Not inertial, online system of box packing quantitative tobacco shred, tobacco pieces with tare weight being removed in real time

A non-inertial, sheet cigarette technology, used in packaging, packaging protection, transportation and packaging, etc., can solve the problems of low measurement accuracy, poor accuracy, large inertia error, etc., and achieve high measurement accuracy, good stability, and low maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings, but the content of the present invention is not limited thereto.

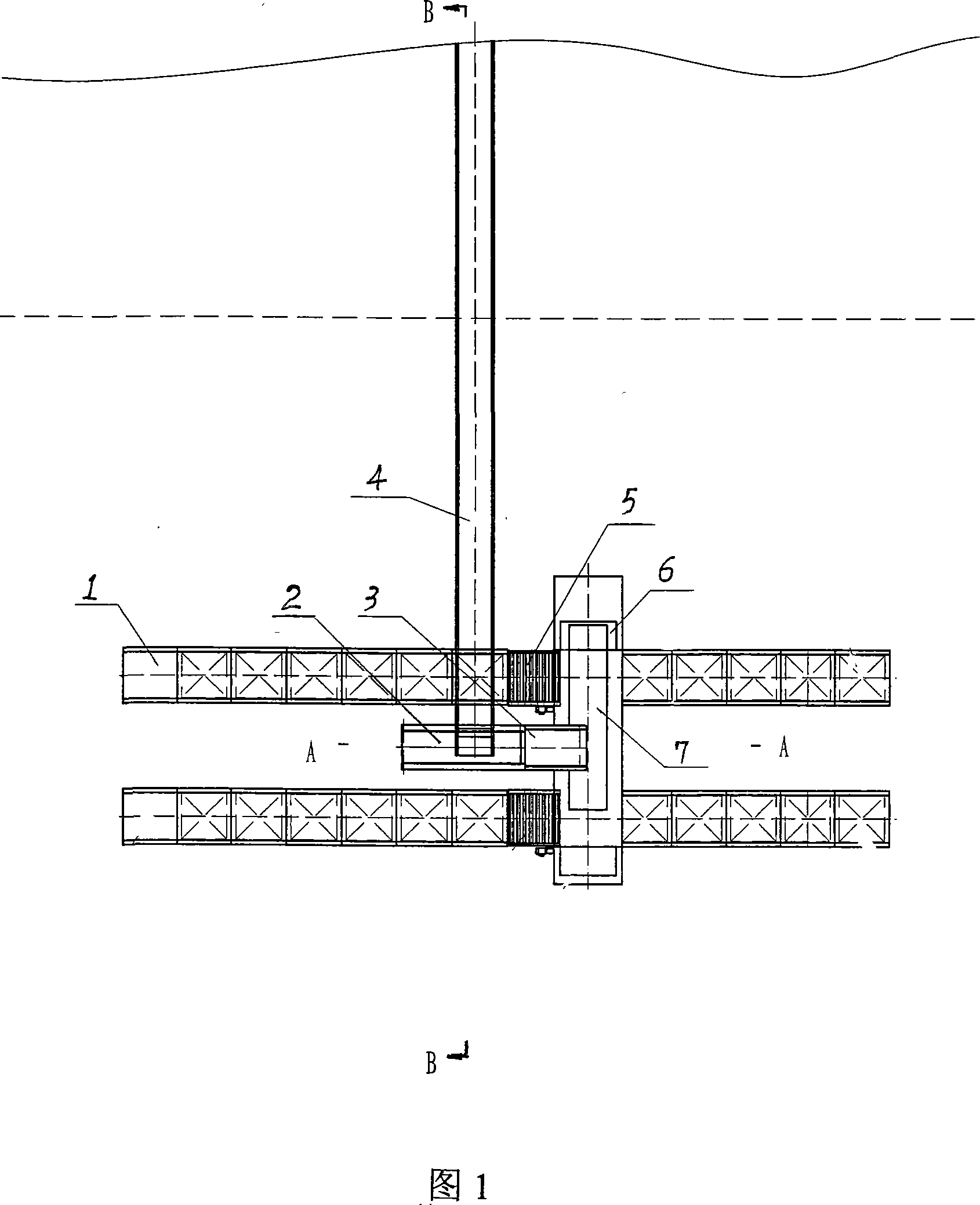

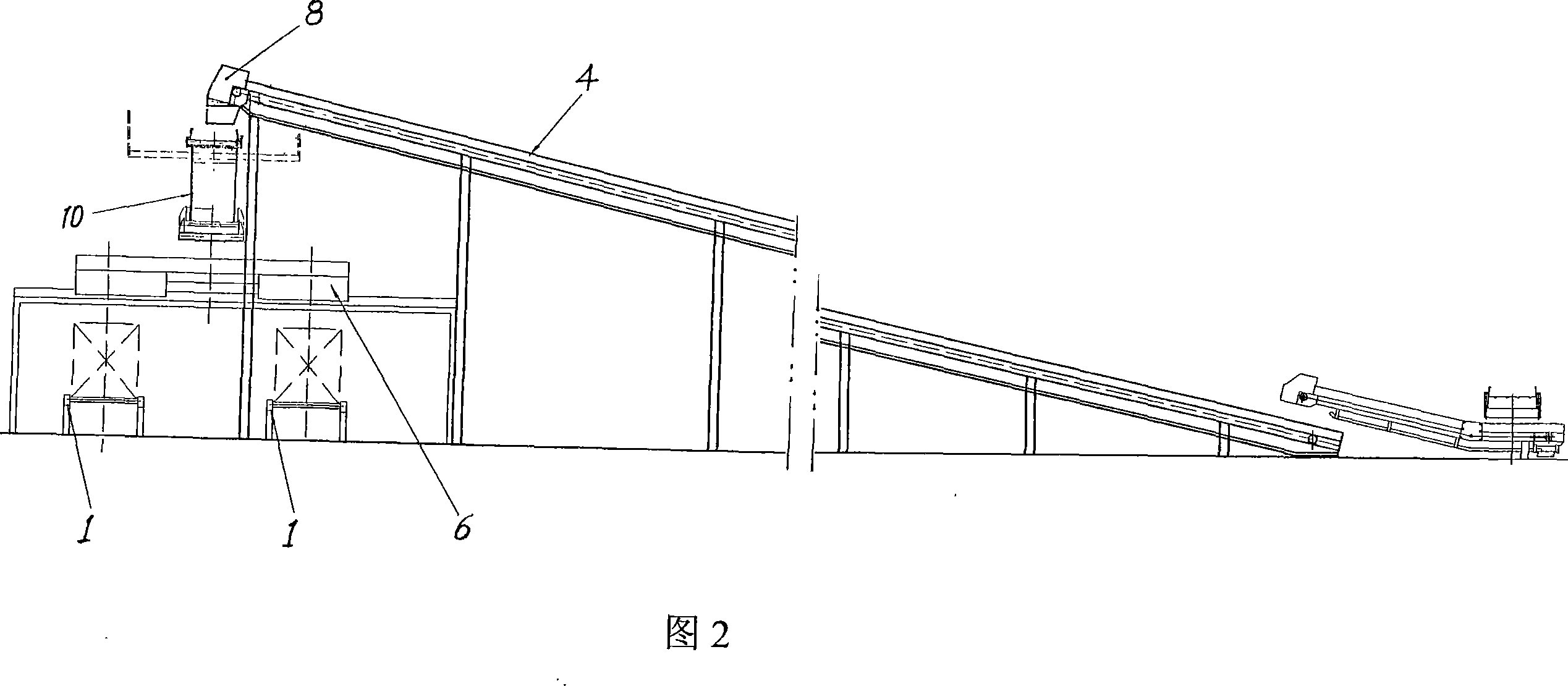

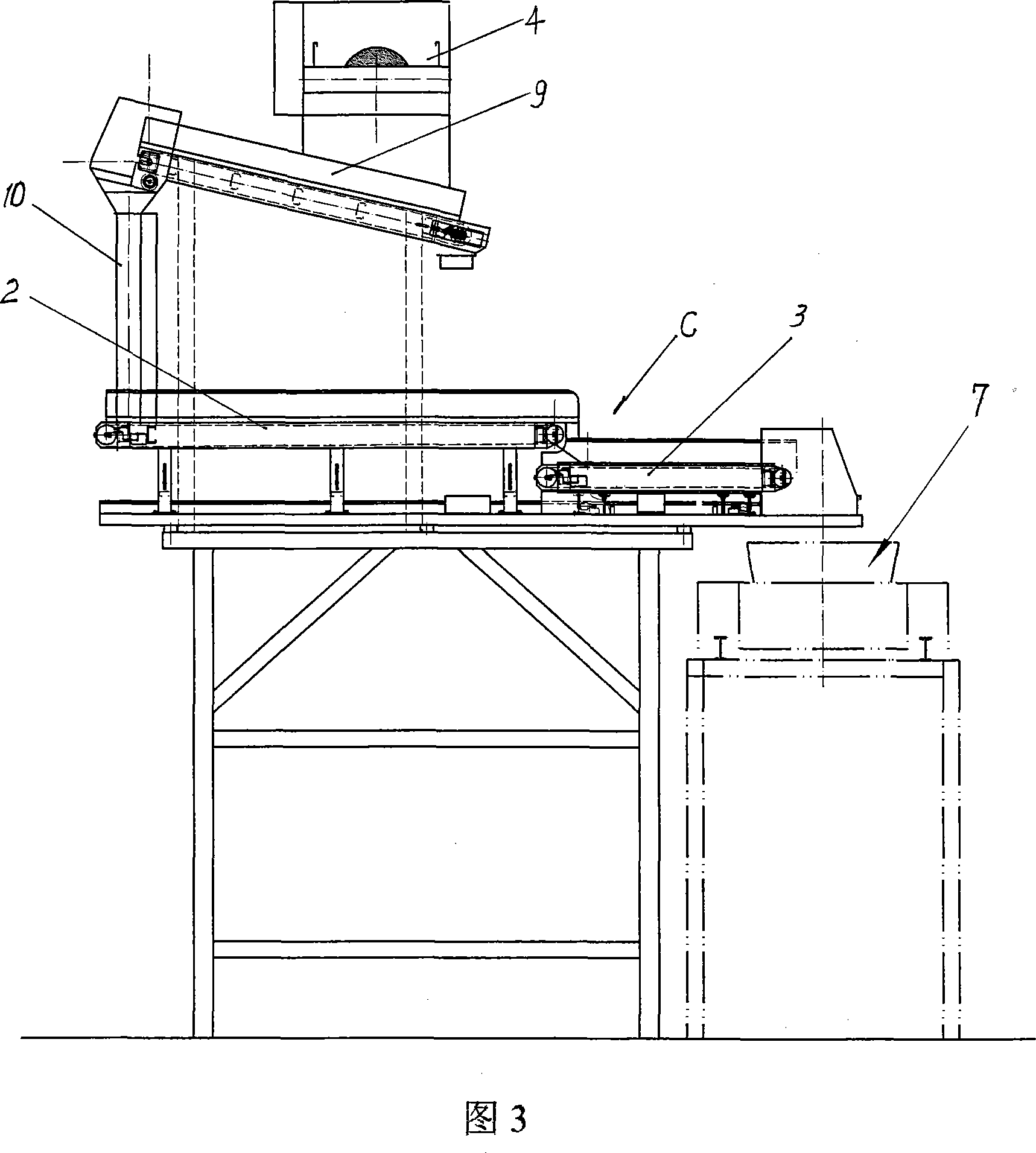

[0040]The material conveyor 4 is an inclined belt conveyor for conveying tobacco sheets or shredded tobacco. The discharge port 8 of the conveyor is set at a high position, and a transitional conveyor belt 9 is provided below the discharge port 8. The storage tank 9 is located below the discharge port 8. The material pipe 10, as shown in Figure 2, the material storage pipe 10 is a vertical pipe, the lower end of which is located above the material input end of the buffer conveyor 2, and the material continuously sent by the conveyor 4 is sent to the buffer conveyor 2 through the material storage pipe 10 Or be stored in the storage pipe 10, the material output end of the buffer conveyor 2 is located above the input end of the full-suspension electronic belt scale 3 below it, and the output end of the electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com