Patents

Literature

67results about How to "Improve leather yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Goat instep leather manufacturing technology

InactiveCN104774980AQuality improvementHigh fullnessTanning treatmentPre-tanning chemical treatmentManufacturing technologyEngineering

The invention discloses a goat instep leather manufacturing technology, which comprises steps of water soaking, meat removing, lime coating, hair removing, lime soaking, lime removing, softening, acid soaking, tanning, blue leather sorting, water draining, grease cutting, re-tanning and dyeing, secondary water draining, vacuumizing, hanging, softening through vibration, stretching, paving on a plate, trimming, and painting. The technology is reasonable, the re-tanning and dyeing step is very important in the technology, the leather quality can be prominently improved by improving the re-tanning and dyeing technology, the growth lines and dorsal ridge lines are completely stretched out, the leather surface becomes finer, the leather yield is increased; the location difference of the leather is reduced, the fullness of whole leather is increased, the leather becomes more moistened, the production cost is reduced, and the leather becomes more natural and environment-friendly.

Owner:ZHEJIANG JINXIN LEATHER

Method for ash-free and no-sulfurizing alkaline liming treatment for making pigskin leather

InactiveCN1900321AImprove leather yieldGood power savingPre-tanning chemical treatmentChemistrySodium sulphide

The no-ash and no-sodium sulfide liming process for making pigskin leather features its greatly reduced pollution, and no use of pollutant sodium sulfide, sodium hydrosulfide and lime makes it easy to treat exhausted waste water. Compared with conventional technological process, the present invention has the advantages of no deposit, reduced waste water exhaust, short production period, saving in material and lowered comprehensive cost.

Owner:SICHUAN UNIV

Crocodile belly skin tanning processing method

ActiveCN104593527ASolve problems such as flat, thin, empty and looseAvoid separationTanning treatmentPre-tanning chemical treatmentBiologyChemistry

The invention relates to a crocodile belly skin tanning processing method. The problems that fats are difficult to remove, dermatome and oracle bone are difficult to soften, scales and shells are difficult to remove, bleaching and fading effects are not good, the finished leather is flat, thin, empty and loose, and the hang drying method is improper and the like are unsolved in the existing crocodile skin tanning technology. The crocodile belly skin tanning processing method comprises the steps of soaking, fleshing, oil film scraping, degreasing and pre-liming, oil film scraping, aldehyde pre-tanning, oil film scraping, liming, oil film scraping, scale brushing, deliming, oil film scraping, united bleaching, softening, oil film scraping, combined bleaching, degreasing, oracle bond softening and bleaching, pickling and softening, tanning, shaving, degreasing, neutralizing, re-tanning, fat-liquoring, leather fluffing, dry cleaning, dyeing, hang drying and coating. The processing technology of Nile crocodile belly raw material skin is provided, and the crocodile skin is soft and plump and elastic, keeps the complete crocodile skin patterns, not only can be processed into dark leather, but also can be processed into light leather and white leather. The leather can be used for processing luggage leather, shoe leather, belt and watch strap leather and the like, and has a very high market value.

Owner:蚌埠启邦科技信息咨询有限公司

Sheep shoe upper leather manufacturing process

InactiveCN104789714AQuality improvementHigh fullnessTanning treatmentPre-tanning chemical treatmentEngineeringSoftening

The invention discloses a sheep shoe upper leather manufacturing process which particularly and sequentially comprises the steps of soaking, fleshing, lime wrapping, depilating, liming, deliming, softening, souring, tanning, blue pelt lot grouping, wringing, shaving, retanning and dyeing, secondary wringing, vacuuming, hanging and airing, vibration softening, stretching, toggling, deburring, leather fluffing and finishing. The process provided by the invention is properly selected, since the retanning and dyeing procedure plays an important role in manufacturing sheep leather, through improvement of the procedures, leather quality is improved obviously, the growth lines and the back-ridged lines of rawhide are completely opened, grain sides are flat and fine, and the yield of leather is increased; the location difference of a leather body is reduced, the fullness of the entire leather is improved, the leather body can be moistened, the production cost is lowered, and the leather is enabled to be natural and environment-friendly.

