High-precision impulse plate flow meter

A flushing plate flowmeter, high-precision technology, applied in the direction of volume/mass flow generated by mechanical effects, dynamic effects by detecting fluid flow, etc., can solve the problems of difficult long-term stable operation, unreasonable structure, etc., and achieve horizontal force transmission Long-term accuracy, simple processing and manufacturing, easy installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

[0025] Parts among the present invention are conventional commercially available products unless otherwise specified.

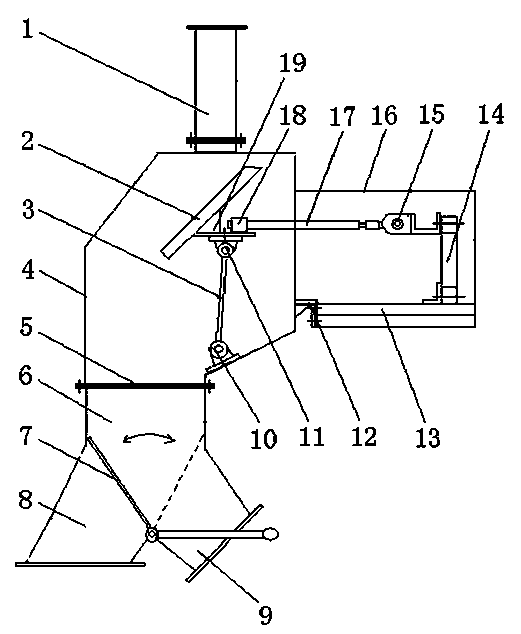

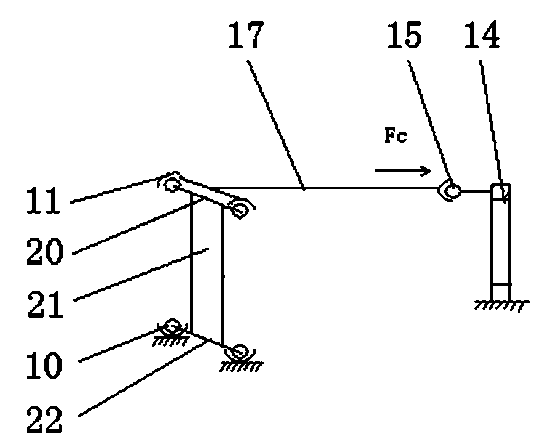

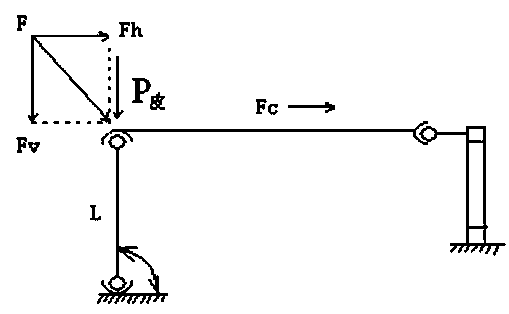

[0026] The high-precision punching plate flowmeter provided by the present invention includes a blanking box 4 with a material inlet diversion groove 1 arranged on it, a discharge port 5 arranged below it, and an inclined impulse plate 2 is arranged inside it, and a force sensor 14, Wherein the inclined impact plate 2 is supported in the blanking box 4 through the parallel hinge mechanism 3 at its lower part, and is matched with the load cell 14 outside the blanking box 4 through the horizontal force transmission push rod 17 at its side; The hinge mechanism 3 includes a vertical plate 21, the upper end of the vertical plate 21 is fixed with an upper hinge shaft 20, and the front and rear ends of the upper hinge shaft 20 are fixed on the fixing part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com