Transparent leather and preparation method thereof

A leather and transparent technology, applied in leather drying, leather/skin/leather/hide chemical treatment equipment, leather surface mechanical treatment, etc., can solve the problem of large amount of transparent liquid, limiting practical application value, affecting natural properties of natural leather products, etc. problem, achieve the effect of improving application value, increasing shrinkage temperature, and maintaining natural characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

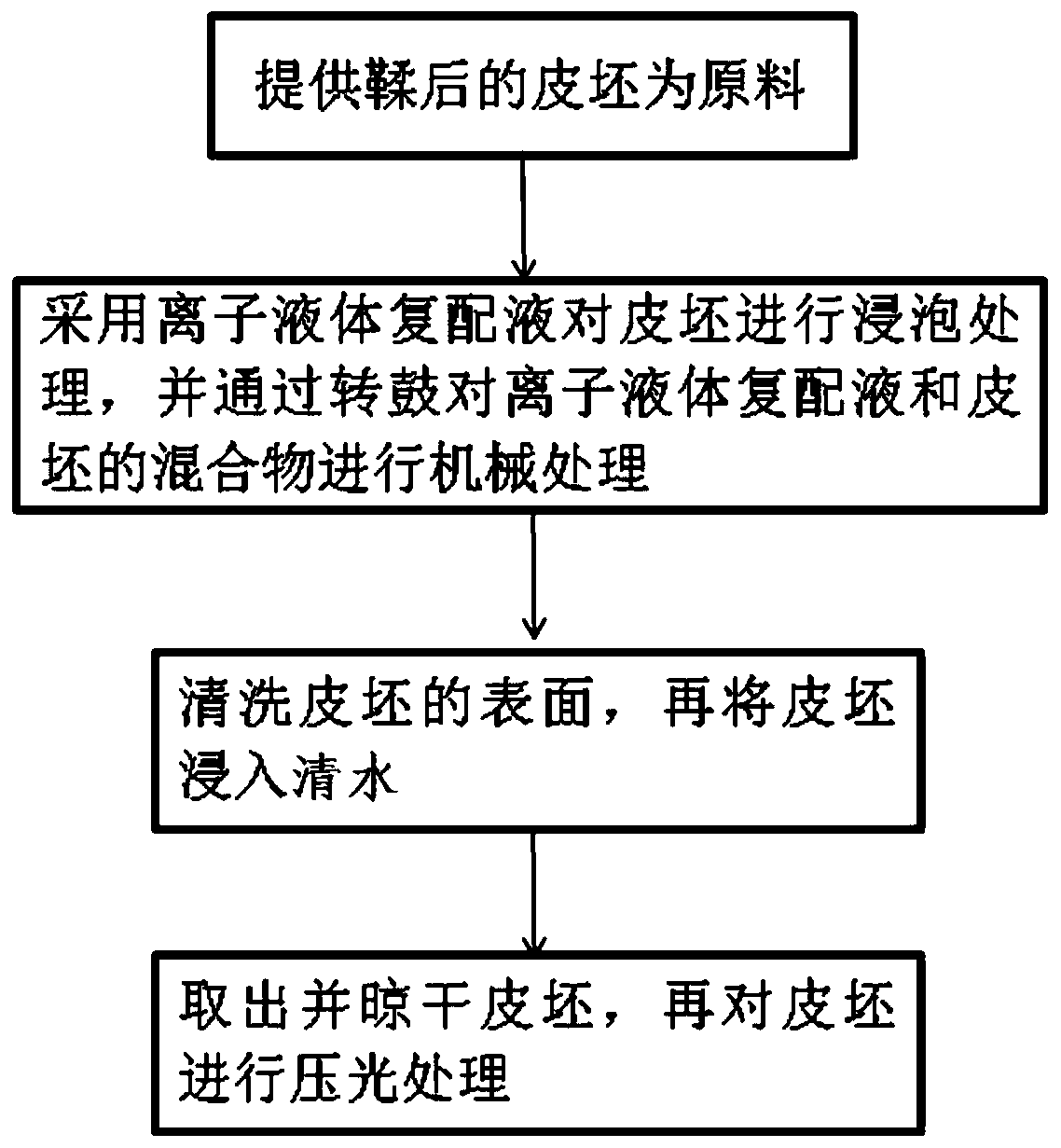

Method used

Image

Examples

Embodiment 1

[0026] Take the wet blue leather obtained after chrome tanning as the raw material (thickness 0.4mm), air it to semi-dry after riding the horse, and soak it in the 1-ethyl-3-methylimidazolium bromide / acetone compound solution (5%) , Make the material-liquid ratio 1:1.5, change the liquid 3 times, apply mechanical action with a rotating drum, rotate speed 10r / min, temperature 45℃, and total treatment time 12h. Observe the penetration through the incision. After the infiltration is completed, the skin surface is thoroughly cleaned with acetone, and then immersed in clean water for 1 hour to make the ionic liquid and organic solvent seep into the water. Take out the leather blank, ride a horse to air dry, and obtain a transparent tanned leather blank after calendering treatment at 110°C. After collecting, filtering and evaporating the above-mentioned waste liquid, acetone and ionic liquid are recovered, and the recovery rates are 70% and 98.6%, respectively. The light transmitta...

Embodiment 2

[0028] Take the wet blue leather obtained after chrome tanning as the raw material (with a thickness of 0.9mm), air it to semi-dry after riding the horse, and soak it in 1-ethyl-3-methylimidazole acetate / absolute ethanol compound solution (45 %), set the material-liquid ratio to 1:0.6, change the liquid once, apply mechanical action with a rotating drum, rotate speed 12r / min, temperature 40°C, and total treatment time 7.5h. Observe the penetration through the incision. After the infiltration is completed, the skin surface is thoroughly cleaned with absolute ethanol, and then immersed in clean water for 1.5 hours to make the ionic liquid and organic solvent seep out into the water. Take out the leather blank, dry it, and obtain a transparent tanned leather blank after calendering at 140°C. After collecting, filtering and evaporating the above-mentioned waste liquid, anhydrous ethanol and ionic liquid are recovered, and the recovery rates are 75% and 97.8%, respectively. The li...

Embodiment 3

[0030] Take the bare skin after retanning and dyeing (the color is red) as the raw material (thickness is 1.4mm), air it to semi-dry after riding the horse, and soak it in 1-butyl-3-methylimidazole hexafluorophosphate / In the water compound solution (25%), the material-to-liquid ratio is 1:1, the solution is changed twice, and the mechanical action is applied by the rotating drum, the rotating speed is 8r / min, the temperature is 50°C, and the total treatment time is 3h. Observe the penetration through the incision. After the infiltration is completed, the skin surface is thoroughly cleaned with running water, and then immersed in clean water for 1.5 hours to make the ionic liquid seep into the water. Take out the leather blank, dry it, and obtain a transparent tanned leather blank after calendering at 80°C. After collecting, filtering and evaporating the above-mentioned waste liquid, the ionic liquid was recovered with a recovery rate of 98.0%. The light transmittance of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com