Belt scale weighing synchronous peeling method and synchronous peeling belt scale

A technology of belt scales and tare weights, applied in the detailed information of weighing equipment, weighing equipment of continuous material flow, weighing, etc., can solve problems such as undiscovered, achieve significant progress, and highlight the effect of substantive features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

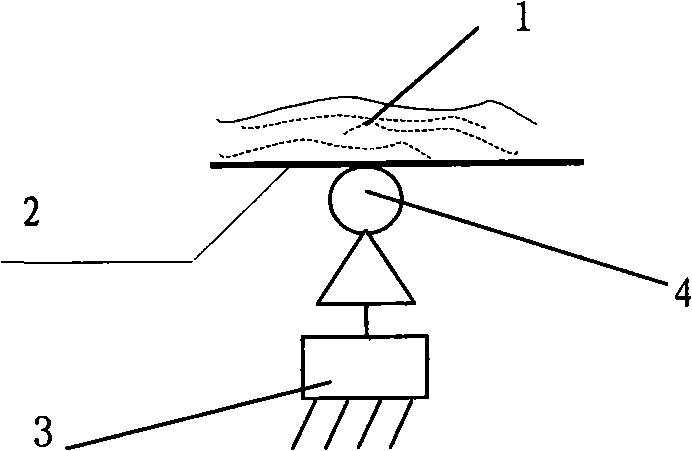

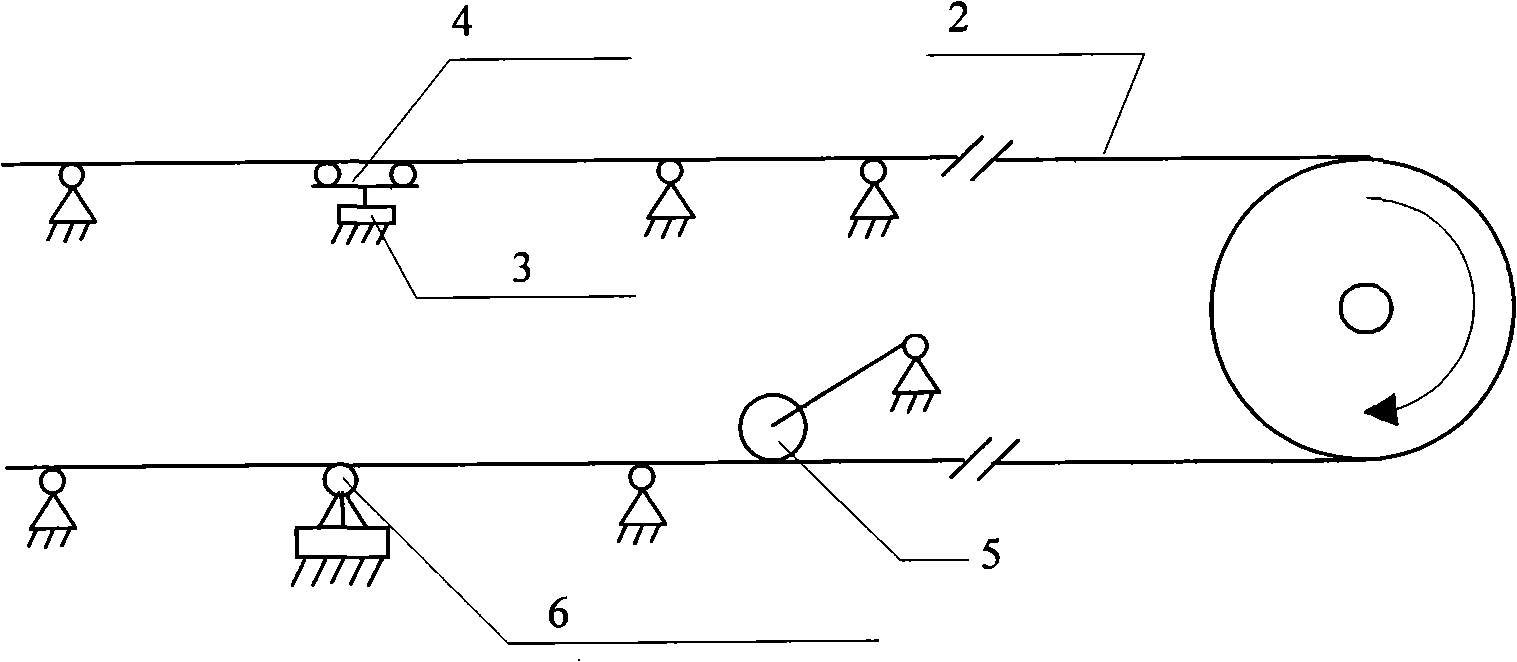

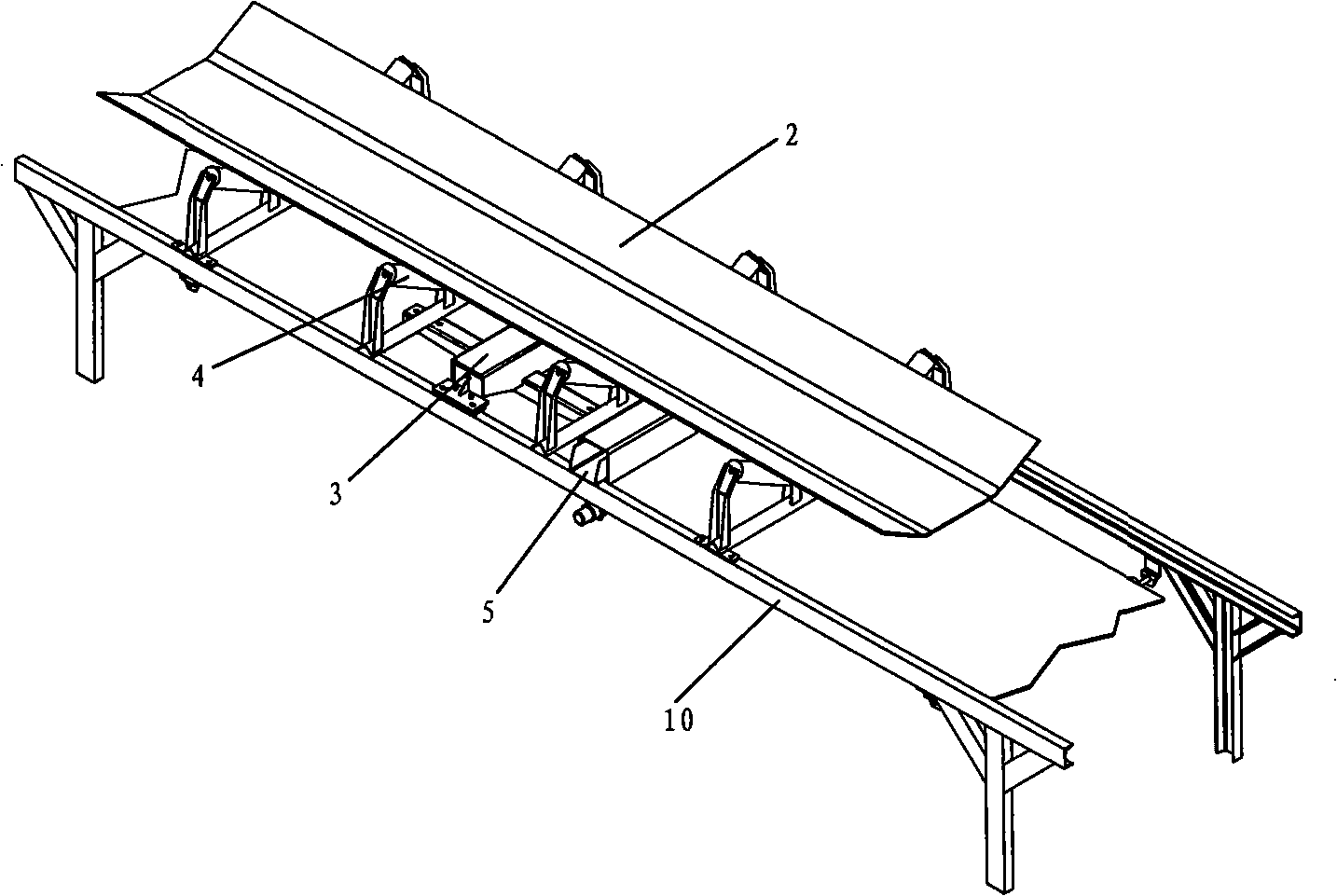

[0027] This embodiment is used to realize the synchronous peeling belt scale of belt scale weighing synchronous peeling method such as Figure 2 to Figure 5 As shown, a group of metering rollers 4 and a loop conveyor belt 2 are installed on the frame 10 . During the loop-back operation, the conveyor belt 2 can be divided into a positive process section carrying materials and an empty return section. The positive process section is carried on the weighing roller 4, and the measuring roller 4 is carried on the load cell 3 installed on the frame to form a weighing platform. In order to realize the weighing synchronous tare method of the belt scale, the frame 10 is fixedly installed with the base plate 5-1 of the tare load cell 5 at the predetermined distance from the load cell of the positive process segment in the return section of the conveyor belt. The upper bears the scale frame 5-2 whose two ends extend downwards from the support plate, and the two support plates support th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com