On-line tare weight subtracting method and system for tobacco packaging

A technology of tobacco leaf and tare weight, which is applied in the field of tare weight removal system structure of re-cured tobacco leaf packaging boxes, can solve problems such as unreliability, lower production efficiency, and inability to eliminate errors in finished product tare weight and net weight values, so as to eliminate doubts and differences Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

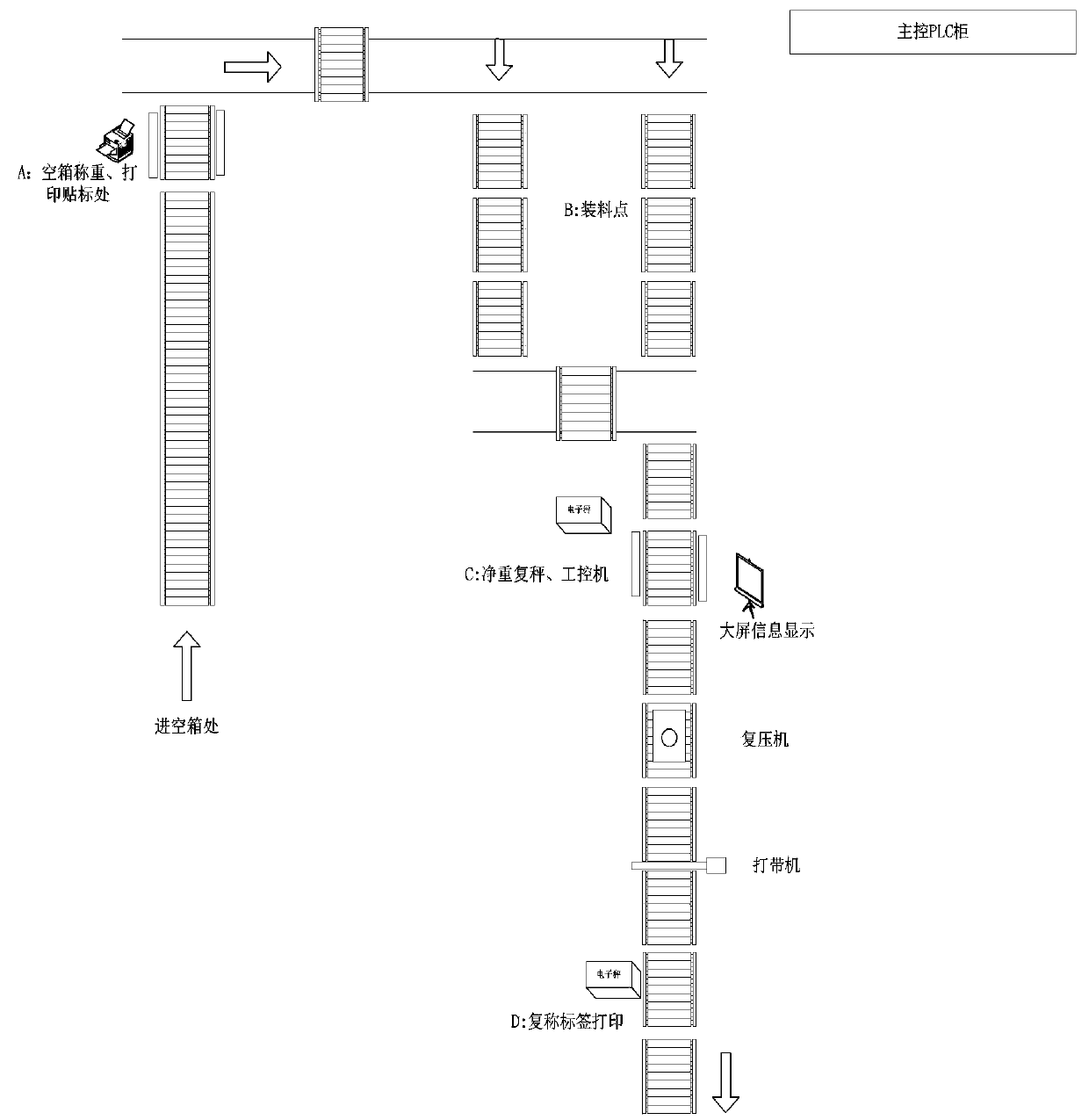

