Patents

Literature

89 results about "Tare weight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tare weight /ˈtɛər/, sometimes called unladen weight, is the weight of an empty vehicle or container. By subtracting it from the gross weight (laden weight), the weight of the goods carried (the net weight) may be determined. This can be useful in computing the cost of the goods carried for purposes of taxation or for tolls related to barge, rail, road, or other traffic, especially where the toll will vary with the value of the goods carried (e.g., tolls on the Erie Canal). Tare weight is often published upon the sides of railway cars and transport vehicles to facilitate the computation of the load carried. Tare weight is also used in body composition assessment when doing underwater weighing.

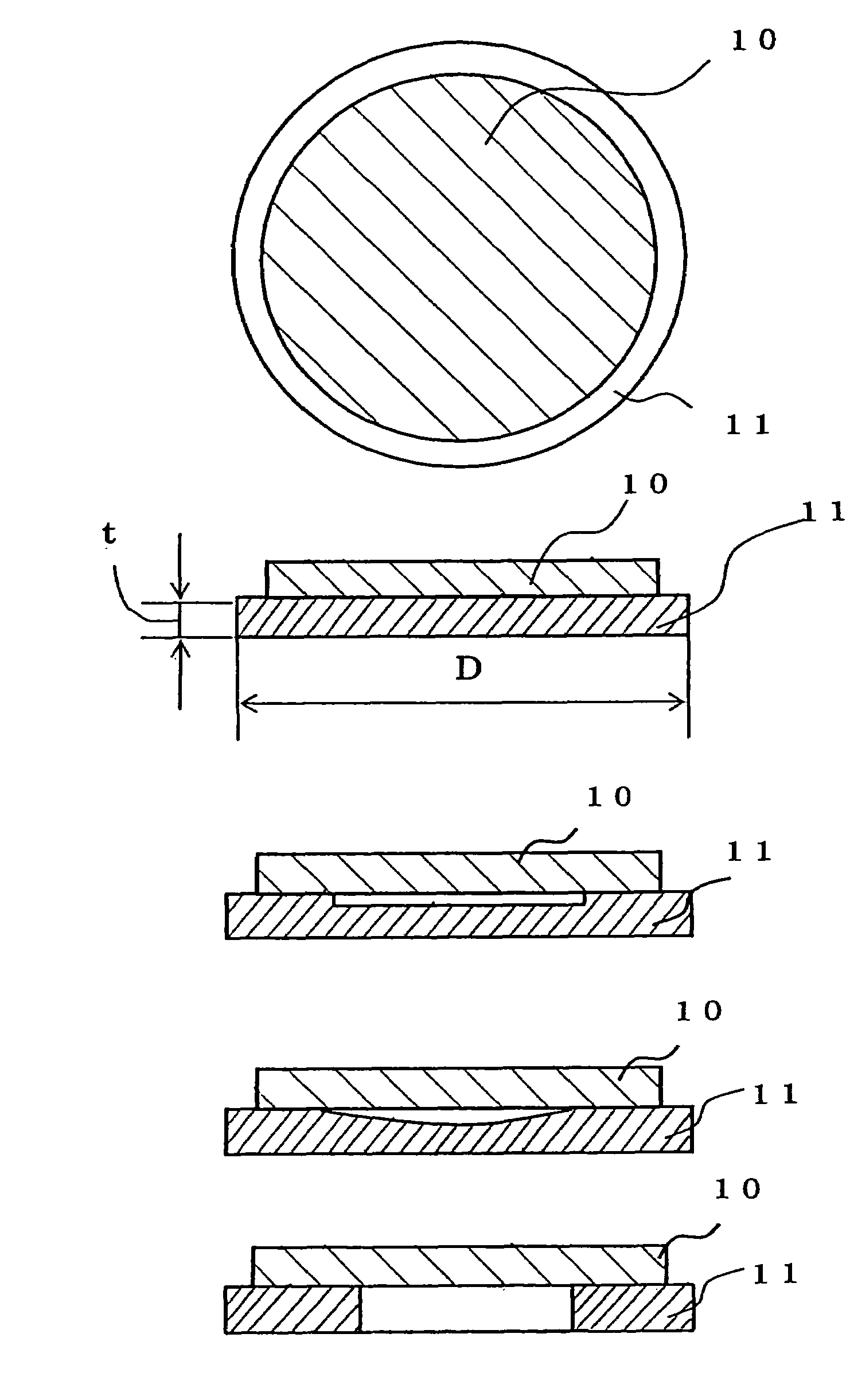

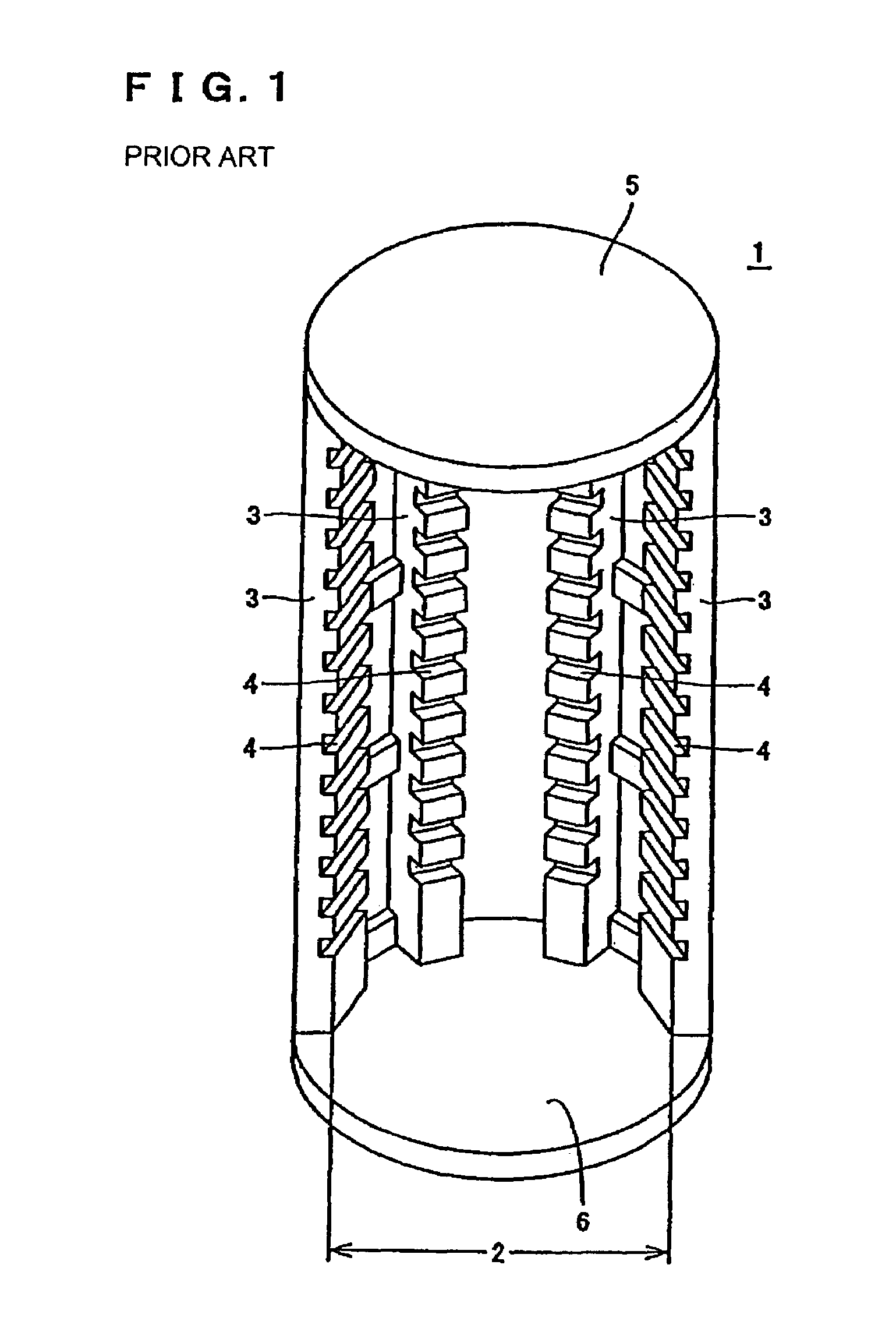

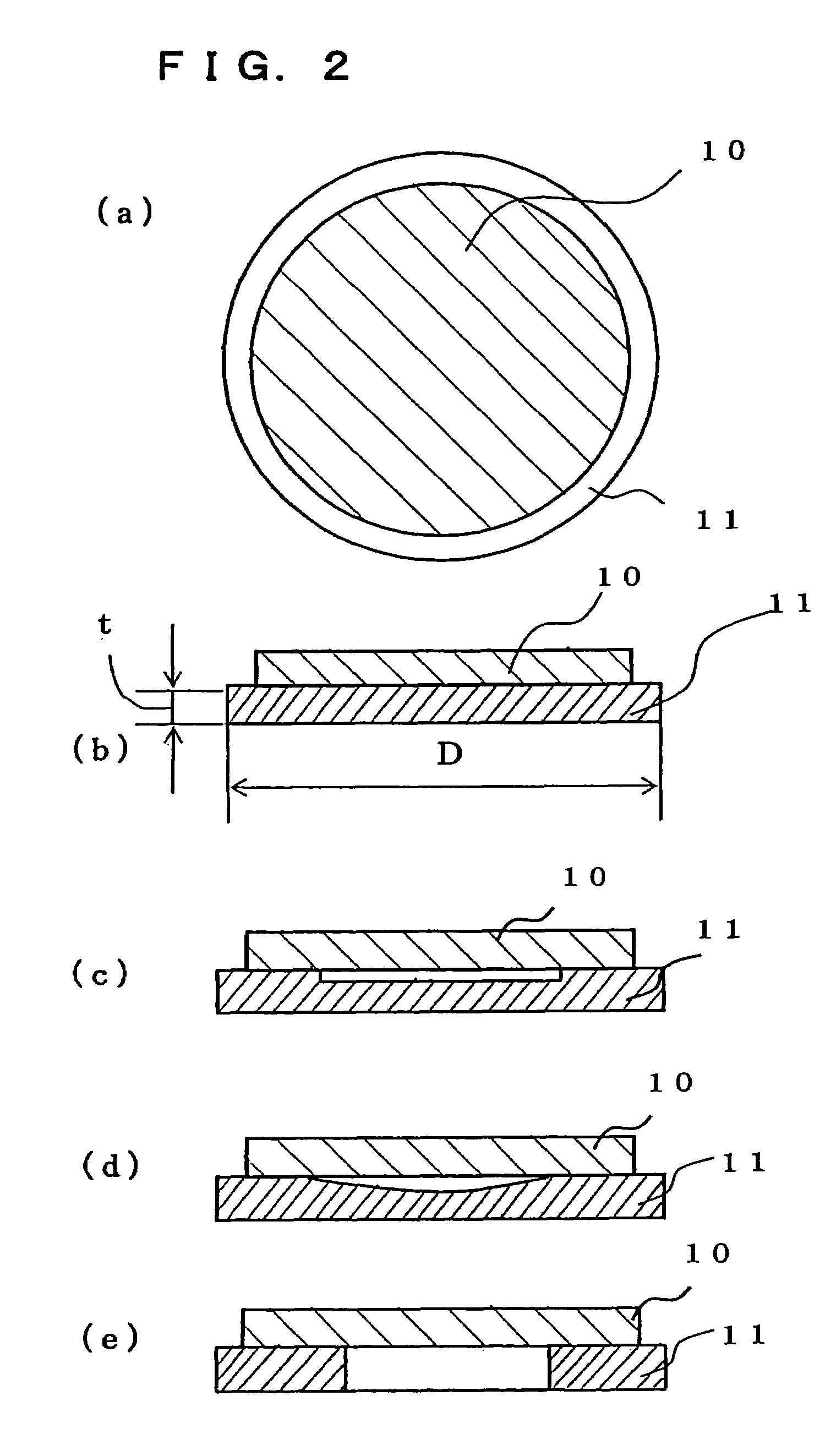

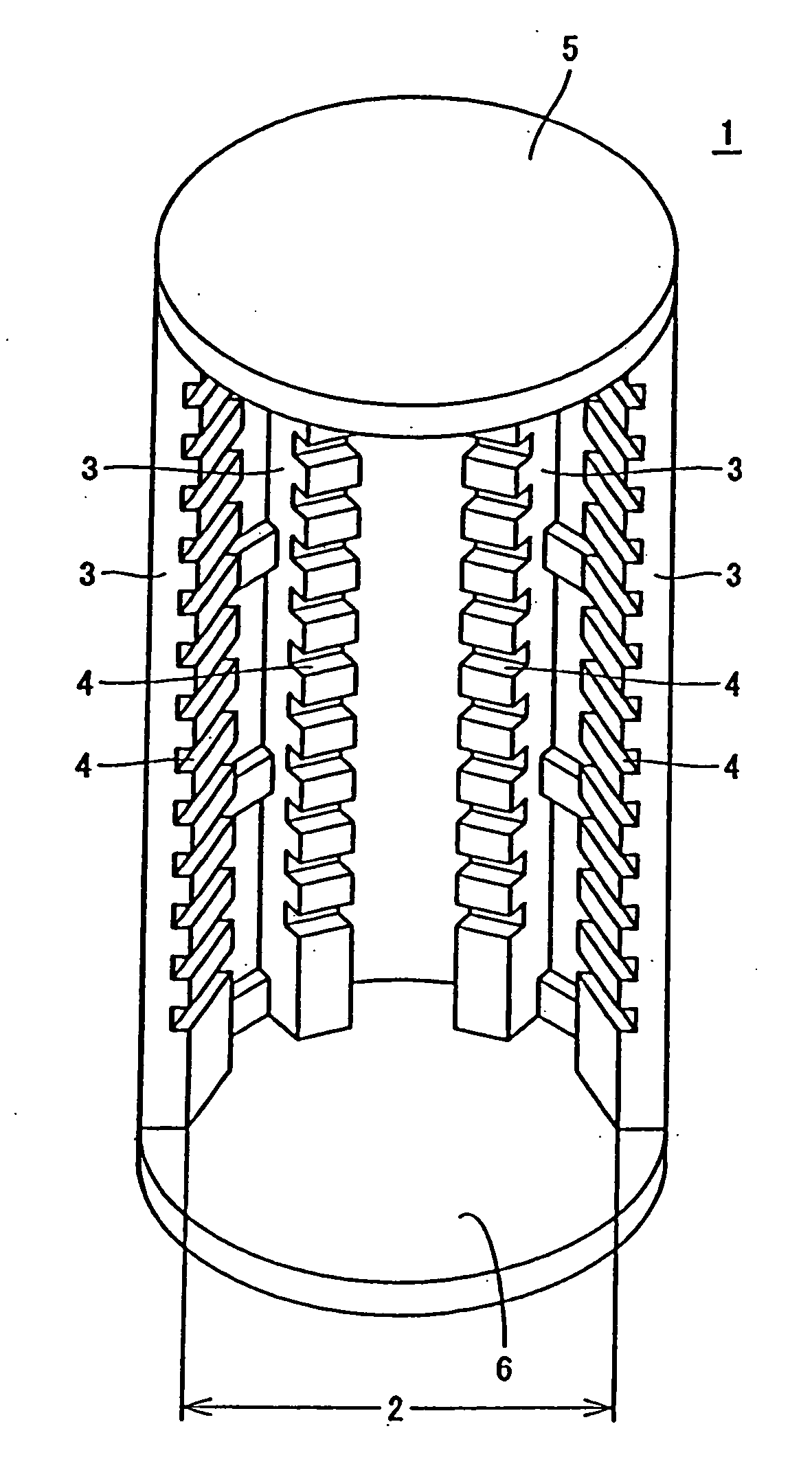

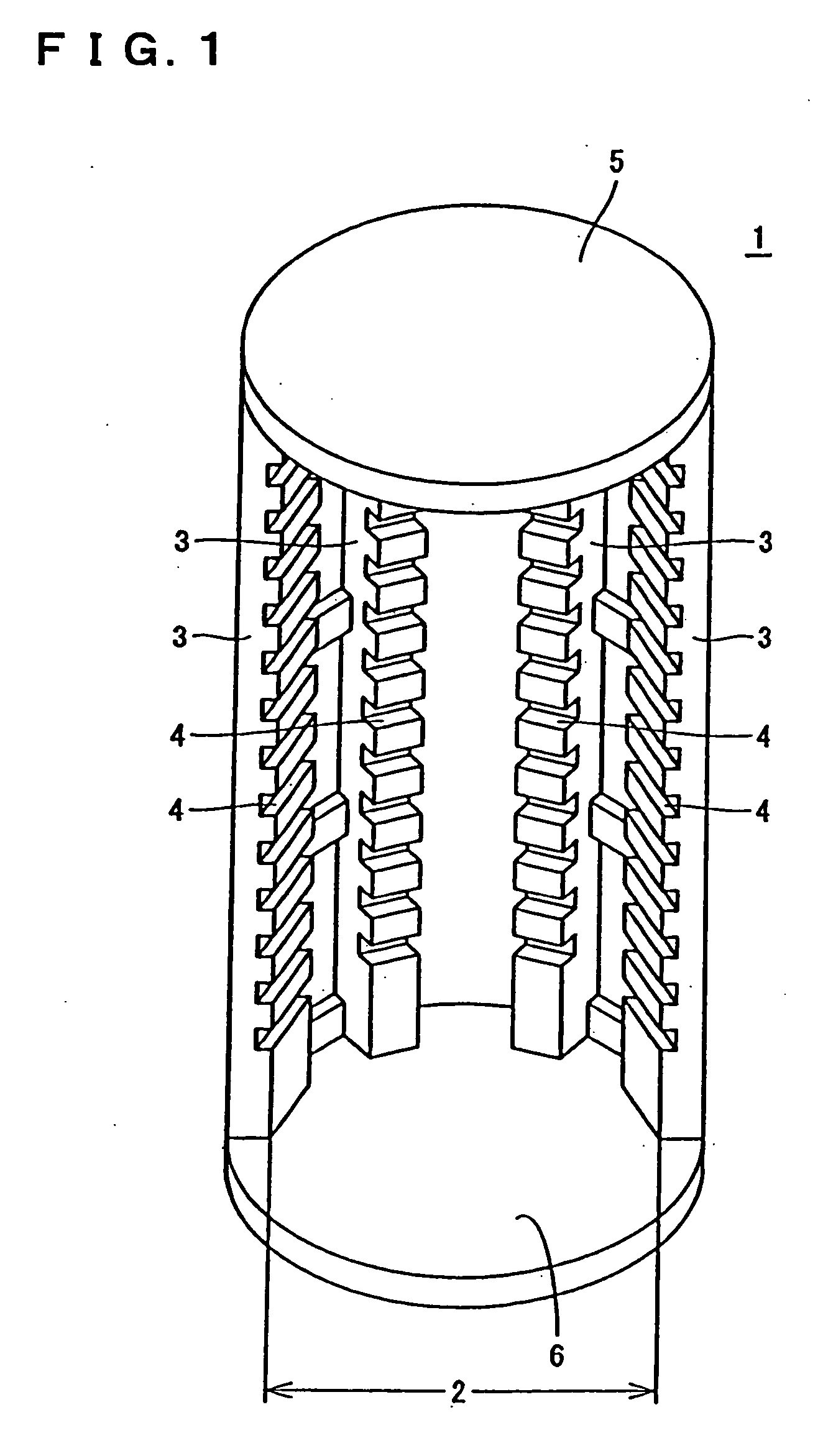

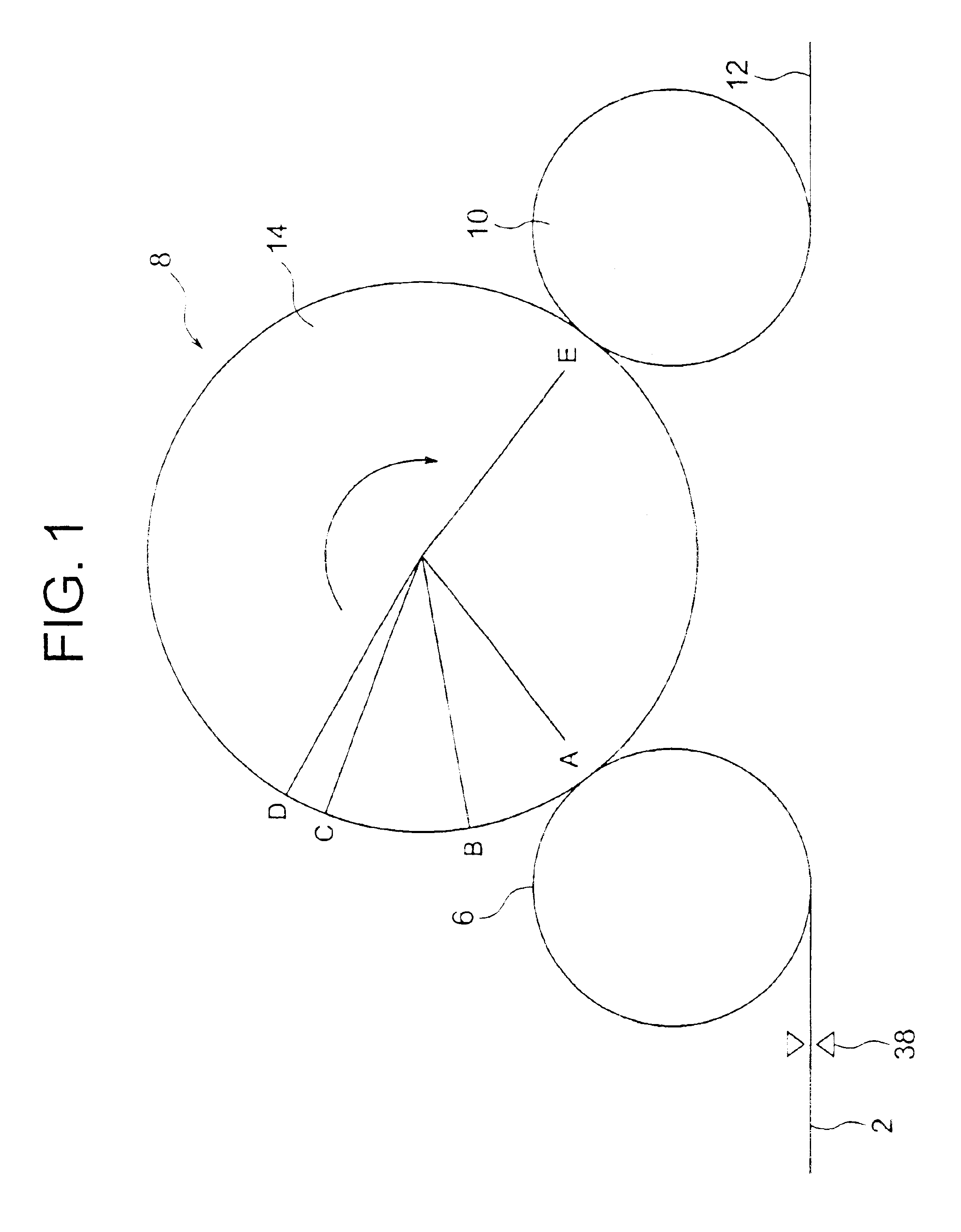

Heat treatment jig for semiconductor wafer

ActiveUS7331780B2Suppress generationSurface planarity and roughnessCharge supportsSemiconductor/solid-state device manufacturingSurface roughnessSemiconductor

A heat treatment jig by the invention comprising: the diameter of a disk-type structure being 60% or more of that of loaded semiconductor wafers; the thickness being 1.0 mm or more but 10 mm or less; the surface roughness Ra of 0.1 μm or more but 100 μm or less at a contacting surface with the wafers; and the surface planarity being specifically controlled in the concentric direction as well as in the diametrical direction, otherwise in place of above planarity, comprising a controlled maximum height in such a way that the maximum height is obtained by the flatness measurement at the multiple positions and the difference between said maximum height and the hypothetical-average-height-plane thus set is 50 μm or less, can reduce the slip generation due to the close adhesion of the wafers and the jig. Owing to this, even if the wafers having large tare weight should be heat-treated, the slip generation can be effectively prevented, thus enabling the jig to be widely used as the reliable heat treatment jig for semiconductor substrates.

Owner:SUMCO CORP

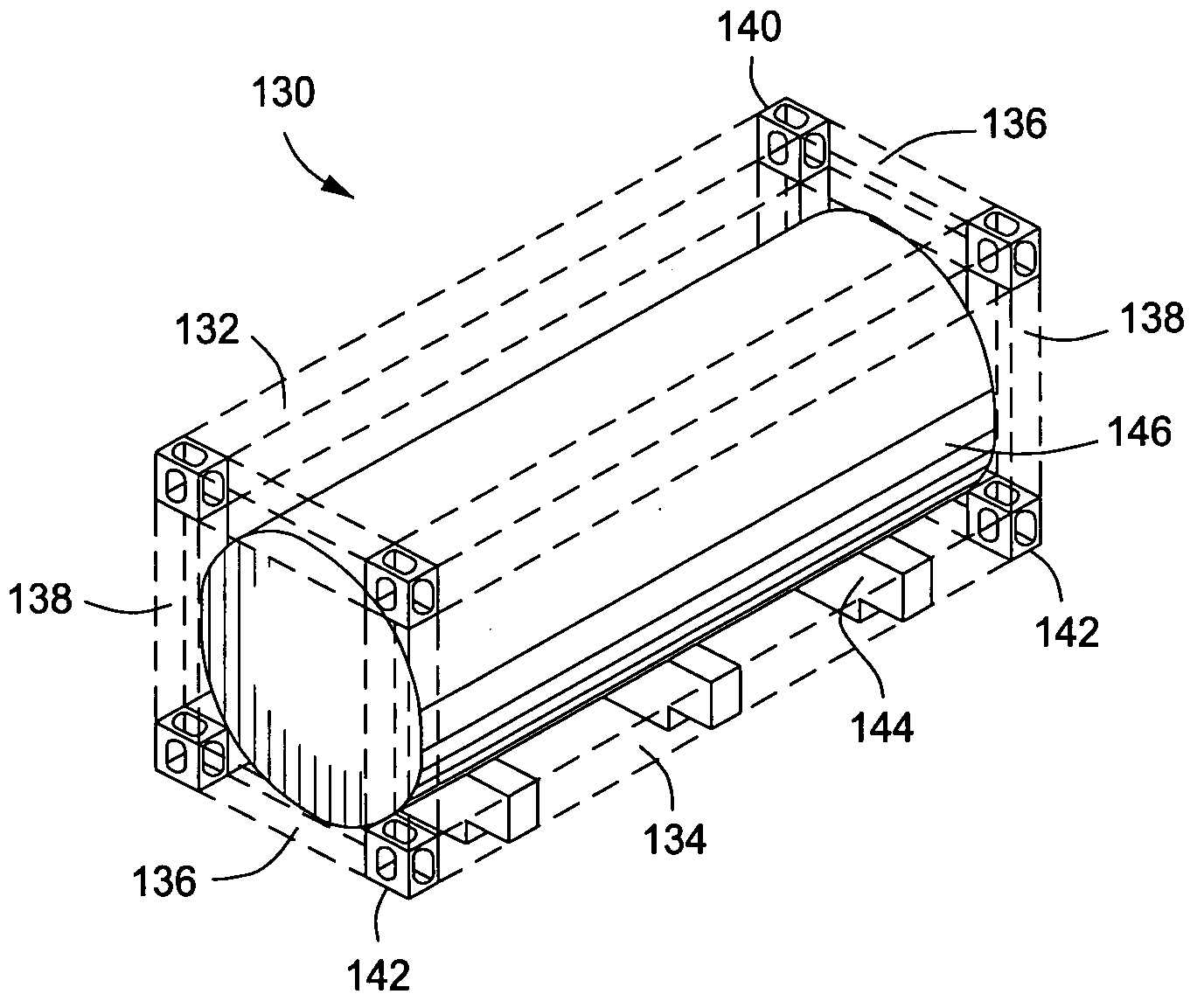

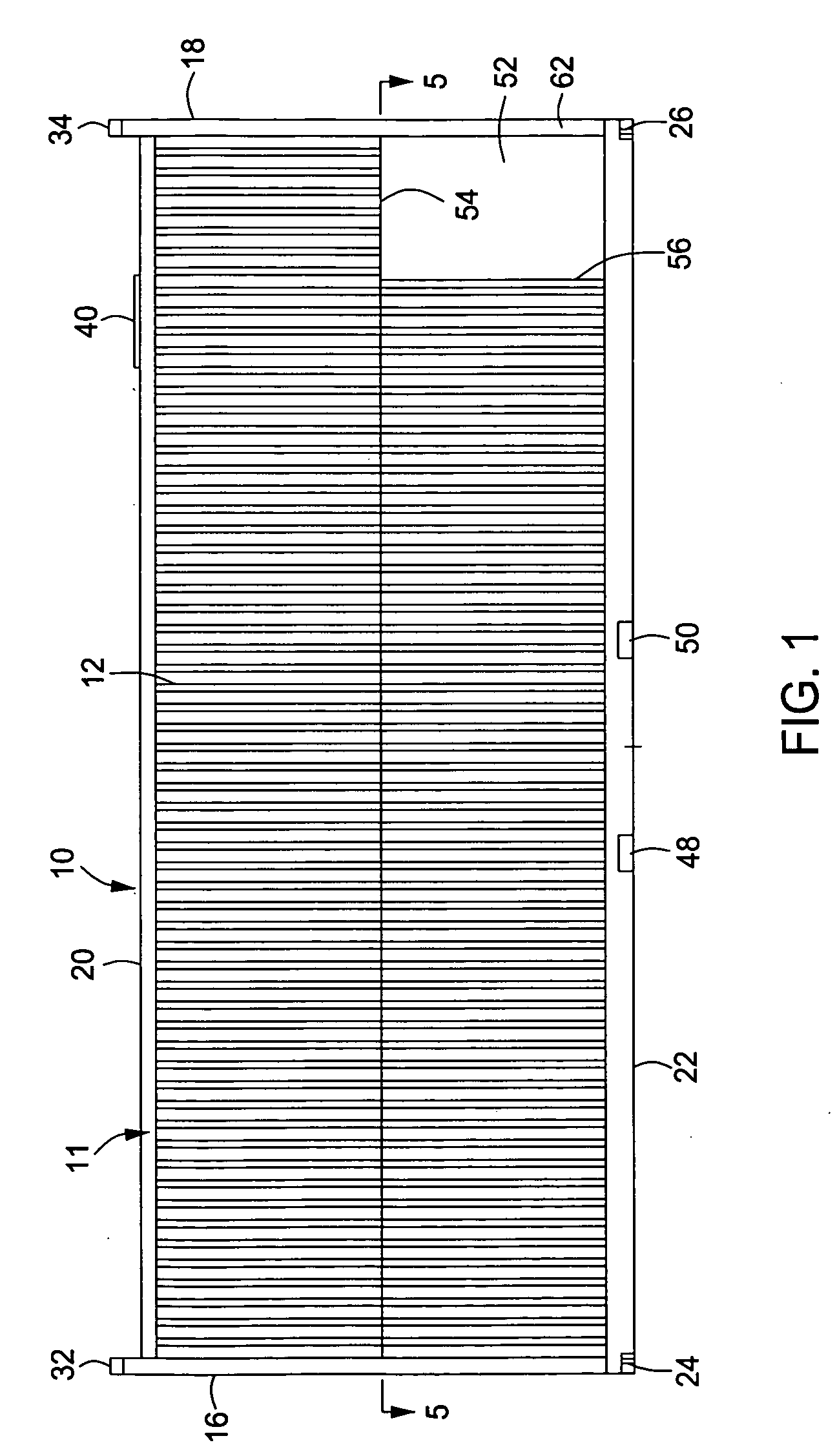

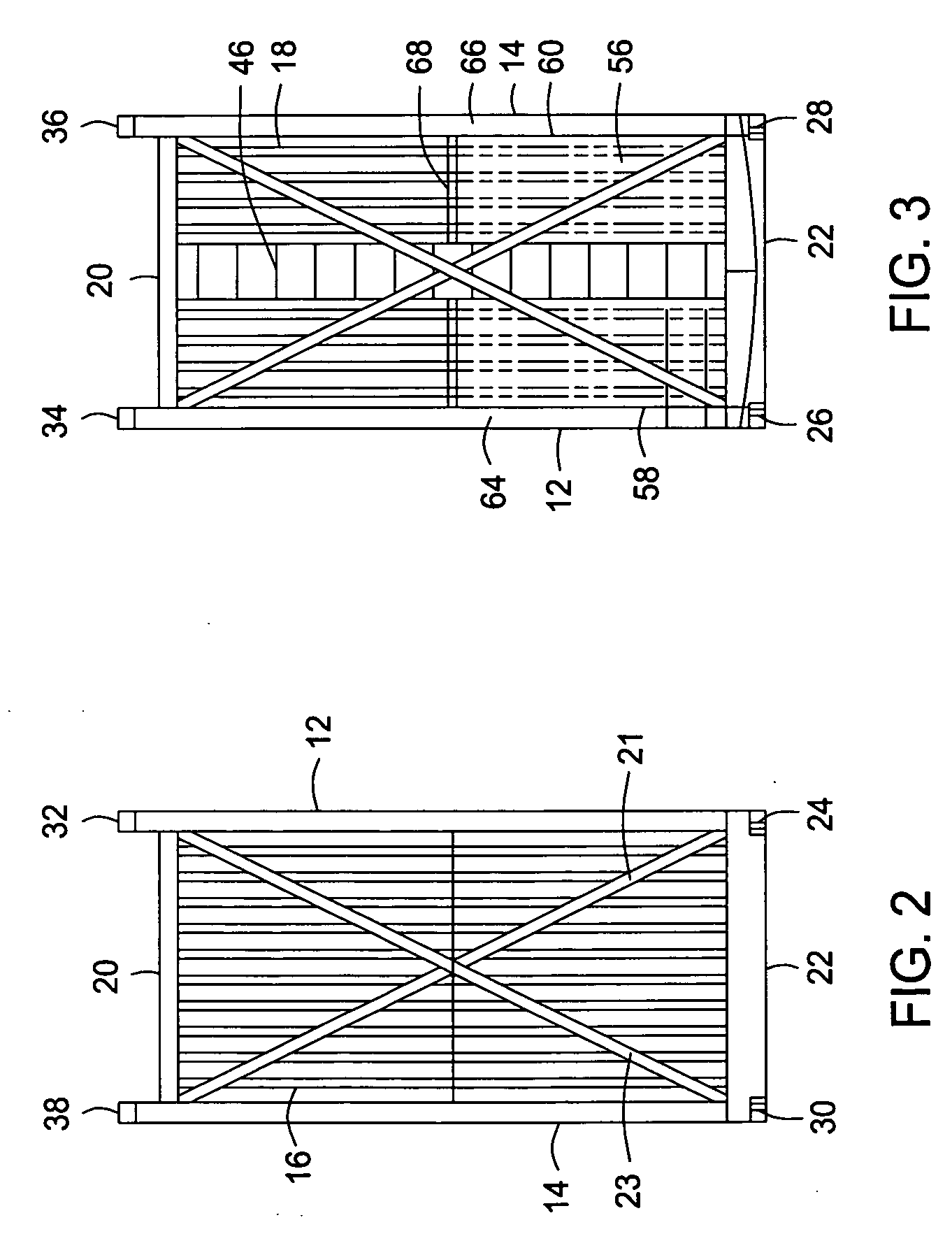

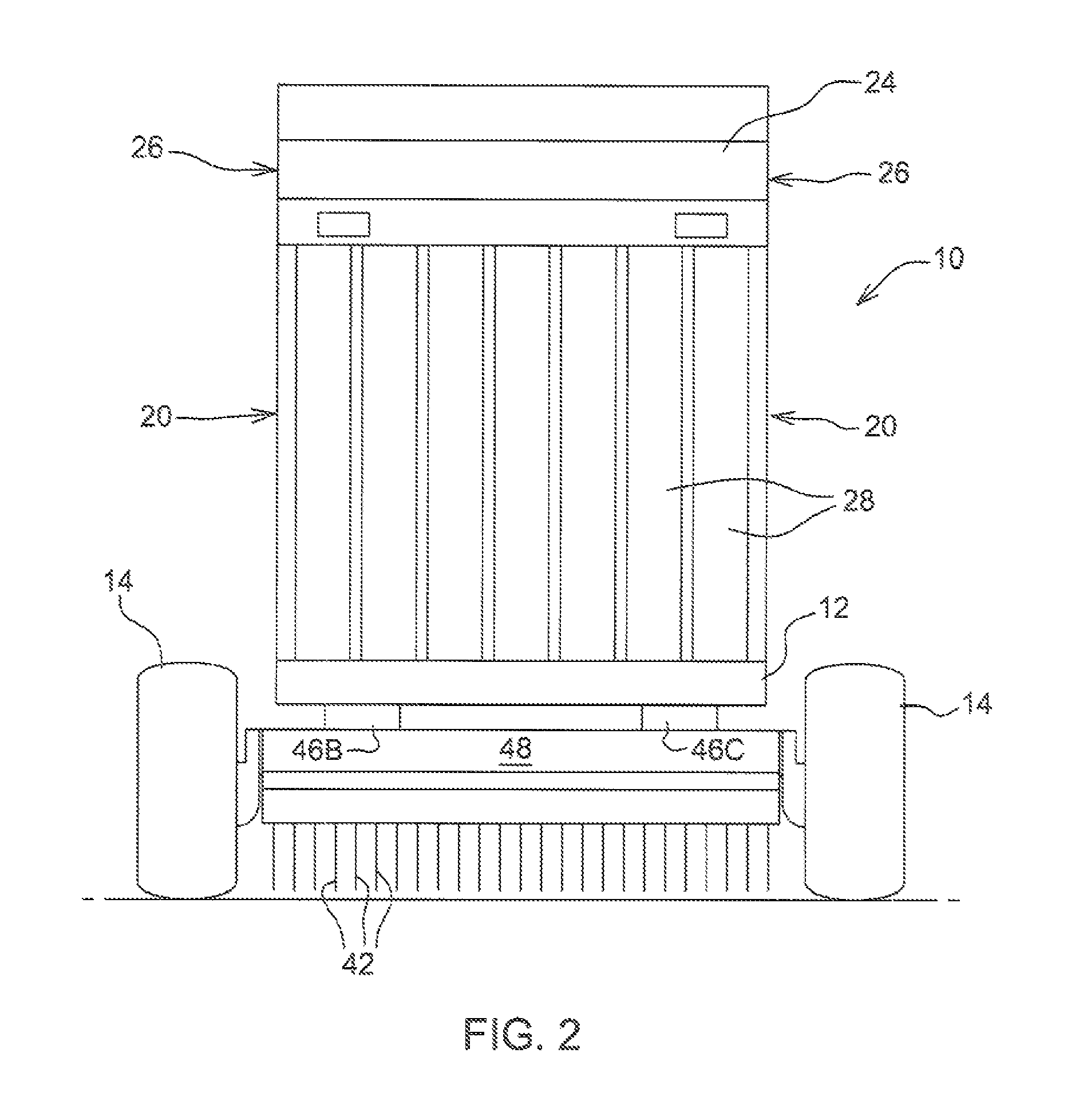

Modular tank unit for ship, barge and rail transportation

InactiveUS20090134171A1Easily and simply installedEasily and simply and removedLarge containersClosures to prevent refillingParticulatesReceiving facility

A modular tank unit for utilizing vessels of opportunity to serve as carriers for transportation and handling of specialty liquids or flowable particulate products or to serve as a terminal ashore receiving and dispensing to truck, rail, barge or other receiving facilities. The modular tank unit has a rectangular intermodal framework of predetermined dimension and tare weight permitting its transportation by cargo vessel, hopper barge and by rail for positioning inland or at shore facilities. A tank may be adapted for other modes of transportation and may be removably secured within the rectangular framework. The modular tank unit in its smaller dimension can be transported empty by rail and can be positioned in the field by portable crane. The modular tank unit defines a pump compartment having a pumping and draining manifold and portable pump and valve assembly for fluid handling, enabling the modular tank unit to be “active” for power energized pumping or “passive” for gravity discharge.

