Automatically weight loading tare weight-removing device for electronic hoist scale

An electronic crane scale and weight technology, which is applied in the field of weight loading and tare-free devices, can solve the problem of being difficult to achieve accuracy and reliability, and it is difficult to objectively reflect the zero point error of the electronic crane scale, the reliability of traceability of the value, and the existence of accuracy. There are risks and other issues, to achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

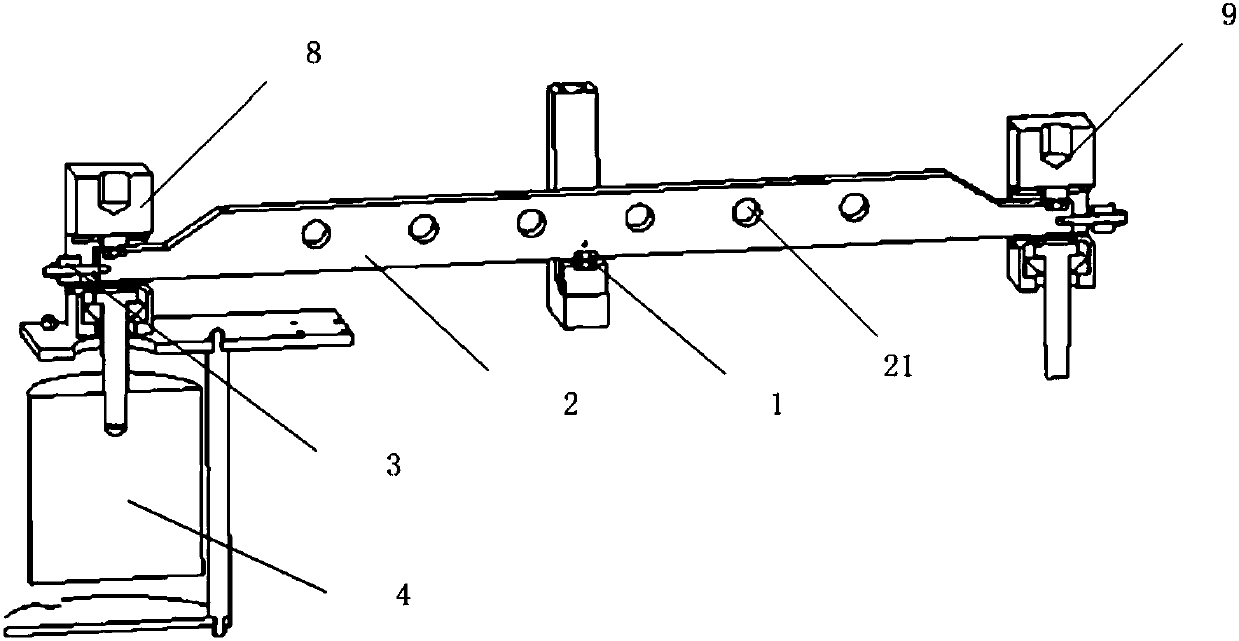

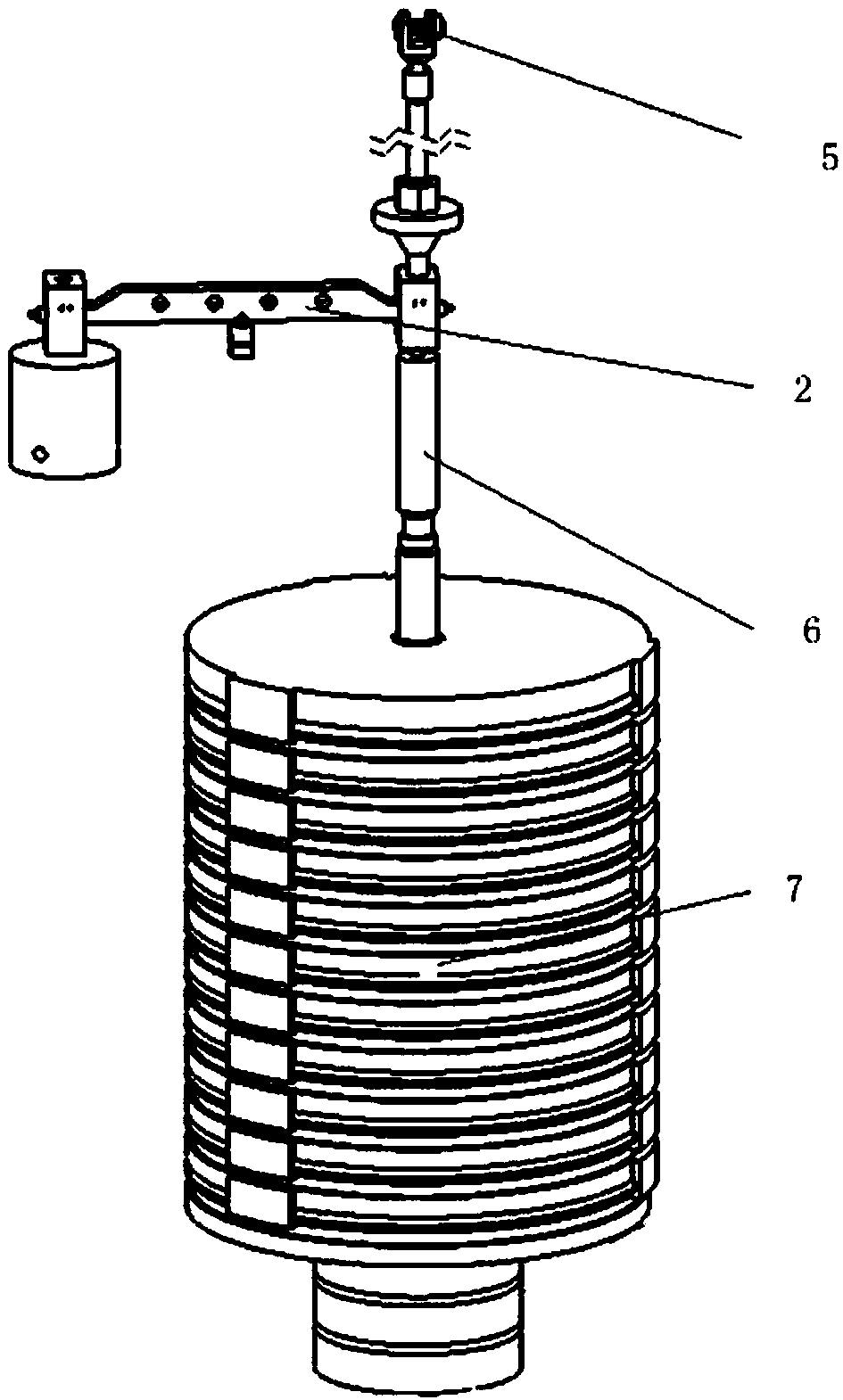

[0031] figure 1 It is a structural schematic diagram of the weight loading exempting peeling device of the electronic crane scale provided by the invention; figure 1 As shown, the present invention provides a weight loading and tare-free device of an electronic crane scale, including: a balance fulcrum 1, a balance lever 2, a weight 3, a first connection assembly 8, a second connection assembly 9, a weight loading Mechanism and counterweight 4, of which:

[0032] The balance lever 2 is arranged on the balance fulcrum 1 and can rotate with the balance fulcrum 1 as a fulcrum. Specifically, the balance fulcrum 1 can be connected to a fixed device, such as a column, a beam, and the like. The balance lever 2 rides on the balance fulcrum 1, and when a force is applied to both ends of the balance lever 2, the balance lever 2 can rotate with the balance fulcrum 1 as a fulcrum.

[0033] The balance weight 3 is arranged on the balance lever 2; the balance weight 3 includes a weight b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com