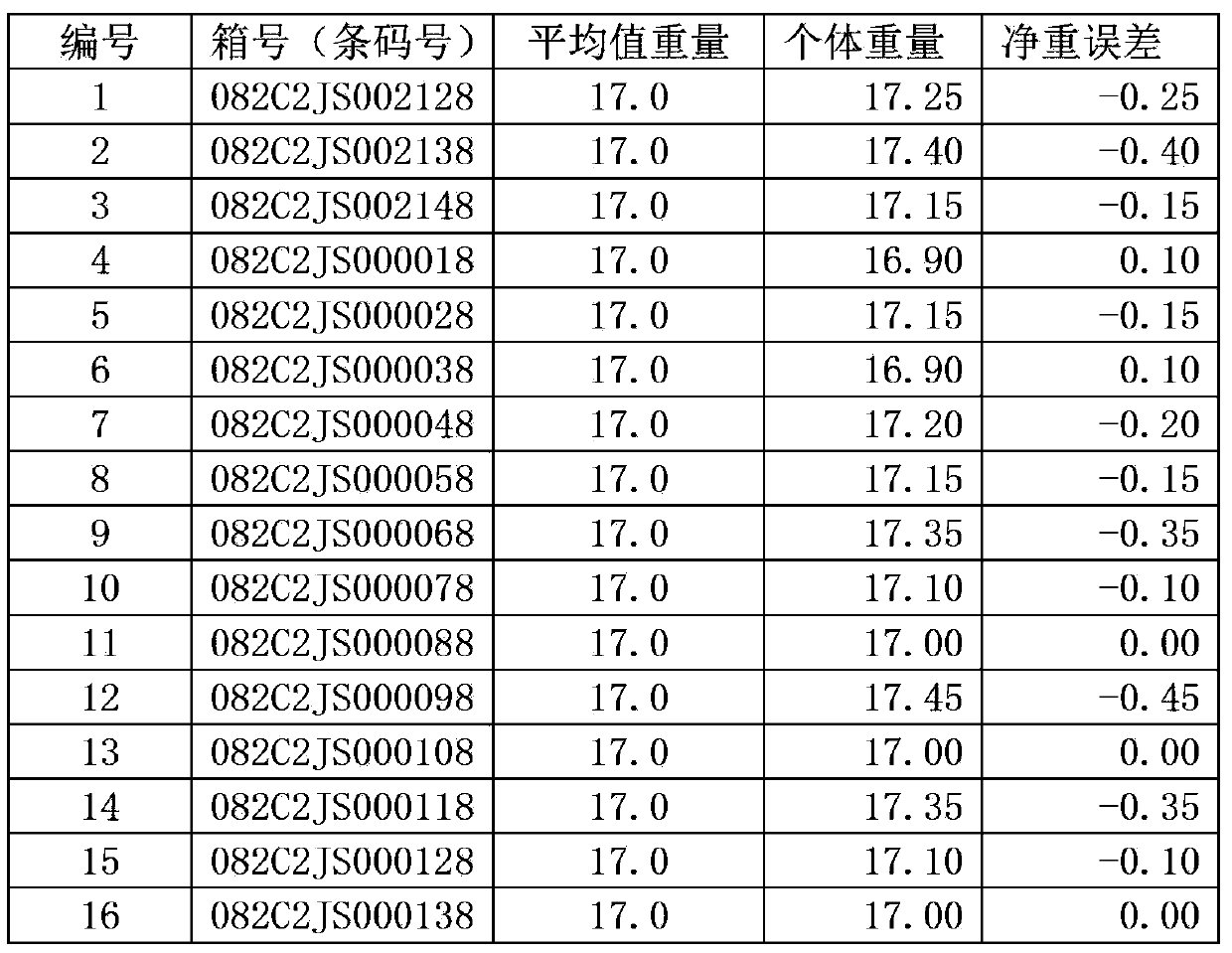

[0013] See figure 1 , figure 2 shown. An on-line taring method for re-cured finished tobacco leaves. The invention uses an electronic scale to weigh the cartons one by one before the empty cartons are loaded, and records the weight values on the cartons in the form of bar codes. After feeding, when the last manual weight value is checked, the empty box weight value recorded by the barcode is read out and displayed on the large electronic screen.