Owner:DEBERARDINIS NICHOLAS W

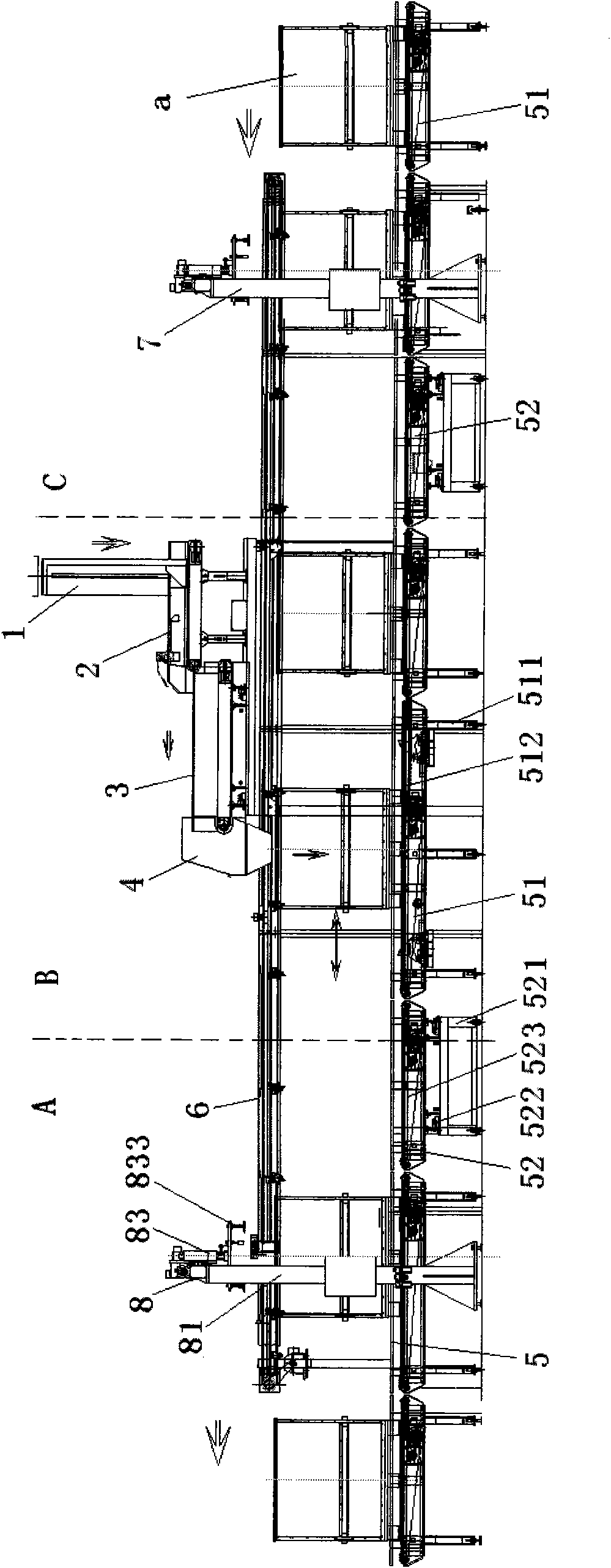

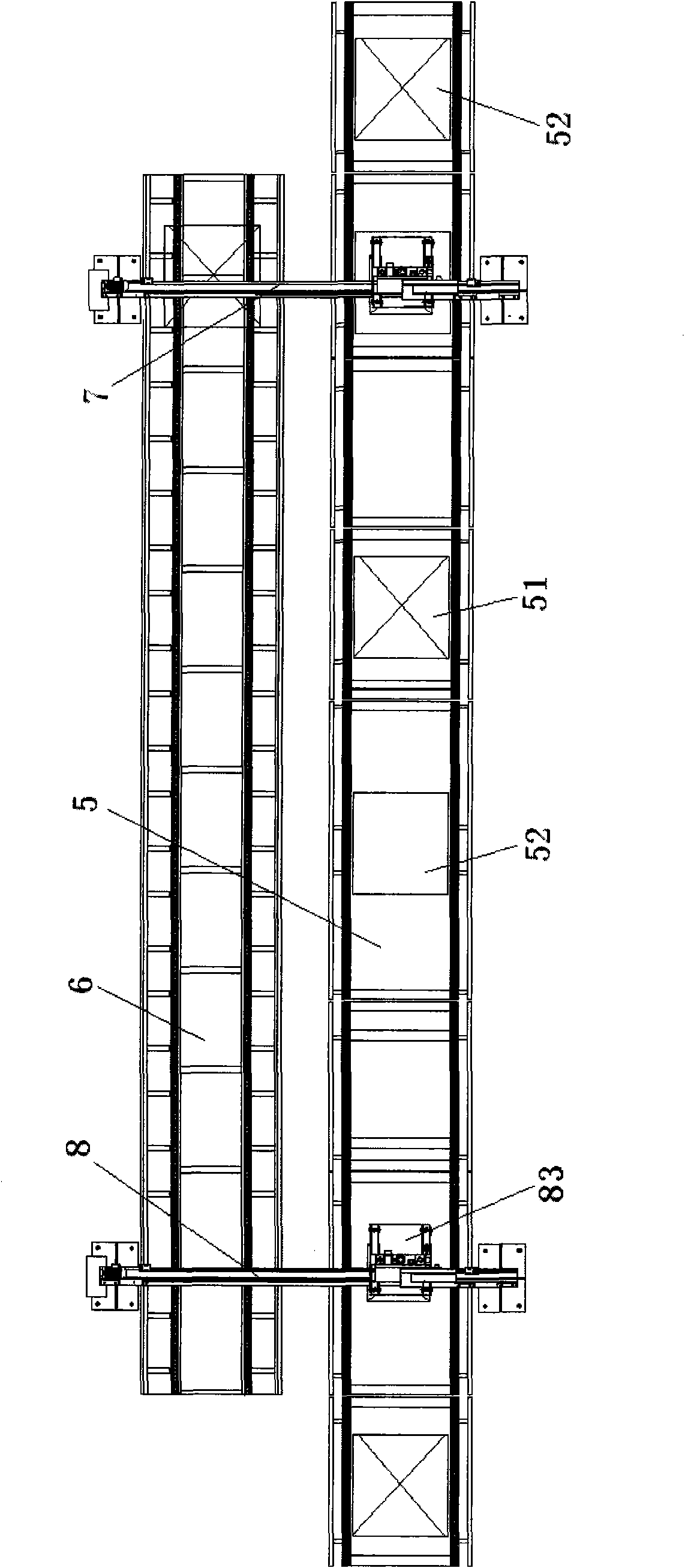

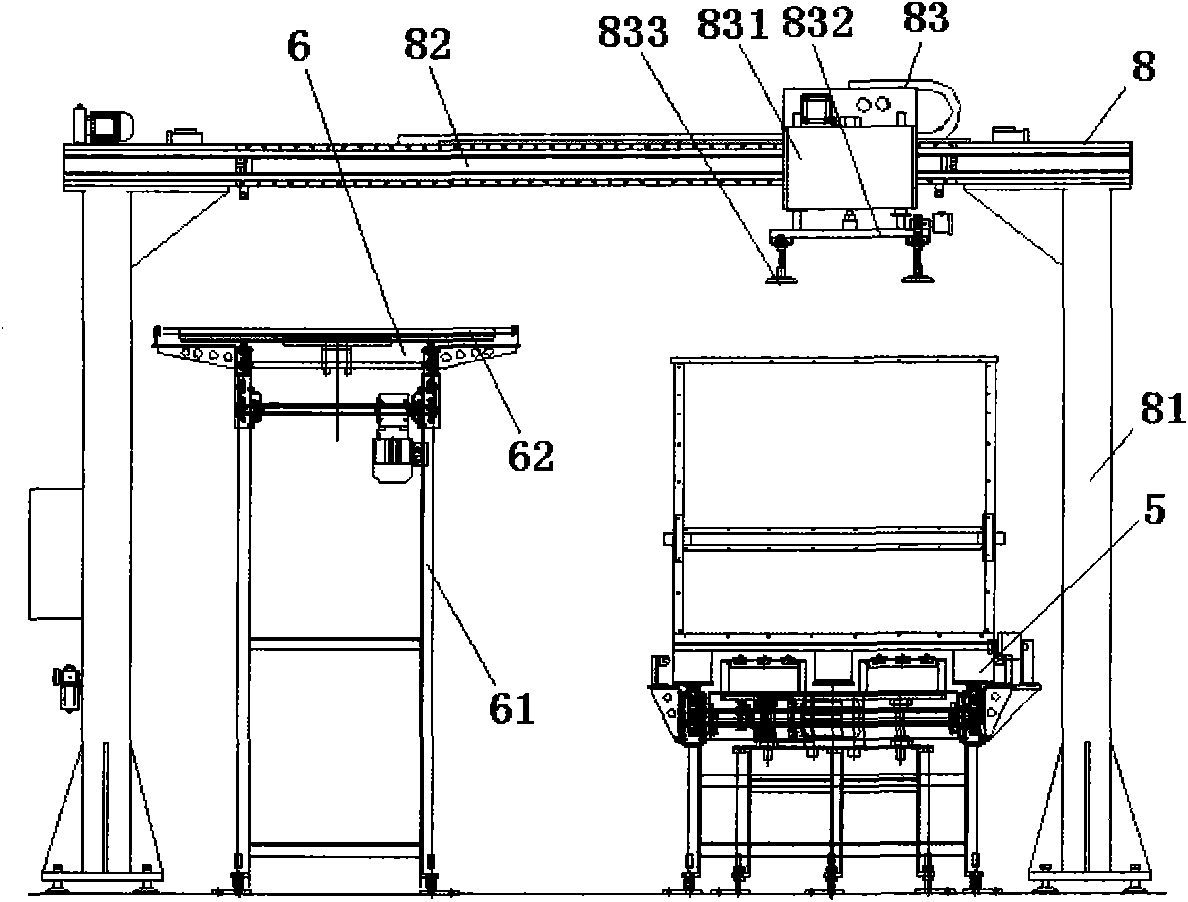

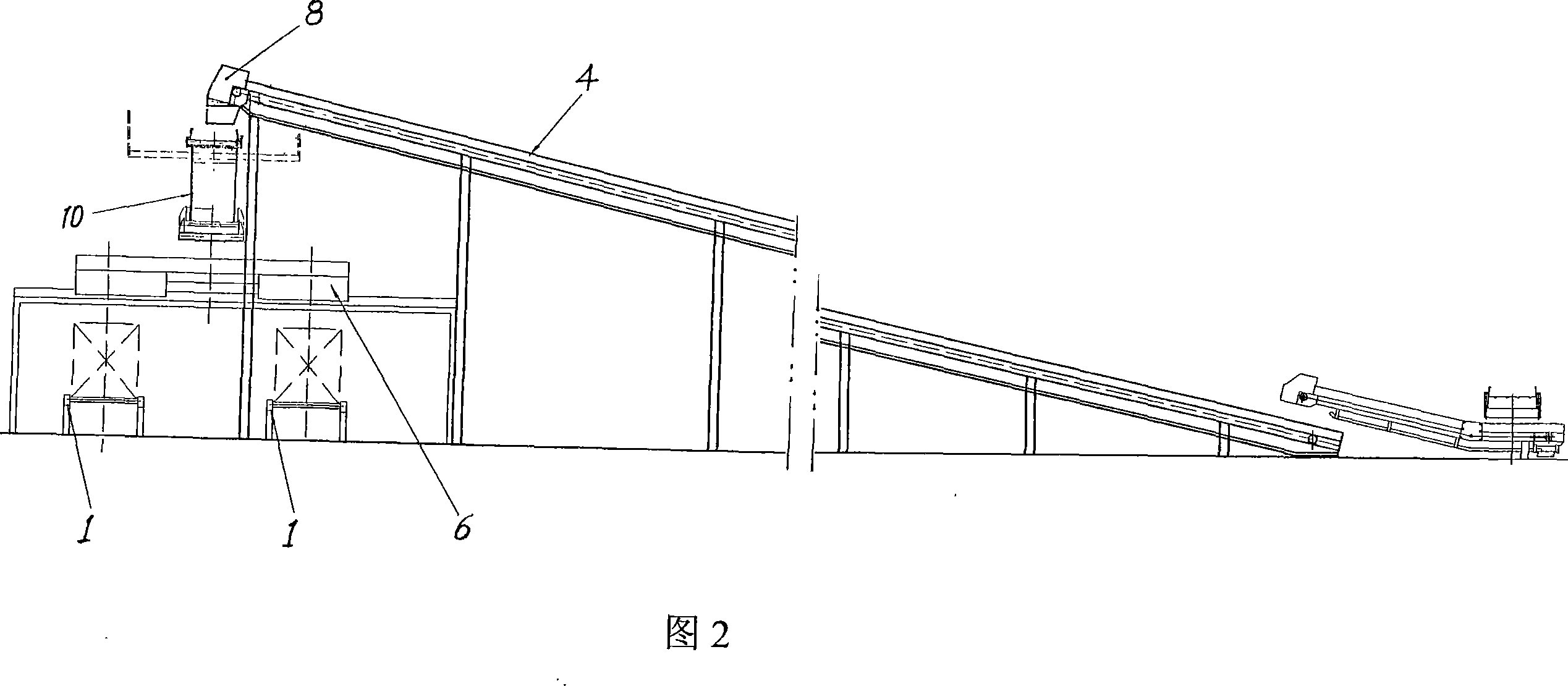

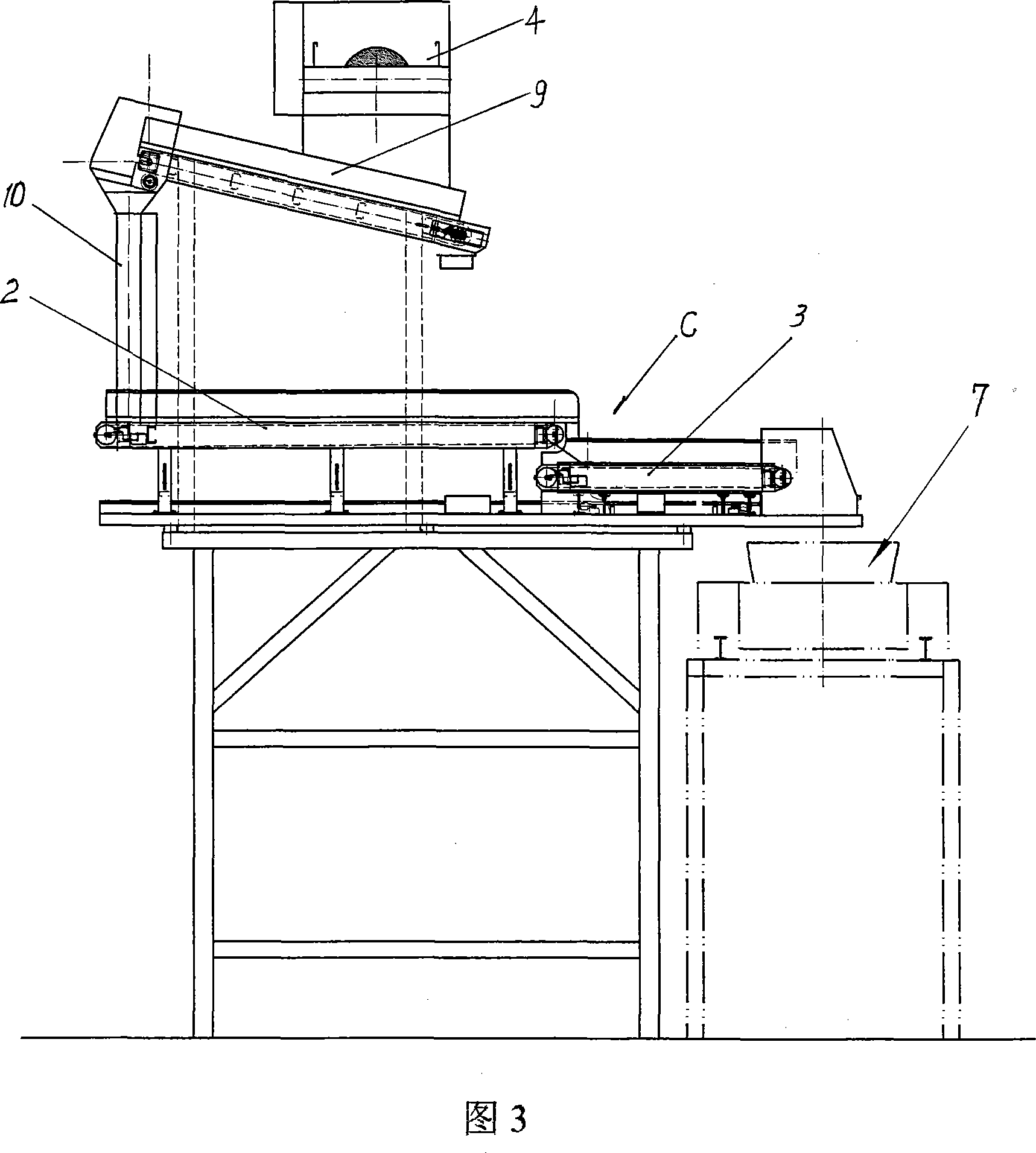

Quantitative boxing device with original box and original cover

The invention provides a quantitative boxing device with an original box and an original cover. The quantitative device comprises a limiting pipe, a buffer conveyor and a full suspension electronic belt scale, and is characterized by further comprising a box body conveyor, a box cover conveyor, a cover taking machine and a capping machine, wherein the cover taking machine and the capping machine are positioned between the box body conveyor and the box cover conveyor. The structure is simple, the occupied area is small, the taking of a cover for an empty box, the accurate charging and the capping for the solid box of a packaging box can be completed automatically in an on-line manner, the dynamic weighing of the empty box and the solid box and the collection of data of net weight of packaged materials, which is obtained by reducing the tare weight in a real-time manner, can be further completed automatically in an on-line manner, and the collected signals are uploaded to a production management information system. The quantitative boxing device is especially applicable to single-point high-precision quantitative boxing for leaves, cut stem, tobacco shreds, cabo, tobacco flakes and other various products in re-baking and primary processing production links in the tobacco industry, can be used alone by matching with a fork-lift truck for use, and can also be in butt joint and combined with a main line for use.

Owner:罗放明

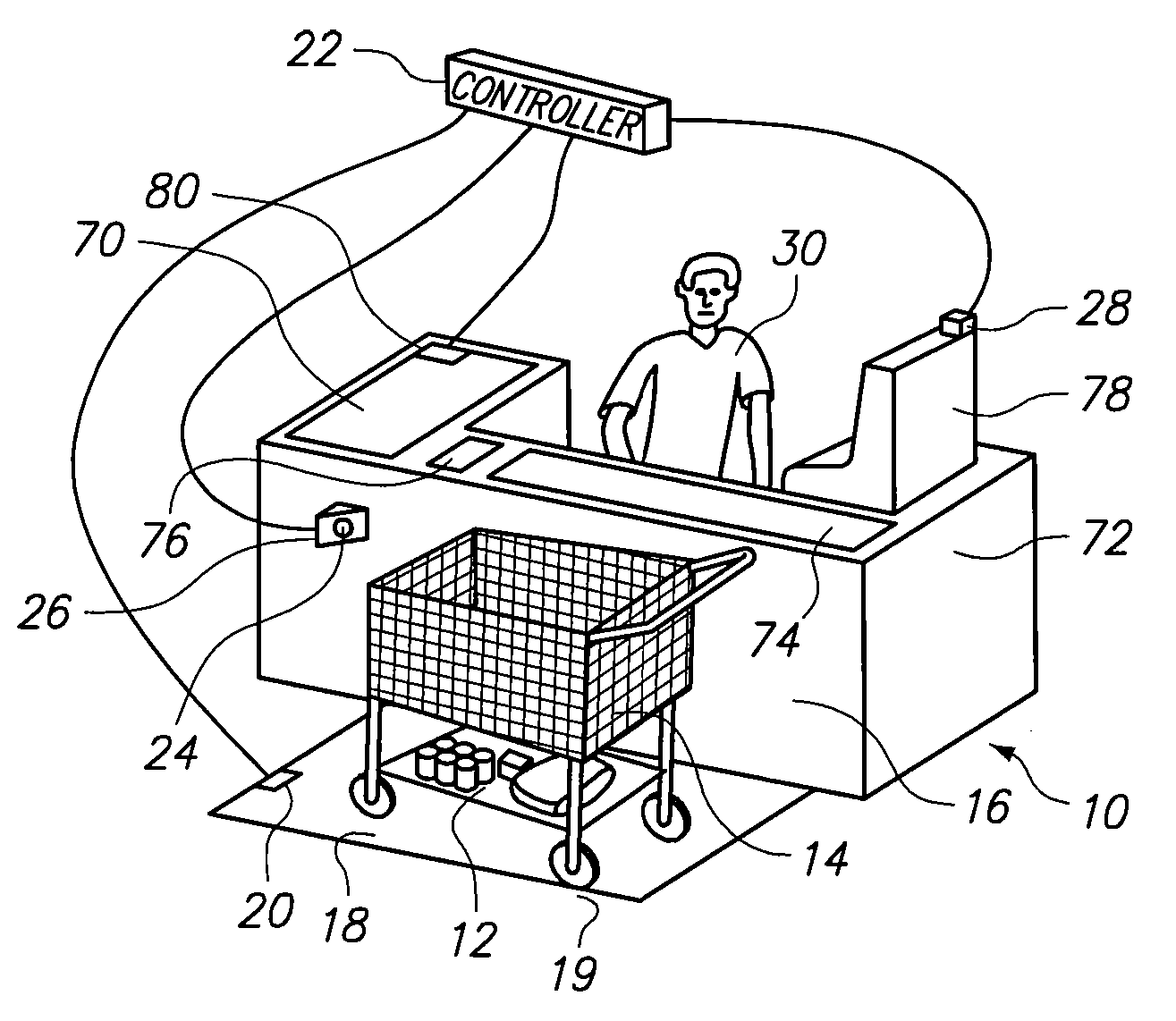

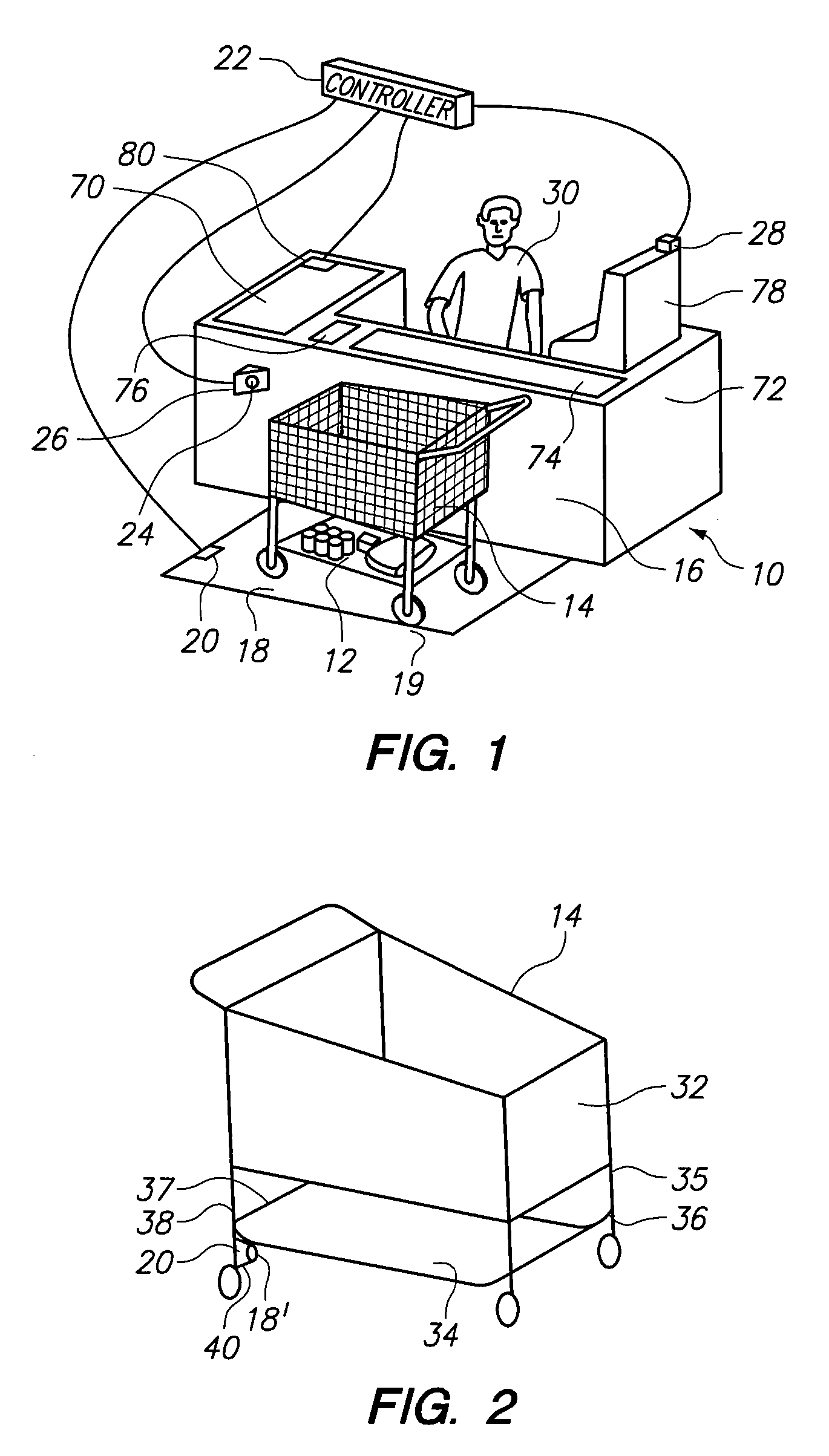

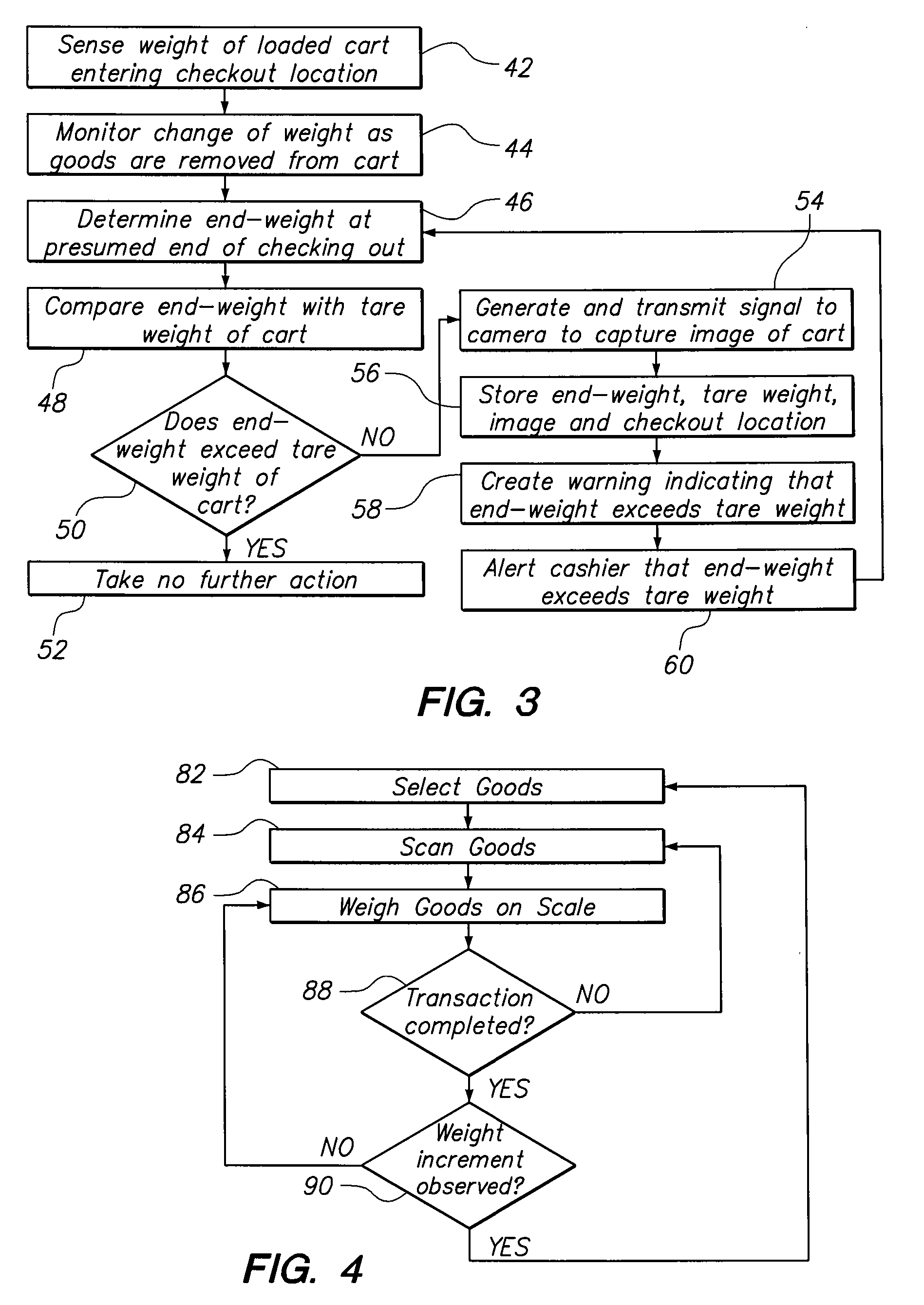

Shopping cart basket monitor

A system prevents non-payment for goods carried through a checkout aisle in a shopping cart. In the system, a scale determines the end-weight of the cart after all goods are presumably removed. Further, a controller compares the end-weight and the tare weight of the cart. When theft is suspected, a camera captures an image of the cart while an indicator at the checkout location alerts the cashier to inspect the cart for unremoved goods. Specifically, the controller creates a signal when the end-weight exceeds the tare weight to instruct the camera to capture the image and to activate the indicator to alert the cashier. The controller may include or be integrated into a network accessible by store management or outside security advisors to examine the performance of cashiers and to determine possible patterns or profiles for theft.