Owner:ZHEJIANG JINXIN LEATHER

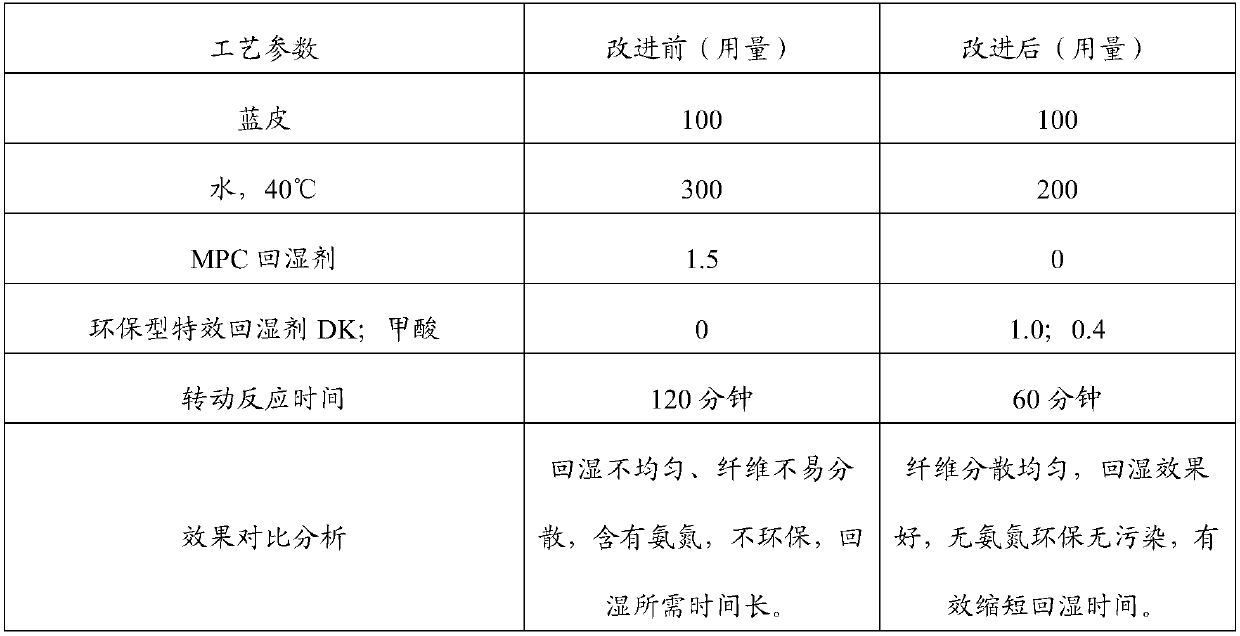

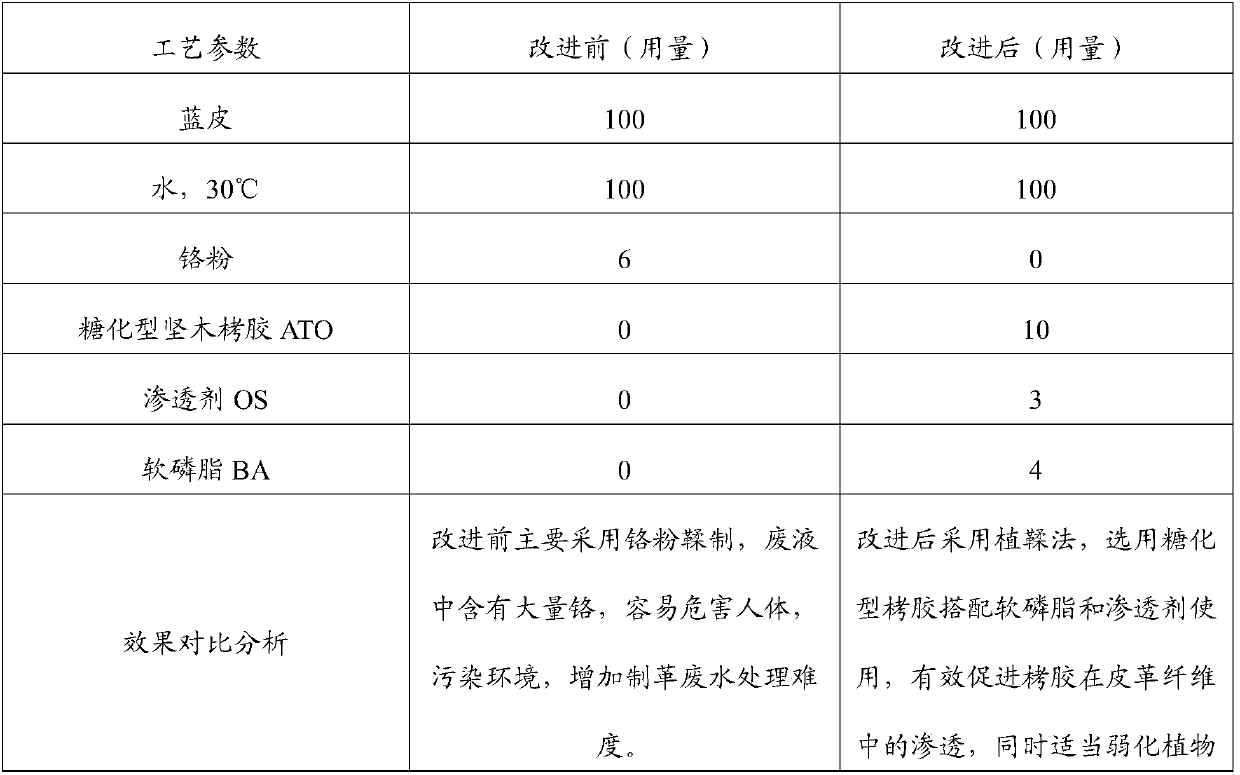

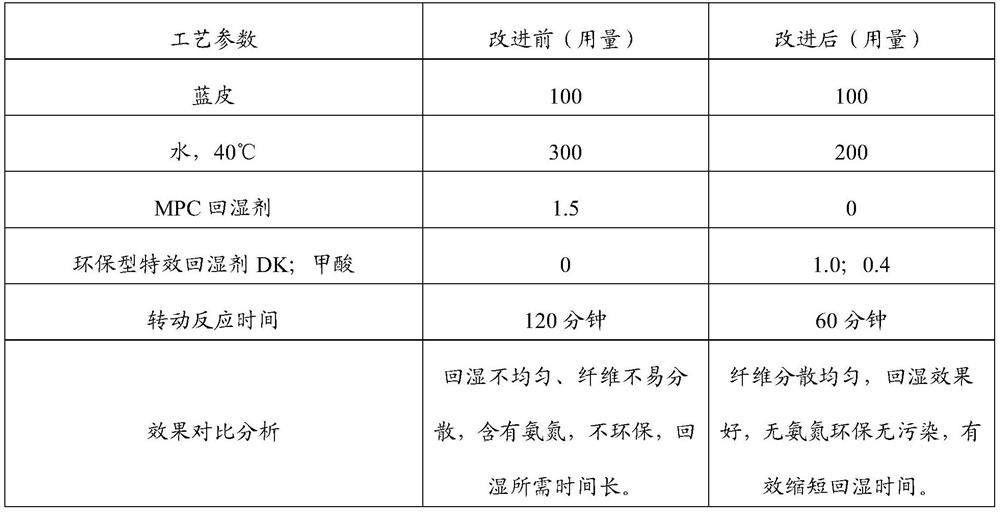

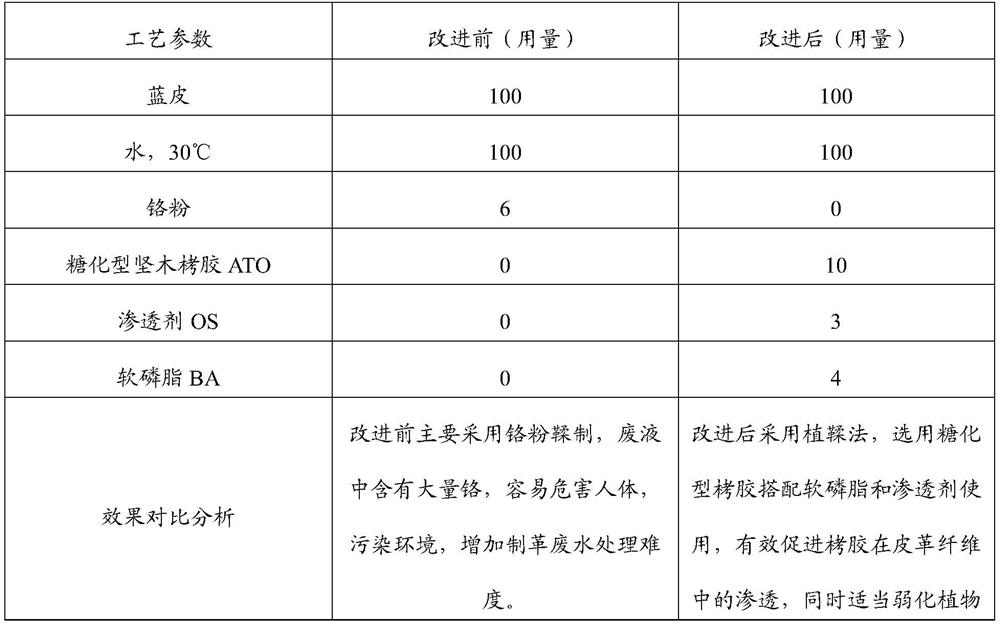

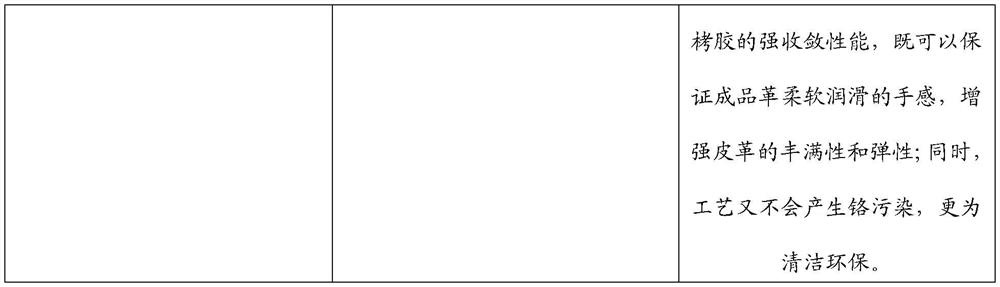

Production method for environmentally-friendly semi-vegetable tanned waxed tyre cow leather

ActiveCN109536646AFast absorptionAbsorb evenlyTanning treatmentPre-tanning chemical treatmentFiberColor changes

The invention discloses a production method for environmentally-friendly semi-vegetable tanned waxed tyre cow leather. The production method comprises the following steps of sequentially carrying outthe processes of material preparing, rewetting, tanning, neutralizing, packed dyeing and fat liquoring. According to the production method, in the rewetting process, an environmentally-friendly special-effect rewetting agent is adopted for softening the leather, so that rapid rewetting can be realized, the moisture can be uniformly absorbed, in addition, leather fibers can be dispersed, the absorption of subsequent materials can be facilitated, the rewetting time can be short, the rewetting effect can be good, and the purposes of cleanness and environmental protection can be achieved; and in the tanning process, a vegetable tannin agent is adopted to replace conventional chromium powder for tanning, so that the physical performance indexes of the chrome tanned leather can be guaranteed, inaddition, the finished leather has a soft and smooth hand feeling and proper fullness and elasticity, and therefore chromium pollution cannot be generated, and cleanness and environmental protectioncan be realized; in the fat liquoring process, grease 101 with the waterproof capability and the waxing effect is adopted, so that the waterproof and anti-aging capabilities of the leather can be improved, in addition, the color-changing effect can be achieved through high-temperature waxing in a subsequent coating process, the fashionable elements of the product are added, and the product grade is improved.

Owner:FENGAN LEATHER

Blue wet leather treatment process

ActiveCN103805722AImprove area yieldReduce dosageLeather manufacturingLeather/skins/hides/pelt chemical treatment apparatusCost savingsChemistry

The invention relates to the technical field of leather processing, and provides a blue wet leather treatment process which increases the yield of leather area, and is lower in loose side rate, uniform to dye, better in leather performance, less in use level of grease, economical, and cost-saving. The process comprises the following steps: splitting; shaving; weighing; rinsing; and retanning. The process is characterized in that at least a shaving treatment is further carried out after retanning step.

Owner:XINGYE LEATHER TECH CO LTD

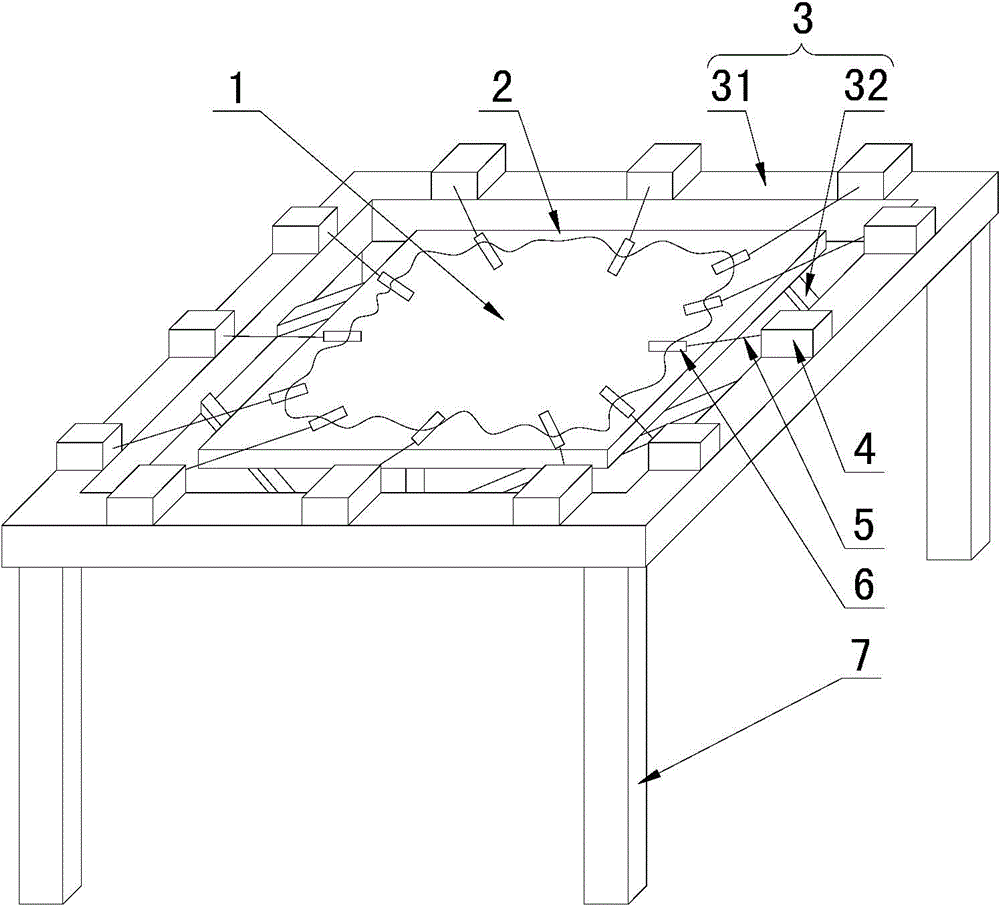

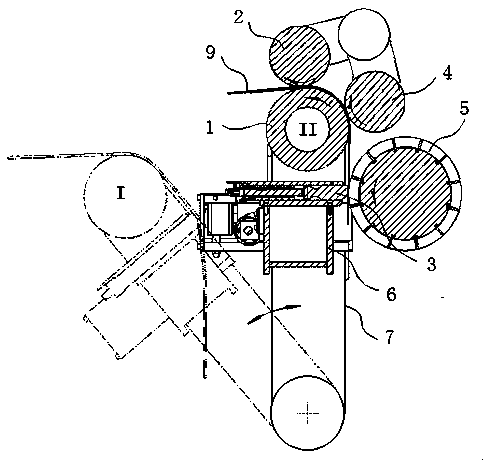

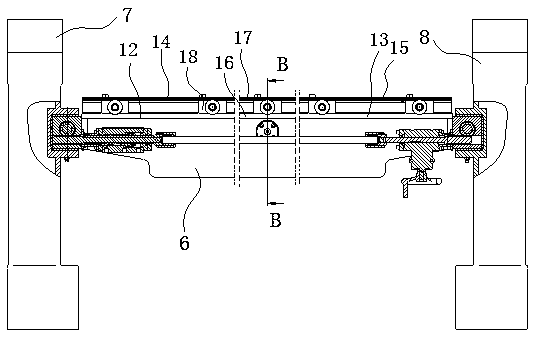

Device for tightly stretching leather

ActiveCN104450987AQuality improvementImprove leather yieldSkins/hides/leather/fur manufacturing apparatusLeather dryingEngineeringMechanical engineering

