Delivery unit of a sheet-processing machine and method for operating a sheet-processing machine

An output device and sheet-fed technology, applied in the direction of thin material handling, transportation and packaging, sending objects, etc., can solve time-consuming and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

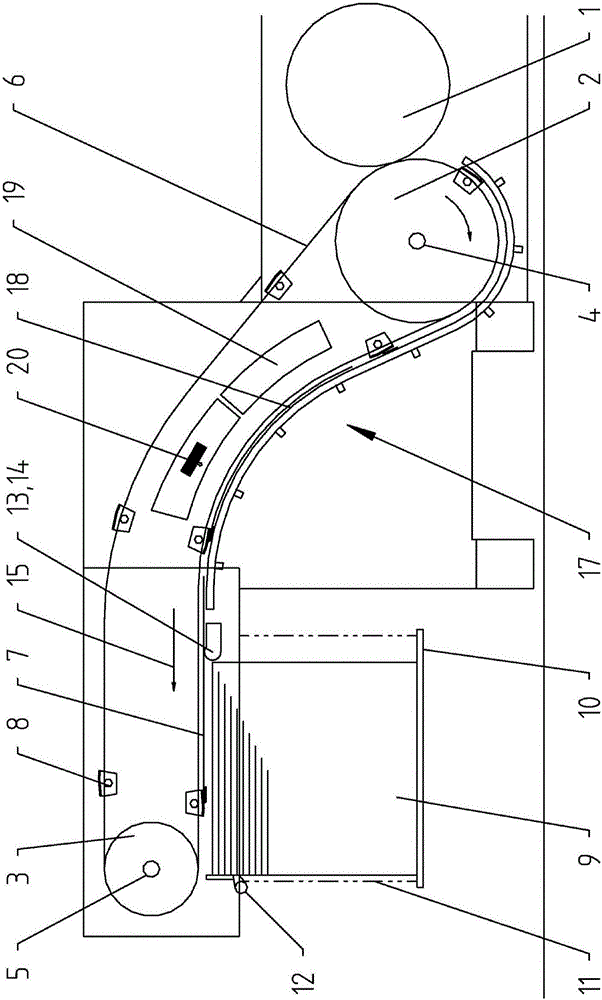

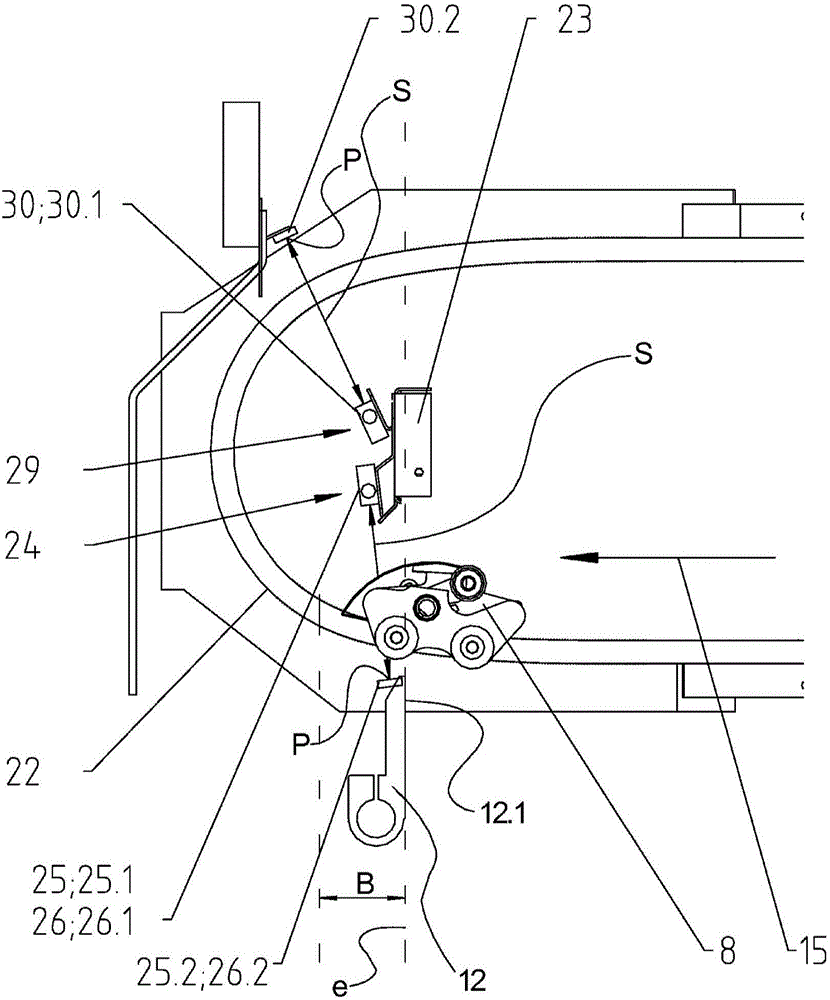

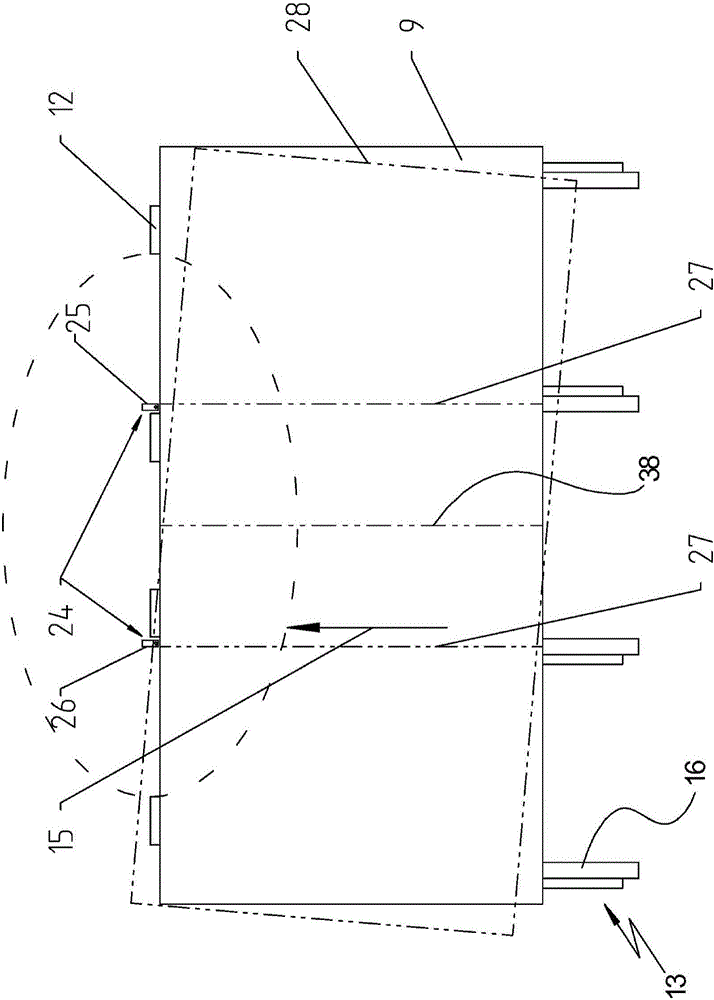

[0046] exist figure 1 The output device of a machine for processing sheets (here in particular a sheet-fed rotary printing press) is shown in . Here, the machine can in particular be operated according to the lithographic method. The last printing cylinder 1 is shown in a sheet-fed rotary printing press. A drive sprocket 2 and a deflection sprocket 3 are shown in the sheet output device. The sprockets 2 and 3 are each connected to a shaft 4 , 5 on which a further drive sprocket 2 or deflection sprocket 3 is arranged at a distance. An endless chain 6 forming a chain loop is guided by means of sprockets 2 , 3 . Between the two sprocket rings, gripper carriages 8 holding the individual sheets 7 are arranged at a constant distance from one another. The sprockets 2, 3 and the revolving chain 6 together with the handle trolley 8 form a sheet-fed feeding system, which can also be composed of other elements. In particular, the steering of the handle trolley 8 can also be carried ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com