Method for producing parchment by using compound enzyme preparation

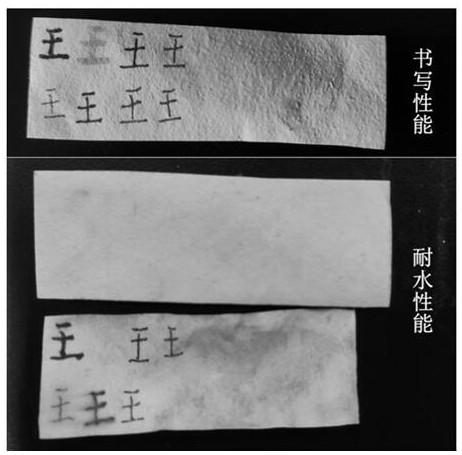

A composite enzyme preparation, parchment technology, applied in application, leather drying, small raw hide/large raw hide/leather/fur treatment, etc., to achieve high-efficiency substrate specificity, good writing performance and water resistance, smooth grain surface Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for producing parchment paper using a compound enzyme preparation, comprising the following steps:

[0034] (1) Pre-soaking water: weigh the skin, at room temperature, the liquid ratio is 1.5, add 500 U / mL lipase and 0.3% fungicide, turn for 5 min per hour, after 4 h, stop the drum overnight, and wash with water the next day .

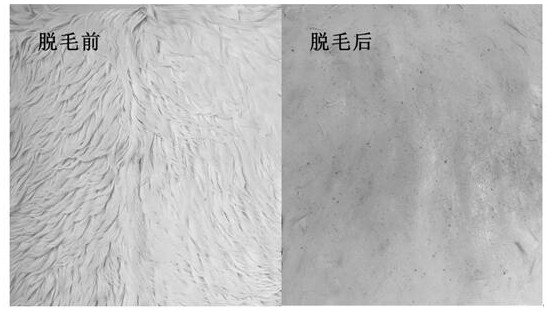

[0035] (2) Main immersion: at room temperature, liquid ratio 1, the concentration of keratinase, glycosidase and lipase added are 40 U / mL, 40 U / mL and 500 U / mL respectively. After removing residual small hairs with 1.5% NaHS, they were washed with water and weighed.

[0036] (3) Liming: liquid ratio 2, add 6% lime, turn 15 minutes per hour, stop the drum overnight, and remove the flesh the next day.

[0037] (4) Liming: liquid ratio 2, add 3% lime, soak for 2-3 days and wash with water.

[0038] (5) Deliming: liquid ratio 2, add 1% formic acid, adjust pH to 6.

[0039] (6) Pickling: liquid ratio 1, add 7% sodium chloride, 2% anhydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com