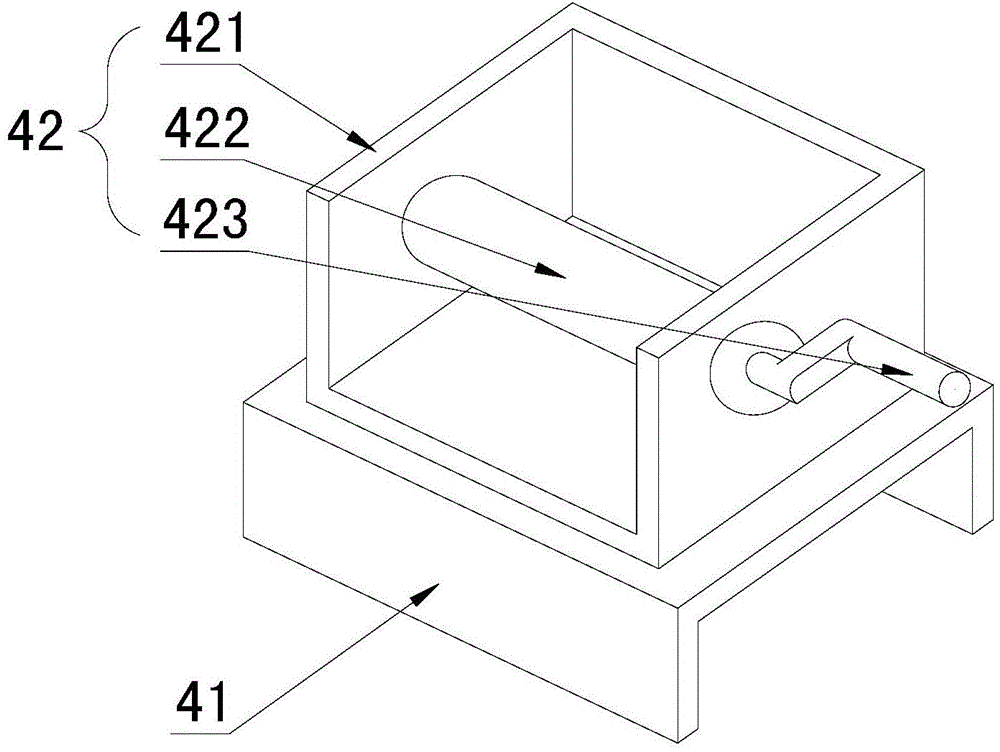

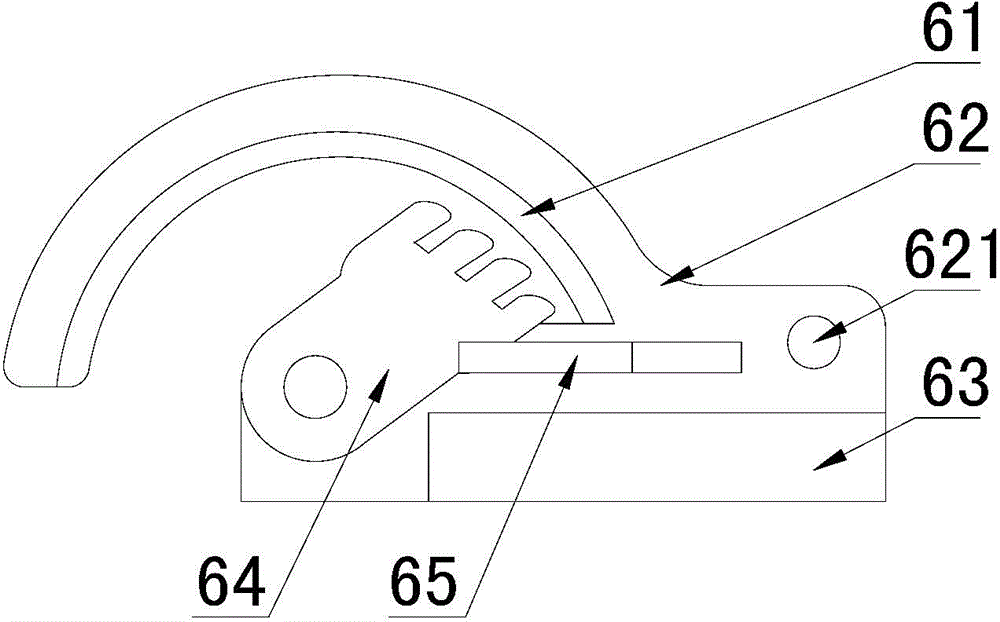

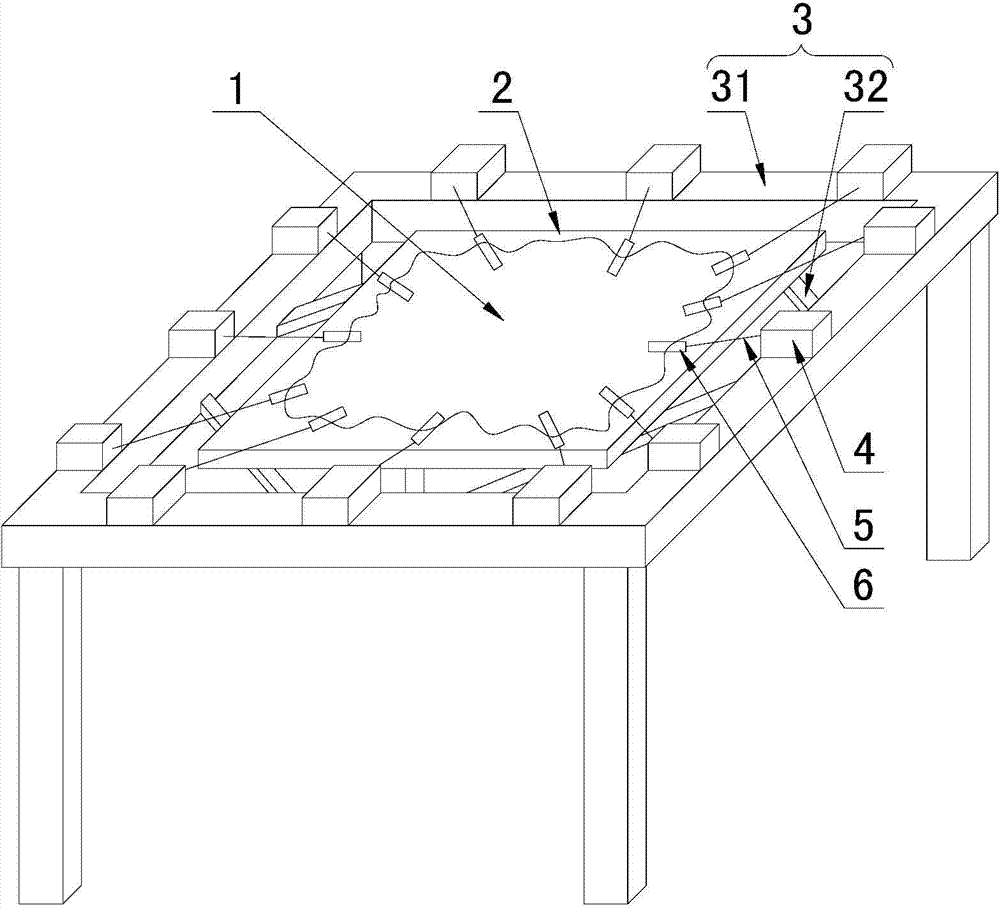

The invention relates to the technical field of leather processing and provides a device for tightly stretching leather. The device comprises a stretching plate (2), a framework (3), a plurality of clips (6) and a plurality of line tensioning pieces (4) corresponding to the clips (6). The device is characterized in that the framework (3) is provided with a supporting part (32) for putting the stretching plate (2); an edge frame (31) of the framework (3) is located at the periphery of the stretching plate (2); one end of each clip (6) is connected with a rope (5) and the other end of each clip (6) is provided with a clamping part for tightly clamping a leather sheet (1); and the line tensioning pieces (4) are distributed at the periphery of the stretching plate (2) and are fixedly connected with the edge frame (31) of the framework (3). By virtue of the device for tightly stretching the leather, the leather sheet (1) can be stretched in a plurality of directions, so that the quality of a leather finished product is improved and the leather yield in leather processing is increased.

Owner:CHONGQING LONGFA LEATHER PROD

Manufacturing method for lasting bacterium resisting and inhibiting type leather

ActiveCN106222328ADurable and excellent antibacterial propertiesImprove antibacterial propertiesTanning treatmentLeather surface finishingLeather industryAmmonium

The invention discloses a manufacturing method for lasting bacterium resisting and inhibiting type leather. According to the manufacturing method, during pretanning, main tanning, retanning filling and dyeing, oxidization chitosan quaternary ammonium salt is used for treating the leather, formyl groups on the oxidization chitosan quaternary ammonium salt react with active groups on the leather so that the chitosan quaternary ammonium salt can be connected to the leather, and the bacterium resisting and inhibiting type leather is manufactured. The manufacturing method can be widely applied to the leather industry.