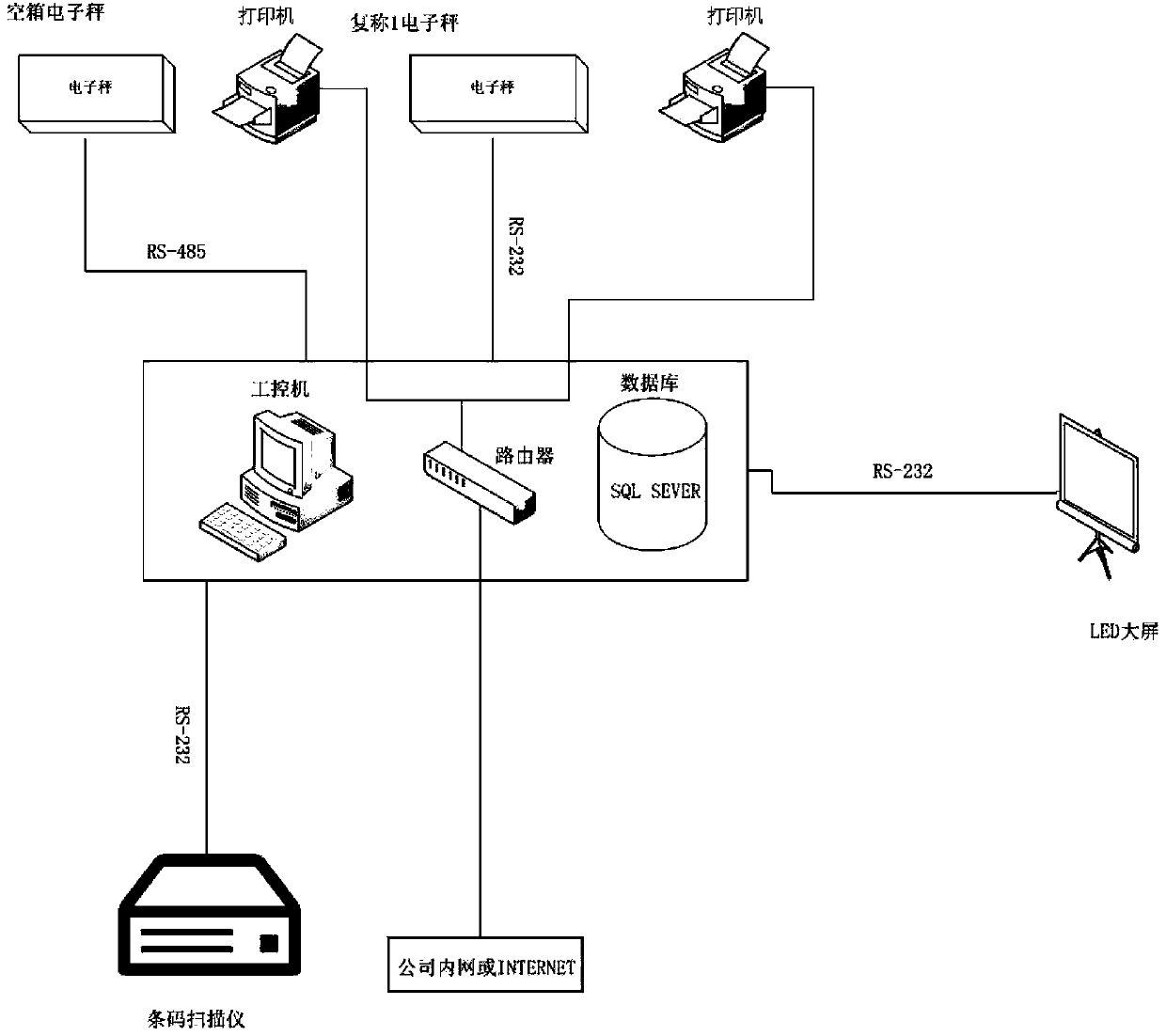

[0014] A system of on-line taring method for rebaked finished tobacco leaves. The present invention uses a computer to connect electronic scale A, electronic scale B, barcode scanner, electronic display screen, printer A, and printer B; wherein, electronic scale A, electronic scale Scale B, barcode scanner, and electronic display are respectively connected to the computer through the serial communication port, and the printer is connected to the computer through a router; It is arranged between the electronic scale A and the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com