Owner:CARTTRONICS

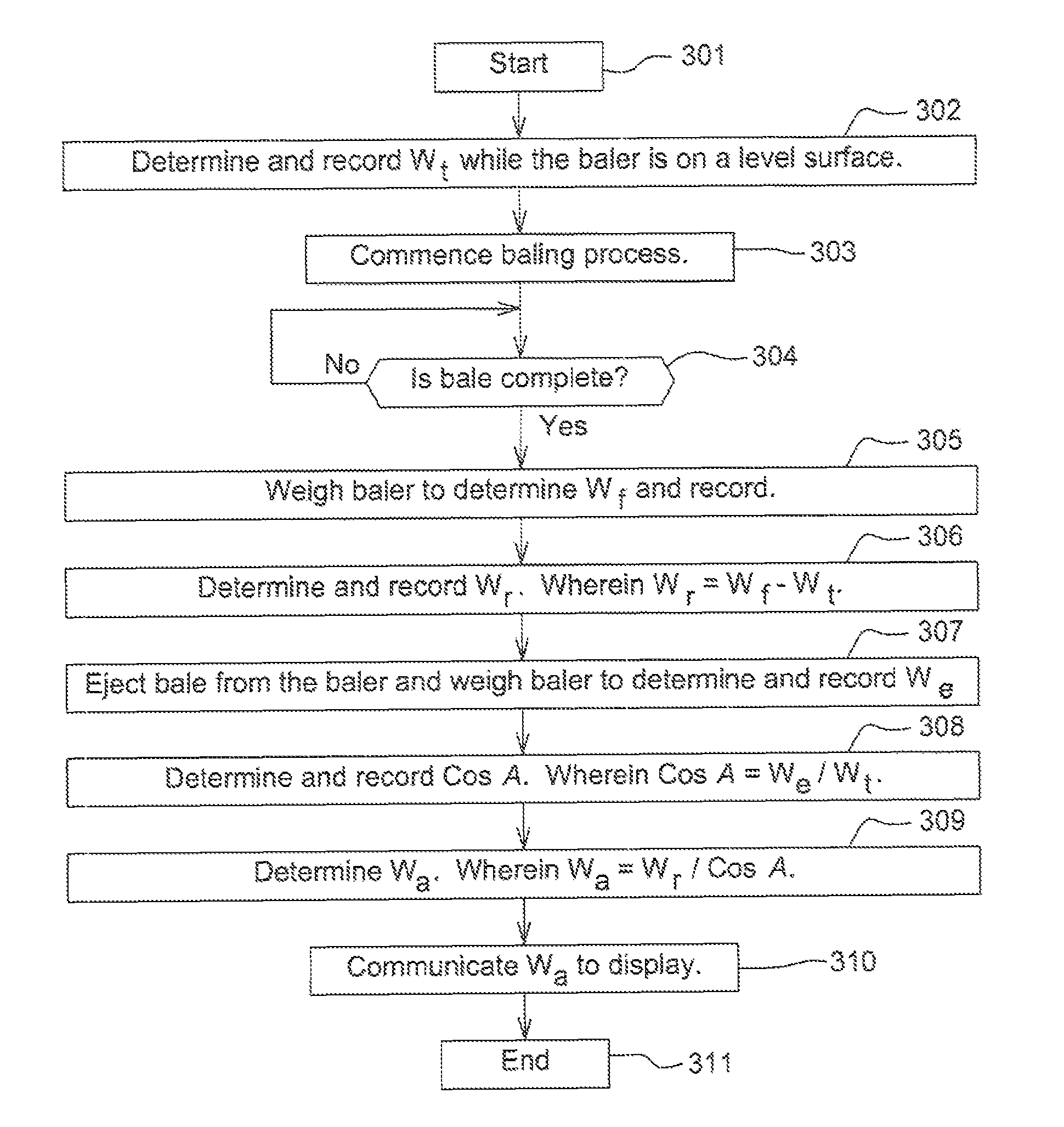

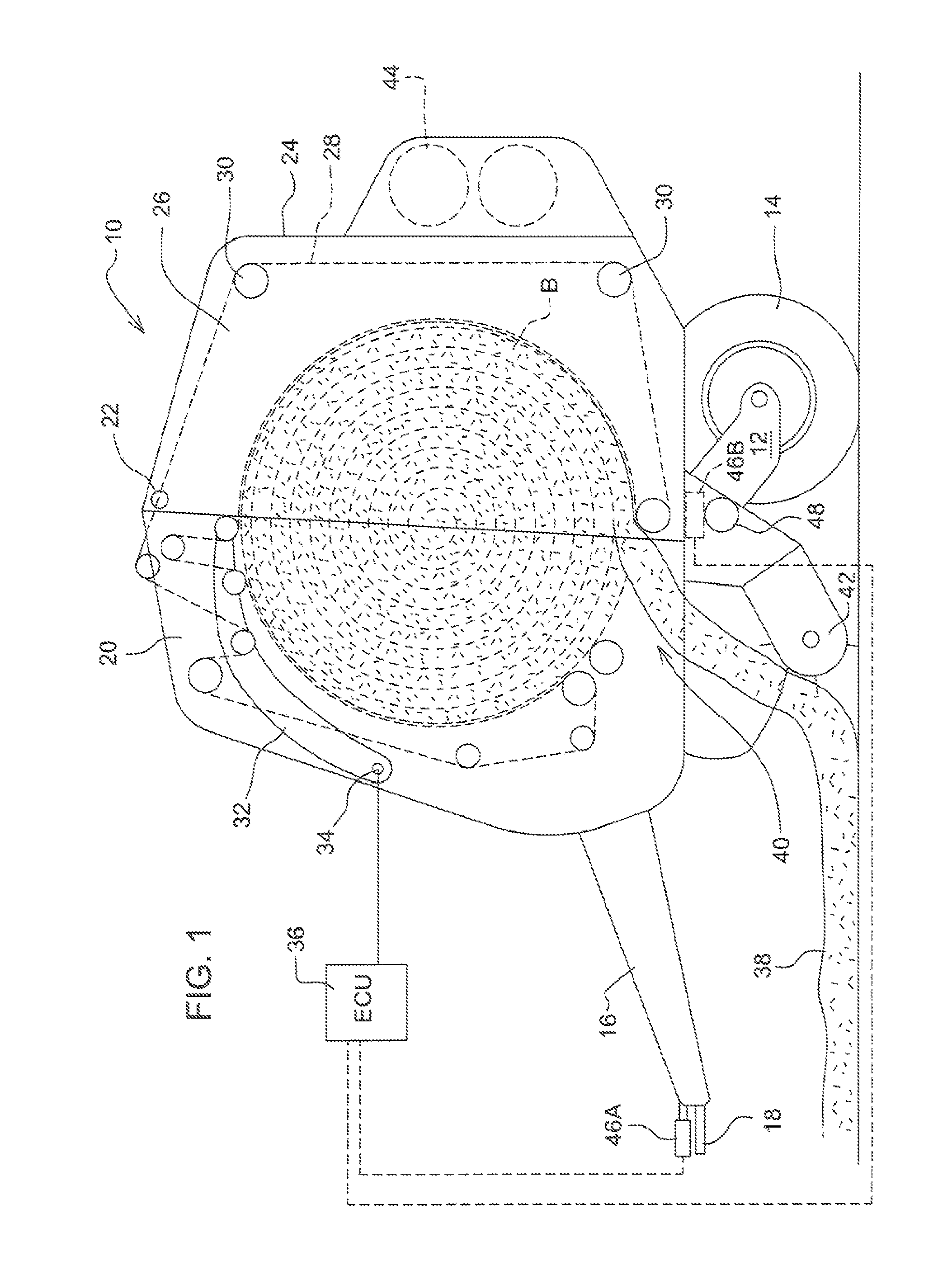

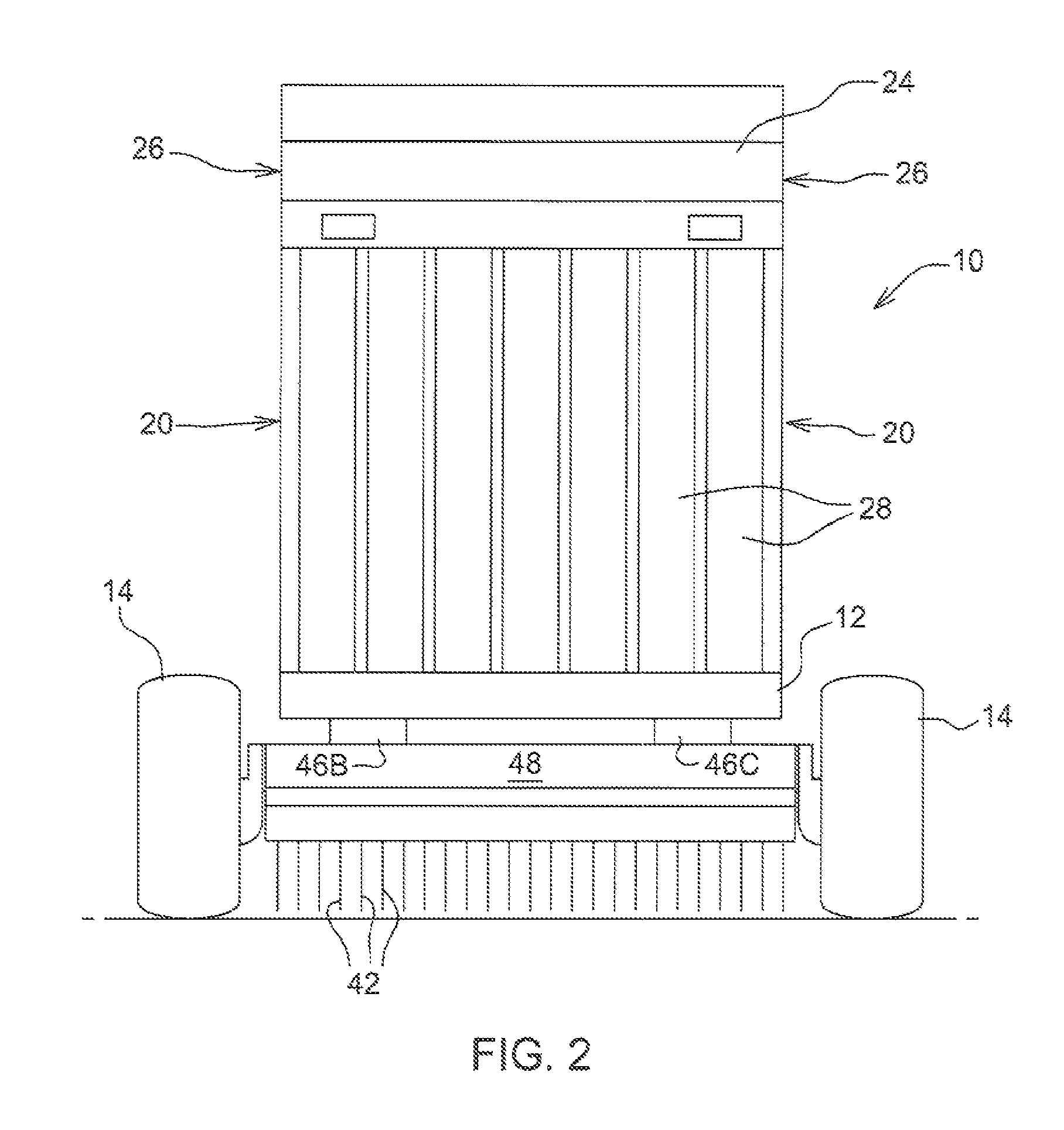

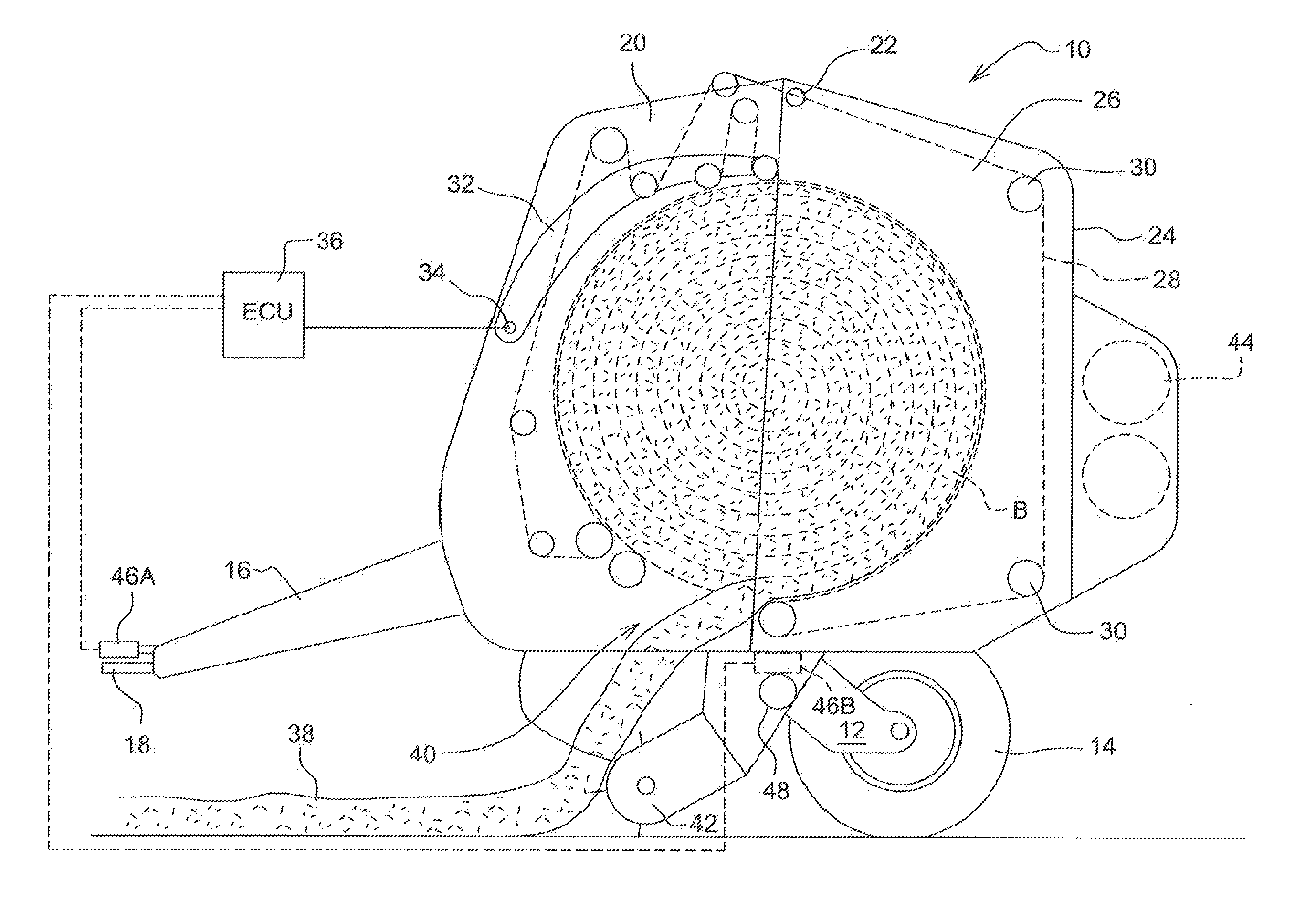

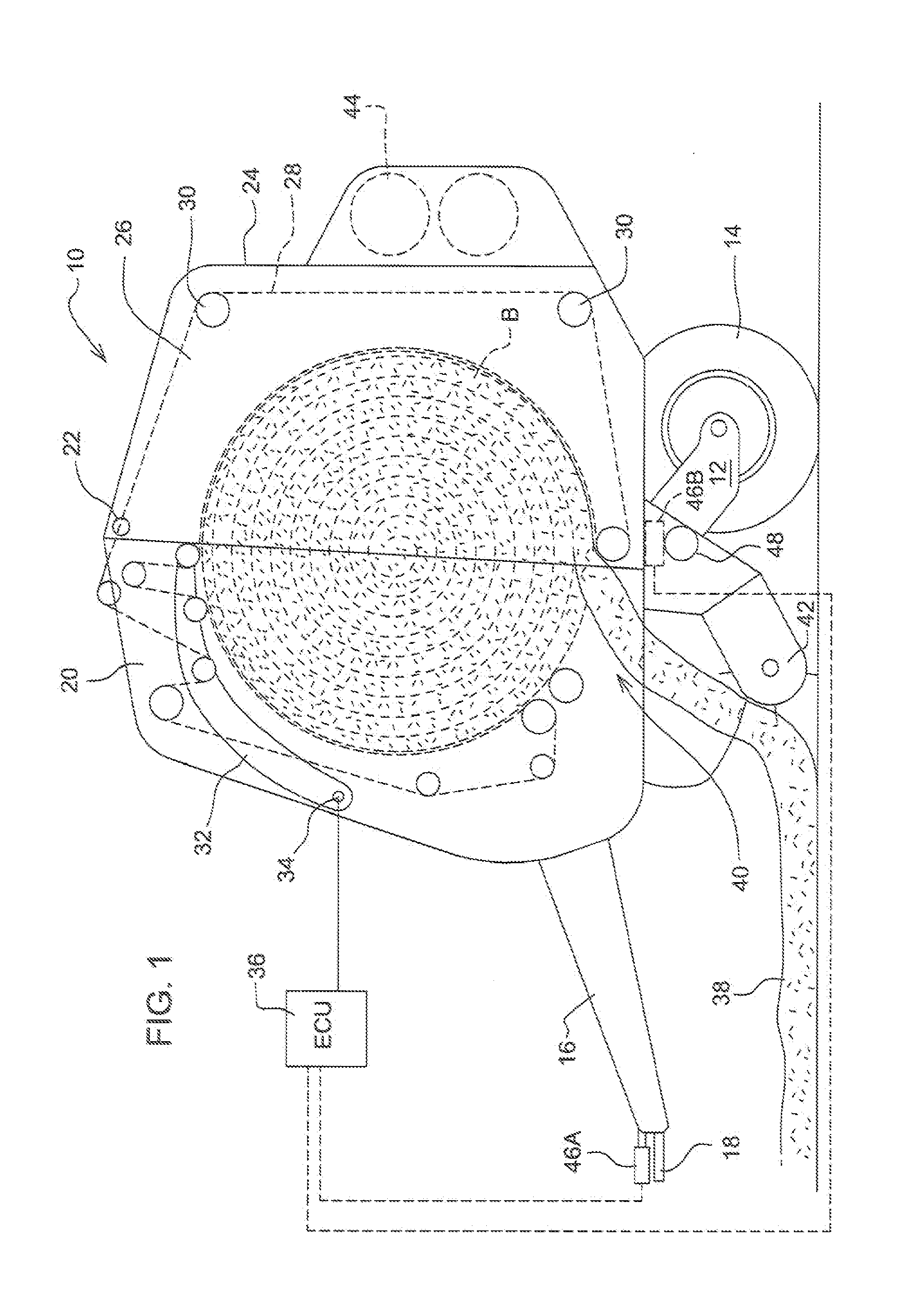

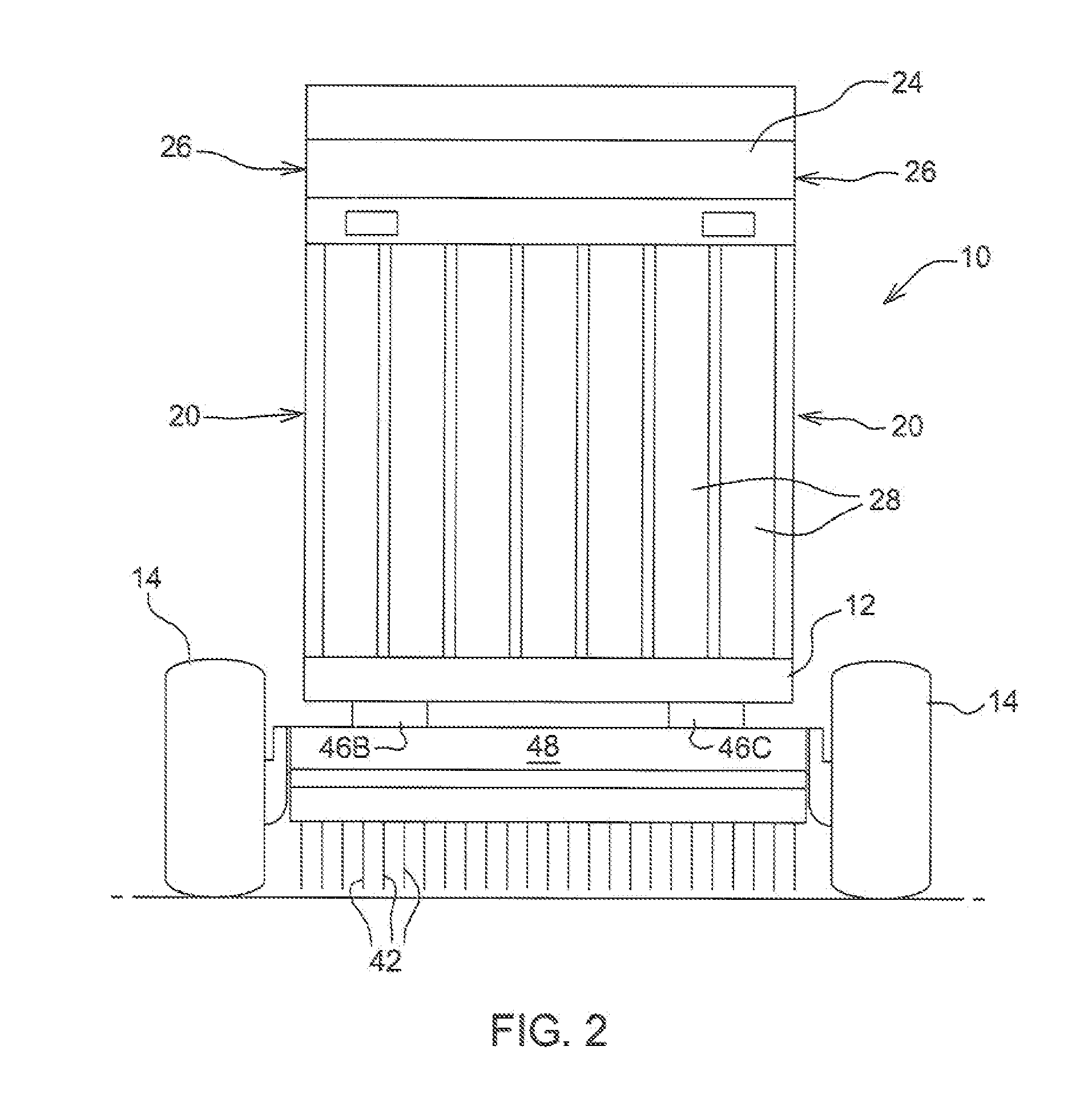

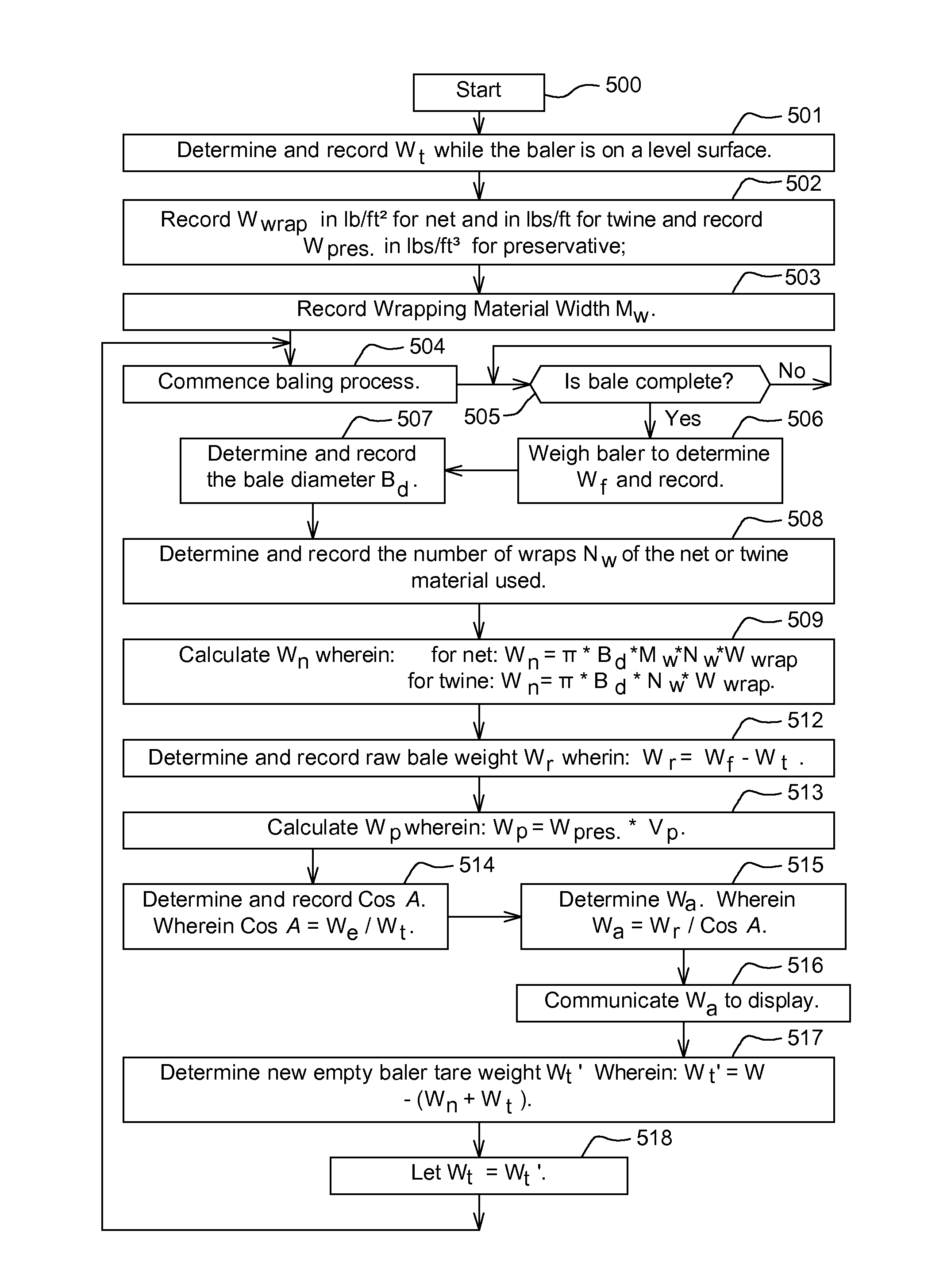

Method for determining agricultural bale weight

ActiveUS8326563B2Increased complexityWeighing apparatus testing/calibrationDigital computer detailsTerrainEngineering

A method is provided for determining the weight of an agricultural bale that compensates for un-level terrain such as hillsides. The method uses an empty baler tare weight and a full baler weight to determine a raw bale weight. The cosine of the slope upon which the baler sits is then calculated based upon the empty baler weight as it sits and the empty baler tare weight. The cosine of the angle of slope and raw bale weight are then used to determine an actual bale weight. Further steps are provided for compensating in the tare weight of the baler for the weight of wrapping material consumed in the formation of each bale.

Owner:DEERE & CO

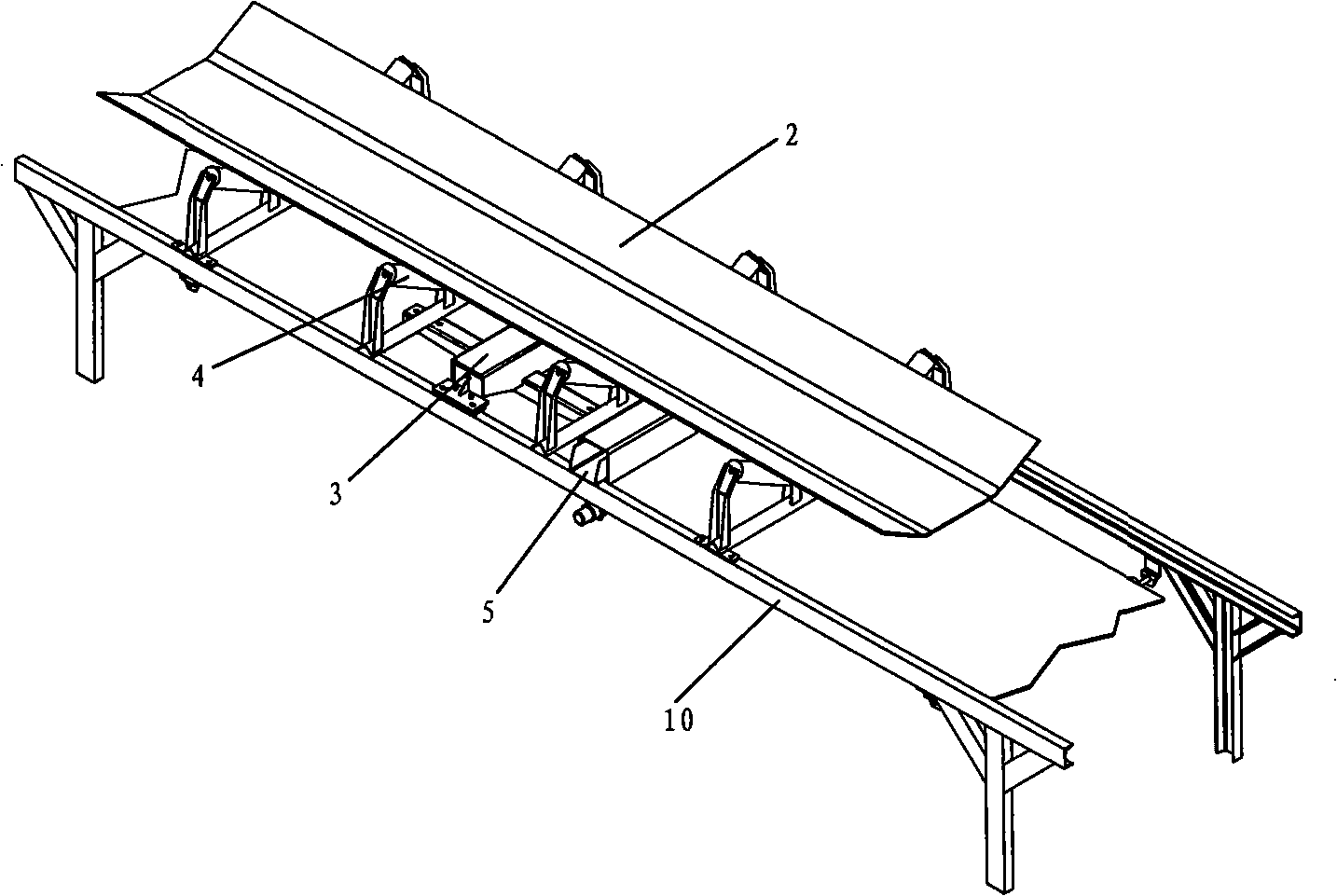

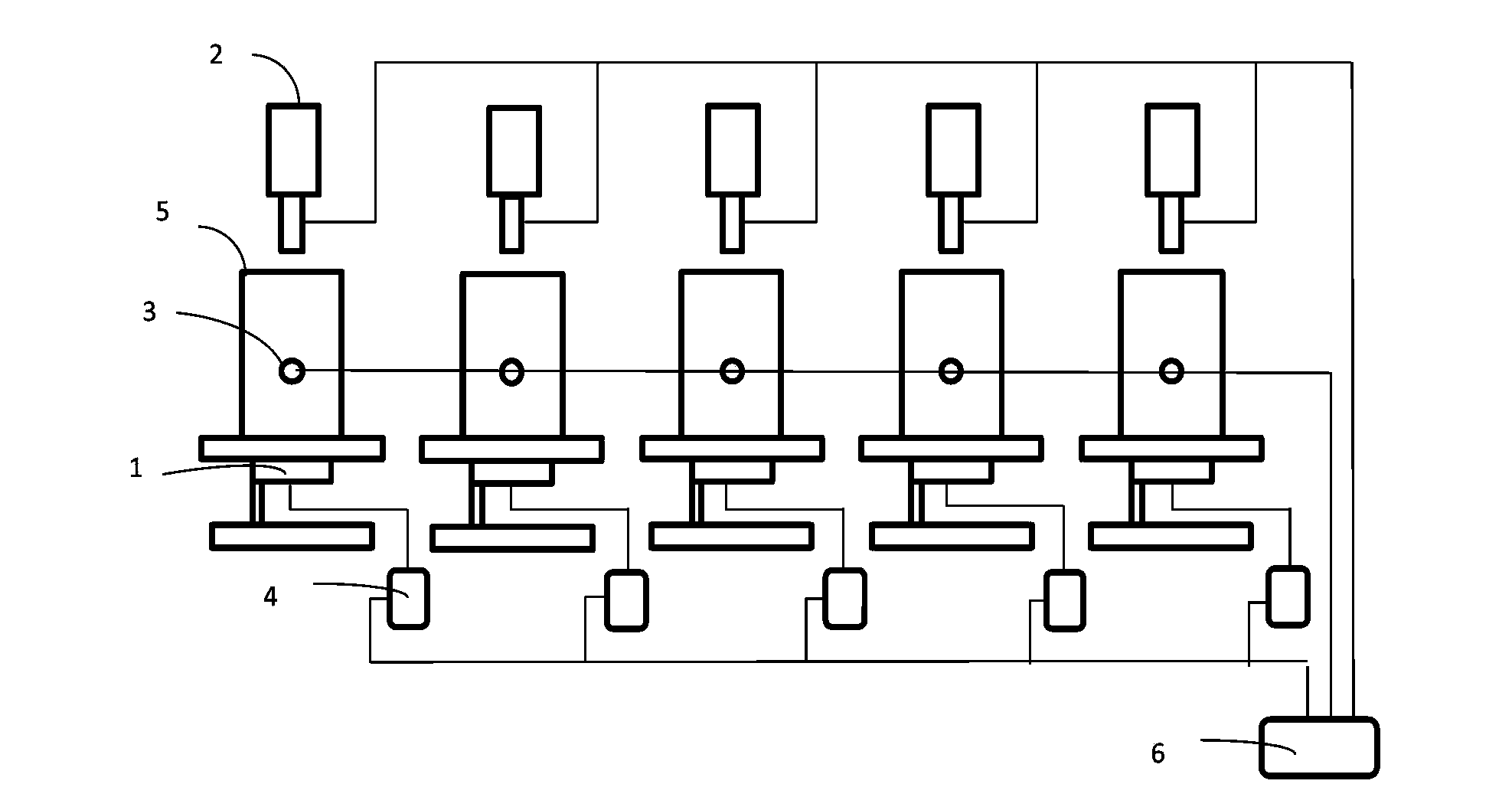

Not inertial, online system of box packing quantitative tobacco shred, tobacco pieces with tare weight being removed in real time

InactiveCN101092188AImprove stabilityReduce maintenanceSolid materialPackaging automatic controlControl systemNet Weight

The invention supplies quantify packaging system used to process non inertia online real time tare removing. It includes material conveyor, storing tube, buffering conveyor, conveying scale, two-way reciprocal conveyor, and packaging conveyor. It can convey the quantify material on electronic belt conveyor scale in bulk to packing box to avoid inertial error, exactly figure out packaged material net weight, reasonably and high effectively achieve packaging production to realize whole compact automatic packing control system.