Owner:SICHUAN UNIV

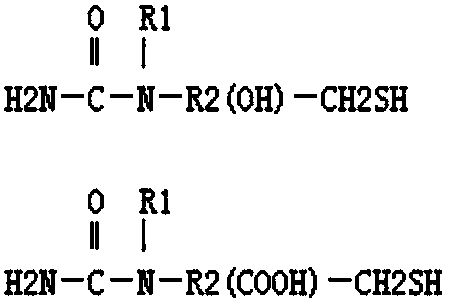

New-type adjuvant for leather production

InactiveCN1676614AImprove physical and chemical propertiesImprove leather yieldPre-tanning chemical treatmentSpecial effectsAdjuvant

A new adjuvant for leather production, and the use of this new adjuvant. The adjuvant contains alcohol compounds, inorganic, lactam compounds and sequestering agents of calcium, etc. The additive can be used in the leather production to generate special effects, capble of significantly improving the leather rate, thickness, fullness, flexibility of the leather, reducing the surface relaxation rate and significantly reducing the sewage discharges.

Owner:张壮斗

Hogskin suede vamp leather after-tanning wet finishing method

InactiveCN103290152ABasically evenNo visible poresLeather surface finishingPulp and paper industryPig skin

The invention discloses a hogskin suede vamp leather after-tanning wet finishing method which comprises the following steps: squeezing of hogskin vamp blue wet leather, primary shaving (flesh side), secondary light shaving (grain surface), wet milling, weighing, rewetting, water washing, retanning, water washing, neutralizing, water washing, primary greasing, filling, water washing, bulging, primary drying, secondary drying, remoistening, softening by vibration, dry milling, weighing, tempering, water washing, dyeing, secondary greasing, top dyeing, water washing, bulging, drying, remoistening, softening by throwing, (other steps), scaling, and warehousing. The finished product has the advantages of thin and short fuzz and no obvious pores, and is basically uniform; and the leather is plump and soft, has the advantages of high thickness, favorable fastness and high yield.

Owner:WENZHOU UNIVERSITY

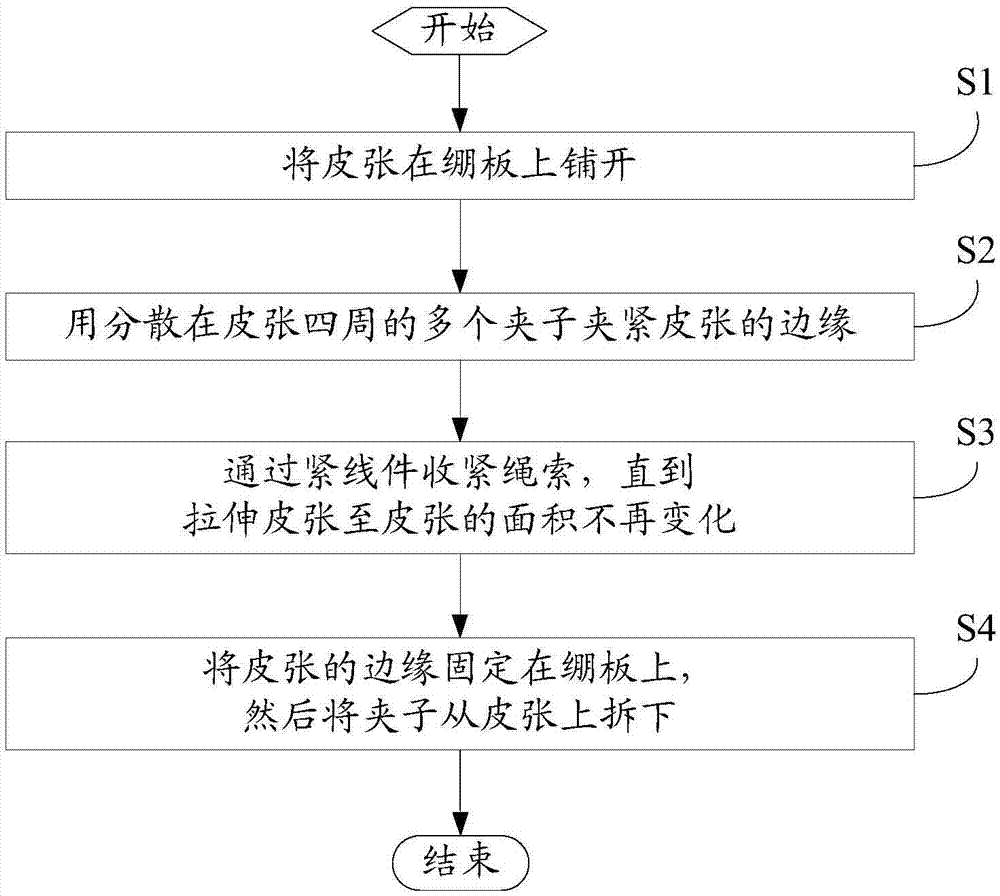

Method for tightening leather

InactiveCN104498641AIncrease the areaQuality improvementLeather stretching/tensioningSkins/hides/leather/fur manufacturing apparatusEngineeringMechanical engineering

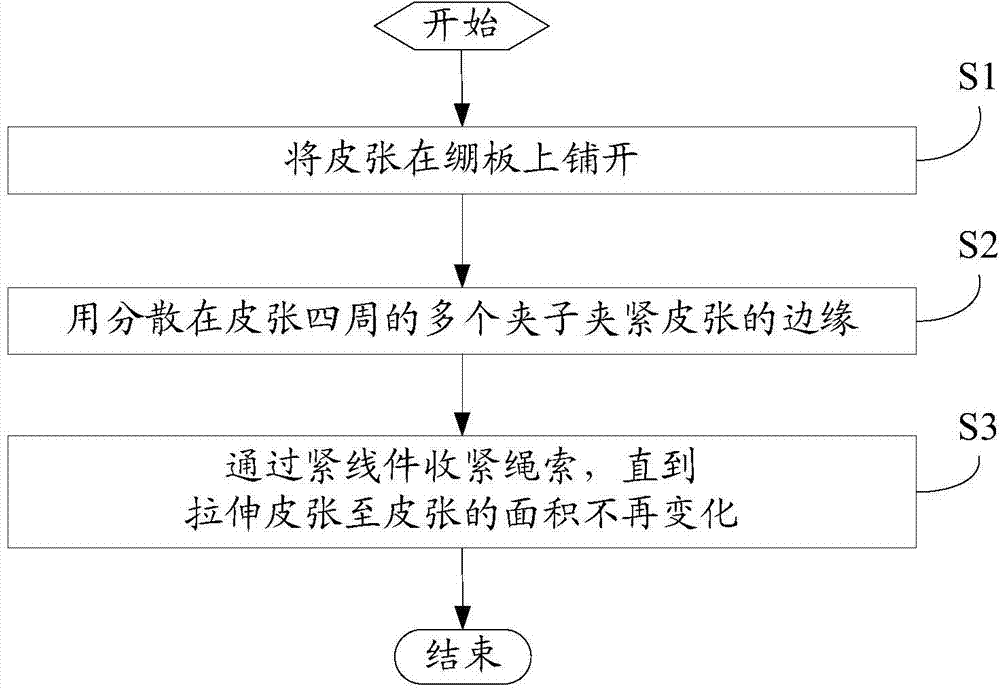

The invention discloses a method for tightening leather. A device for tightening leather is used for the method; the device comprises a tightening plate, a framework, a plurality of clips and a plurality of wire stringing elements, wherein the tightening plate is used for accommodating leather; the frame of the framework is positioned on the periphery of the tightening plate; one end of each clip is connected with ropes; the plurality of wire stringing elements correspond to the clips; the framework is provided with a support part for accommodating the tightening plate; the wire stringing elements are dispersively arranged on the periphery of the tightening plate, and are fixedly connected with the frame of the framework. The method comprises the following steps: spreading the leather on the tightening plate; clamping the edge of the leather by the plurality of clips which are dispersed at the periphery of the leather; tightening the ropes by the wire stringing elements and stretching the leather until the area of the leather is not changed. The method for tightening the leather is characterized in that the leather can be tightened more uniformly so as to obtain a relatively large leather area, and the quality of leather products and the leather yield for leather processing are improved effectively.

Owner:CHONGQING LONGFA LEATHER PROD

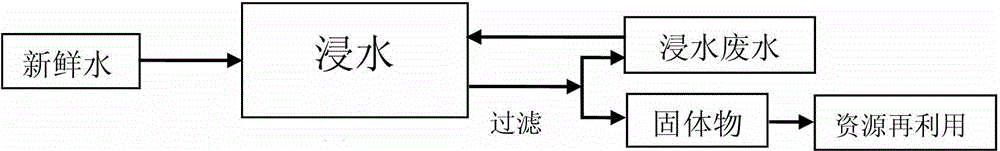

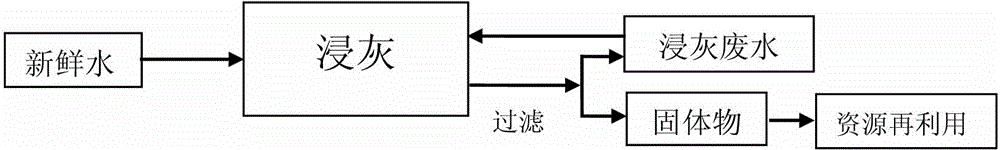

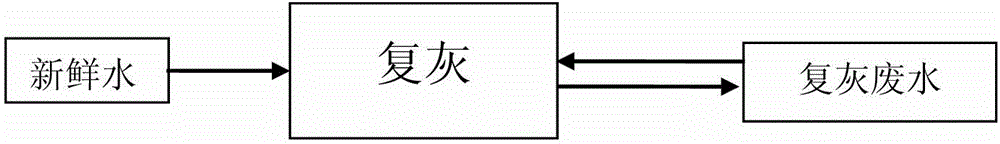

Leather manufacturing method achieving three-waste discharge reduction

InactiveCN105779667ADoes not affect executionQuality is not affectedTanning treatmentPre-tanning chemical treatmentWastewater reusePollution

The invention provides a leather manufacturing method achieving three-waste discharge reduction. The leather manufacturing method can comprehensively achieve reduction of three-waste discharge in the leather manufacturing process. Through wastewater reuse, solids are inhibited from decomposing or dissolving and are recycled; and exhaust emission is reduced through reduction of volatilization of wastewater, the solids and chemical materials. The leather manufacturing method is specially characterized in that soaking, liming, reliming, lime removal and softening, pickling chrome tannage, degreasing, retanning, neutralizing and dyeing are conducted independently, water is saved by over 70%, and energy is saved by over 20%; emission of solid waste is reduced by over 70%; the chemical materials are saved by 15% to 100%, and pollution to air due to volatilization of the chemical materials is reduced; and by the adoption of the method, the quality of leather can be improved remarkably.

