Leather manufacturing method achieving three-waste discharge reduction

A technology of three wastes and waste water, which is applied in dyeing, leather degreasing, small raw hide/big raw hide/leather/fur treatment, etc. It can solve the problems of odorous gas emission, waste of renewable resources, and reduce the discharge of three wastes, etc., and achieve the weight gain of the second layer The effect of increasing the rate, improving the tear strength, and reducing the discharge of three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

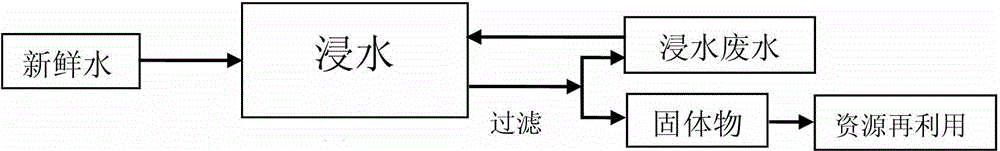

[0032] as attached figure 1 As shown, in the immersion process, the collected immersion wastewater is input to the immersion drum by the acid and alkali resistant pump, and the process of using the immersion wastewater for immersion is: based on the weight of the original skin, 180% of the immersion wastewater, Yishengbao-III 0.15% , ELIPO-S0.15%, temperature 22°C, turn for 10 minutes, 0.4% immersion aid, 0.3% degreaser, 0.6% soda ash, turn for 30 minutes / stop for 30 minutes, combined with turning and stopping for 4 times; 0.35% fungicide , rotate for 30 minutes, then rotate for 5 minutes / stop for 55 minutes, overnight; continue to rotate for 20 minutes the next day, pH9.0, temperature 23 ° C, Baume degree 4.0; after immersion, the wastewater is discharged into the wastewater pool, and the hair in the wastewater is filtered and meat dregs and other substances;

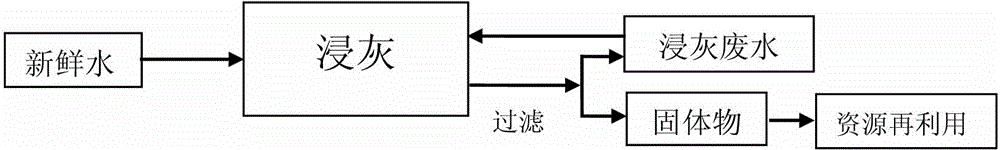

[0033] as attached figure 2 As shown, in the liming process, in the liming process, the collected liming wastewat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com