Owner:罗放明

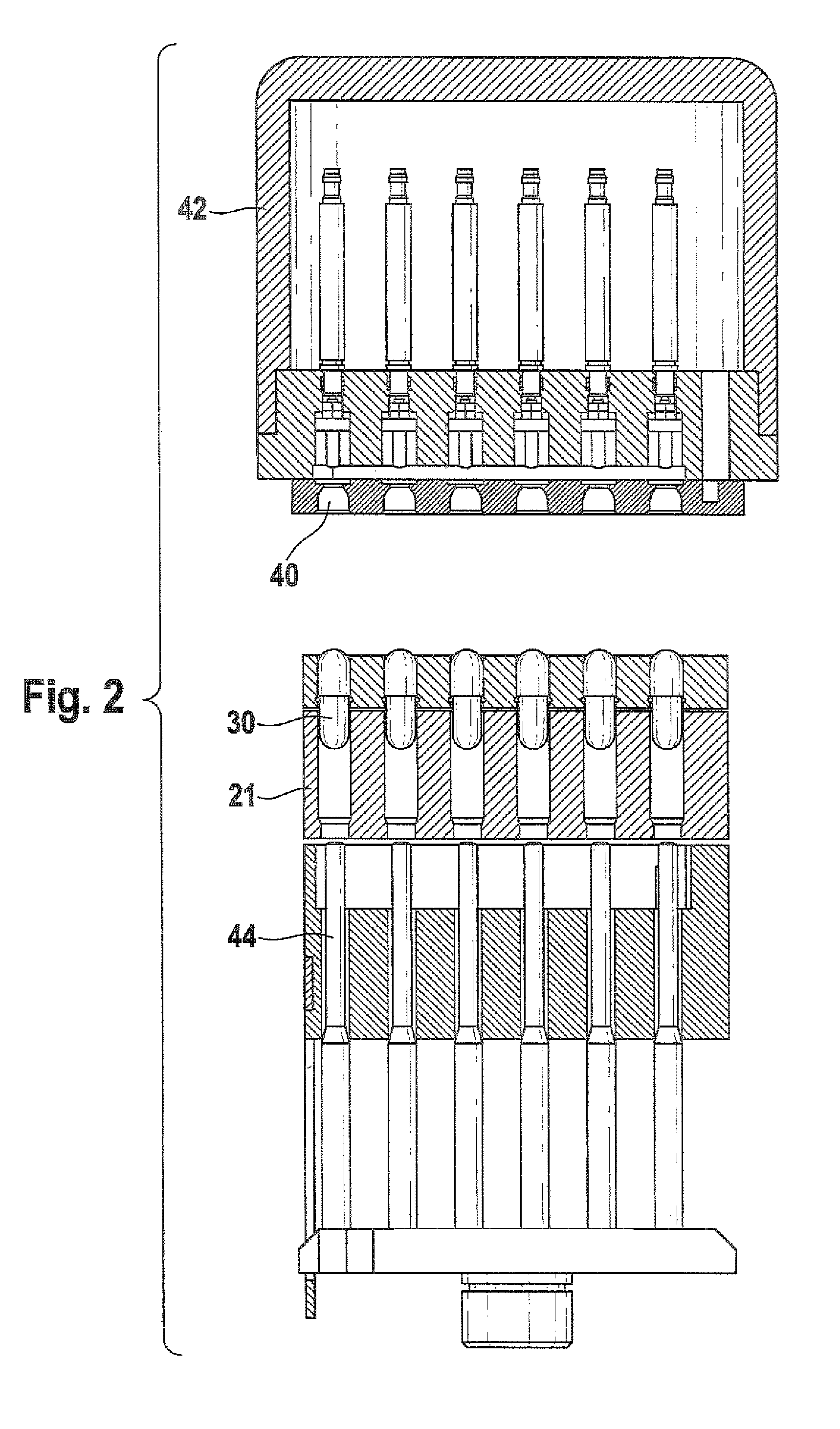

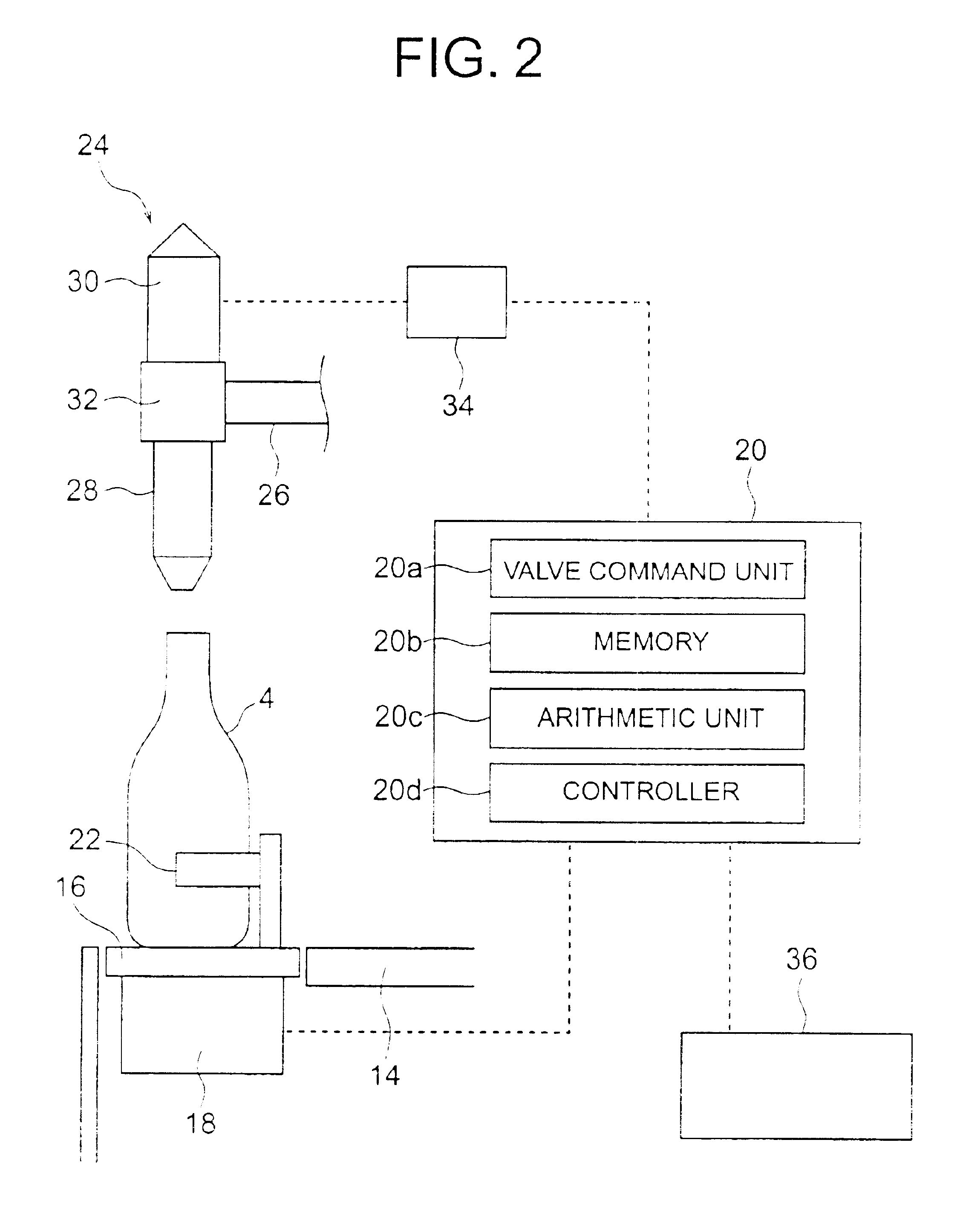

Weighing device for a packaging machine

ActiveUS8266874B2High precisionReliably and quickly removedPackaging by pressurising/gasifyingPackaging under vacuum/special atmosphereEngineeringNet Weight

Owner:SYNTEGON TECHNOLOGY GMBH

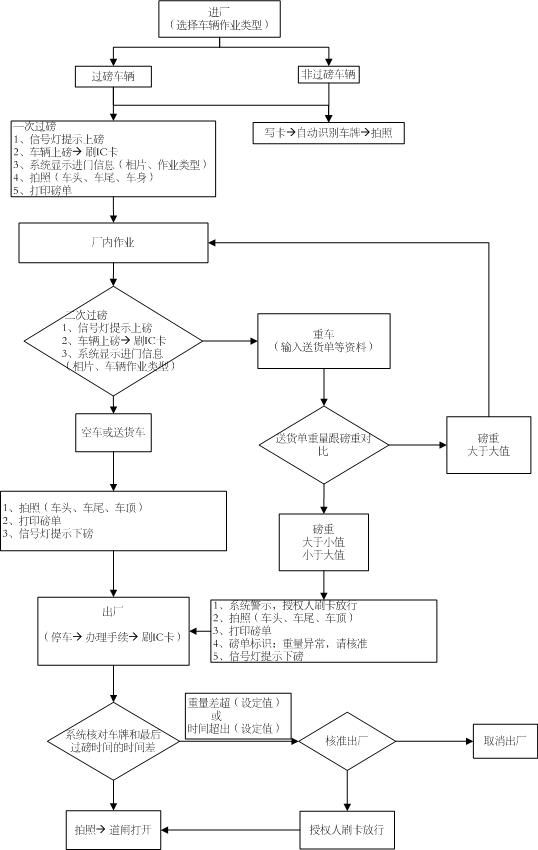

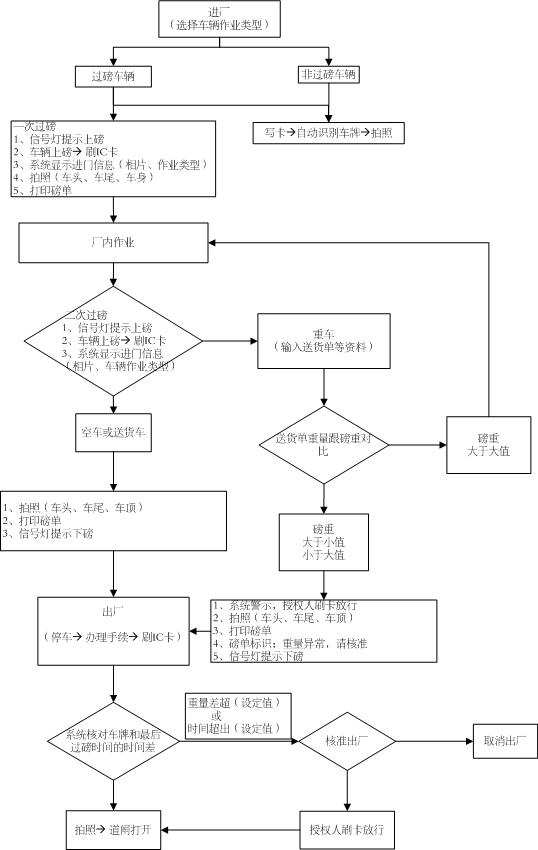

IC (Integrated Circuit) access control system

InactiveCN101958012ARun reasonablyFaster turnaroundIndividual entry/exit registersControl systemEnterprise resource planning

The invention relates to the technical field of safety management, in particular relates to an IC (Integrated Circuit) card access control system which comprises at least one card reader as well as a camera, a control system and a weighing system. The card reader is arranged at the entrance of a plant for reading the information of the IC card, the camera is used for shooting three positions, i.e. the front part, the middle and the rear part of a IC card vehicle after the IC card is read by the card reader, the control system and the weighing system are connected to the card reader and the camera through communication lines, and the control system judges whether a vehicle needs weighing or not according to the information read by the card reader and judges the loaded weight of the vehicle according to the vehicle tare weight prestored in the control system after the vehicle is weighed. The invention normatively manages vehicles entering or exiting the plant, automatically recognizes the number plate of a vehicle entering the plant, reduces manual operation, records access records every time through shooting, has anti-theft effect and is tightly combined with an ERP (Enterprise Resource Planning) system so as to improve the turnaround speed of containers and remarkably decrease the production cost.

Owner:LEE & MAN PAPER MFG

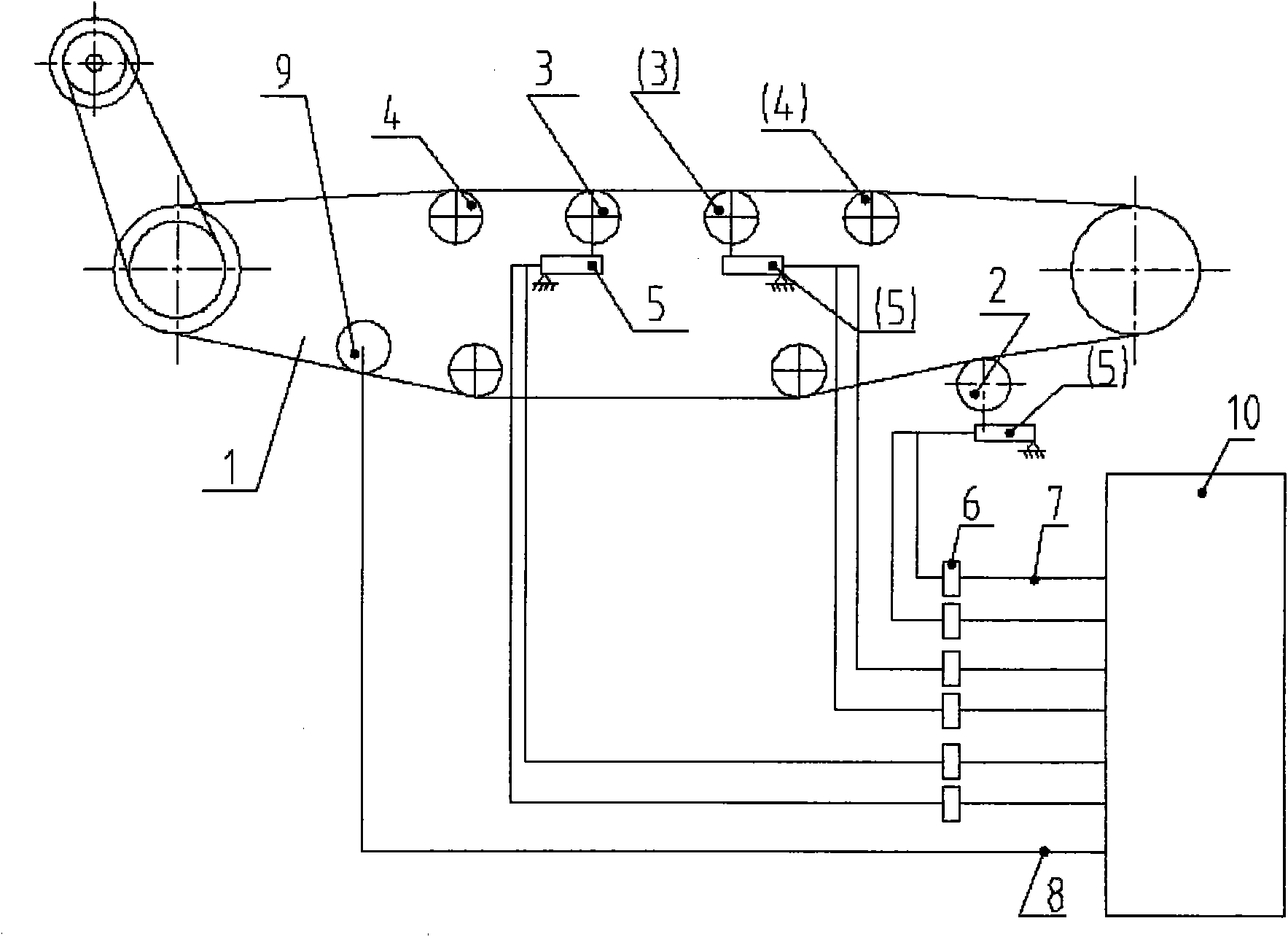

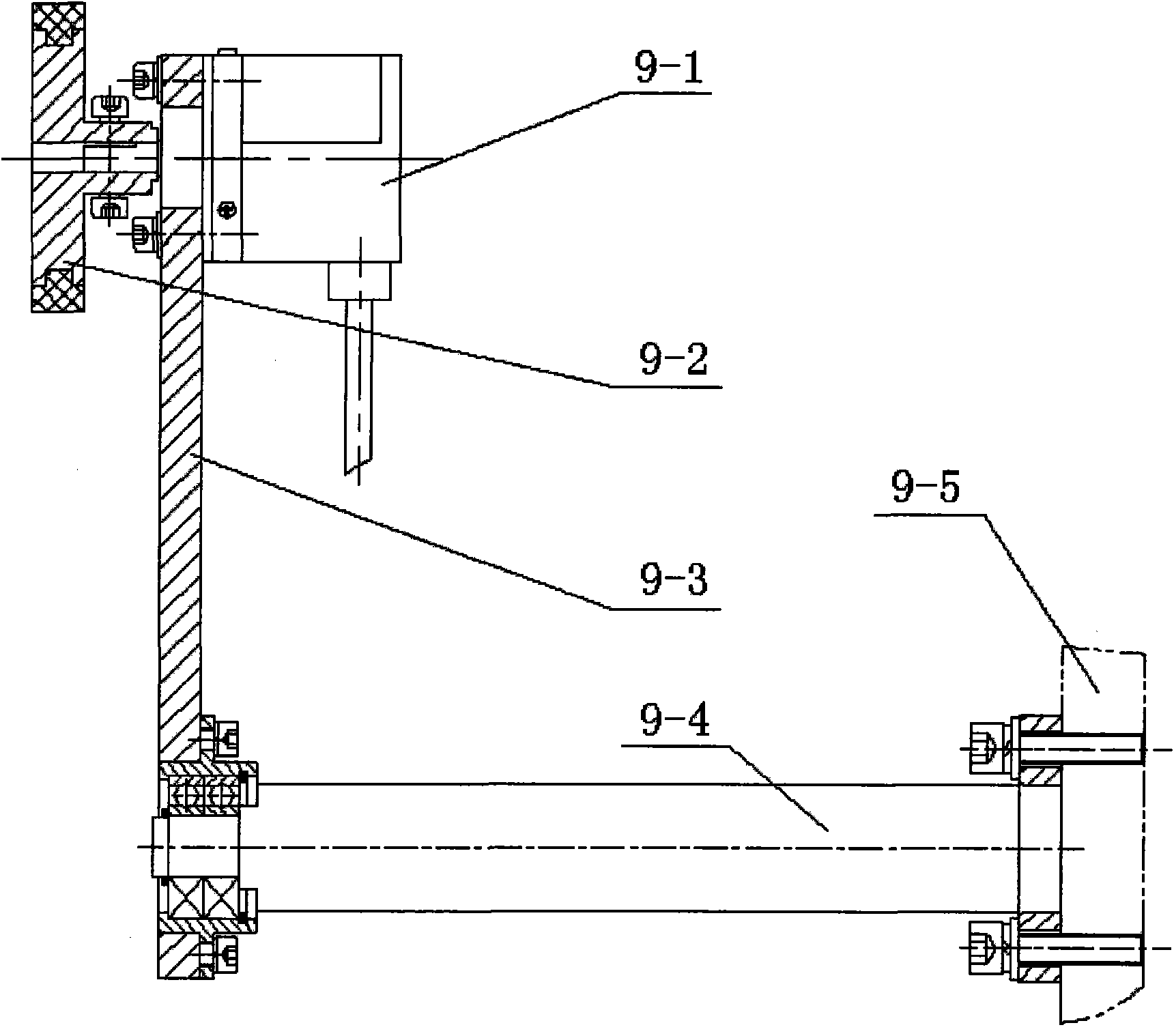

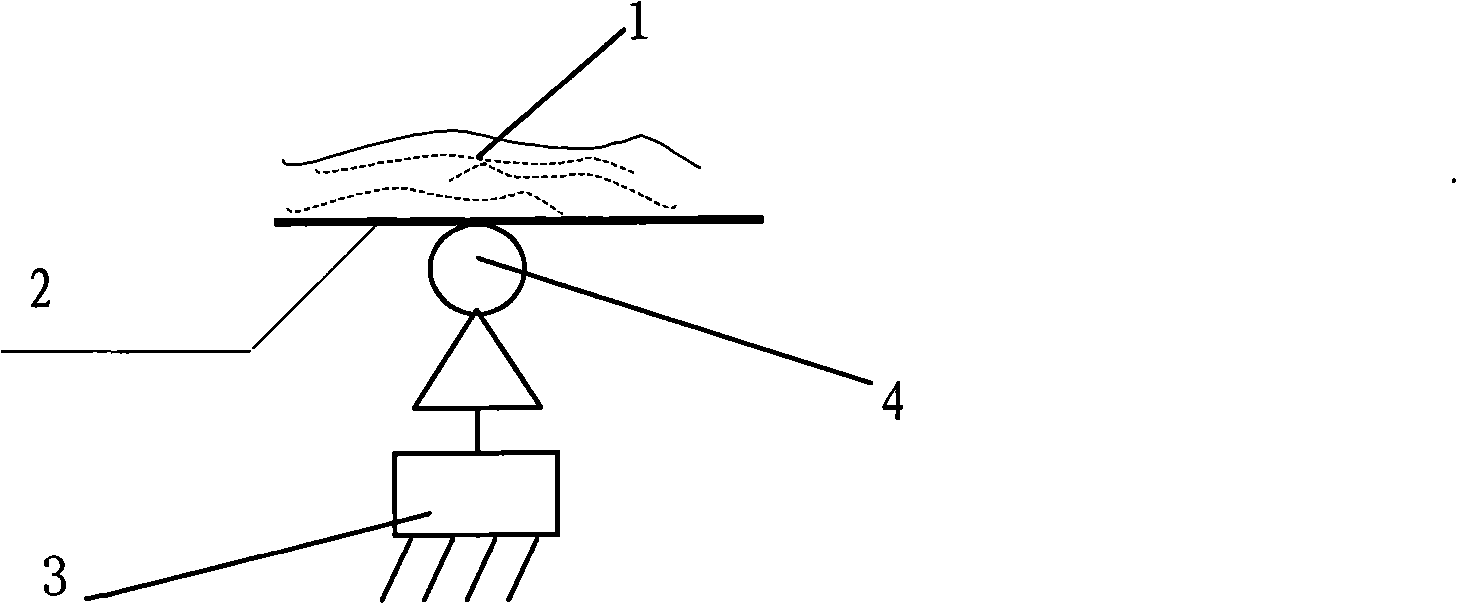

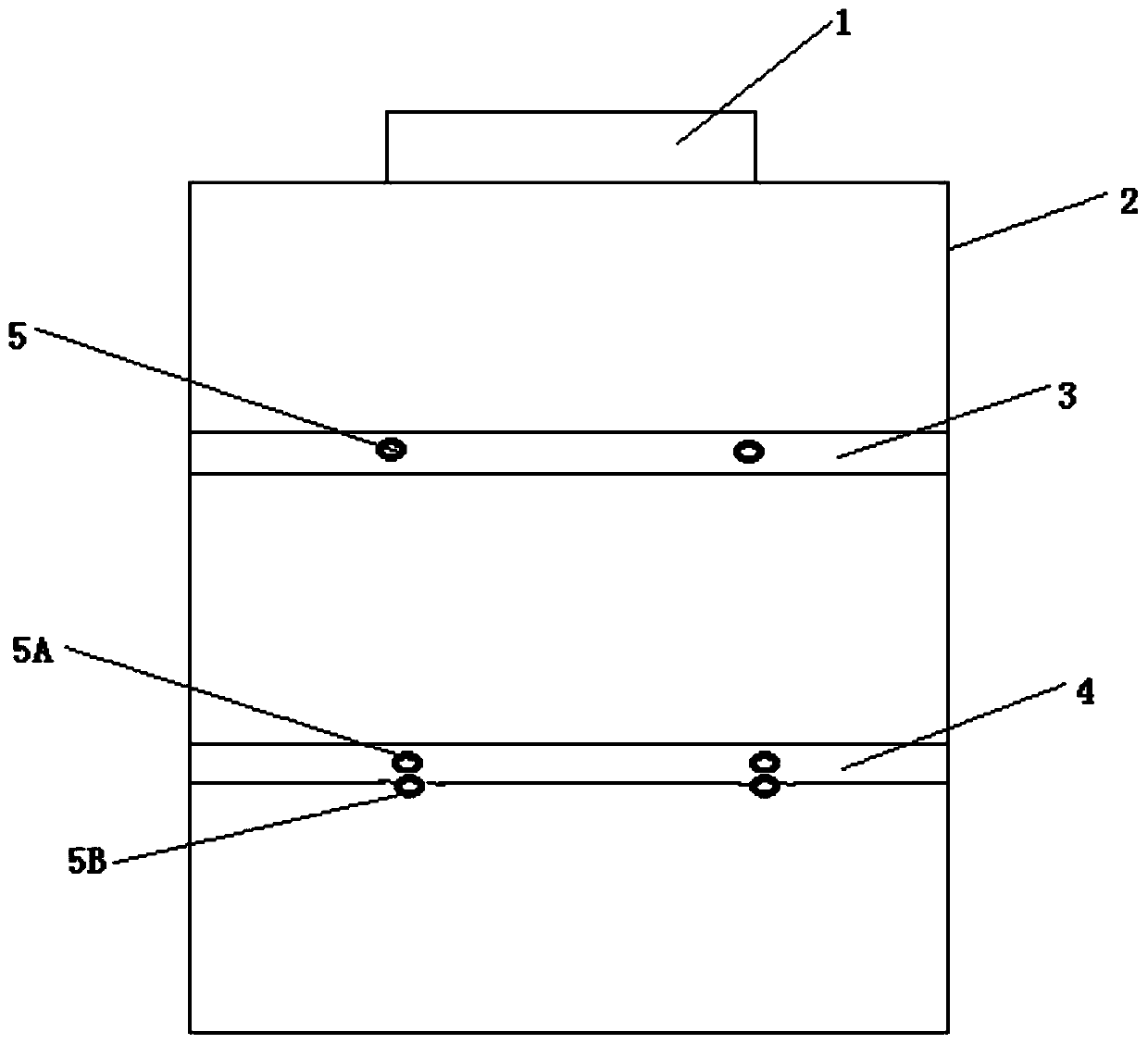

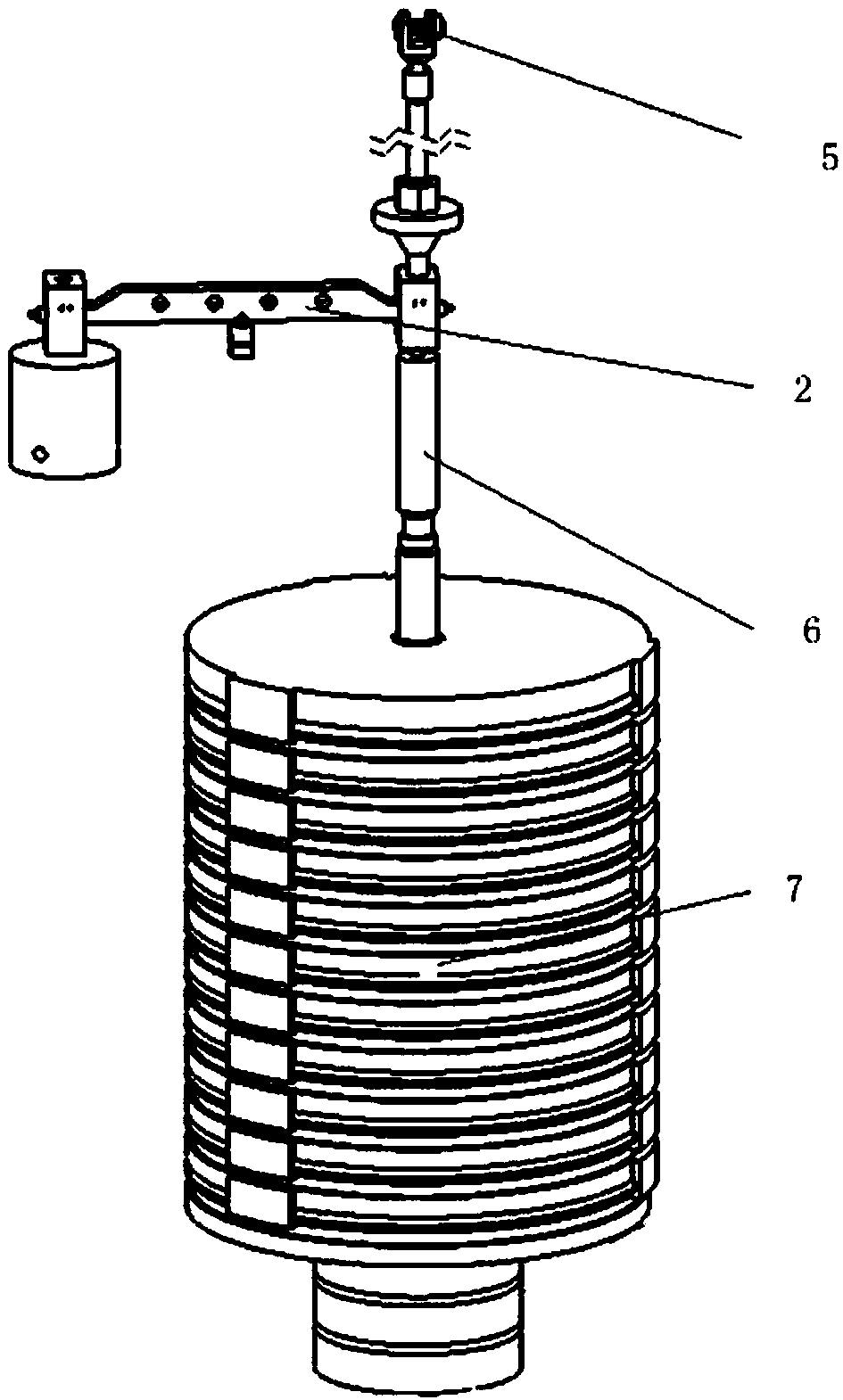

Suspension-type electronic belt scale capable of detecting tare weight in real time

InactiveCN101561311AImprove stabilityGuaranteed accuracyWeighing apparatus for continuous material flowWeighing auxillary devicesSingle supportBelt speed

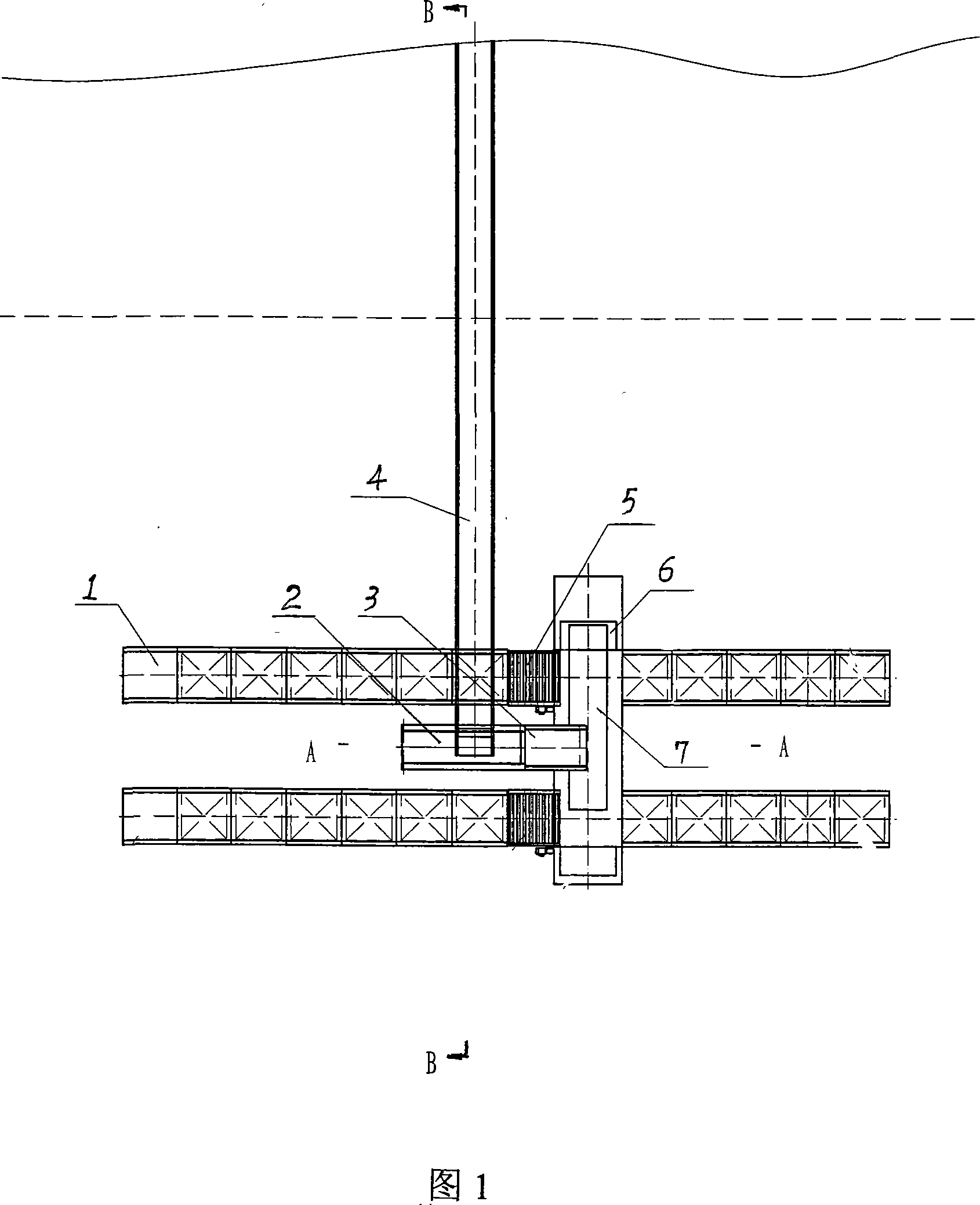

The invention relates to a suspension-type electronic belt scale capable of detecting the tare weight in real time, which is characterized by mainly comprising a belt conveyor, suspension-type single-support roller weighing supports, an online real-time tare weight detector, a plurality of weighing sensors, a belt speed detector, a signal transmitter and a signal processor, wherein the single-support roller weighing supports are suspended by being directly supported by the weighing sensors; two or more than two suspension-type single-support roller weighing supports form a suspension-type weighing platform which is placed inside the belt conveyor; the online real-time tare weight detector is connected with the weighing sensors which are connected with the signal transmitter; the signal transmitter is connected with the signal processor; and the belt speed detector contacts a belt of the belt conveyor and is connected with the signal processor. The suspension-type electronic belt scale eliminates the speed detection deviation caused by various intermediate conversion links, can precisely detect the tare weight in real time at any moment, has a simple, concise and compact structure and high measuring accuracy, and is convenient to assemble and maintain.