Owner:张壮斗

Leather patching method

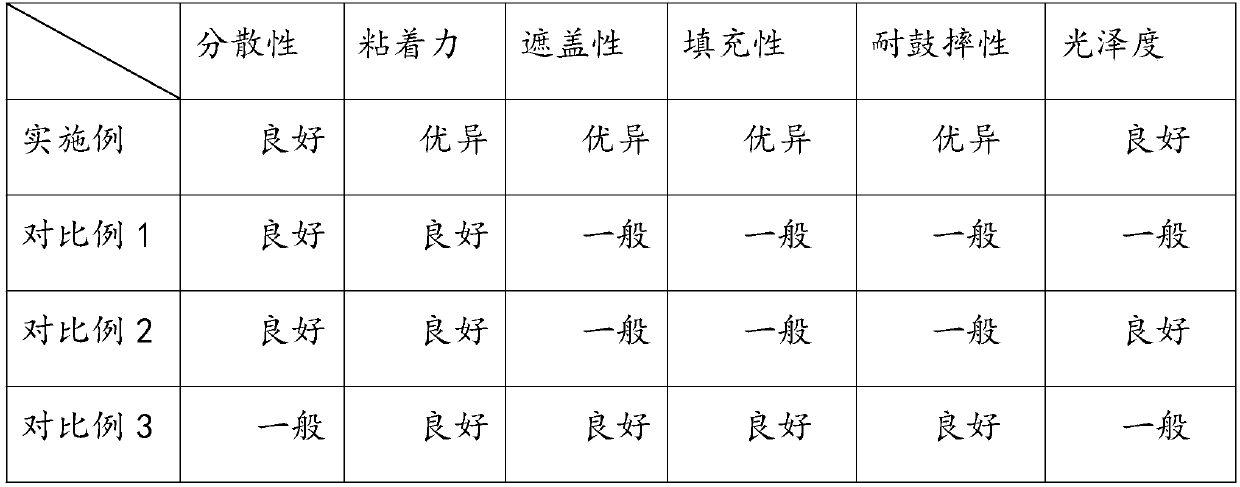

InactiveCN109576420ASmooth grainIncrease coverageLeather surface finishingUltimate tensile strengthCoating

The invention relates to the technical field of leather chemistry and engineering and provides a leather patching method. A polyurethane foam resin material is introduced into a patching agent for patching to create a hollow-system patching agent, density of the patching agent is reduced while strength is excellent and stable, and accordingly an elastic stable object is formed. In addition, by combination of mechanical operations such as roller coating and press polishing, the patching agent can be firmly filled at defective or damaged parts of crust leather. The technical defects of lack of falling resistance and proneness to recessing of traditional patching coatings are overcome, a production cycle is shortened, and production efficiency is improved.

Owner:XINGYE LEATHER TECH CO LTD

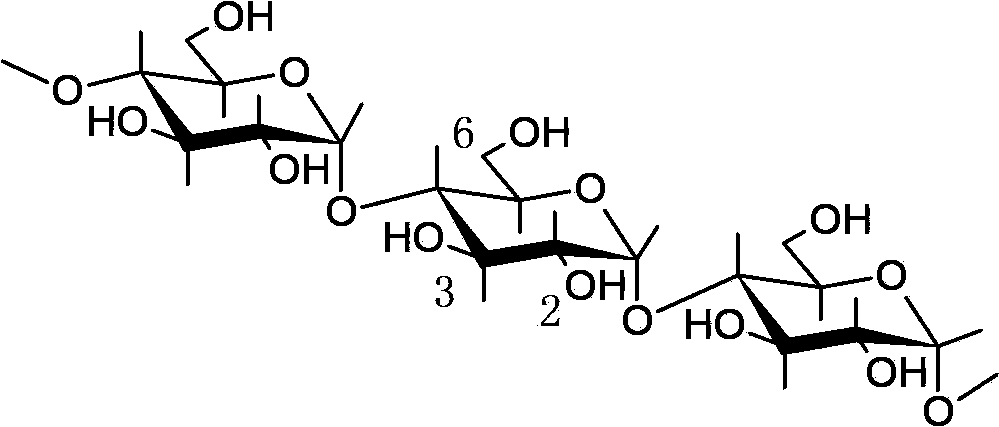

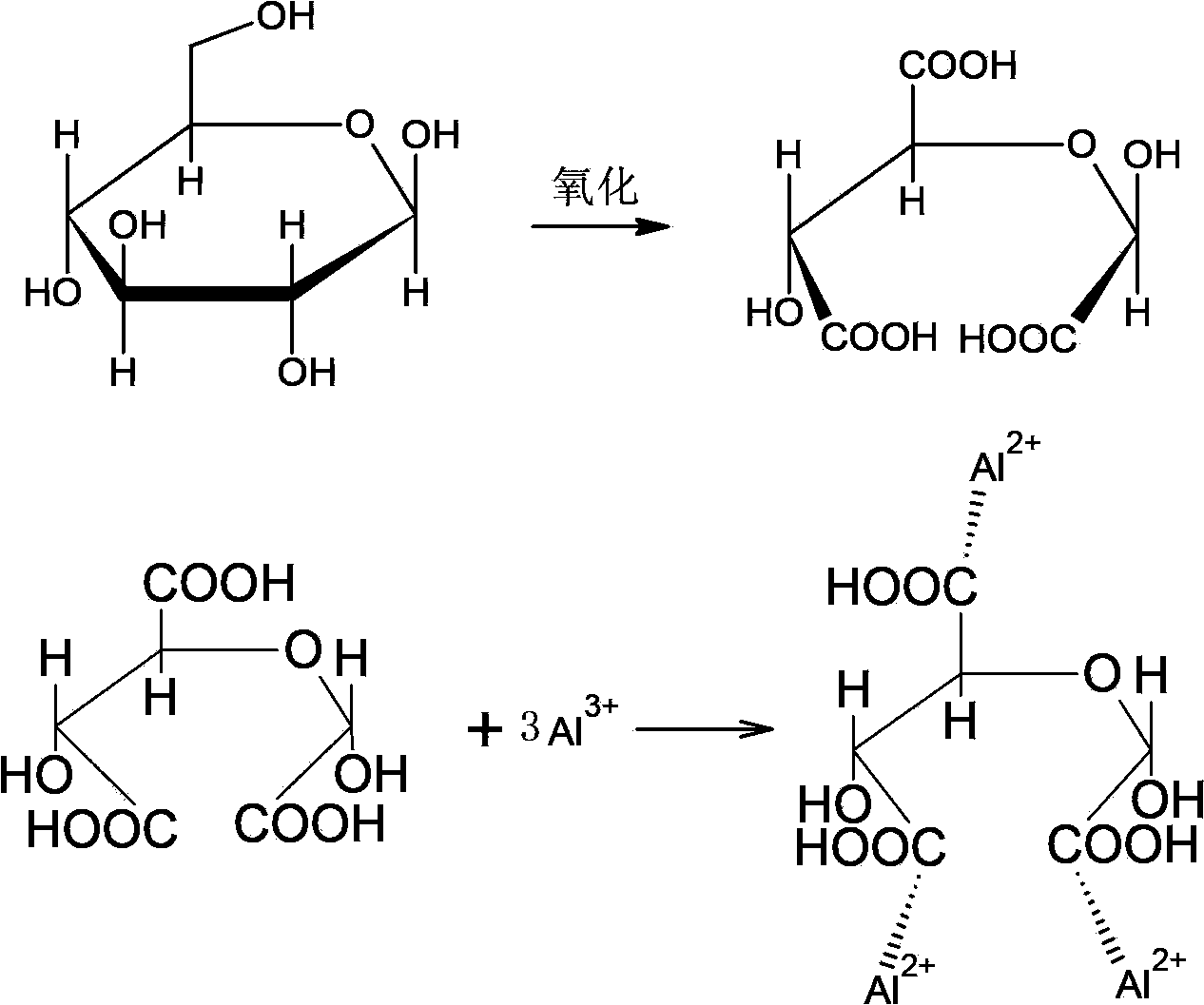

A kind of preparation method of aluminum-oxidized starch complex tanning agent

InactiveCN102747173BNo toxicityWide variety of sourcesTanning treatmentAluminum IonRotary evaporator

A preparation method of an aluminum-oxidized starch complex tanning agent comprises steps of: first mixing starch and water, adding concentrated nitric acid and a catalyst, and stirring for reaction, washing reaction products with ethanol or acetone to obtain the oxidized starch; and evenly mixing the oxidized starch and aluminum ions, oscillating, steaming out excessive water by a rotary evaporimeter, and drying the obtained product. The method of the invention can effectively improve the tanning property of the aluminium tanning agent, maintain original advantages of the aluminum tanning agent and greatly mitigate the phenomenon of detanning. The method of the present invention employs nitrate as an oxidant to oxidize hydroxyl groups to generate oxidized starch with high degree of carboxylic substitution, and utilizes a principle of acid degradation to reduce the relative molecular mass of the oxidized starch, so as to obtain aluminum-containing macromolecular tanning agent with good permeability, high absorption rate and excellent tanning property. The obtained leather tanning agent has good tanning and filling performances, and is suitable for main tanning and retanning; after the main tanning, a pickled skin has a shrinkage temperature raised to 90 DEG C, gains pure white leather body and obvious thickness increase; and after retanning, a product has good elasticity, bright color, gloss, and soft and full handle.

