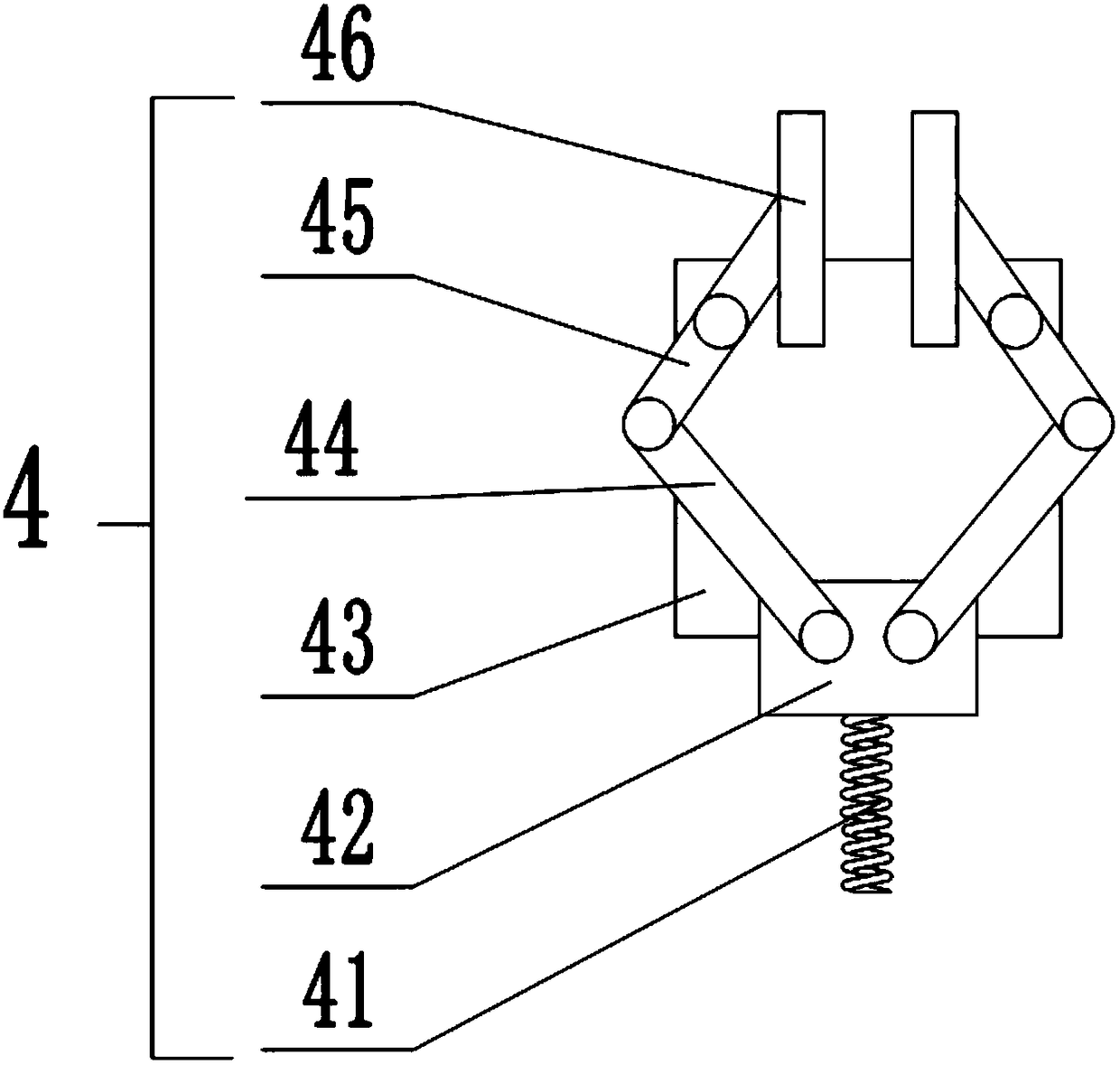

[0016] The reference signs in the drawings of the description include: conveyor belt 1, pulley 2, heating device 3, air pipe 31, fan 32, electric heating pipe 33, clamping mechanism 4, first spring 41, push block 42, frame 43 , the first connecting rod 44, the second connecting rod 45, the clamping plate 46, the magnet block 5, the conveyor belt 6, the vibration protrusion 7, the belt 8, the cam 9, the runner 10, the piston rod 11, the piston 12, the second Spring 13, intake pipe 14.

[0017] The embodiment is basically as attached figure 1 , attached figure 2 Shown: an automatic leather drying device, including a frame, a conveyor belt 1, and a pair of pulleys 2 for driving the conveyor belt 1, a heating device 3 is provided on one side of the conveyor belt 1, and the heating device 3 is arranged on the frame. The heating device 3 is provided with an air supply port,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com