Owner:玉溪市浩森工贸有限公司

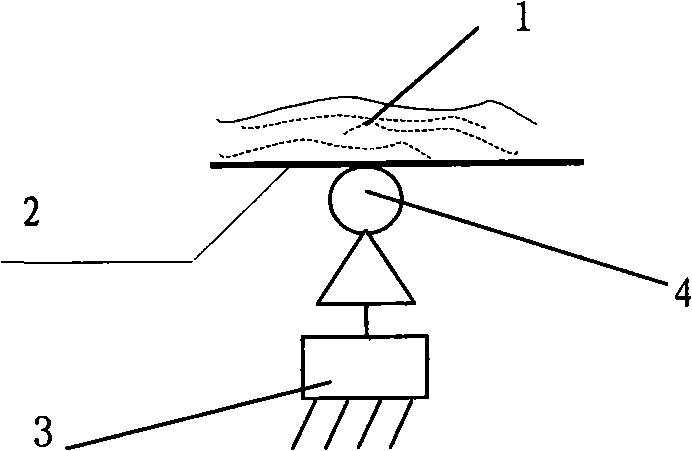

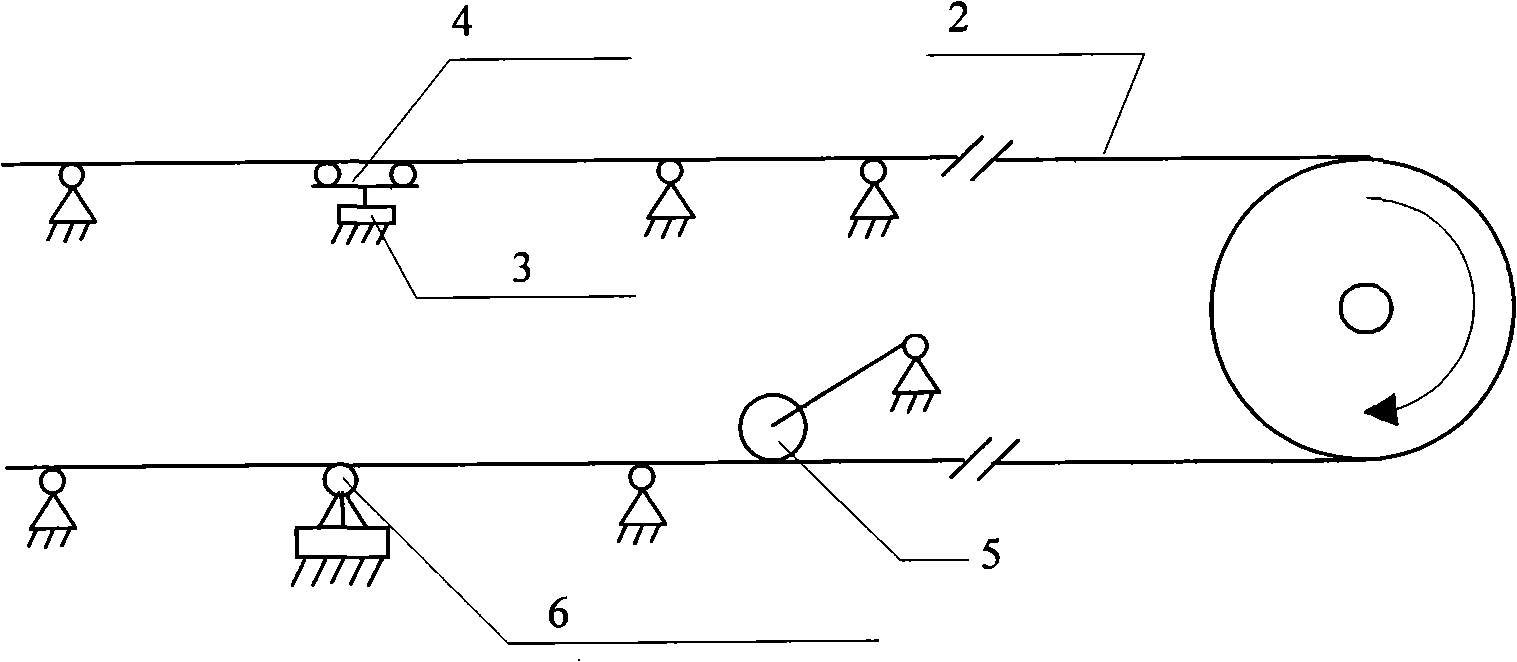

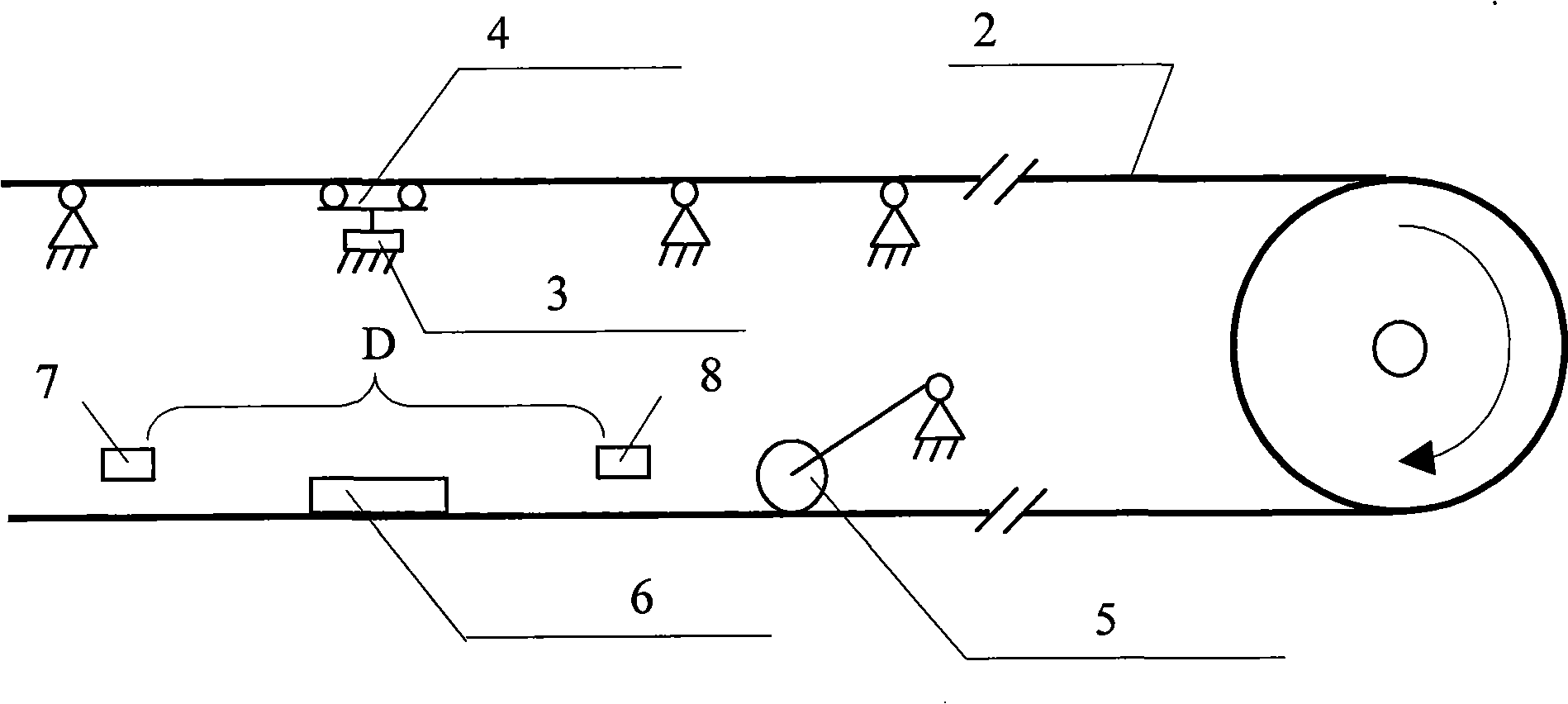

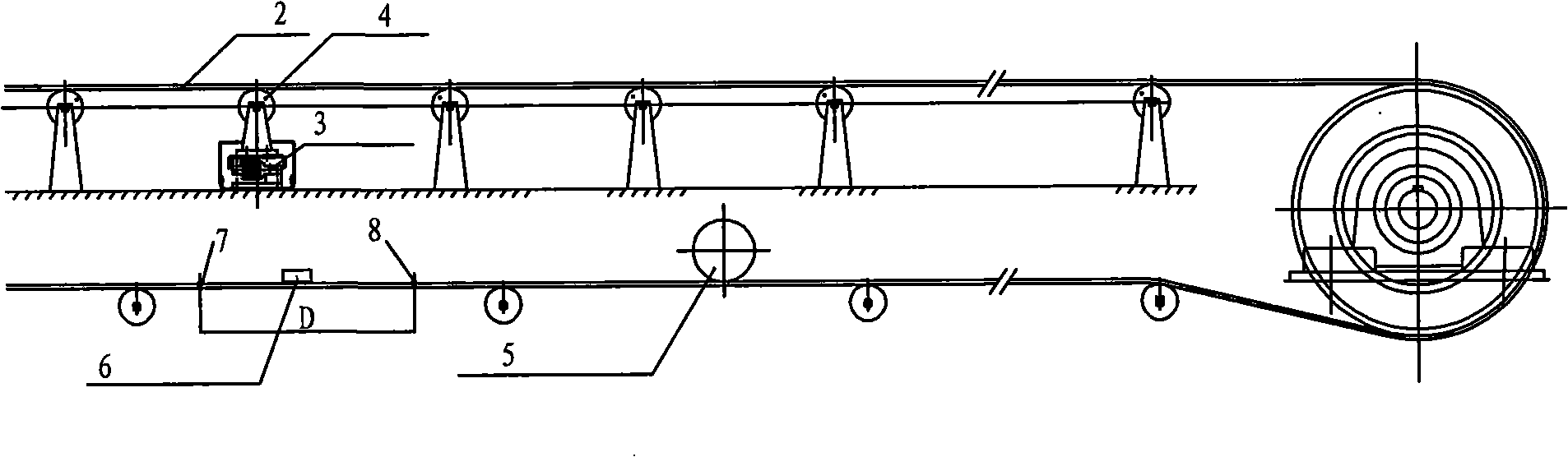

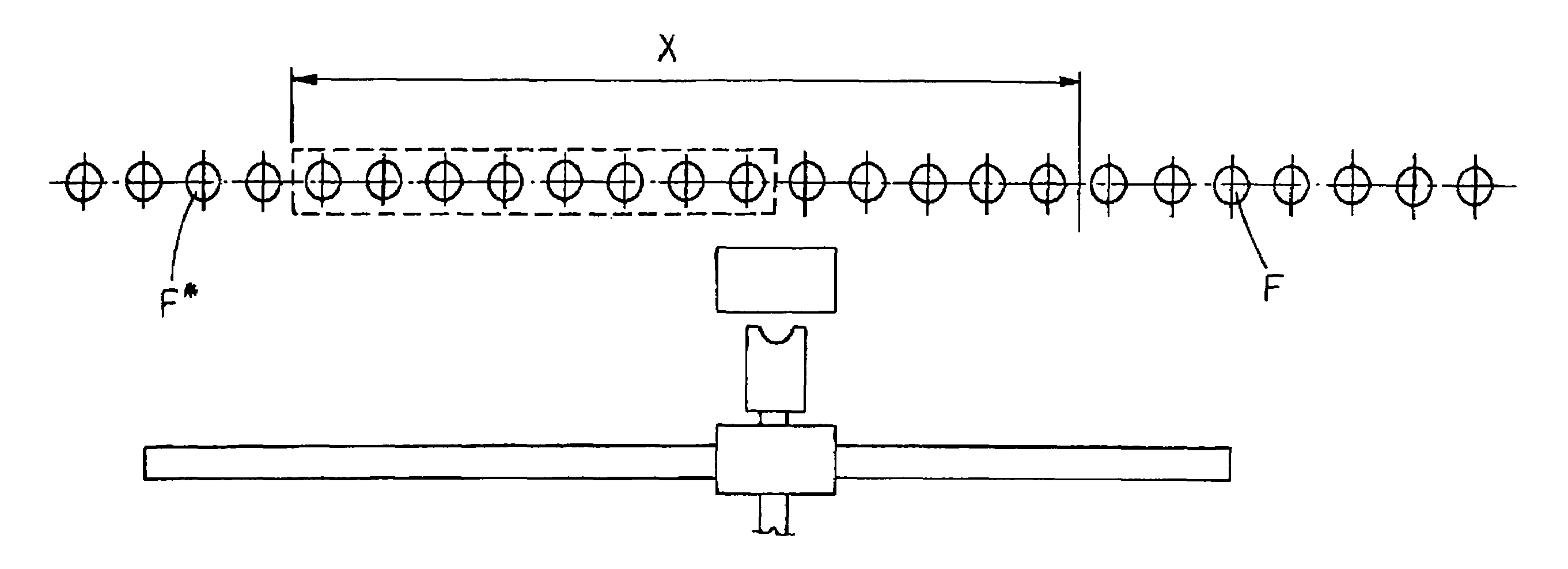

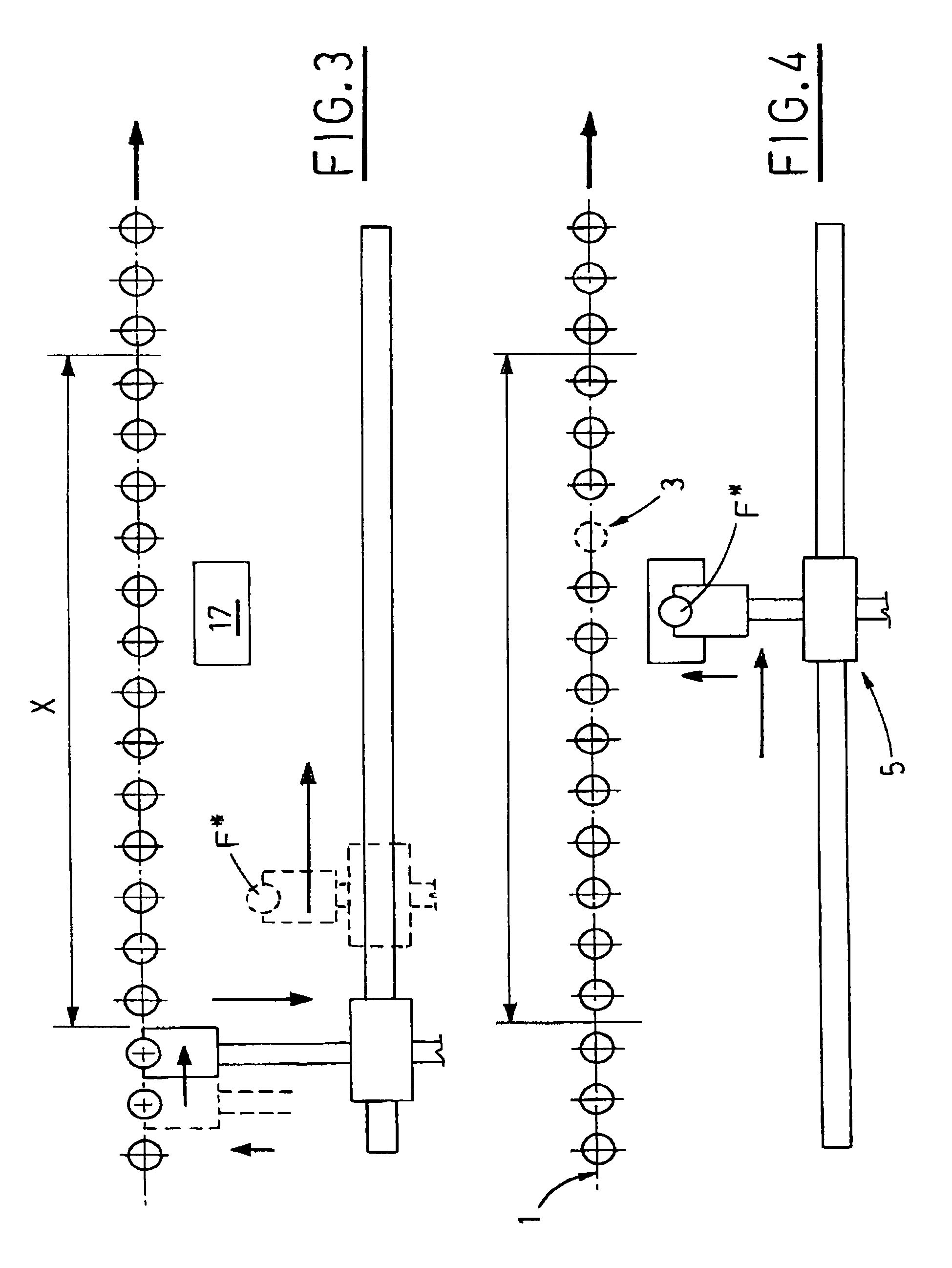

Belt scale weighing synchronous peeling method and synchronous peeling belt scale

InactiveCN101261151AAvoid measurement errorsIdeal weighing resultsWeighing apparatus for continuous material flowWeighing auxillary devicesEngineeringLoad cell

The invention relates to a belt weigher weighing synchronous skinning method and a belt weigher which realizes the method, belonging to the weighing measurement technical field. In the method, as a tare weight sensing device is arranged at the position of the prearranged distance from the delivery belt returning section of a belt weigher frame to a positive advancing section belt weighing sensor, after the weighing of the belt weigher runs, the gross weight data that the bearing delivery belt passes through the positive advancing section weighing sensor and the tare data that the empty-loaded delivery belt passes through the returning section tare weight sensing device are recorded; the lagged time of the delivery belt running from the weighing sensor to the tare weight sensing device is worked out according to the running speed of the delivery belt and the prearranged running distance; finally, the skinned net weight data is obtained by taking away the tare weight data recorded in the lagged time from the real-time recorded gross weight data. As the method of the invention realizes deducting the synchronous tare weight during the skinning, whether the delivery belt is abraded or bonded to material, the net weight data with enough precision can be obtained; compared with the prior art, the method of the invention has outstanding practical characteristics and obvious progress.

Owner:NANJING SANAI IPC CO LTD

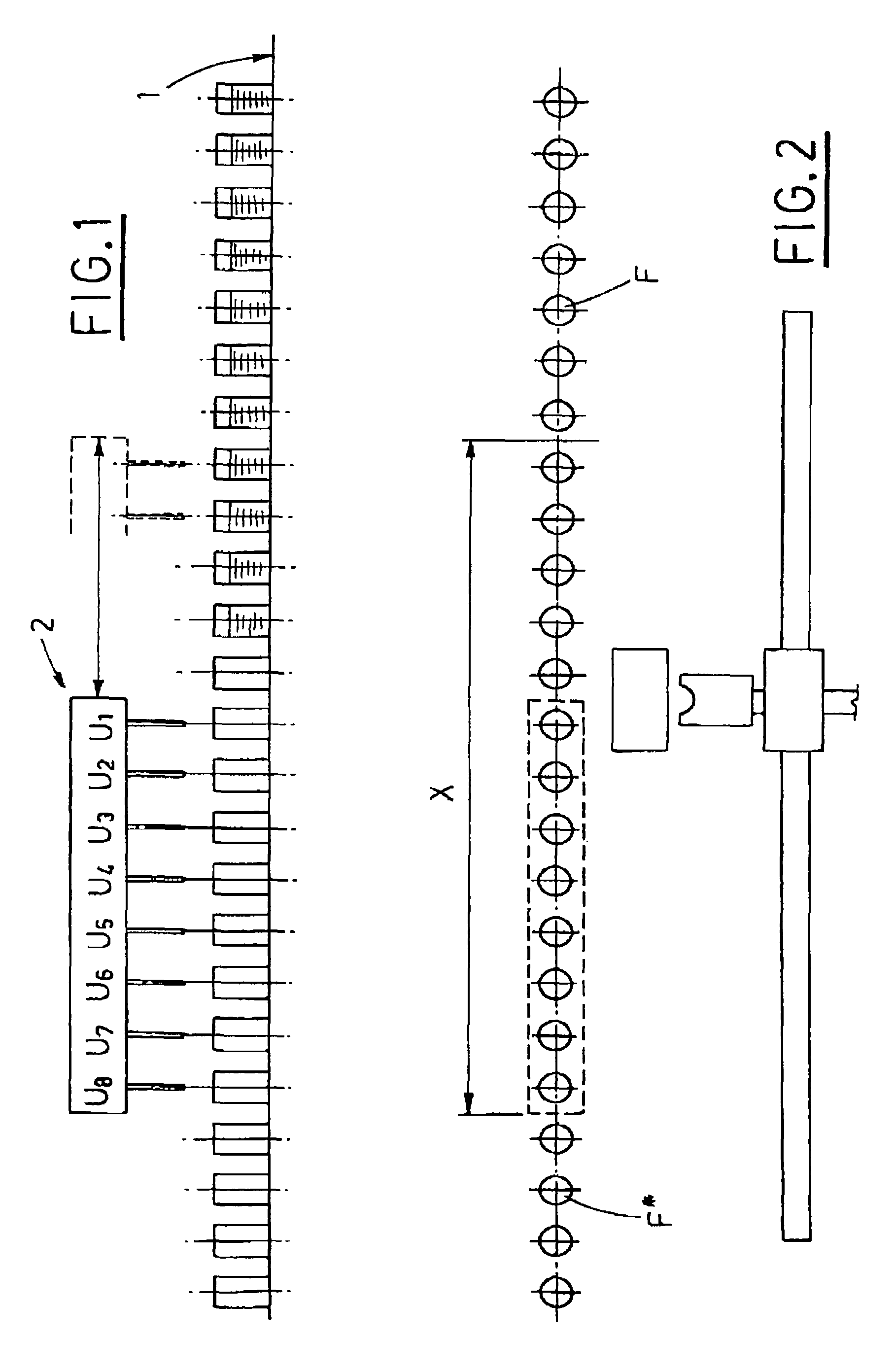

Belt balance weighing subsection decortication method

ActiveCN101281054AImprove accuracyEliminate the error of the line density meanWeighing apparatus for continuous material flowWeighing auxillary devicesDecortication procedureLinear density

The invention relates to a weighting and section cutting method for belt weigher, belonging to weighting and measuring technical field. The method comprises disposing a first sensing marker on preset position of convey belt of the belt weigher, disposing a monitoring device and a impulse speed measuring sensor on frame of the belt weigher, recording intervals between two times when the first sensing marker to be detected and total impulse amount emitted by the impulse speed measuring sensor during the time interval; uniformly dividing the whole convey belt in average sections according to preset amount, and dividing the total impulse amount into numbered impulse groups corresponding to the sections; respectively recording tare weight and gross weight of each section ; sequentially subtracting section gross weight of each numbered impulse group with corresponding tare weight, accumulating net weight of material to be conveyed in each section of convey belt in order to obtain total weight of the material to be conveyed. The method can eliminate difference between fixed threshold and linear density average of each convey belt section, and avoid phenomenon of ''none material weighting'' or ''material not weighting'', effectively enhance the weighting accuracy.

Owner:NANJING SANAI IPC CO LTD

Low density rocket motor insulation

A composition of elastomeric insulation is provided. This composition is suitable to be used as a non-asbestos insulation in a solid rocket motor. In this embodiment, an EPDM rubber, a polyaramide fiber, a liquid EPDM rubber and an aluminum hydroxide are used to substitute the hazardous asbestos in traditional insulation materials to prevent environmental contamination. With careful formulation control, density of the composition based on this embodiment can be tailored to lower than 1.0 gm / cm3. Thus enable the insulation to be especially applicable in the areas of lower ablation rate in a solid rocket motor to reduce tare weight of the rocket motor. Moreover, since no chlorinated organic fire retardant compound is used therein, the additional advantage of low smoke density and low smoke toxicity is exhibited.

Owner:NAT CHUNG SHAN INST SCI & TECH

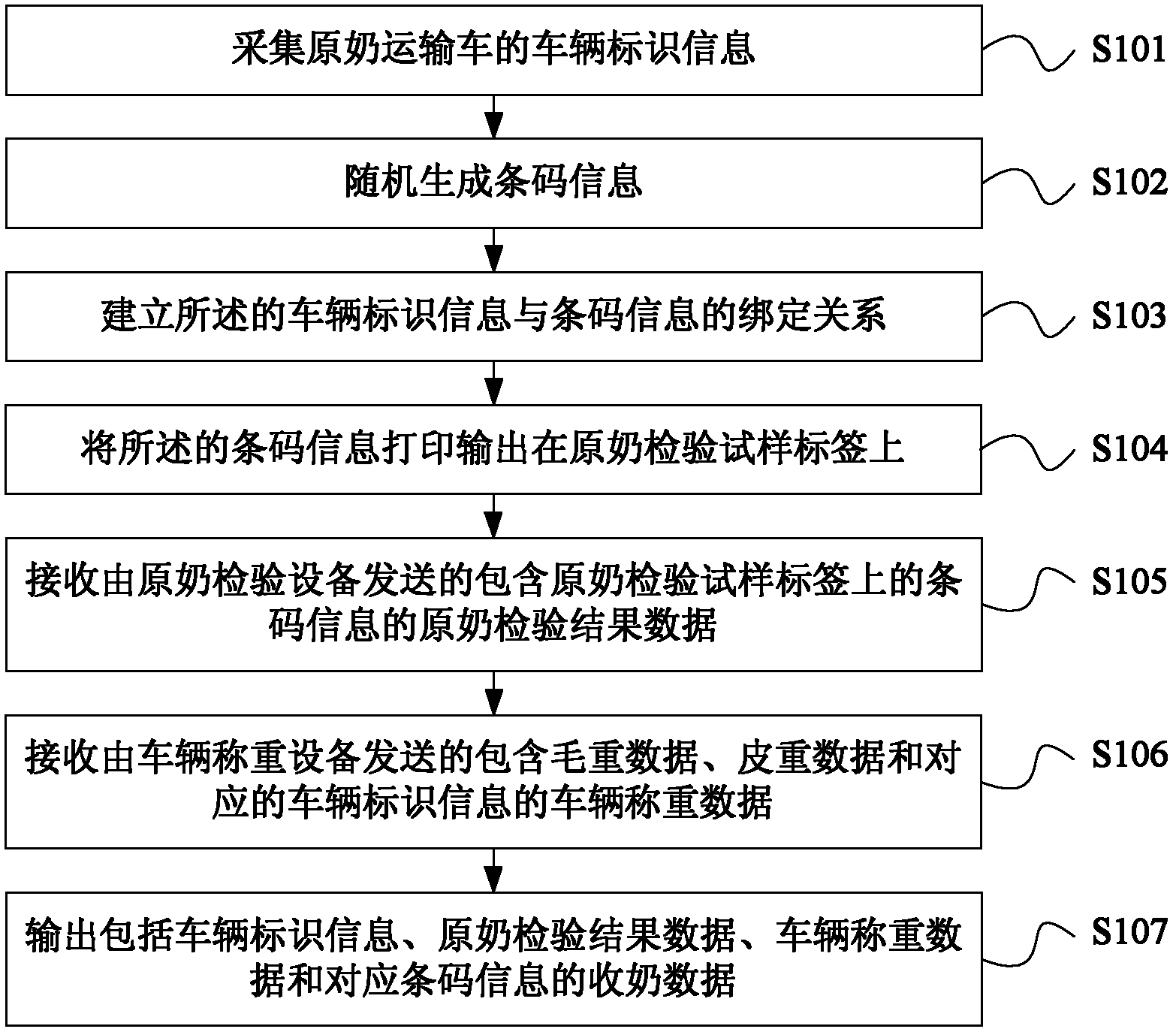

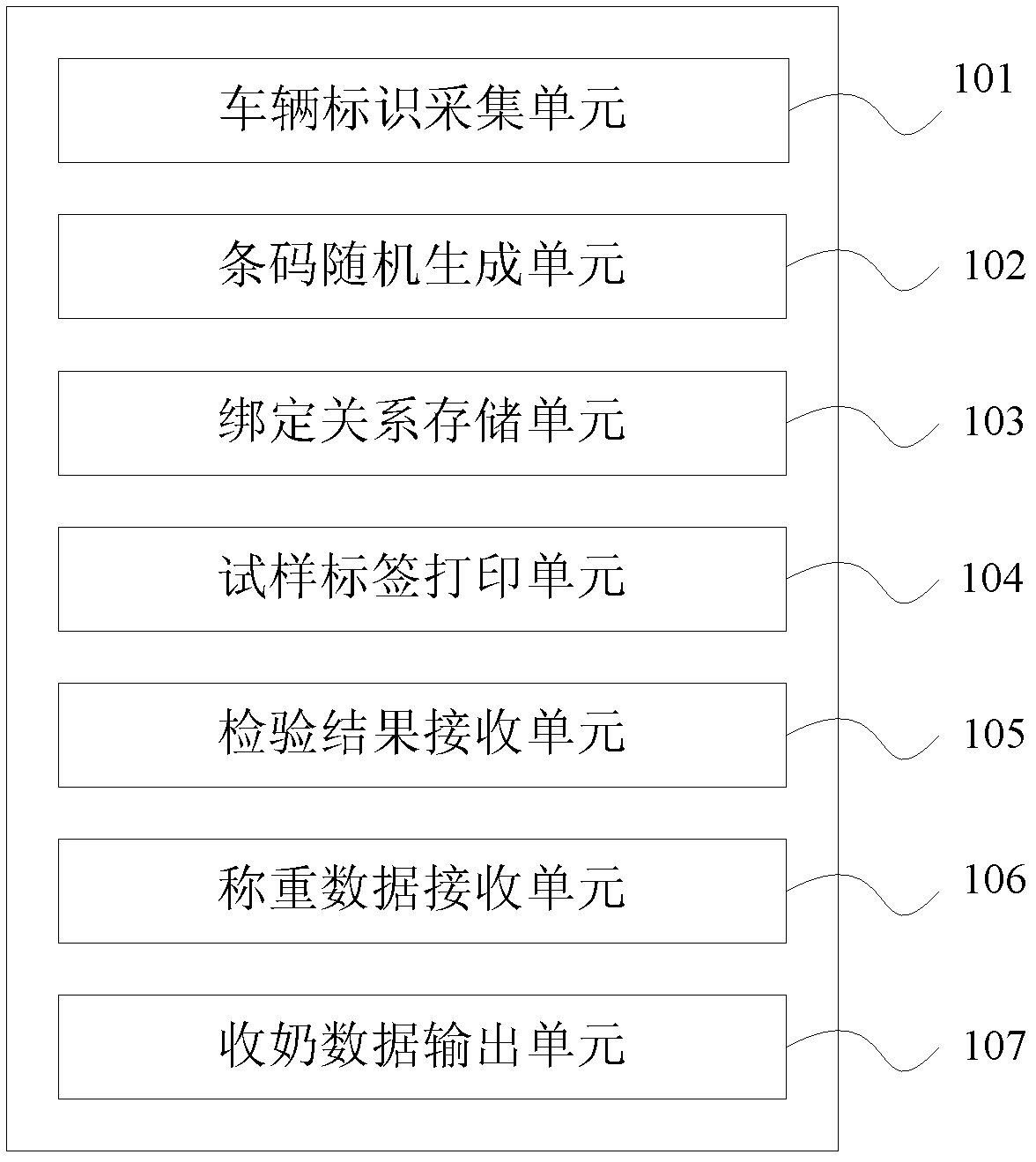

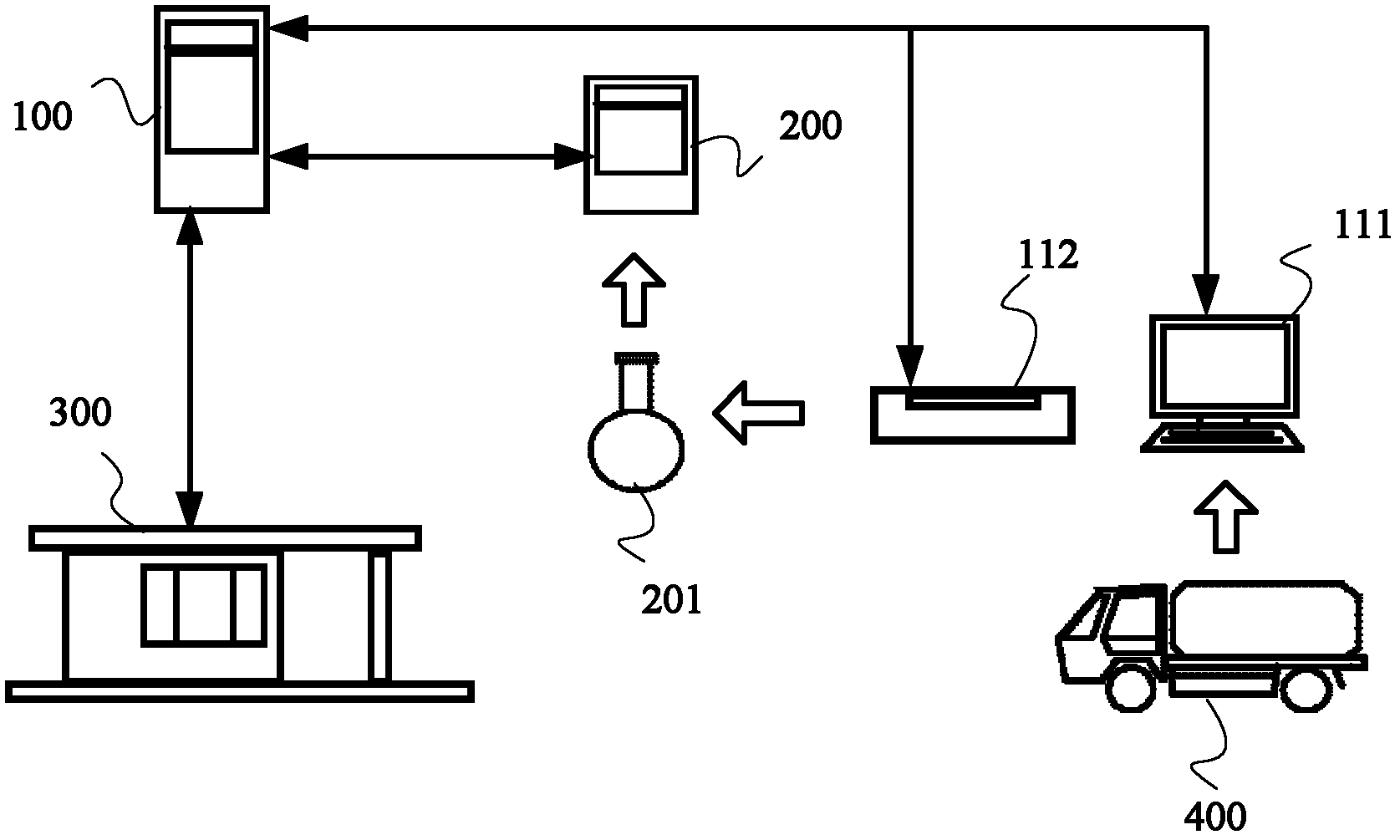

Method, server and system for processing milk collection data

ActiveCN102426633AAchieve sharingImprove calculation accuracyTransmissionSpecial data processing applicationsPurchasingSample Label

The invention provides a method, a server and a system for processing milk collection data. The method comprises the following steps of: acquiring the vehicle identification information of a raw milk transport vehicle; randomly generating bar code information; establishing a binding relationship between the vehicle identification information and the bar code information; printing and outputting the bar code information on a raw milk check sample label; receiving raw milk check result data which comprises the bar code information on the raw milk check sample label and is sent by raw milk check equipment; receiving vehicle weighting data which comprises gross weight data, tare weight data and the corresponding vehicle identification information and is sent by vehicle weighting equipment; and outputting milk collection data which comprises the vehicle identification information, the raw milk check result data, the vehicle weighting data and the corresponding bar code information. By the invention, the problems of acquisition, transmission and processing of weighting data and check data in raw milk purchasing are solved.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