Owner:SHAANXI UNIV OF SCI & TECH

Method for making flexible dry milled leather through low-grade wet blue leather

ActiveCN107988451AImprove firmnessHigh fullnessLeather stretching/tensioningSpecial leather manufactureLower gradeLow graded

The invention relates to the technical field of leather making process, and provides a method for making flexible dry milled leather through low-grade wet blue leather. The method comprises the stepsof water squeezing shaving and weighing of the selected low-grade wet blue leather, softening and rising, washing, neutralizing, washing, grease adding, washing, drum outlet standing, water squeezingextension, primary hanging airing drying, softening, dyeing, washing, color registering, washing, surface treatment, washing, drum outlet standing, water squeezing extension, secondary hanging airingdrying, flesh side water spraying and standing, vibration staking, milling and coating. On the basis of the traditional process, three procedures of retanning, filling and vacuum drying in the after-tanning wet machining segment can be removed, the whole operation flow is short, the method is suitable for large-batch production use, the cost is reduced by 30%, the leather yield is increased by 20%, the leather hand feeling is soft and light, the leather body is rich and elastic, the pattern is full and uniform, and the utilization rate is high.

Owner:XINGYE LEATHER TECH CO LTD

Finishing method for improving lamination degree of coating and crust leather

The invention relates to the technical field of leather making chemistry and engineering and provides a finishing method for improving the lamination degree of a coating and crust leather. According to the finishing method, non-ionic polyurethane resin without charges and a non-ionic oil wax auxiliary agent are selected as main body materials of a finishing agent; the surface tension of a finishing agent is reduced so that the leveling property and the permeability are improved; a technology is balanced and primary and secondary aspects in each phase and each operation are grasped; the lamination degree of the coating and the crust leather is improved; an ideal thin film is formed on the surface of the crust leather through the finishing agent and a shell is not easy to form after the coating is repeatedly bent or stretched; the non-ionic oil wax auxiliary agent has good filling and covering effects and can be used for improving the flatness and fineness of a particle surface of the crust leather; injuries on the particle surface of the crust leather are covered; the grading rate and utilization rate of the crust leather are improved.

Owner:XINGYE LEATHER TECH CO LTD

High-range cattle hide sleeping mat leather manufactured through cooperation of zirconium-aluminum-titanium and tanning agent

ActiveCN105219894AEliminate hazards to human health and the environmentImprove leather yieldTanning treatmentHuman healthEnvironmental geology

The invention discloses a manufacturing method for high-range cattle hide sleeping mat leather manufactured through cooperation of zirconium-aluminum-titanium and a tanning agent. Chromium and formaldehyde are not used during the production process, and damage of the chromium and the formaldehyde to human bodies is avoided. Compared with traditional sleeping mat leather production, the cattle hide sleeping mat leather manufactured through cooperation of the zirconium-aluminum-titanium and the tanning agent has the following advantages that (1) an obtained leather blank is light in color, and light-color leather production is facilitated; (2) the yield of leather is high, and economic benefits of an enterprise are increased; (3) the grain side is flat and fine, can be slightly coated, and is suitable for manufacturing high-range sleeping mat leather; (4) compared with sleeping mat leather produced with vegetable tanning agents, the high-range cattle hide sleeping mat leather is good in filling performance and soft in hand feeling; (5) the high-range cattle hide sleeping mat leather does not contain chromium and formaldehyde and can not damage human health.

Owner:SICHUAN UNIV

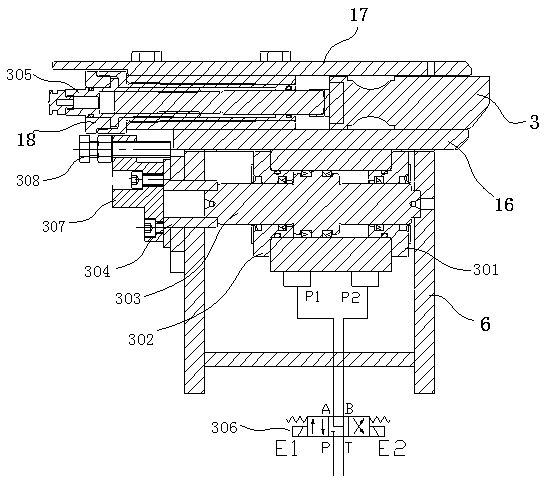

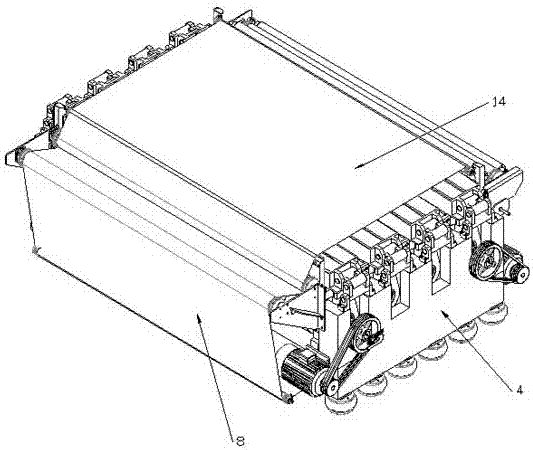

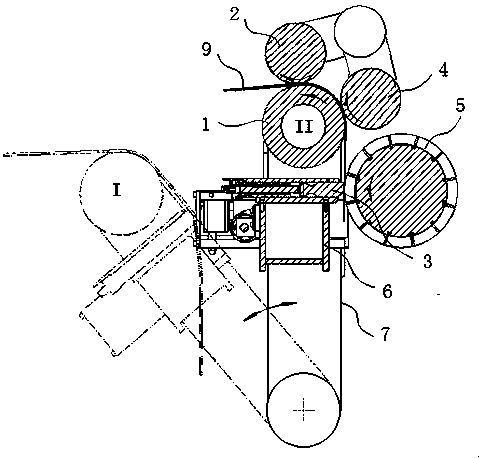

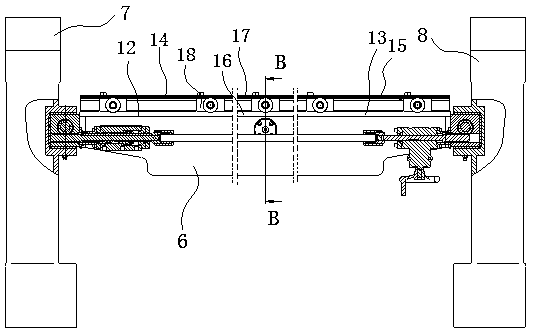

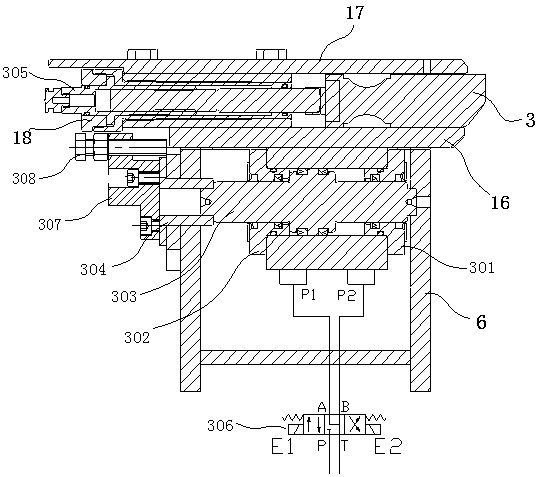

Device for regulating and supporting meat-removing rubber rod as well as processing humps of meat-removing machine

ActiveCN105567882ASimple structureIngenious designLeather manufacturingSkins/hides/leather/fur manufacturing apparatusEconomic benefitsEngineering

The invention discloses a device for regulating and supporting a meat-removing rubber rod as well as processing humps of a meat-removing machine. The device comprises a plurality of fixed limiting plates, a plurality of movable limiting plates, meat-removing rubber rod regulating mechanisms, a hump oil cylinder, a hump limiting block and a three-position hydraulic direction-changing valve, wherein a rubber bracket is welded with each fixed limiting plate as a whole; the plurality of meat-removing rubber rod regulating mechanisms are respectively fixed among the fixed limiting plates through bolts; the hump oil cylinder comprises a cylinder barrel and a piston; the piston is axially fixed to the rubber bracket by a fixing sleeve through a bolt, and cannot move left; the lower movable limiting plate is fixed to the hump oil cylinder; several meat-removing rubber rod regulating mechanisms are fixed to the lower movable limiting plate; the upper movable limiting block is fixed to the meat-removing rubber rod regulating mechanisms through bolts; and the meat-removing rubber rod is connected to all meat-removing rubber rod regulating mechanisms, and can move left and right along with the rotation of a regulating nut to regulate a gap between the meat-removing rubber rod and a meat-removing knife roll. The device can prevent leather on the humps from being damaged, so that the leather yield is increased, and the economic benefits of the leather making enterprises are improved.

Owner:扬州扬宝机械有限公司

Novel additive for leather pickling procedure

InactiveCN106811557AAvoid damageAvoid pollutionTanning treatmentPre-tanning chemical treatmentOrganic acidSulfonate

The invention provides a novel auxiliary agent used in leather pickling process and usage of the novel auxiliary agent. This additive contains organic acid compounds, fatty alcohol polyoxyethylene ether surfactants, alkylbenzene sulfonate surfactants and calcium and magnesium ion chelates. This additive is used in the pickling process of the leather industry, which can effectively improve the absorption of chromium, reduce the use of chromium powder, and at the same time improve the yield and tensile strength of leather. In the low pH value, it can avoid the damage of high mechanical action to the leather surface, and can also improve the firmness, fineness and softness of the leather grain. Especially it has obvious effect on skin samples that have not been deashed in the previous process.

