Leather patching method

A technology of leather and wound repairing agent, applied in leather surface treatment, small raw hide/large raw hide/leather/fur treatment, small raw hide/large raw hide/leather hide/fur chemical treatment, etc. Easy to dent and other problems, to achieve the effect of thin and soft coating, not easy to dent, strong filling and covering power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

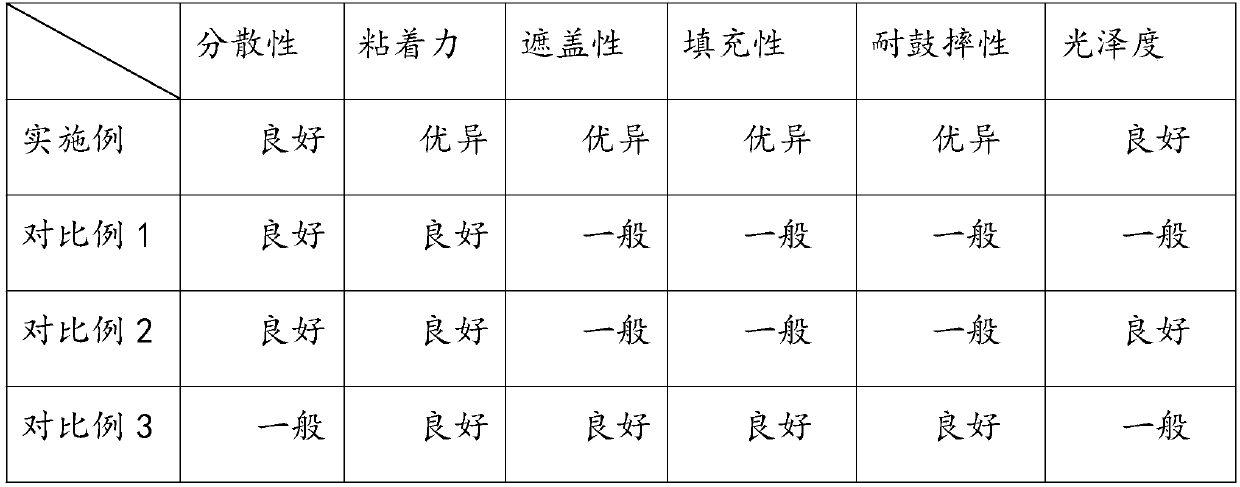

Examples

Embodiment 1

[0031] A method for repairing leather wounds, comprising the following steps in sequence:

[0032] (1) Crude leather is softened by vibration: the strength of softening by vibration is grade 5;

[0033] (2), dry vacuum: dry vacuum temperature 40 ℃, dry vacuum time 90 seconds, vacuum degree -0.1Mpa;

[0034] (3) Grinding: For inner grinding, use 320-mesh sandpaper to treat the meat surface of the crust leather; for grinding the surface, use 600-mesh sandpaper to treat the defects or disabled parts of the crust leather grain surface; control the moisture content of the crust leather during leather grinding at 15-20%;

[0035] (4), dust removal clean surface;

[0036] (5), wound repair: wound repair agent roller coating, the wound repair agent coating amount is 12g / sf; Wherein, the preparation method of wound repair agent is: first 40 parts of water and 30 parts of casein RODA bind TU 688 / B ( Deruipi Chemical Co., Ltd.) mixed, fully stirred, the stirring speed was 950r / min, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com