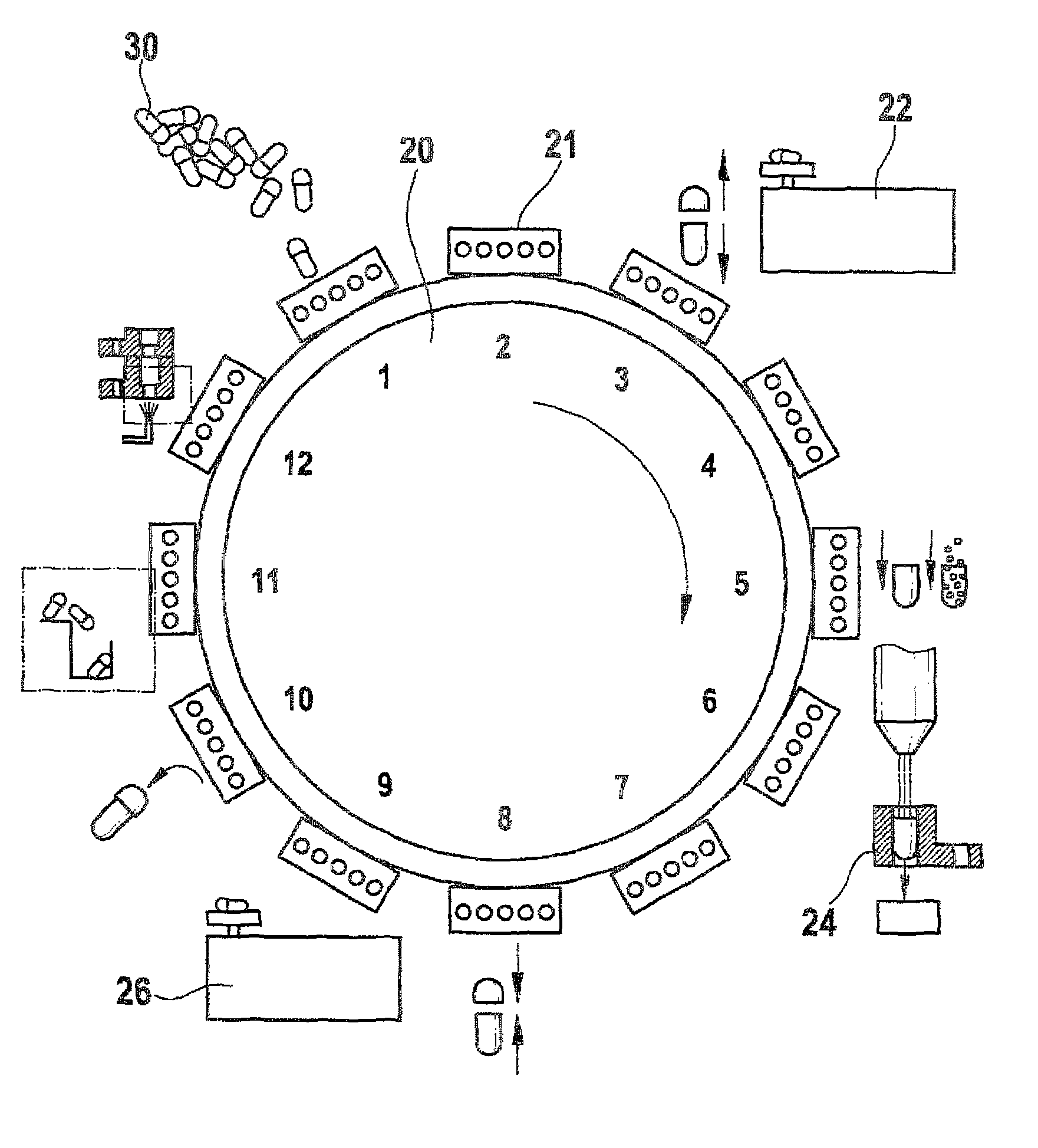

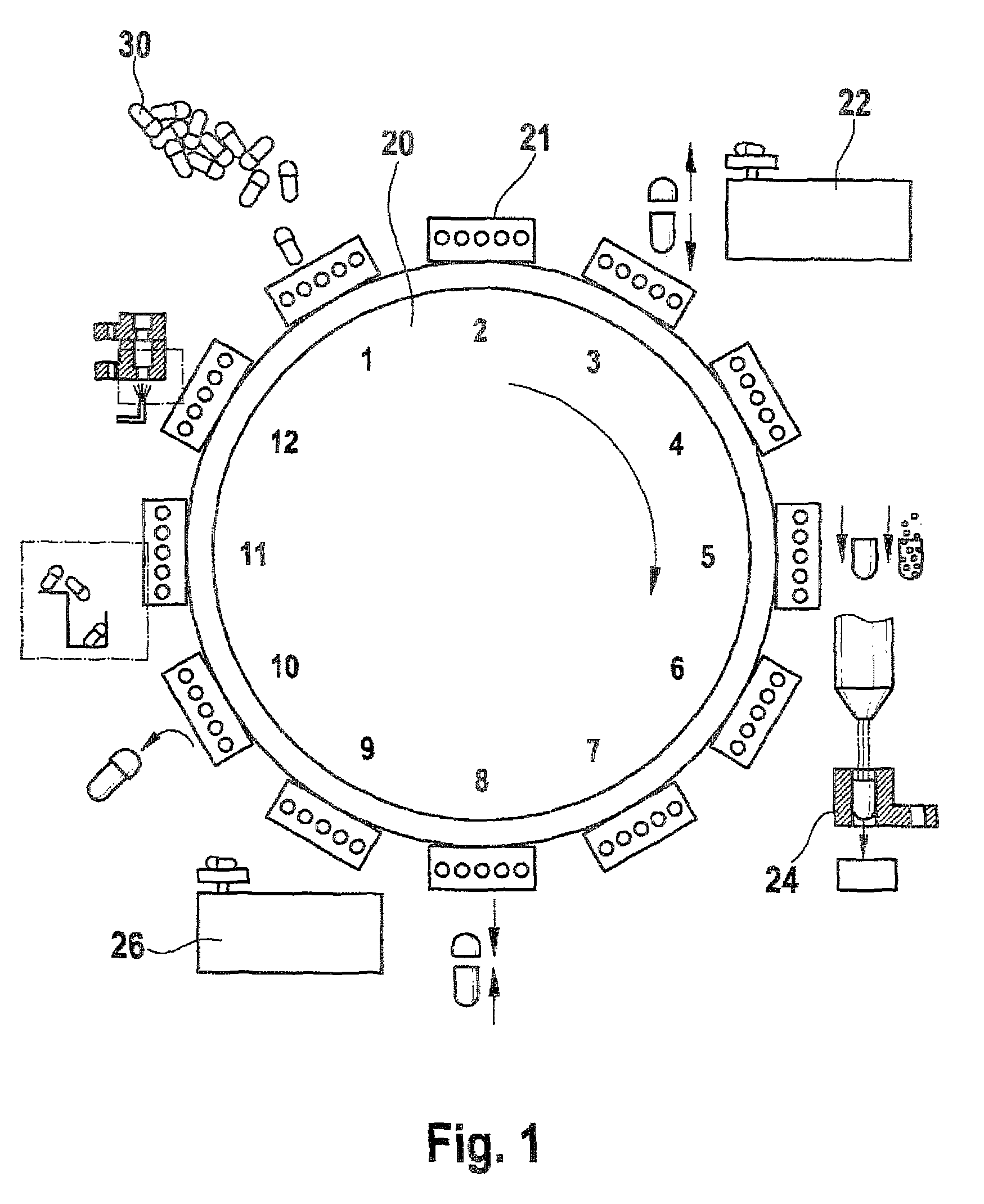

Method for statistic weighing of a product introduced into containers in a filling machine

ActiveUS7503353B2Reduce handlingReduce installationSolid materialMaterial check-weighingEngineeringTest group

According to a method for statistical weighing of a product supplied by a plurality of nozzles into containers, an empty container, belonging to a withdrawing group, is withdrawn to define an empty seat in the withdrawing group. The withdrawn empty container is weighed by a scale, to determine a tare weight, and then introduced in an empty seat made in a test group of containers, is a position designed to match with a selected nozzle to be tested. After introducing product into the weighed, empty container, by the selected nozzle, the filled container is withdrawn and weighed by the same scale to determine a gross weight. The exact quantity of product introduced into the filled container is thus determined by difference between the tare and gross weights.

Owner:MARCHESINI GROUP SPA

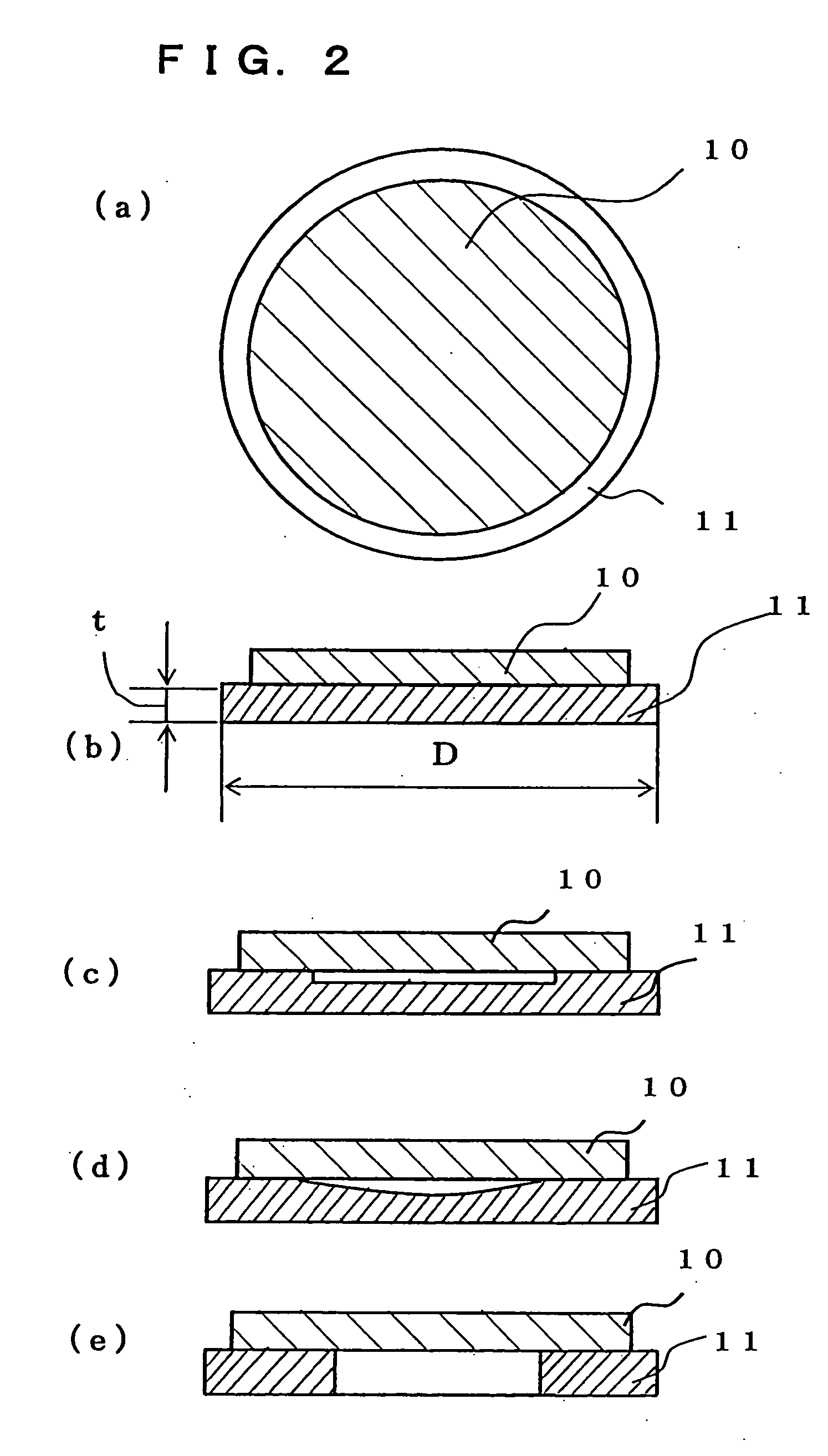

Heat treatment jig for semiconductor wafer

ActiveUS20060078839A1Improve surface flatnessAvoid tensionCharge supportsSemiconductor/solid-state device manufacturingSurface roughnessMillimeter

A heat treatment jig by the invention comprising: the diameter of a disk-type structure being 60% or more of that of loaded semiconductor wafers; the thickness being 1.0 mm or more but 10 mm or less; the surface roughness Ra of 0.1 μm or more but 100 μm or less at a contacting surface with the wafers; and the surface planarity being specifically controlled in the concentric direction as well as in the diametrical direction, otherwise in place of above planarity, comprising a controlled maximum height in such a way that the maximum height is obtained by the flatness measurement at the multiple positions and the difference between said maximum height and the hypothetical-average-height-plane thus set is 50 μm or less, can reduce the slip generation due to the close adhesion of the wafers and the jig. Owing to this, even if the wafers having large tare weight should be heat-treated, the slip generation can be effectively prevented, thus enabling the jig to be widely used as the reliable heat treatment jig for semiconductor substrates.

Owner:SUMCO CORP

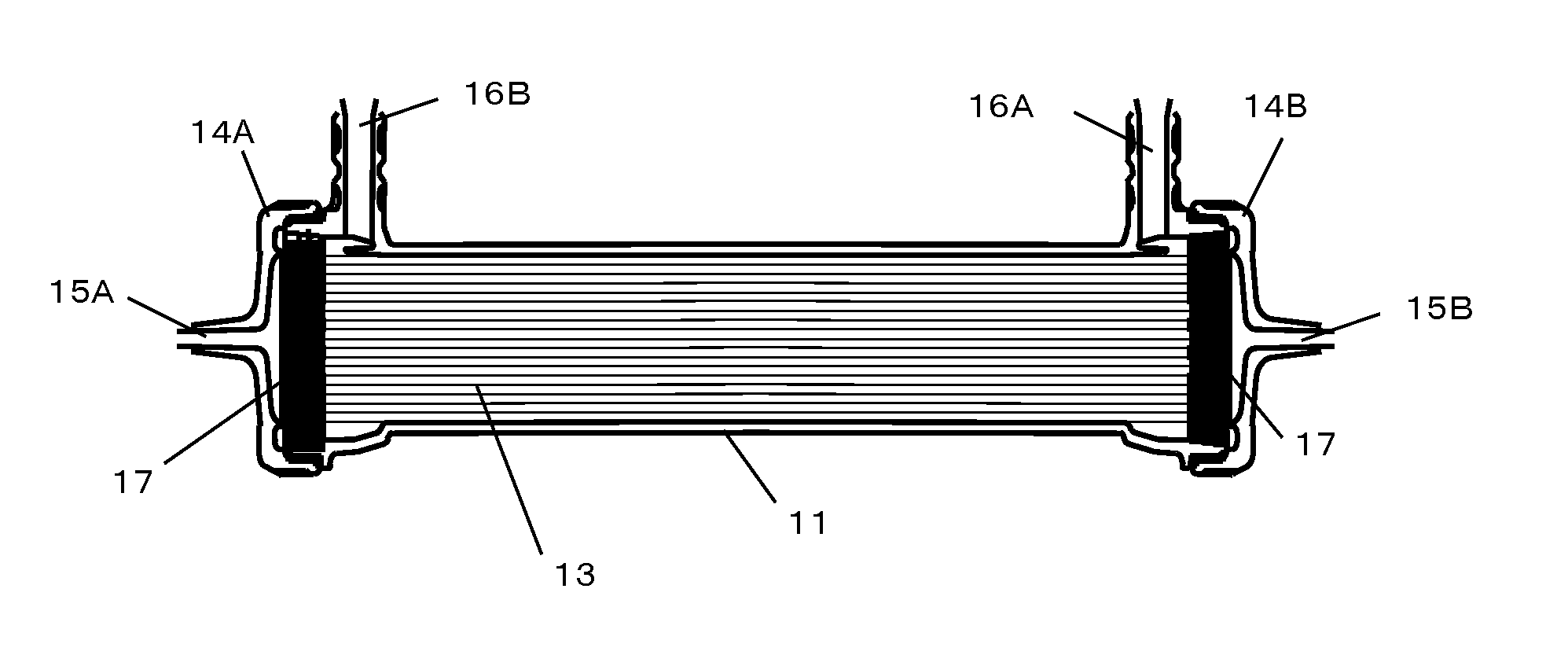

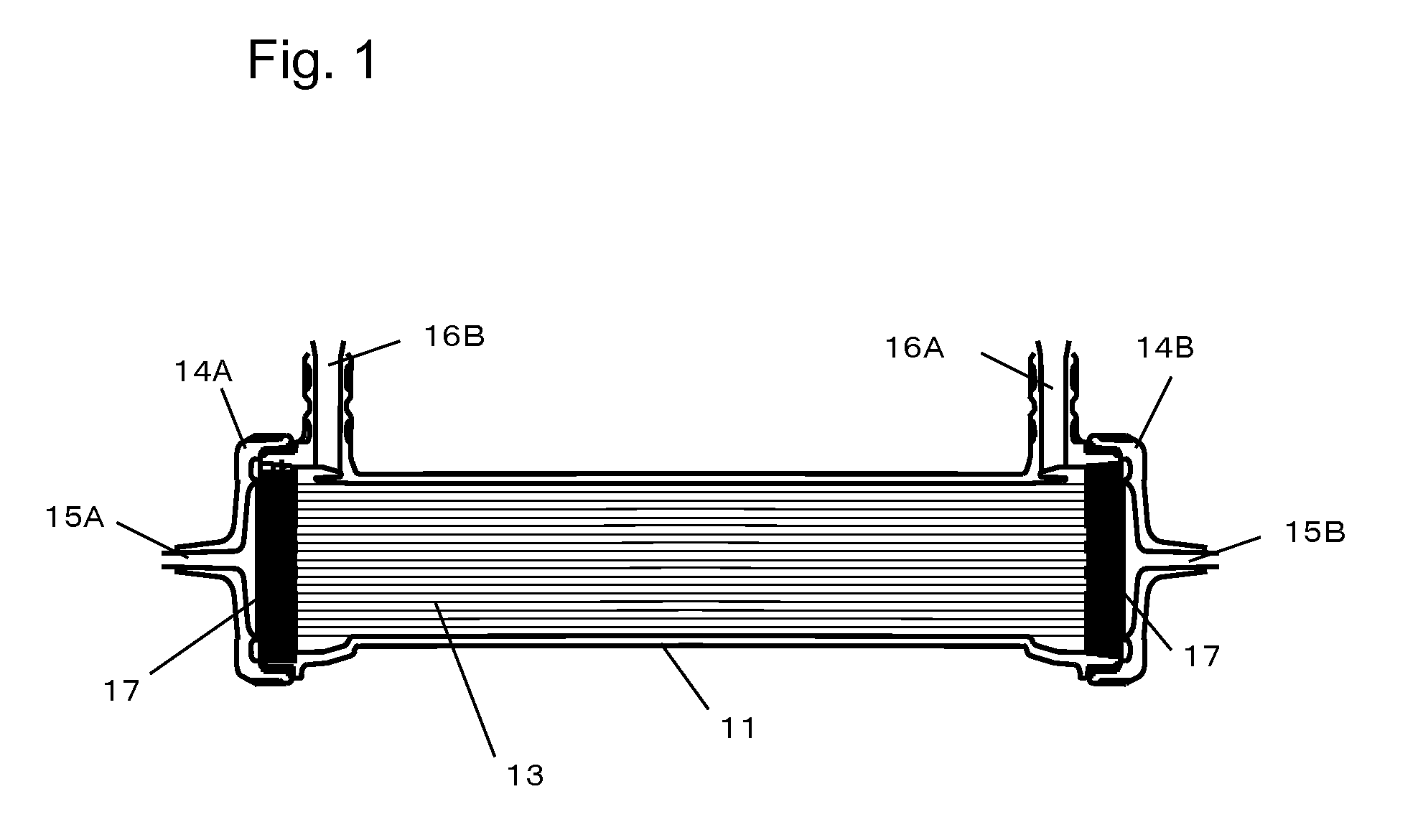

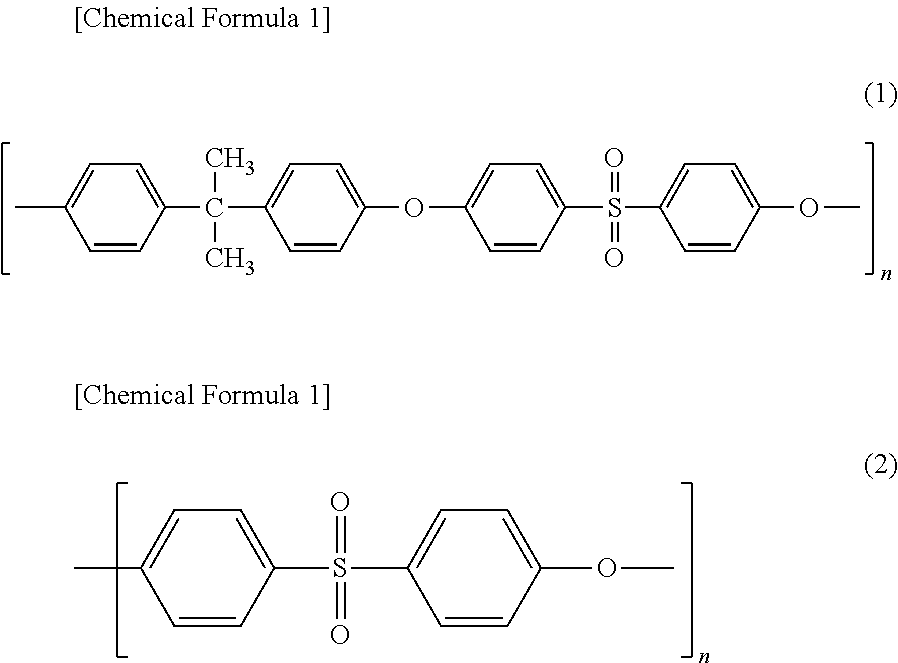

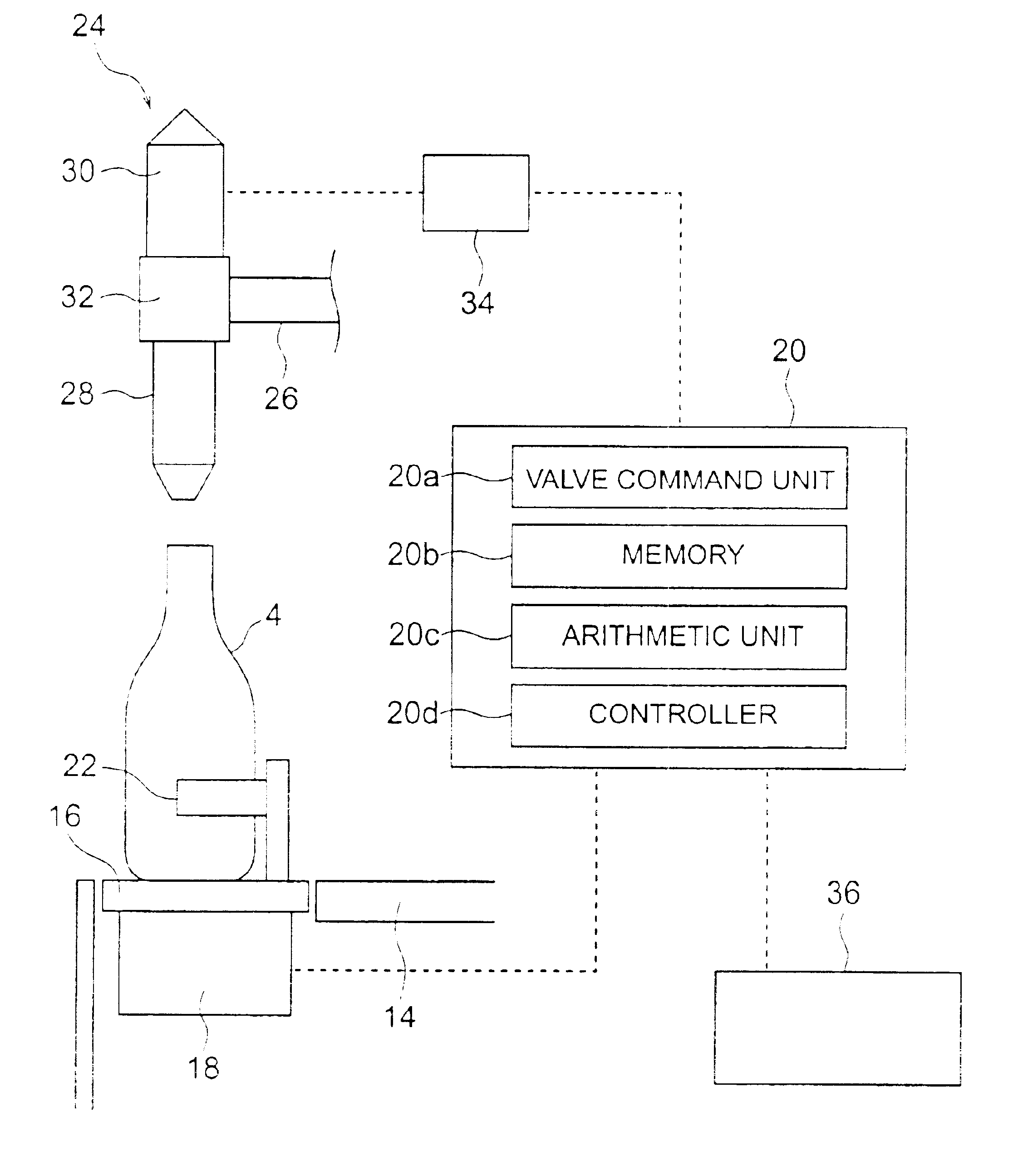

Hollow fiber membrane module, method for producing hollow fiber membrane, and method for producing hollow fiber membrane module

InactiveUS20150343394A1Prevent elutionGood blood compatibilityMembranesSemi-permeable membranesHydrophobic polymerNitrogen

An object of the present invention is to provide a dry-type hollow fiber membrane module which is excellent in blood compatibility and elutes little eluted substance, and a hollow fiber membrane built in the module, and a method for producing a hollow fiber membrane module. Disclosed is a hollow fiber membrane module including a built-in hollow fiber membrane including a hydrophobic polymer and a hydrophilic group-containing polymer, the hollow fiber membrane module satisfying the following items: (a) the water content of the hollow fiber membrane is 10% by weight or less relative to the tare weight of the hollow fiber membrane, (b) the hydrophobic polymer contains no nitrogen, the hydrophilic group-containing polymer contains nitrogen, and the nitrogen content of the hollow fiber membrane is 0.05% by weight or more and 0.4% byweight or less, (c) the content of the hydrophilic group-containing polymer in the inner surface of the membrane is 20% by weight or more and 45% by weight or less, and (d) the consumption amount of an aqueous potassium permanganate solution (2.0×10−3 mol / L) used for titrating an eluted substance in 10 mL of a last part of a priming liquid is 0.2 mL or less per 1 m2 of a membrane area.

Owner:TORAY IND INC

Rotary weight filler

Owner:SHIBUYA IND CO LTD

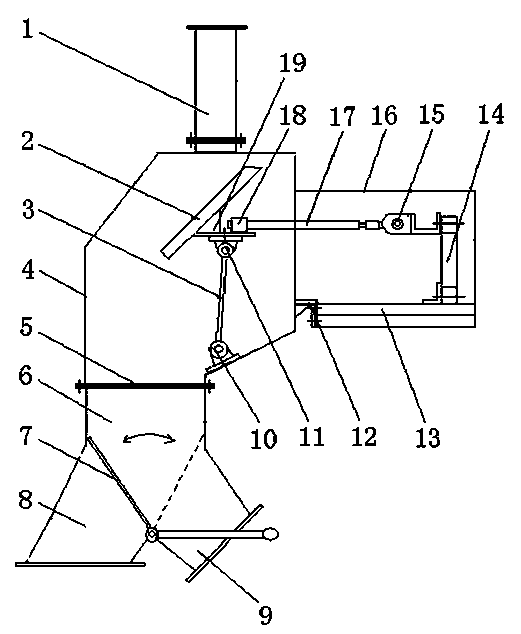

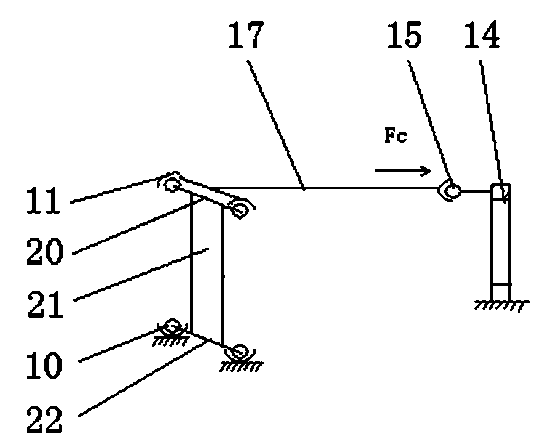

High-precision impulse plate flow meter

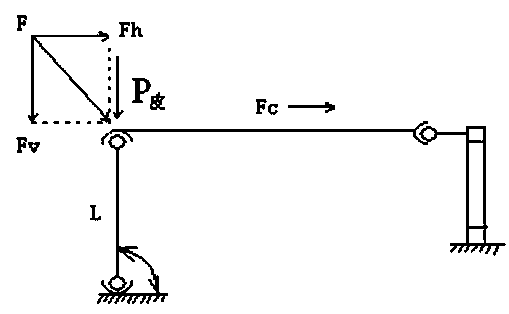

ActiveCN103954323AEasy to processEasy to install and maintainVolume/mass flow by dynamic fluid flow effectHorizontal forceEngineering

The invention provides a high-precision impulse plate flow meter which comprises a blanking box with an upper feeding diversion trench, a lower discharge port and an inner oblique impulse plate, as well as a force transducer, and is characterized in that the oblique impulse plate is supported in the blanking box by a parallel hinge mechanism at the lower part of the oblique impulse plate and is connected with the force transducer outside the blanking box through a horizontal force transmission pushing rod at the side part of the oblique impulse plate in a matching way at the same time. Through the high-precision impulse plate flow meter, only horizontal component force which is generated in the horizontal direction and is in direct proportion to the flow rate is accurately transmitted to the force transducer so as to obtain an interference-free clear original flow rate signal; component force, eccentric impact torque and other interference forces in the vertical direction are transmitted by the parallel hinge mechanism to the bottom of the blanking box so as to be naturally balanced; the problem of zero drift caused due to tare weight change generated by damp sticky materials and the like is solved; and the high-precision impulse plate flow meter can stably work for a long time, and the actual measurement precision is within 1 percent.

Owner:陈立明

Continuous baby weighing method of baby incubator

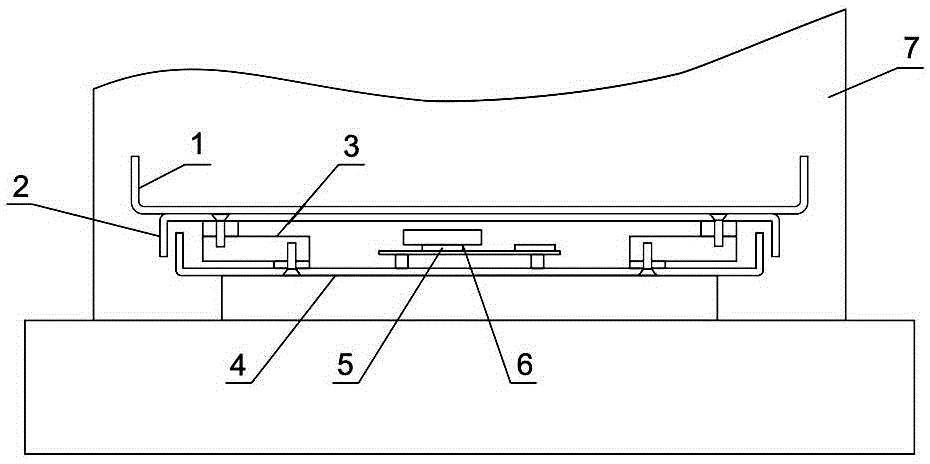

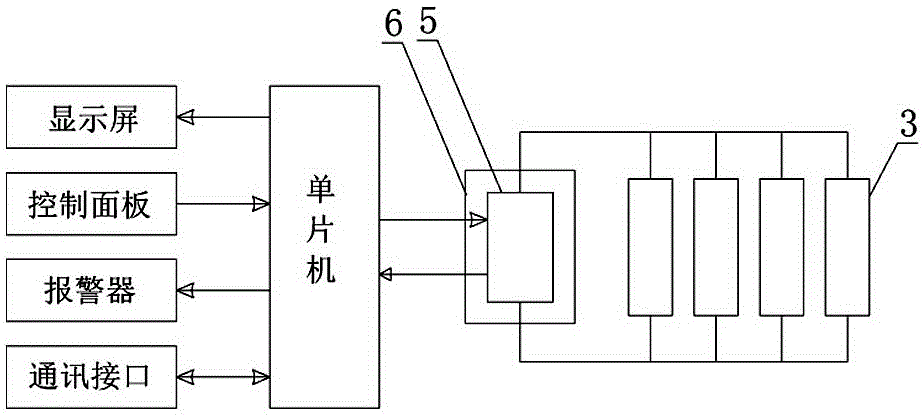

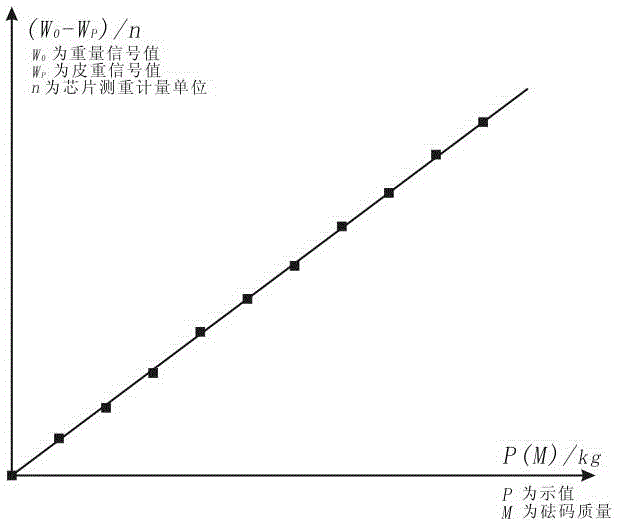

ActiveCN106595819AGood value for moneySolve the problem of inconsistent temperature changesWeighing apparatus with automatic feed/dischargeMicrocontrollerMicrocomputer

The invention discloses a continuous baby weighing method of a baby incubator. The method comprises the following steps: firstly, constructing a baby scale; secondly, adjusting the baby scale: 1: a, measuring tare weight Wp; b, measuring gross weight Wo; c, calculating a value of weight sampling net weight W at the temperature To; d, calculating a standard weight coefficient Kw; e, sampling the temperature To during calibration; and f, storing data; and 2, determining a temperature compensation coefficient; thirdly, running the baby scale; and fourthly, holding a baby to automatically remove the tare weight. The advantages of the method are mainly as follows: the baby scale adopts a common weighing chip and a common weighing sensor, and a temperature compensation mode through a program written by a single-chip microcomputer enables continuous weighing to be realized and is high in cost performance; and the adoption of a hear dissipation fin arranged on the weighing chip solves a problem that temperature changes are inconsistent when the weighing chip and the weighing sensor stay in a temperature changing environment, and effectively prevents a zero drift problem.