Owner:QINGDAO SENMEIKE CHEM TECH CO LTD

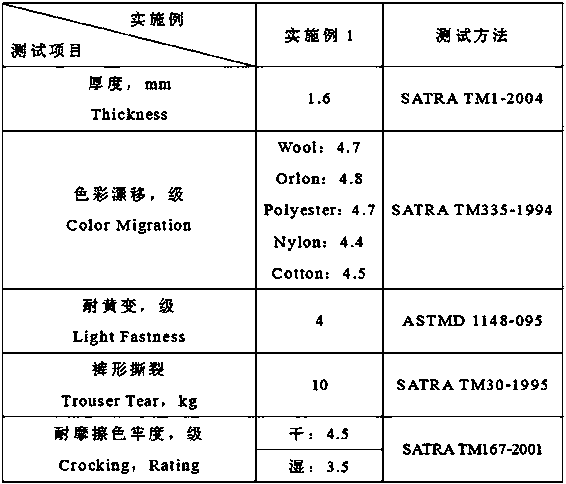

White anti-yellowing cow split leather and manufacturing method thereof

ActiveCN110938717AFeel plumpFeel roundTanning treatmentPre-tanning chemical treatmentPulp and paper industryBiology

The invention relates to white anti-yellowing cow split leather and a manufacturing method thereof, and belongs to the technical field of leather manufacturing. The manufacturing method of the white anti-yellowing cow split leather comprises the following steps that wet blue leather is sequentially subjected to rewetting, primary retanning, alkali extraction, secondary retanning, primary dyeing, main fat liquoring, secondary dyeing, plate pasting, drying, softening, buffing and drum milling, and the white anti-yellowing cow split leather is obtained. The white cow split leather prepared by theinvention is free of powder falling in the use process, high in quality and excellent in performance.

Owner:漳州香洲皮革有限公司

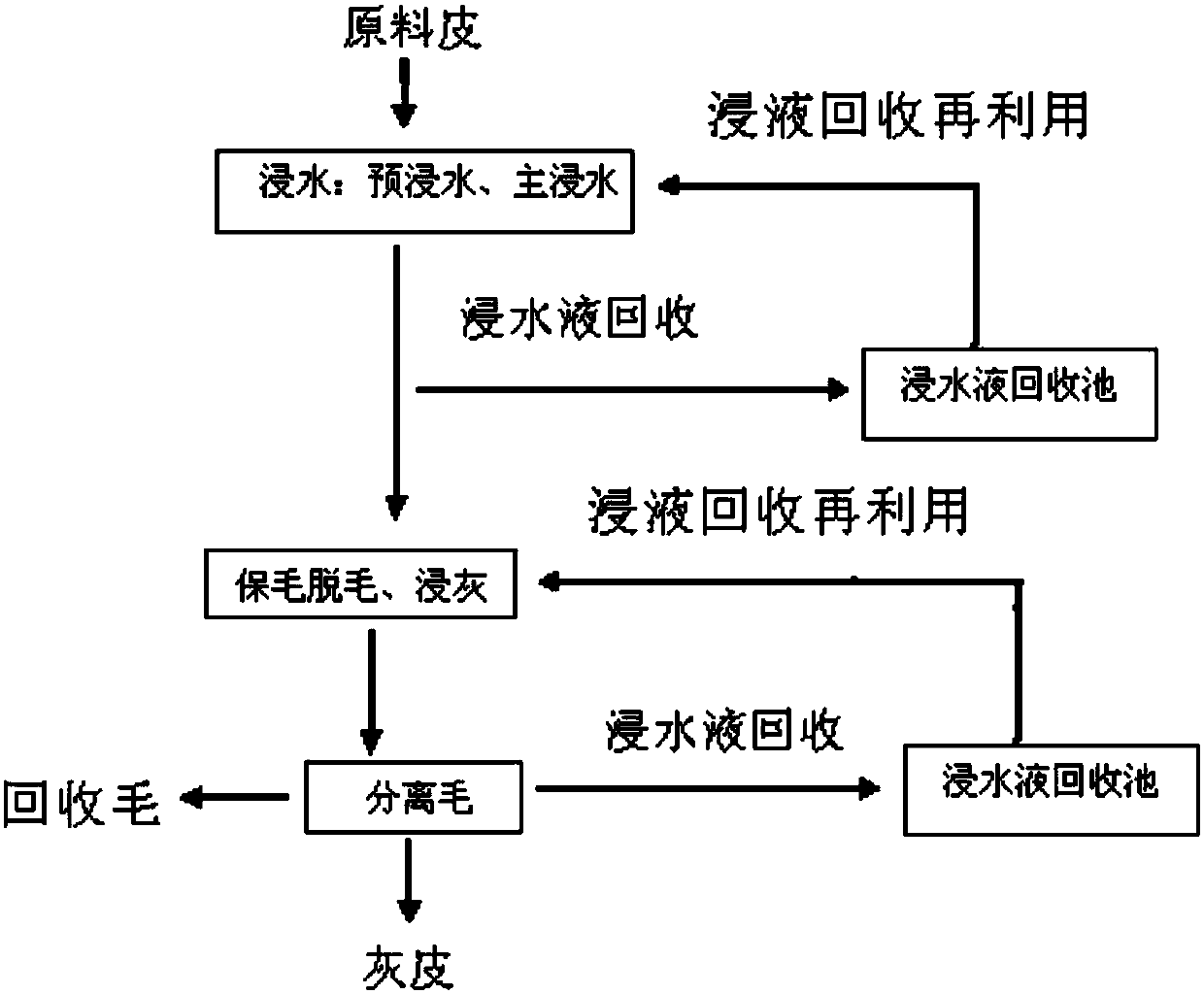

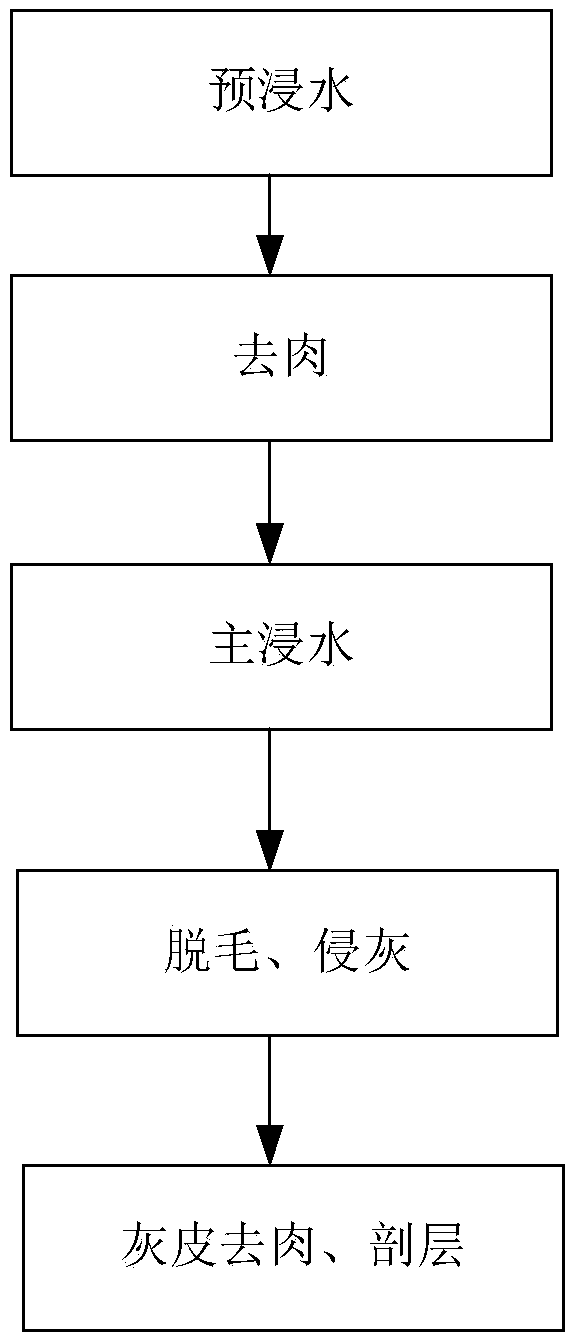

Leather manufacturing method with hair saving and hair removing functions

InactiveCN107619887AReduce dosageReduce removalLeather manufacturingPre-tanning chemical treatmentSulfideChemistry

The invention relates to the technical field of leather manufacturing, in particular to a leather manufacturing method with the hair saving and hair removing functions. The leather manufacturing method comprises the following steps: pre-soaking in water; flesh removing; main soaking in water; unhairing and liming; and flesh removing on limed skin and splitting. According to the leather manufacturing method provided by the invention, a sulfydryl urea compound LM and an expanding agent LS, namely an organic chelate alkali, are utilized in the hair saving and liming process, so that the sulfide consumption in the lime-soda liming process can be reduced by 66.6%, the lime consumption can be reduced by 74.3%, and the COD emission in the liming process can be reduced by 80%. However, the properties of finished leather are still good.

Owner:NINGXIA JINHAI LEATHER IND

Low-chromium high-absorption tanning method

PendingCN114085933AEasy to contact and absorbReduce the amount of chromium usedTanning treatmentPre-tanning chemical treatmentSulfuric acidRaw material

The invention provides a low-chromium high-absorption tanning method. The low-chromium high-absorption tanning method comprises the following steps: step 1, weighing and metering: weighing raw material leather as a material metering basis for subsequent procedures of soaking, liming, washing, pre-deliming, deliming, softening, pickling, tanning and the like; step 2, soaking: adding water which submerges the raw leather into the raw leather; step 3, liming; step 4, washing with water; step 5, pre-deliming; step 6, deliming and softening: adding 0.5-1 time of 30 DEG C water, adding 0.8% of a deliming agent and 0.2% of a degreasing agent, adding sulfuric acid to adjust the pH value to 3.5, and adding 0.5% of softening compound enzyme and 0.5% of an auxiliary agent; step 7, pickling and tanning: adding 1.5% of a pickling aid, rotating for 60-90 minutes, adding 2-3% of a chrome tanning agent, rotating for 60-90 minutes, adding 1-1.5% of a tanning aid, and rotating for 60-90 minutes; the method has the characteristics of reducing environmental pollution and ensuring that the quality index of a finished product is not reduced.

