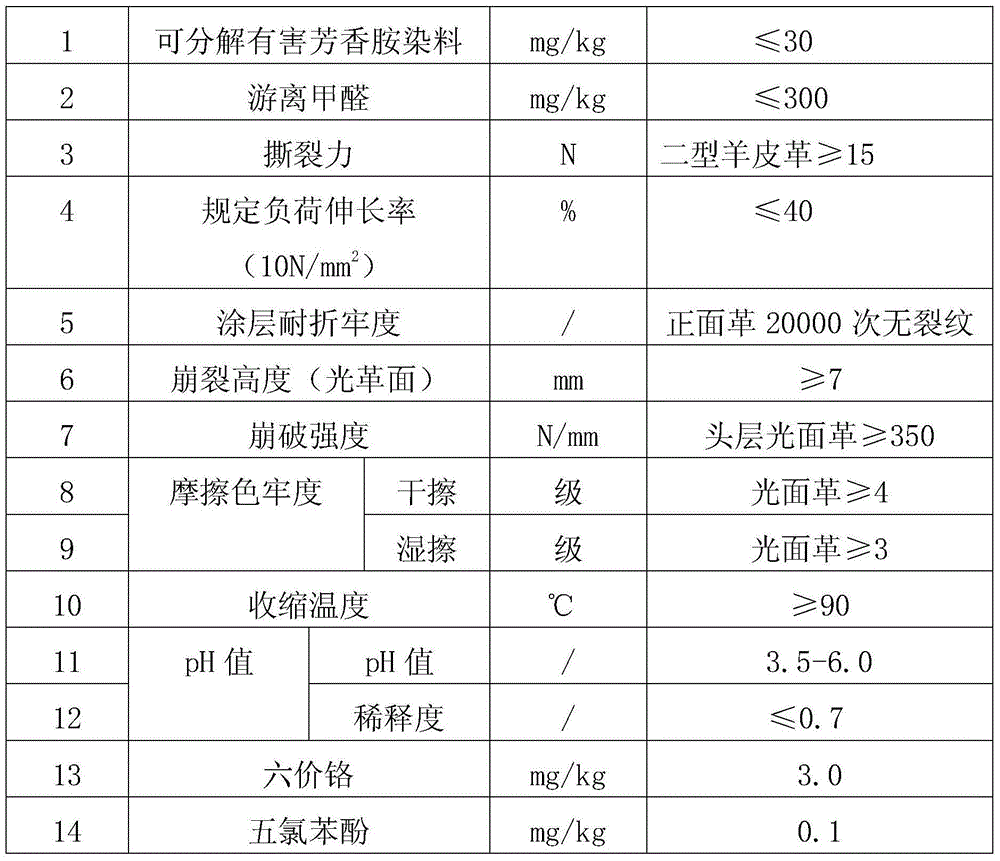

Sheep shoe upper leather manufacturing process

A production process and technology for shoe upper leather, which is applied in the field of sheep shoe upper leather production technology, can solve problems such as the gap between product performance and quality grade, and achieve the effects of improving fullness, flat and fine grain, and reducing part difference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] A kind of sheep shoe upper leather production process, concrete operation process is as follows:

[0021] Fur: The domestic Hankou sheep skin is the preferred material. This skin is thick, rich, yellowish with fleshy red, and the grain is flat and fine.

[0022] Soaking in water: the purpose is to return the moisture of the raw hide to the fresh hide state, remove inorganic and organic dirt such as sediment, blood stains, salt and preservatives on the hide, and remove part of the soluble non-fibrin in the hide to infiltrate the material of the subsequent process And lay the foundation for the role. Use water between 18-22°C, the liquid ratio is 300 times the tare weight, the speed is 3-4 rpm; the time is 18-22 hours; add an appropriate amount of preservatives and immersion aids, and the ratio of skin to liquid and the temperature to the specified value, rotate for 1 hour, stop for 1 hour, then rotate for 5-10 minutes every hour after that, the total rotation time is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com