Owner:ZHENGZHOU DISON INSTR & METER

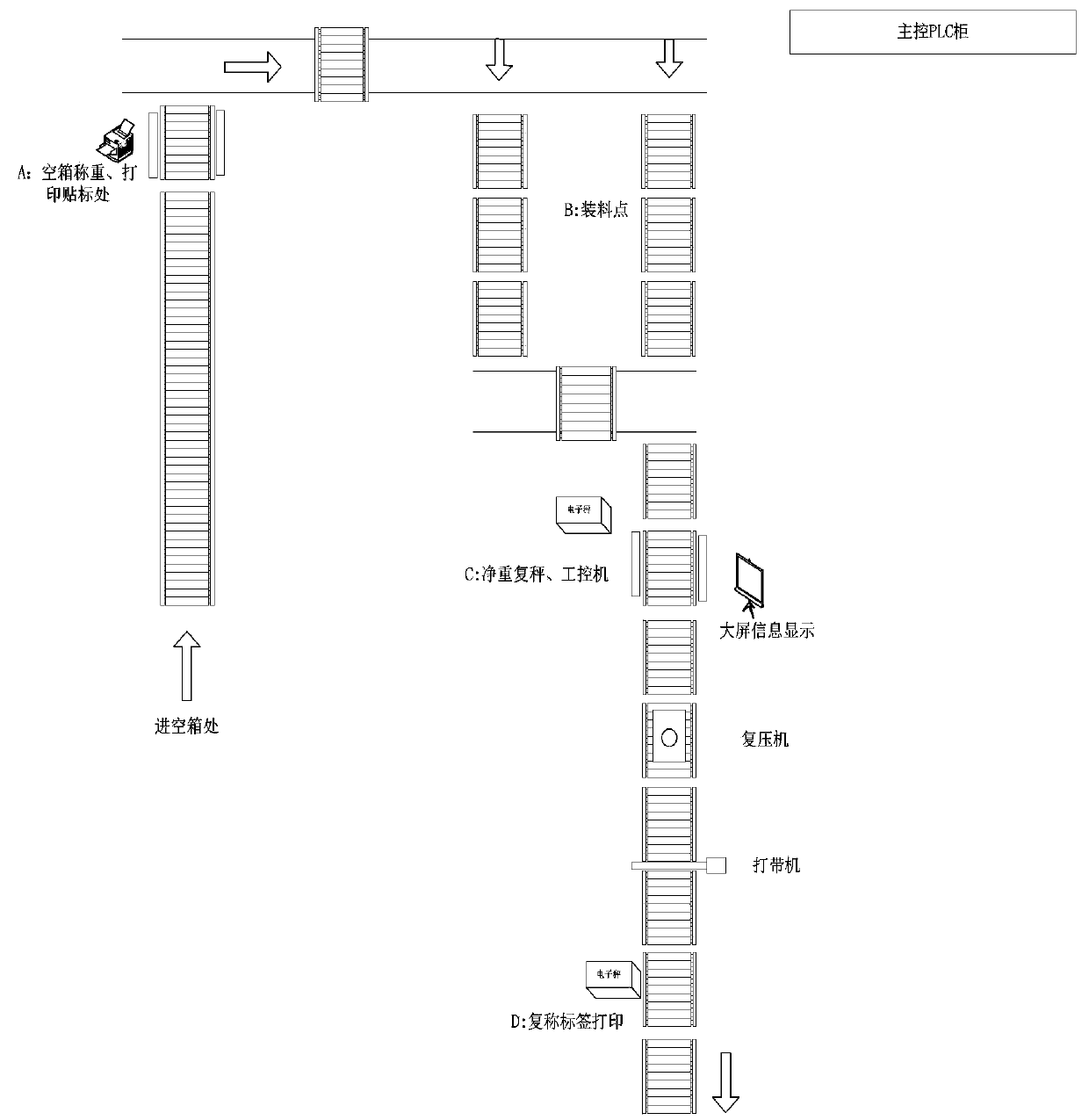

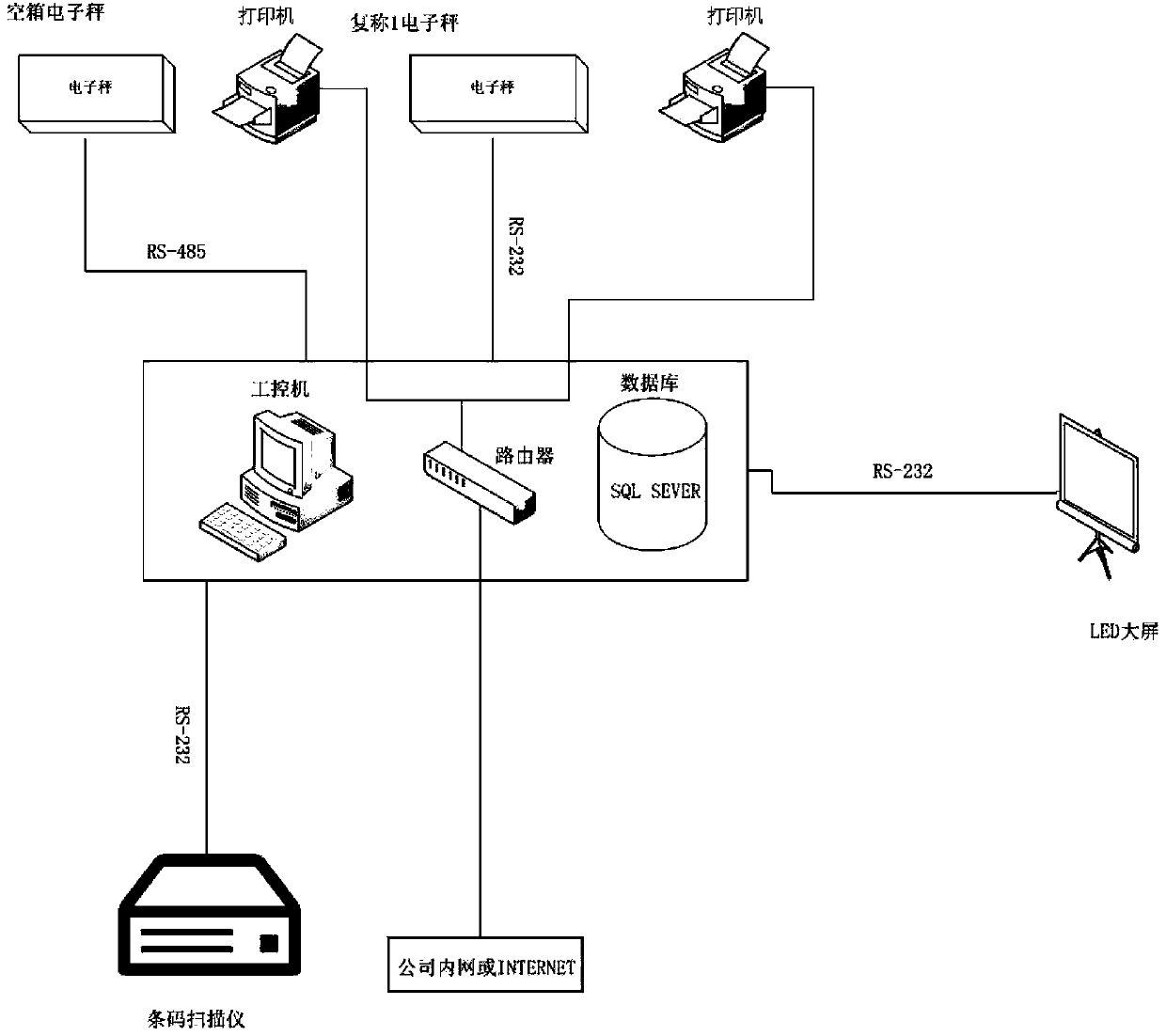

On-line tare weight subtracting method and system for tobacco packaging

InactiveCN103395521AAccurately record gross weightEliminate differencesPackaging automatic controlCartonEngineering

Disclosed is an on-line tare weight subtracting method and system for tobacco packaging. The method includes adopting an electronic scale to weigh cartons one by one before empty cartons are fed in for charging, recording weight values on the cartons in a bar code mode, and reading the carton weight values recorded by bar codes and displaying the carton weight values on a large electronic screen during the last process of manually checking the weight values after charging is finished. The method and the system have the advantages that values of gross weight, tare weight and net weight of finished products can be recorded accurately, differences among individuals are eliminated completely, errors between tare weight and net weight due to mistaken using of the cartons are avoided, and doubts of customers are removed completely.

Owner:QILIN REDRYING FACTORY YUNNAN TOBACCO REDRYING +1

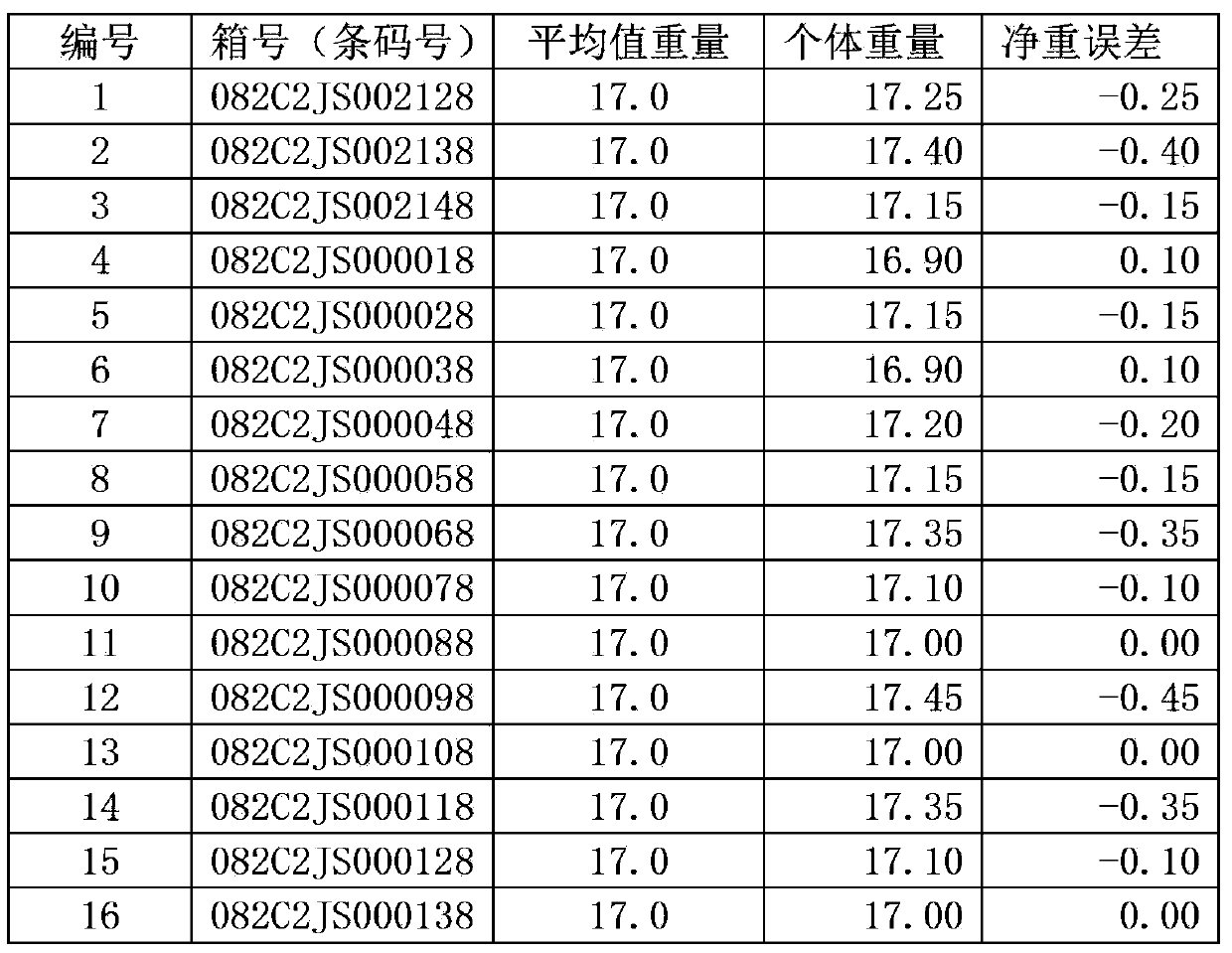

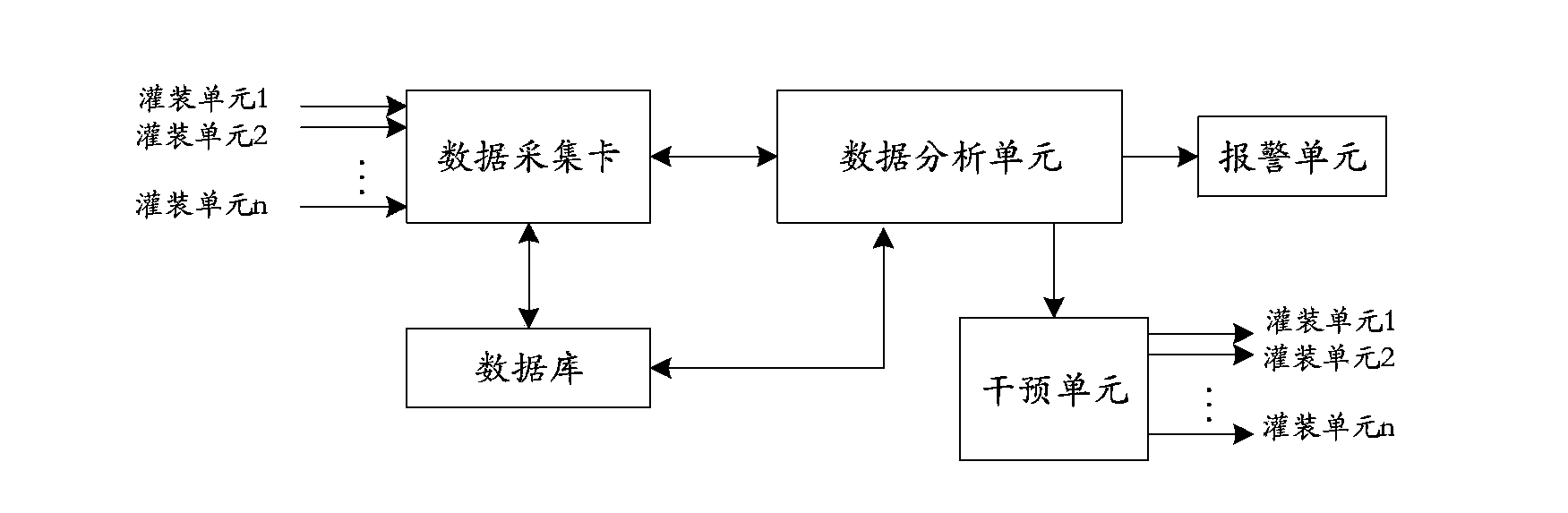

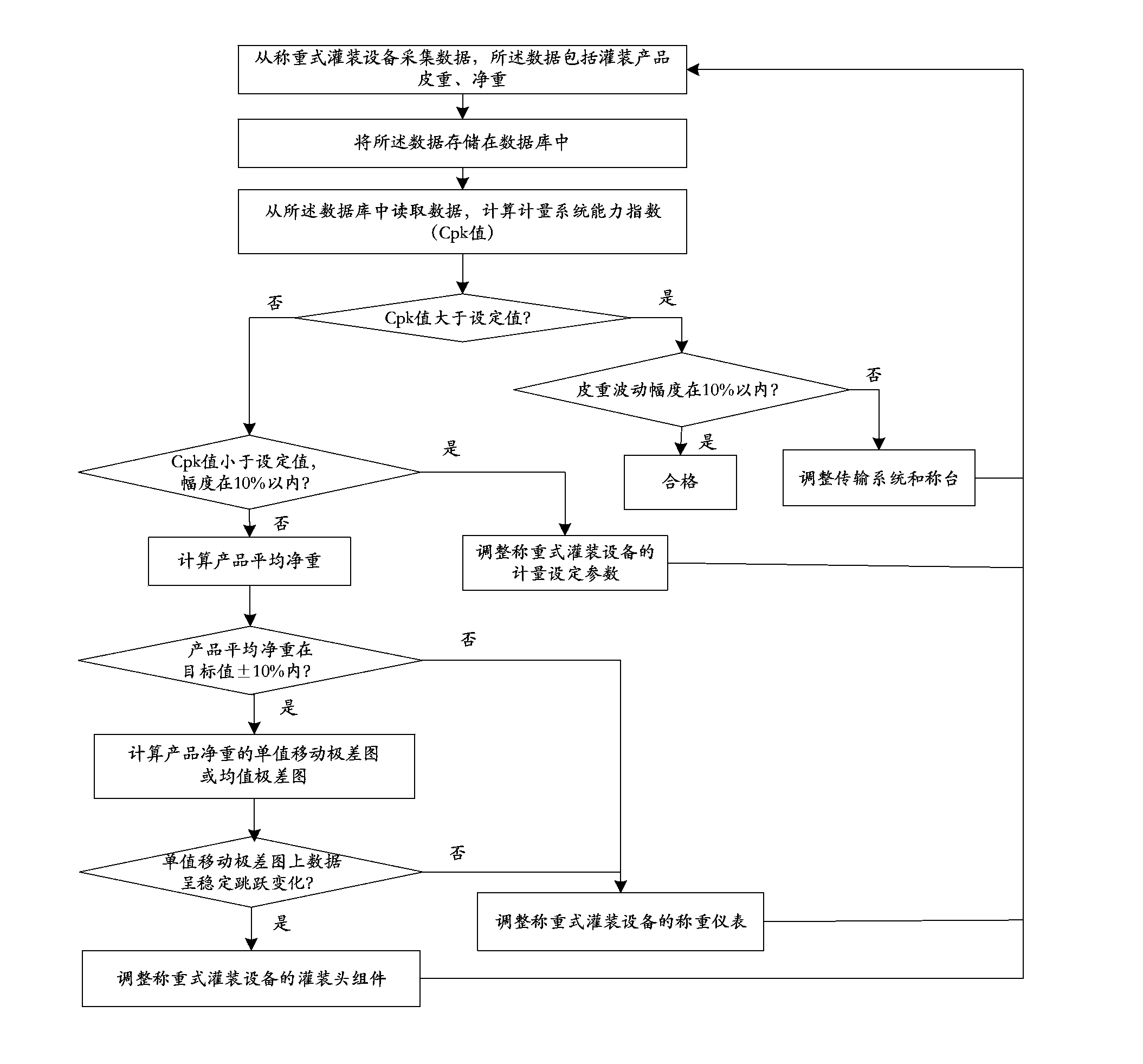

Online SPC analysis system and method for metering process capability of gravimetric filling equipment

InactiveCN103786933AAdd other process auxiliary informationRealize online continuous monitoringPackaging automatic controlIntervention measuresAnalysis data

The invention provides an online SPC (Statistical Process Control) analysis system for metering process capability of gravimetric filling equipment. The system comprises a data acquisition card for real-time online acquisition of data, including the tare weight of products and the net weight of the products, of the gravimetric filling equipment, a database for storing the data, and a data analysis unit for reading the data to be analyzed from the database and analyzing the tare weight of products, the net weight of the products, the average tare weight of the products, the average net weight of the products or the capability index of a metering system. The online SPC analysis system for the metering process capability of the gravimetric filling equipment is capable of outputting the results of analysis in real time so that the operating personnel can take intervention measures according to the results, and therefore, stable control of the production process and reduction of risks in the metering process are realized. The invention also provides an online SPC (Statistical Process Control) analysis method for the metering process capability of the gravimetric filling equipment.

Owner:CHINA PETROLEUM & CHEM CORP

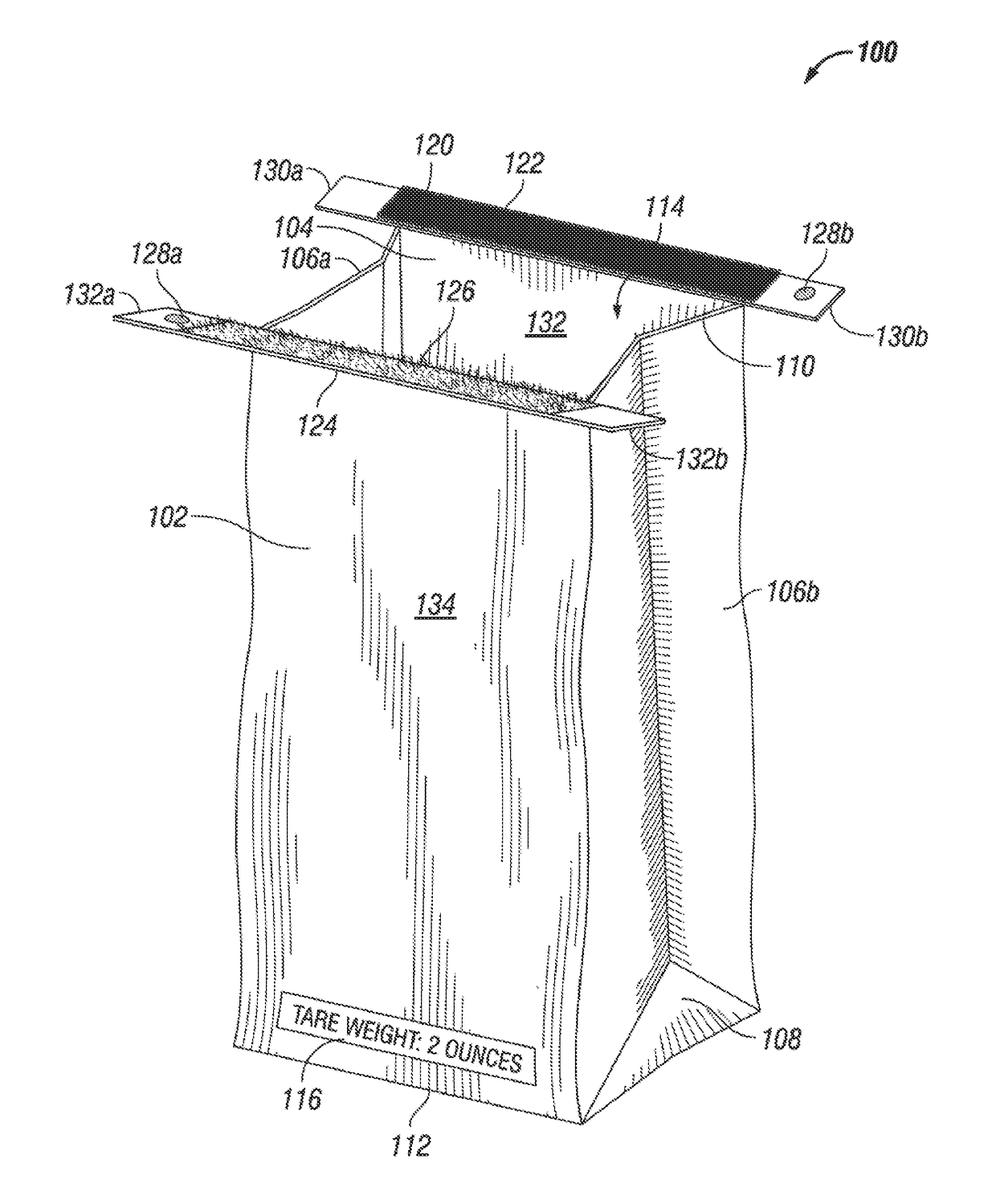

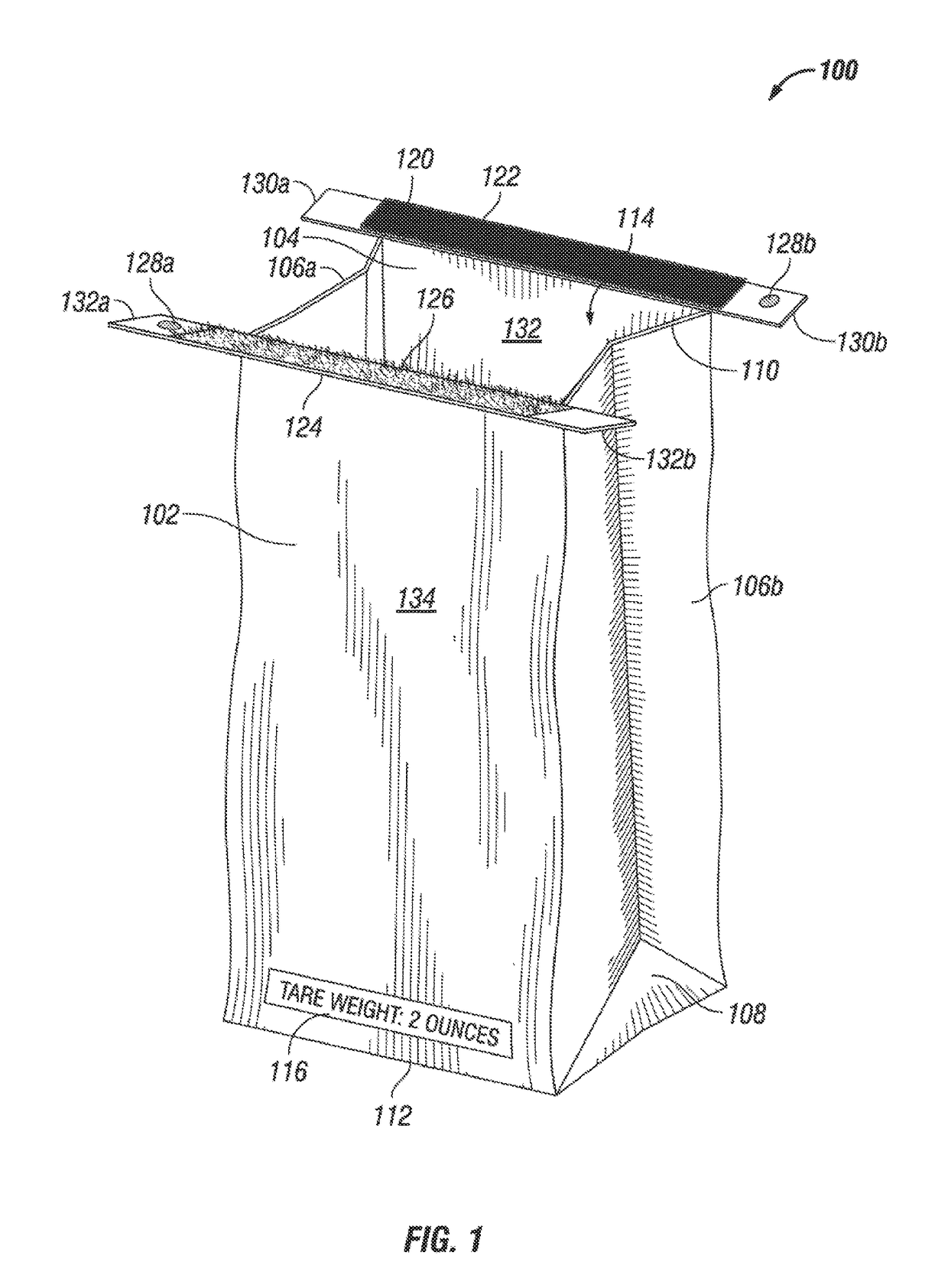

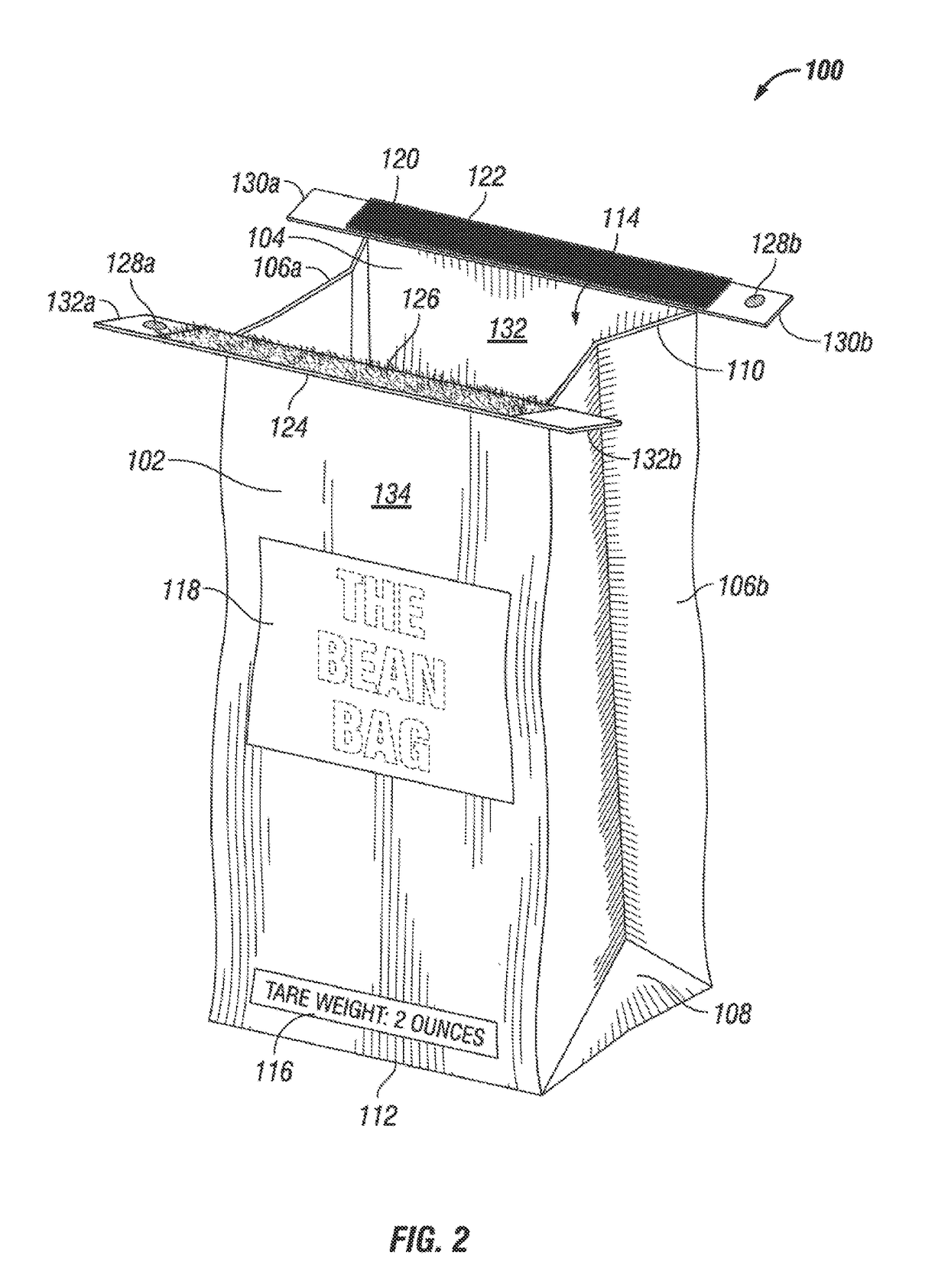

Reusable labeled coffee bean bag and method of operation

A reusable labeled coffee bean bag and method of operation provides a bag that can be reused to fill with coffee beans from a typical in-store coffee grinder. This reduces paper waste and creates sustainability. The bag comprises: a front panel, a rear panel, two gusseted side panels, and a bottom panel. The panels are defined by an interior surface having a polymer-containing coating to inhibit oxidation and degradation of coffee. The panels also comprise an exterior surface having an integrated tare weight label to enable accurate weighing and pricing. At least one identification label detachably attaches to the panels or a grommet to display information pertinent to the beans. A pair of fastenable closure strips having hooks and loops are releasably fastenable to seal transversely across the entire width of the bag to maintain freshness and prevent spilling beans. A grommet on the fastening strip enables attachable labeling.

Owner:BODINGTON TIA

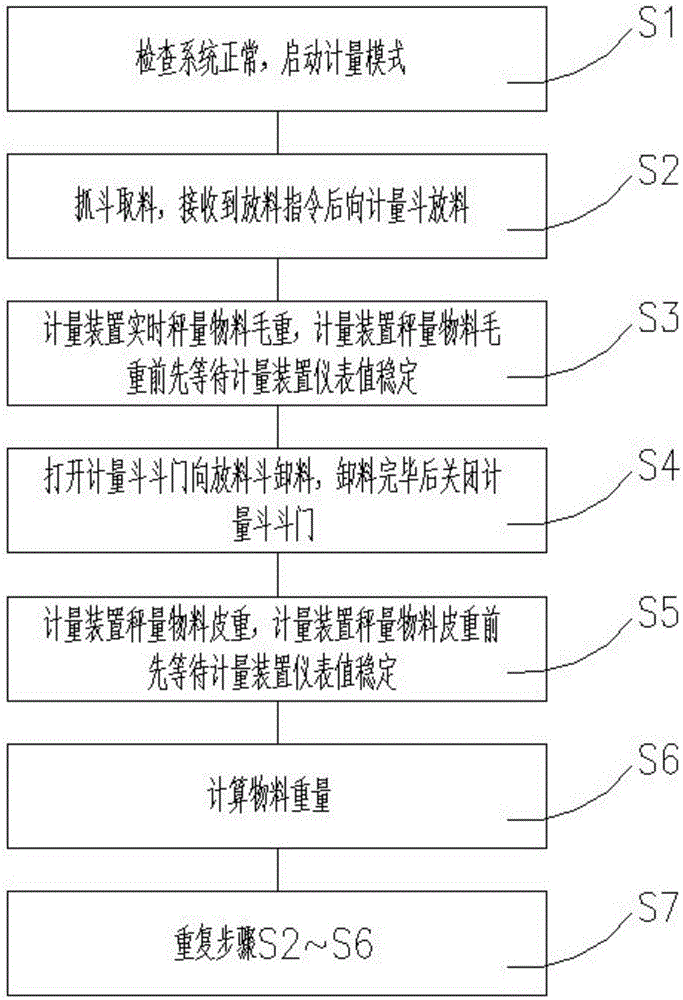

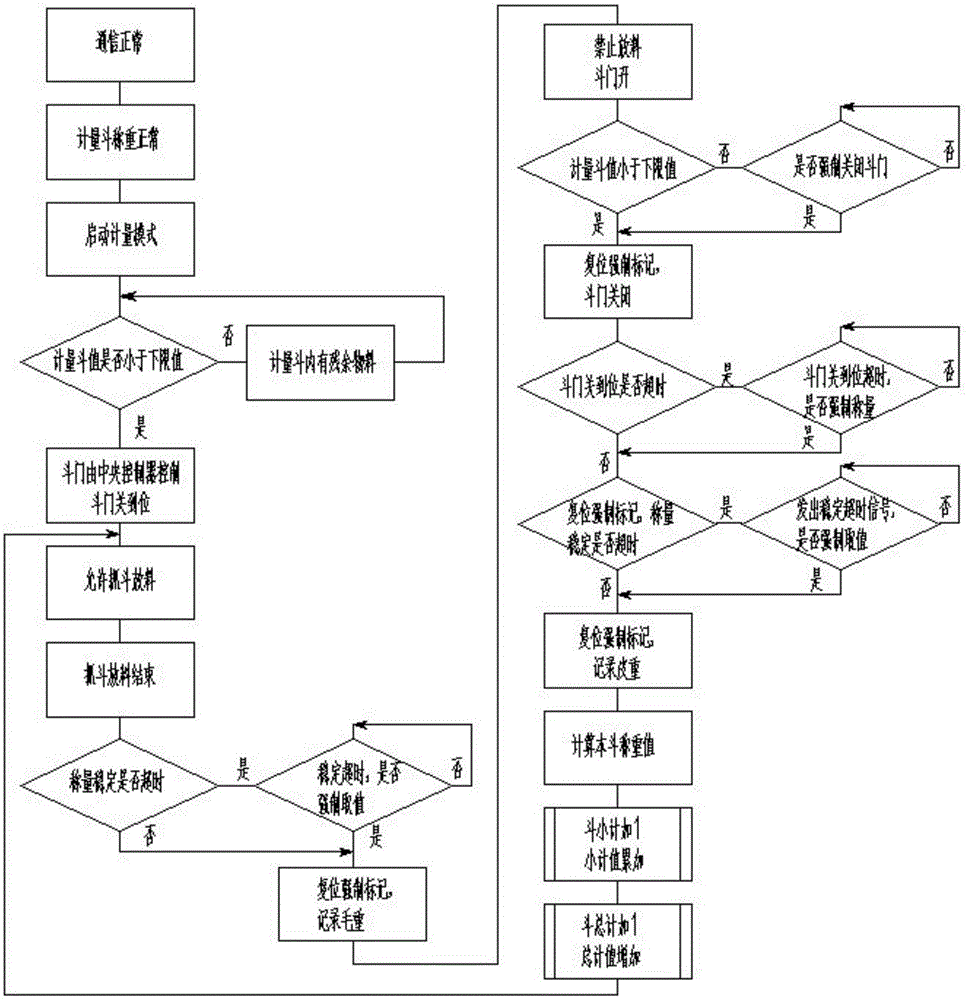

Ship unloader metering mode control method

ActiveCN105021263AEasy to manageGuaranteed accuracySpecial purpose weighing apparatusDischarge efficiencyMode control

The invention relates to a ship unloader metering mode control method. The method comprises the following steps: S1) detecting whether a system is normal and starting a metering mode; S2) carrying out grab hopper material taking, and after receiving a material discharging instruction, discharging material to a measuring hopper; S3) weighing rough weight of the material in real time through a metering device, wherein the metering device carries out material rough weight weighing after the instrument value of the metering device is stable; S4) opening a gate of the measuring hopper and discharging the material to a discharge hopper, and after discharging is finished, closing the gate of the measuring hopper; S5) weighing tare weight of the material through the metering device, wherein the metering device carries out material tare weight weighing after the instrument value of the metering device is stable; S6) calculating the weight of the material; and S7) repeating the steps S2)-S6). The reasonable and high-efficiency ship unloader metering mode control method guarantees metering precision of a ship unloader and improves discharging efficiency of the ship unloader, and guarantees transaction fairness and enterprise production operation efficiency.