Owner:河北省皮革研究院

A kind of production technology of cowhide Napa leather

ActiveCN105132596BUniform leatherImprove leather yieldLeather manufacturingTanning treatmentFiberManufacturing technology

The invention relates to the technical field of the leather manufacturing technology, and provides a production technology of cow skin nappa leather. A series of problems that due to the fact that the structure of the abdomen and the part between the ribs and the hips of the cow skin is thin and fiber is woven loosely, in the processing process, the part of the abdomen and the part between the ribs and the hips are prone to being excessively loose, the part deviation is large, and face loosening is likely to happen are solved through the production process of the cow nappa soft-face leather. The integral procedure of the technology is simple, easy to achieve, convenient to operate and practical. The grain on the abdomen and the part between the ribs and the hips is easy to open in the tan preprocessing working section of the cow skin through tanning preprocessing, retanning processing and post-tanning mechanical processing, and the whole skin body fiber is even and loose. Even and slow tanning is carried out in the tanning working section, step-by-step and multi-time even filling is carried out in the retanning working section, the whole cow skin leather is even and consistent in the manner that filling is conducted after loosening, the leather is soft but not loose, and the leather yield and the utilization rate of finished cow skin are greatly increased.

Owner:XINGYE LEATHER TECH CO LTD

Nano-material leather assistant

InactiveCN104292942APromote absorptionImprove mildew resistanceCoatingsOrganic sulfonic acidCalcium sulfide

The invention relates to a nano-material leather assistant. The nano-material leather assistant includes 20-30% of a nano-material, 50-60wt% of a wetting agent, 60-70wt% of a dispersant, 10-30wt% sodium hydroxide, 15-35wt% of sulfonic acid, 17-26wt% of calcium sulfide, 70-80wt% of a binder and 80-90wt% of an organic sulfonic compound. The organic sulfonic compound is composed of organic sulfonic acid and disodium ethylenediaminetetraacetate, and a weight ratio of the organic sulfonic acid to disodium ethylenediaminetetraacetate in the organic sulfonic compound is 3:7-7:3. The combination of the nano-material and the organic sulfonic compound improves the properties of the nano-material leather assistant, enhances the mildew and bacterium resistance of formed leather, so the obtained leather has plump hand feeling and fine grain surface; and the assistant has the advantages of chromium absorption improvement, reduction of the emission of neutral salt and chromium in sewage, and improvement of the yield and the tensile strength of the leather.

Owner:QINGDAO JIASHANG CREATIVE CULTURE

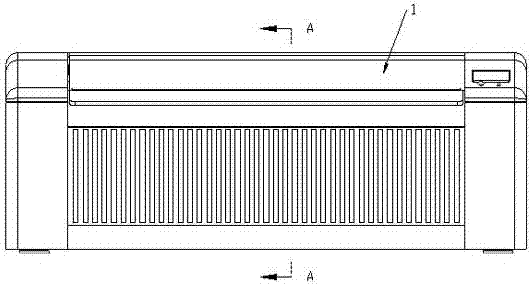

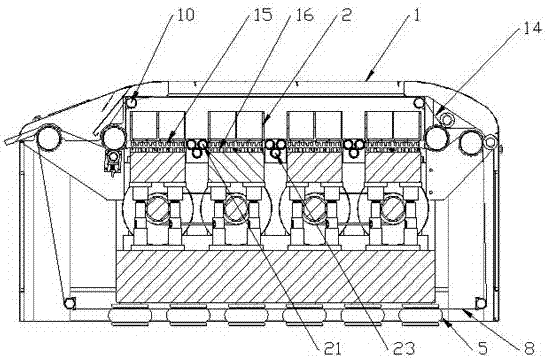

A New Oscillating Softening Machine

ActiveCN104894301BReduce the appearance of wrinkled skinReduce or avoid the phenomenon of wrinkled skinSkins/hides/leather/fur manufacturing apparatusLeather softeningEngineeringMechanical engineering

The invention relates to a novel oscillating staking machine. The novel oscillating staking machine comprises a frame, a worktable, a staking mechanism and a conveying mechanism, wherein the staking mechanism and the conveying mechanism are mounted on the frame, the staking mechanism is composed of vibration seats and fixed seats sequentially mounted on the frame from top to bottom together, the vibration seats correspond to the fixed seats one by one, and a nail plate and a hole plate are mounted at the lower ends of the vibration seats and the upper ends of the fixed seats. The conveying mechanism comprises an upper conveying mechanism and a lower conveying mechanism jointly, and a gap storing leather is reserved between the upper conveying mechanism and the lower conveying mechanism; the worktable is mounted at the feed end of the frame, and the conveying mechanism arranged at the rear end of the worktable forms a leather feed area. The novel oscillating staking machine has the advantages that the vibration seats are arranged at the upper ends, and the fixed seats are arranged at the lower ends; by the arrangement, the vibration seats act, the leather is arranged on the fixed seats and cannot move, and wrinkle of the leather can be effectively reduced or avoided.

Owner:NANTONG SIRUI ENG

Coating processing technology for imitated oily frosted leather

PendingCN112725545AUniform particlesHigh affinityWax coatingsLeather stretching/tensioningPhospholipidChlorinated paraffins

The invention discloses a coating processing technology for imitated oily frosted leather. The coating processing technology comprises the following steps of carrying out drying and finishing on crust leather, carrying out roller coating of grease, carrying out standing, carrying out ironing with a sand roller, carrying out pre-priming-coating, carrying out priming coating, carrying out ironing with a smooth roller, carrying out floating coating, carrying out top coating, carrying out standing, carrying out ironing with the smooth roller, carrying out ironing with a pore roller, carrying out ironing with the smooth roller and carrying out surface treatment so as to obtain the finished leather, wherein the grease used in the process of roller coating of the grease is prepared from 100-125 parts of water, 75-80 parts of mixed emulsion of sulfated synthetic grease and phospholipid, 20-25 parts of chlorinated paraffin and 100-125 parts of penetrant. According to the coating processing technology, the finished leather has the frosted touch feeling, is high in oiliness feeling, good in air permeability and perspiration performance and soft and full in leather body, the comfortable and natural genuine leather feeling and excellent hygienic performance of natural leather are better highlighted, and leather products such as shoes, boots, bags and suitcases and sofas made of the finished leather are attractive, elegant and noble and belong to high-quality products in the leather products; and meanwhile, excellent rubbing color fastness is achieved, and the dry rubbing resistance, the wet rubbing resistance and the sweat rubbing resistance can all reach the fourth level or above.

Owner:XINGYE LEATHER TECH CO LTD

Shaped tanning method of leather

InactiveCN1920058AFine grainLow elongationTanning treatmentPre-tanning chemical treatmentMetalRaw material

The invention relates the leather shaped tanning method, comprising the following steps: using hogskin, cowhide and goatskin as raw materials, treating them, making the grain of the skins adhibit to the metal plate or mechanically resistant material plate, scraping the flesh side with scratch board, on the flesh side putting the material which can make tanning liquor flow, on the material putting metal plate or mechanically resistant material plate, forcing on the plate, putting them into tanning liquor, making them move, heating, and getting the product.

Owner:CHINA LEATHER & FOOTWEAR IND RES INST

Novel auxiliary for leather pickling process

InactiveCN107868852AAvoid damageAvoid pollutionPre-tanning chemical treatmentLeather industryOrganic acid

The invention provides a novel auxiliary agent used in leather pickling process, and the usage of the novel auxiliary agent. This additive contains organic acid compounds, fatty alcohol polyoxyethylene ether surfactants, alkylbenzene sulfonate surfactants and calcium and magnesium ion chelates. This additive is used in the pickling process of the leather industry, which can effectively improve the absorption of chromium, reduce the use of chromium powder, and at the same time improve the yield and tensile strength of leather. In the low pH value, it can avoid the damage of high mechanical action to the leather surface, and can also improve the firmness, fineness and softness of the leather grain. Especially it has obvious effect on skin samples that have not been deashed in the previous process.

Owner:青岛九洲千和机械有限公司

Meat removal glue stick adjustment support and hump processing device for meat removal machine

ActiveCN105567882BSimple structureIngenious designLeather manufacturingSkins/hides/leather/fur manufacturing apparatusEconomic benefitsEngineering

The invention discloses a device for regulating and supporting a meat-removing rubber rod as well as processing humps of a meat-removing machine. The device comprises a plurality of fixed limiting plates, a plurality of movable limiting plates, meat-removing rubber rod regulating mechanisms, a hump oil cylinder, a hump limiting block and a three-position hydraulic direction-changing valve, wherein a rubber bracket is welded with each fixed limiting plate as a whole; the plurality of meat-removing rubber rod regulating mechanisms are respectively fixed among the fixed limiting plates through bolts; the hump oil cylinder comprises a cylinder barrel and a piston; the piston is axially fixed to the rubber bracket by a fixing sleeve through a bolt, and cannot move left; the lower movable limiting plate is fixed to the hump oil cylinder; several meat-removing rubber rod regulating mechanisms are fixed to the lower movable limiting plate; the upper movable limiting block is fixed to the meat-removing rubber rod regulating mechanisms through bolts; and the meat-removing rubber rod is connected to all meat-removing rubber rod regulating mechanisms, and can move left and right along with the rotation of a regulating nut to regulate a gap between the meat-removing rubber rod and a meat-removing knife roll. The device can prevent leather on the humps from being damaged, so that the leather yield is increased, and the economic benefits of the leather making enterprises are improved.

Owner:扬州扬宝机械有限公司

A kind of production method of environment-friendly semi-vegetable tanned waxy bovine leather

ActiveCN109536646BFast absorptionAbsorb evenlyTanning treatmentPre-tanning chemical treatmentOil and greaseFiber

The invention discloses an environment-friendly production method of semi-vegetable tanned wax-modified bovine leather, which includes the steps of material preparation, rewetting, tanning, neutralization, filling dyeing and fatliquoring in sequence. Wetting agent softens leather, which can not only achieve fast rehumidification and evenly absorb water, but also disperse leather fibers and facilitate the absorption of subsequent chemical materials. In the tanning process, using vegetable extract tanning agent instead of conventional chrome powder tanning can not only ensure the physical performance index of chrome tanned leather, but also ensure that the finished leather has a soft and lubricated feel, suitable plumpness and elasticity. No chromium pollution, clean and environmentally friendly. In the fatliquoring process, the grease 101 with waterproof ability and wax change effect is used, which can not only increase the waterproof and anti-aging ability of the leather itself, but also produce a color change effect through high temperature wax change in the subsequent finishing process, adding fashion elements to the product and improving the product. grade.

Owner:FENGAN LEATHER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com