Production method for environmentally-friendly semi-vegetable tanned waxed tyre cow leather

A production method and an environmentally friendly technology, applied in the field of leather manufacturing, can solve the problems of inconspicuous rewetting effect, lack of fashion elements, and ordinary quality grades, etc., to achieve the effect of adding fashion elements, reducing the difficulty of environmental protection treatment, and soft and lubricating hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further explain the technical solution of the present invention, the following will be described in detail in conjunction with the examples.

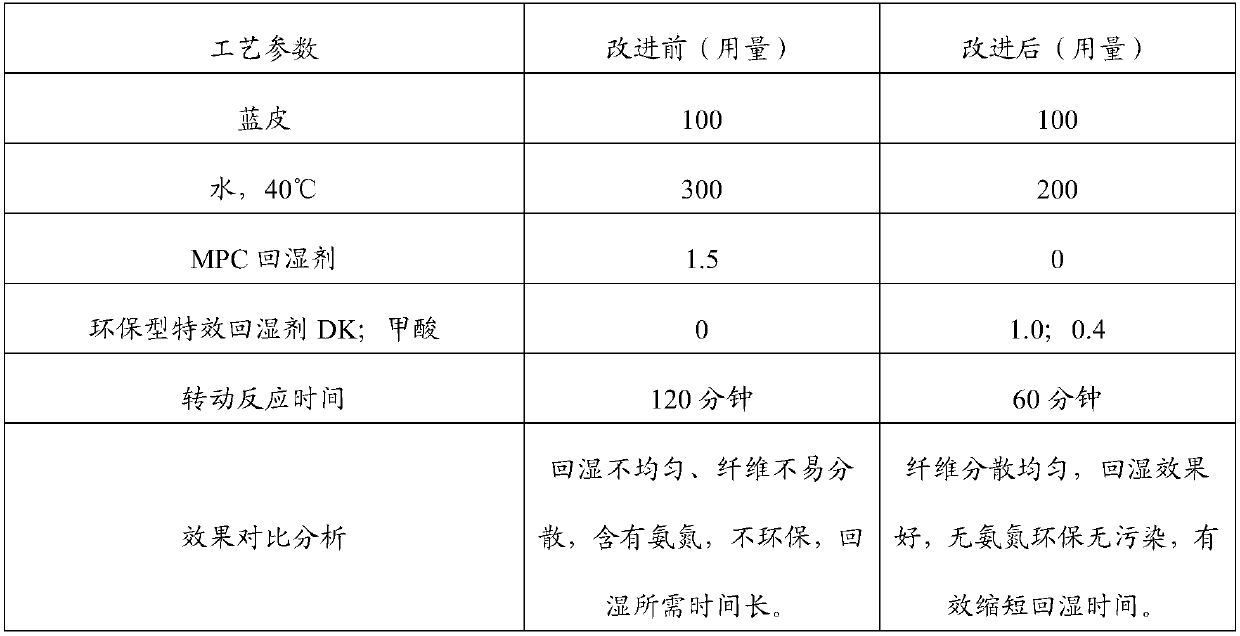

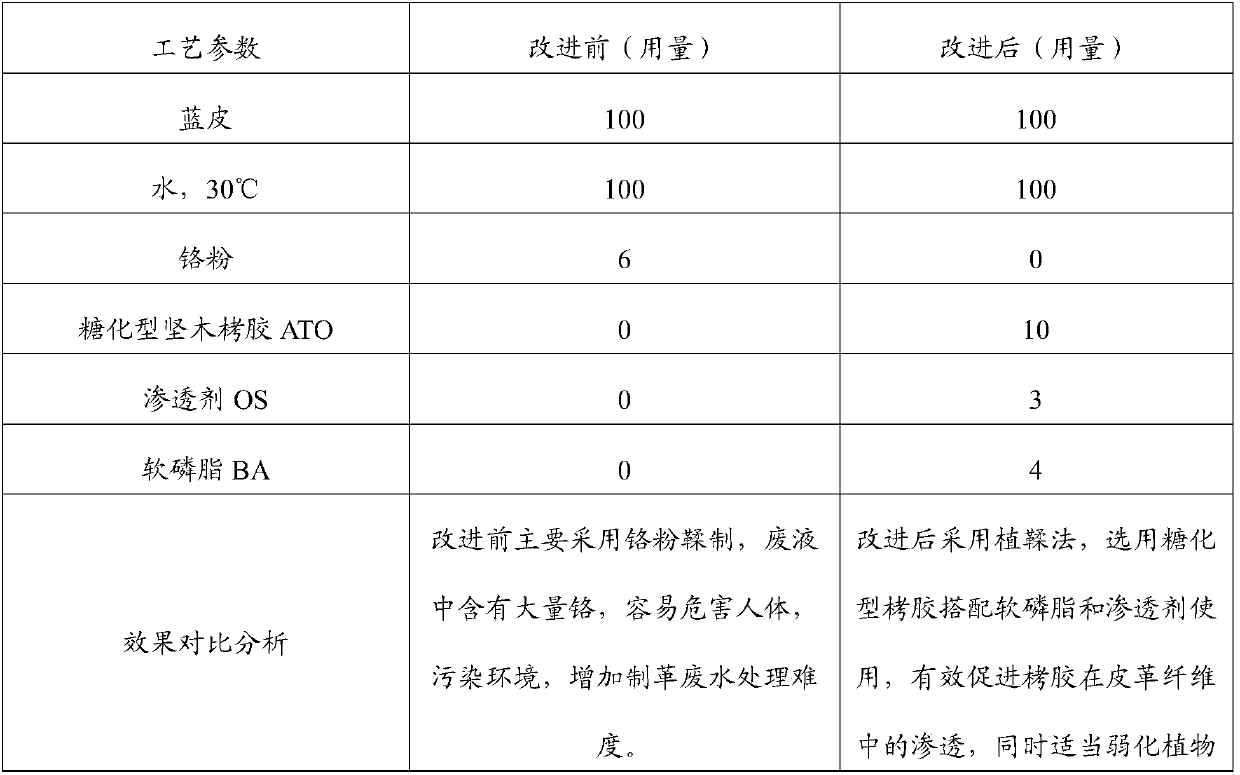

[0024] The invention discloses an environment-friendly production method of semi-vegetable tanned wax-modified bovine leather, which comprises sequentially performing a material preparation process, a rewetting process, a tanning process, a neutralization process, a filling and dyeing process, a fatliquoring process, and a vacuum, Drying, rehydration, softening and buffing. Among them, vacuum, drying, regaining moisture, softening and grinding are all conventional processes, and will not be described in detail here. All amounts of materials hereinafter are in parts by weight.

[0025] In the material preparation process, select fetal calf blue leather for use, and the present embodiment selects 100 parts of fetal calf blue leather and puts into the drum, wherein the drum is a conventional tool for leather processing,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com