Owner:HANGZHOU HUAXIN MECHANICAL & ELECTRICAL ENGINEERING CO LTD +1

Method For Determining Agricultural Bale Weight

ActiveUS20140090904A1Increased complexityWeighing apparatus testing/calibrationBalingTerrainEngineering

A method is provided for determining the weight of an agricultural bale that compensates for un-level terrain such as hillsides. The method uses an empty baler tare weight and a full baler weight to determine a raw bale weight. The cosine of the slope upon which the baler sits is then calculated based upon the empty baler weight as it sits and the empty baler tare weight. The cosine of the angle of slope and raw bale weight are the used to determine an actual bale weight. Further steps are provided for compensating in the tare weight of the baler for the weight of wrapping material consumed in the formation of each bale.

Owner:DEERE & CO

Method for adjusting a tare weight of an agricultural baler to reflect usage of preservative in treating formed bale

ActiveUS9267836B2Increased complexityWeighing apparatus testing/calibrationBalingTerrainPreservative

A method is provided for determining the weight of an agricultural bale that compensates for un-level terrain such as hillsides. The method uses an empty baler tare weight and a full baler weight to determine a raw bale weight. The cosine of the slope upon which the baler sits is then calculated based upon the empty baler weight as it sits and the empty baler tare weight. The cosine of the angle of slope and raw bale weight are then used to determine an actual bale weight. Further steps are provided for compensating in the tare weight of the baler for the weight of wrapping material and / or preservative consumed in the formation of each bale.

Owner:DEERE & CO

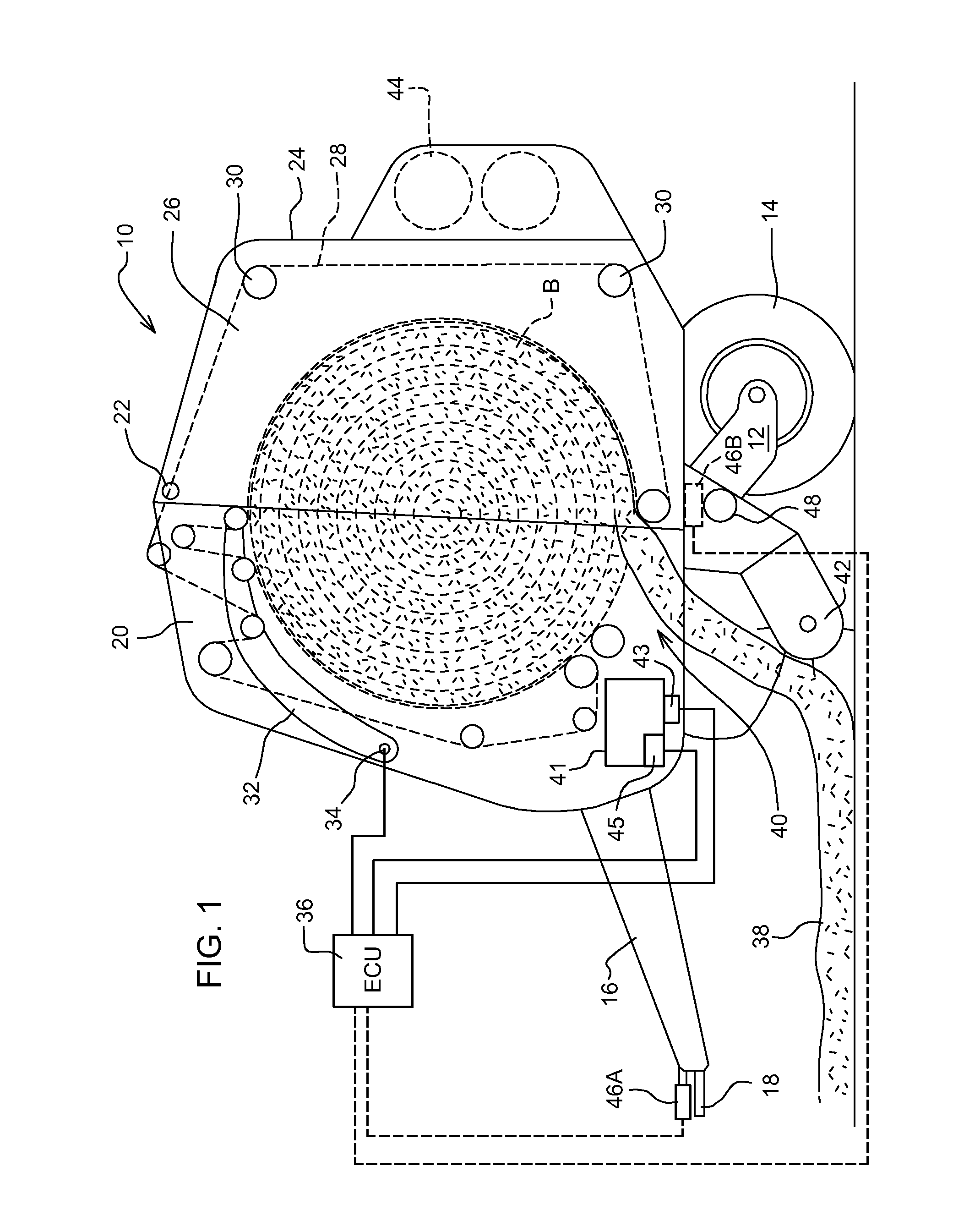

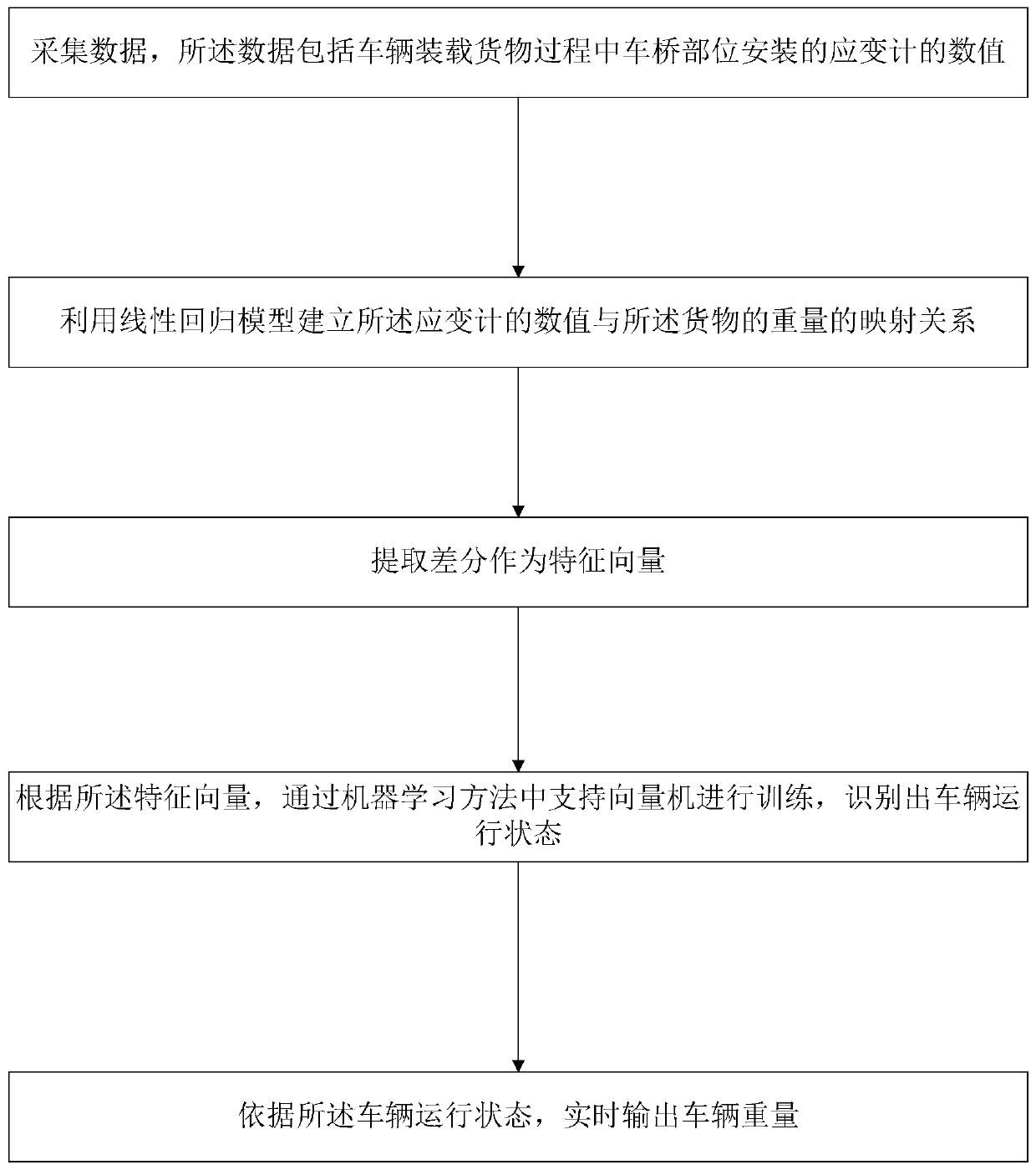

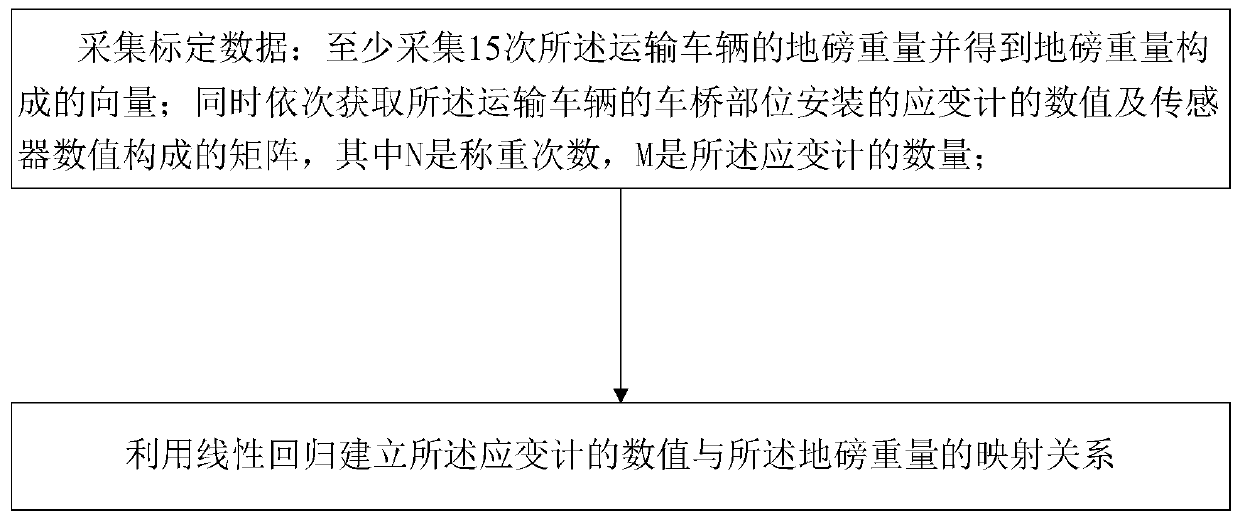

Dynamic vehicle load weighing method and system

ActiveCN111089643AHigh precisionRelieve backlog pressureSpecial purpose weighing apparatusFeature vectorIn vehicle

The invention provides a dynamic vehicle load weighing method and system. The method comprises the steps that S1, data is collected, wherein the data comprises values on a strainmeter installed on anaxle part of a vehicle in the cargo loading process; S2, a linear regression model is utilized to establish a mapping relation between the values on the strainmeter and the weight of cargos; S3, differences are extracted to serve as feature vectors; S4, according to the feature vectors, training is performed through a support vector machine in a machine learning method to recognize the vehicle operating state; and S5, according to the vehicle operating state, vehicle weight is output in real time. Through the dynamic vehicle load weighing method and system, time spent on acquiring net weight by calculating tare weight and gross weight of a truck is saved, and time required for truck weighing is shortened; the precision of cargo capacity is improved, and the pressure of cargo overstock in atransfer center is relieved; the load weight of the vehicle is acquired in real time to trace cargo loss; an early warning is given in time in case of truck overweight; manpower cost is saved, and transport efficiency is improved; and disturbance of oil consumption, cooling liquid and other external factors is avoided.

Owner:深圳市汉德网络科技有限公司 +1

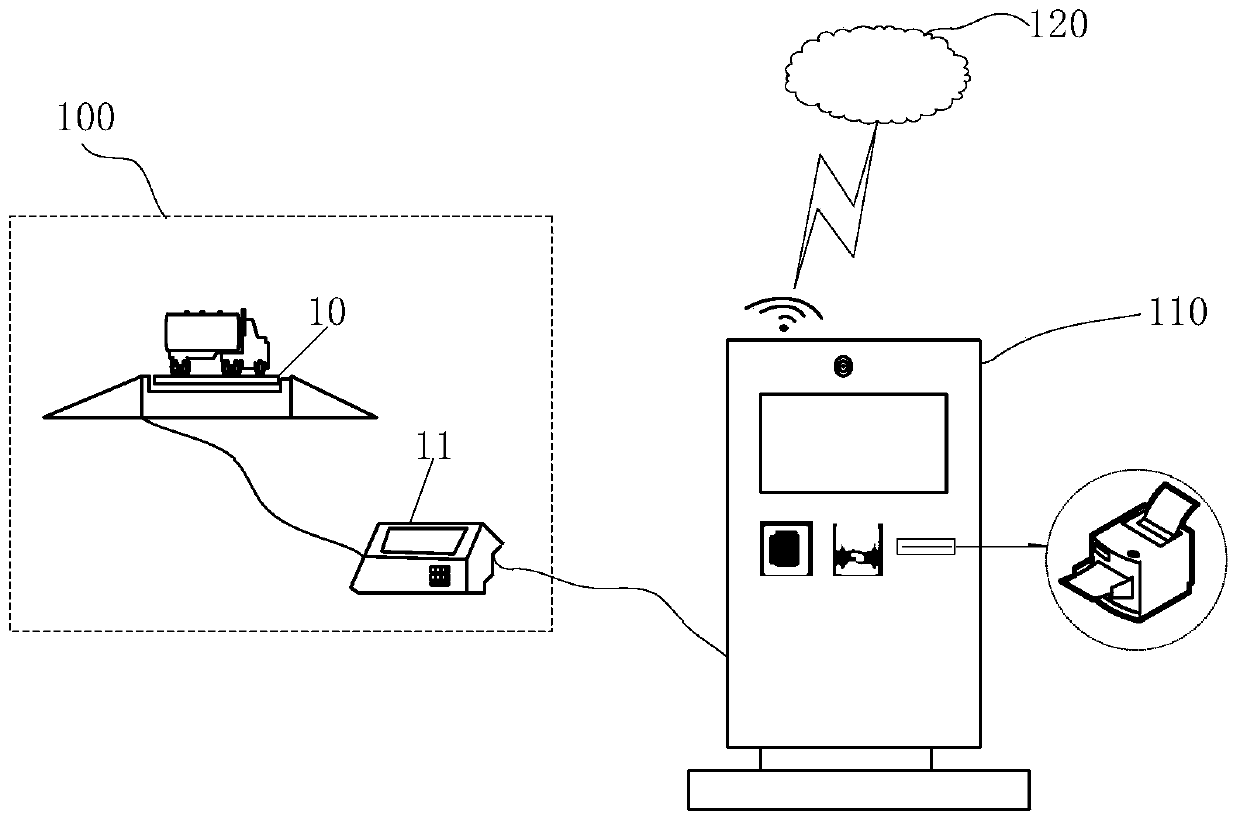

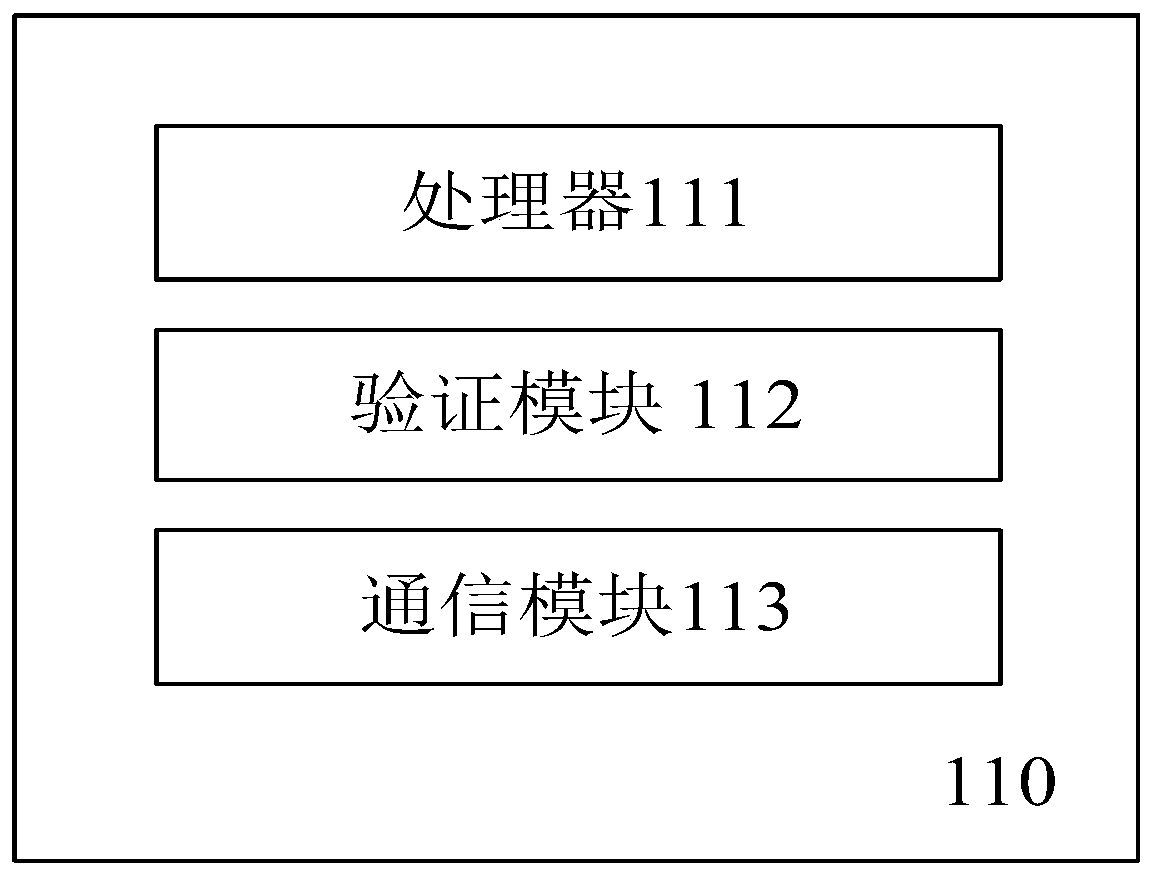

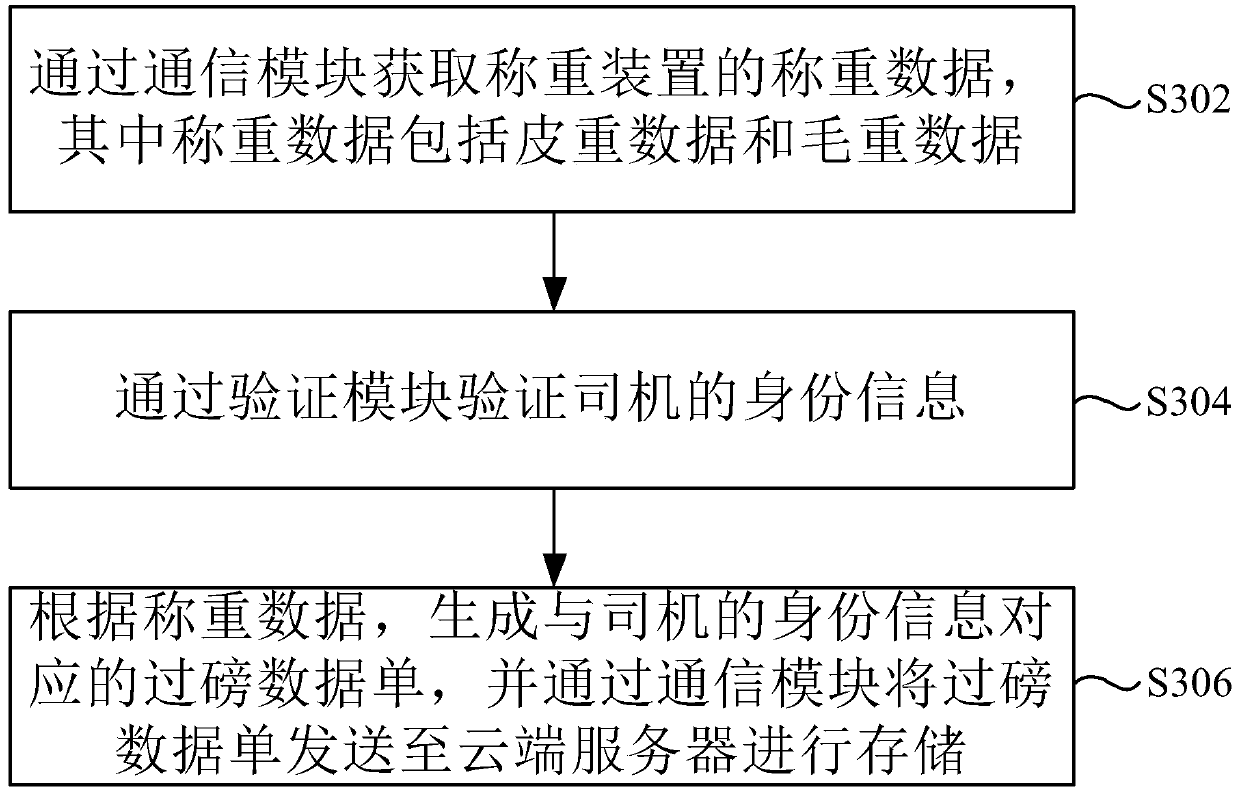

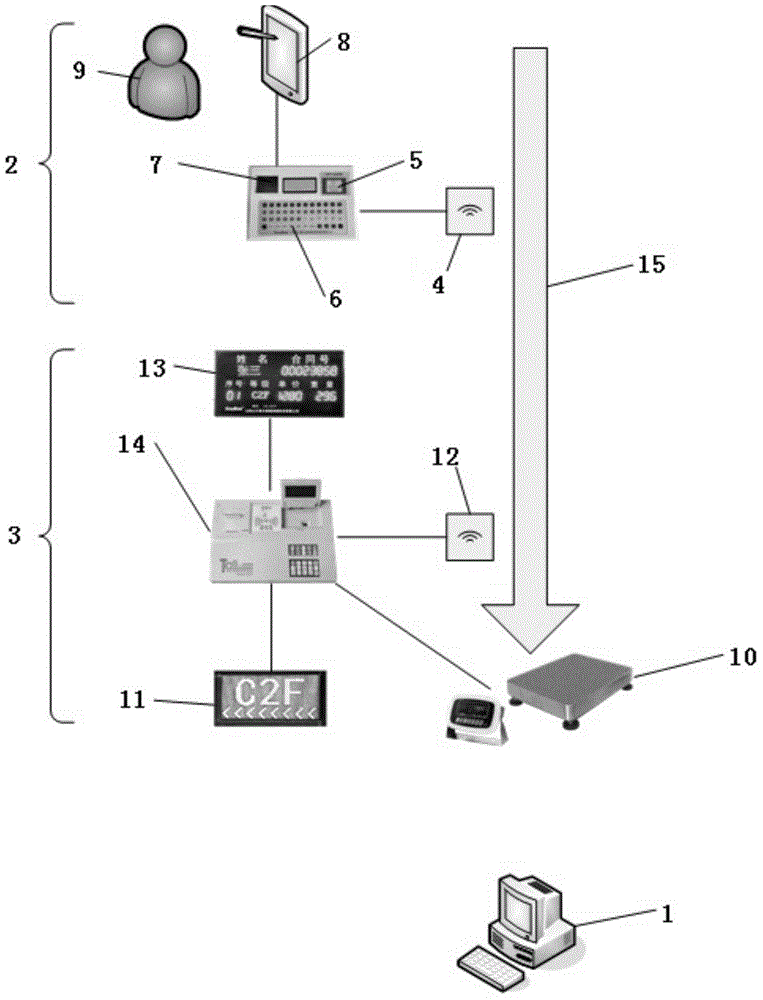

Intelligent weighing system

InactiveCN109764948AKeep safeReduce labor costsSpecial purpose weighing apparatusTerminal equipmentComputer terminal

The application discloses an intelligent weighing system which comprises a weighing device, self-service terminal equipment and a cloud server, wherein the weighing device is connected with the self-service terminal equipment; the self-service terminal equipment is in communication connection with the cloud server; the self-service terminal equipment comprises a processor, a verification module and a communication module; and the processor configures instructions for processing the following operations of: acquiring weighing data of the weighing device by the communication module, wherein theweighing data comprises tare weight data and rough weight data; verifying identity information of a driver by the verification module; and generating a weighing data sheet corresponding to the identity information of the driver according to the weighing data and sending the weighing data to the cloud server by the communication module to carry out storage.

Owner:北京魔力象限科技有限公司

Unattended tobacco leaf purchasing system and operation method thereof

InactiveCN104915781APut an end to setting too much tare weightReduce lossesBuying/selling/leasing transactionsResourcesIdentity recognitionLower grade

The invention relates to an unattended tobacco leaf purchasing system, which comprises a financial host, an intelligent grading device, an unattended weighing device and a tobacco basket transmission device, wherein the intelligent grading device comprises a first electronic tag recognition module, a tobacco grower identity recognition module, a keyboard, a micro printer and a tobacco grower determination module; and the unattended weighing device comprises a weighing control module, and an electronic scale, a weighing state display module, a second electronic tag recognition module and a voice display screen which are connected with the weighing control module respectively. Tare weight control is carried out according to upper-grade tobaccos, middle-grade tobaccos and lower-grade tobaccos, setting of more tare weight to reduce deficient stock by a tobacco station can be eliminated, disputes between the tobacco grower and the tobacco station due to improper tare weight can be eliminated, benefits of the tobacco grower can be ensured, the tobacco station can maintain the purchasing order conveniently, and deficient stock by the tobacco station can be reduced.

Owner:山东浪潮新科信息技术有限公司

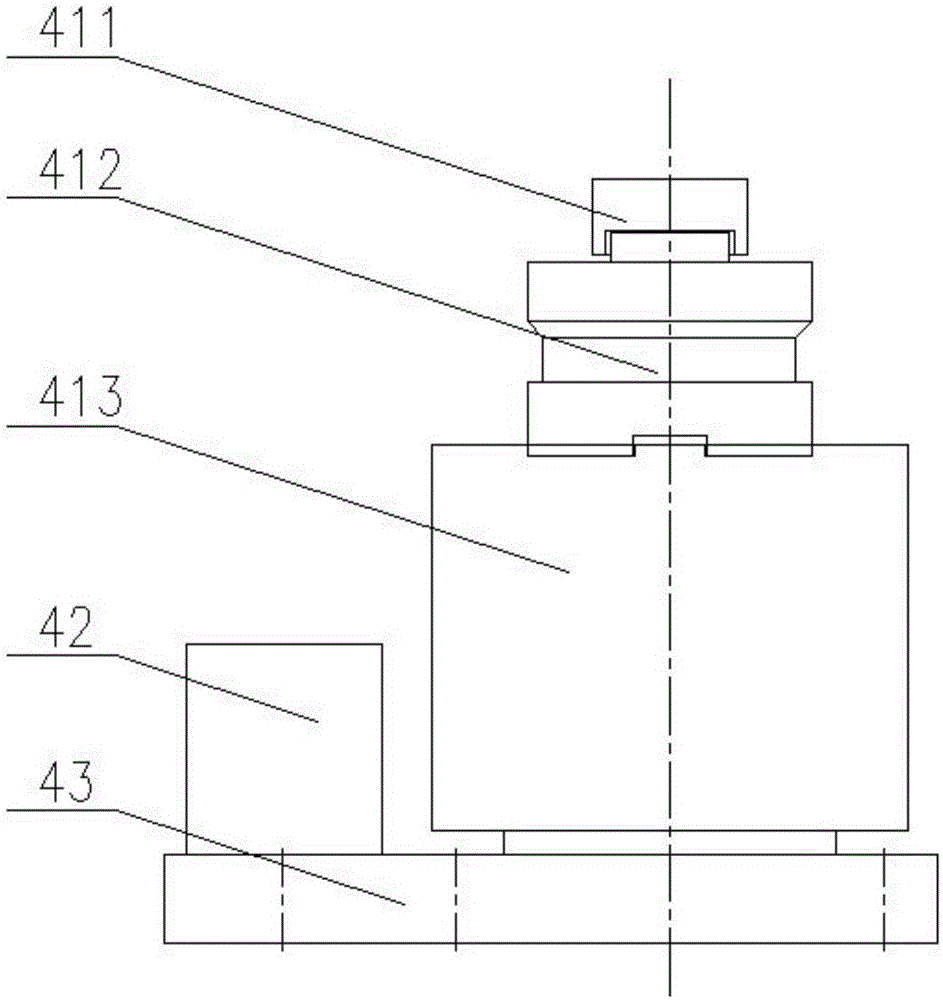

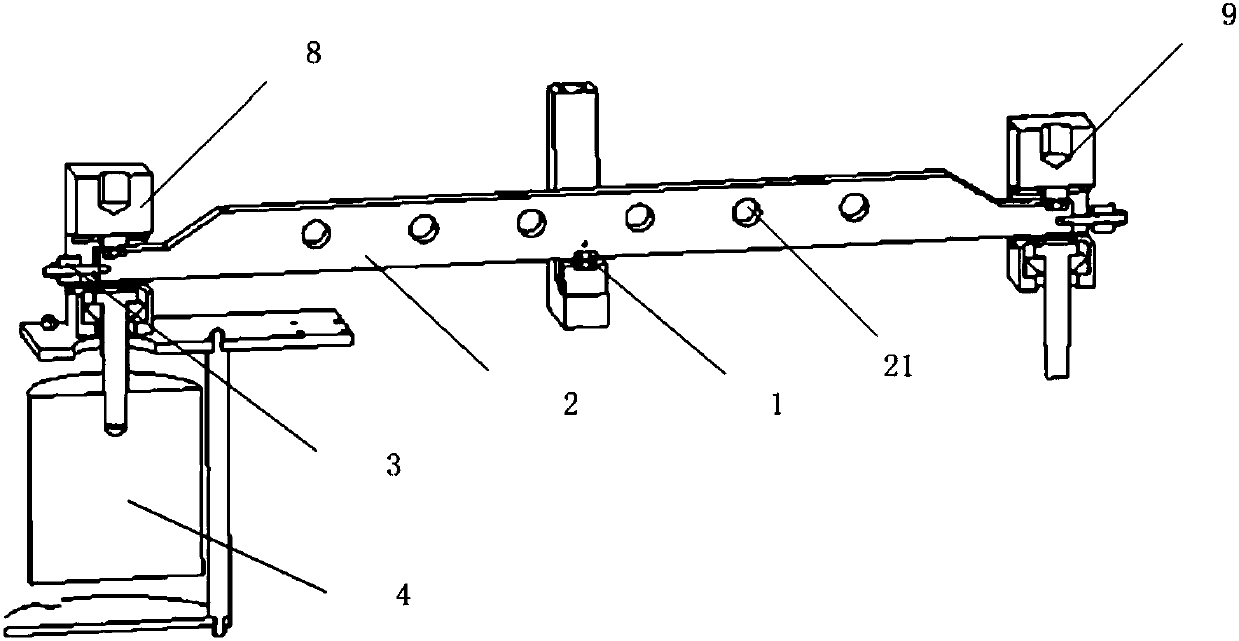

Automatically weight loading tare weight-removing device for electronic hoist scale

InactiveCN108020311AGuaranteed testingVersatilityWeighing apparatus testing/calibrationMechanical engineeringTare weight

The invention discloses an automatically weight loading tare weight-removing device for an electronic hoist scale, a balance lever is arranged on a balance fulcrum, and the balance lever can rotate with the balance fulcrum being used as a fulcrum; a balance counterweight is arranged on the balance lever; the balance counterweight includes a counterweight body and a connecting rod, the connecting rod is connected with the balance lever, and the counterweight body is arranged on the connecting rod and can move on the connecting rod; a first connecting assembly and a second connecting assembly are arranged on both ends of the balance lever; one end of a weight loading mechanism is connected with the first connecting assembly while the other end is used for hanging balance weights; the secondconnecting assembly is connected with a weight connecting device of the electronic hoist scale; the balance weights can be loaded on the weight loading mechanism and therefore weight of the weight connecting device is balanced. Via the device disclosed in the invention, the electronic hoist scale can be connected with the weight connecting device, balance can be realized via leverage principles, and that detection of the electronic hoist scale can be started from zero can be ensured.

Owner:苏州市计量测试研究所

Preparation method of chromium-free leather

ActiveCN109234477AReduce processShorten the production cycleTanning treatmentPre-tanning chemical treatmentFiberChromium free

The invention discloses a preparation method of chromium-free leather. Firstly naked leather is dehydrated by adopting an organic solvent 1 till the water content is lower than 10%, white wet leatheris obtained, and the organic solvent is recycled; an organic solvent 2 with the tare weight being 30-200% and a reactive substance with the tare weight being 2-20% are added and rotated for 120-600 minutes, and bath liquid is recycled; and finally drying is conducted, and dyeing and filling operations can be done before drying. The white wet leather is prepared through dehydration by adopting thesolvent, then the reactive substance is added to react with the hydrophilic group on the collagenous fiber, the hydrophilic group is blocked, the waterproof performance is improved, accordingly the leather with fiber dispersed is sufficiently and durably fixed, and preparation of the chromium-free leather is finally achieved. The preparation method is characterized in that the production period isshort, the procedure is simple and easy to operate, the prepared leather has the good softness, good gas permeability and high tension stress.

Owner:SICHUAN UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com