Cleaner production method of ecological tanning of Tan sheep skin

A clean production, Tan sheepskin technology, applied in chemical treatment before tanning, small raw hide/large raw hide/leather/fur treatment, small raw hide/large raw hide/leather hide/fur chemical treatment, etc. Tan sheepskin is difficult to export, chrome tanning waste liquid pollutes the environment, etc., to achieve the effect of strong anti-oxidative reduction effect, reduce daily maintenance costs, and reduce environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

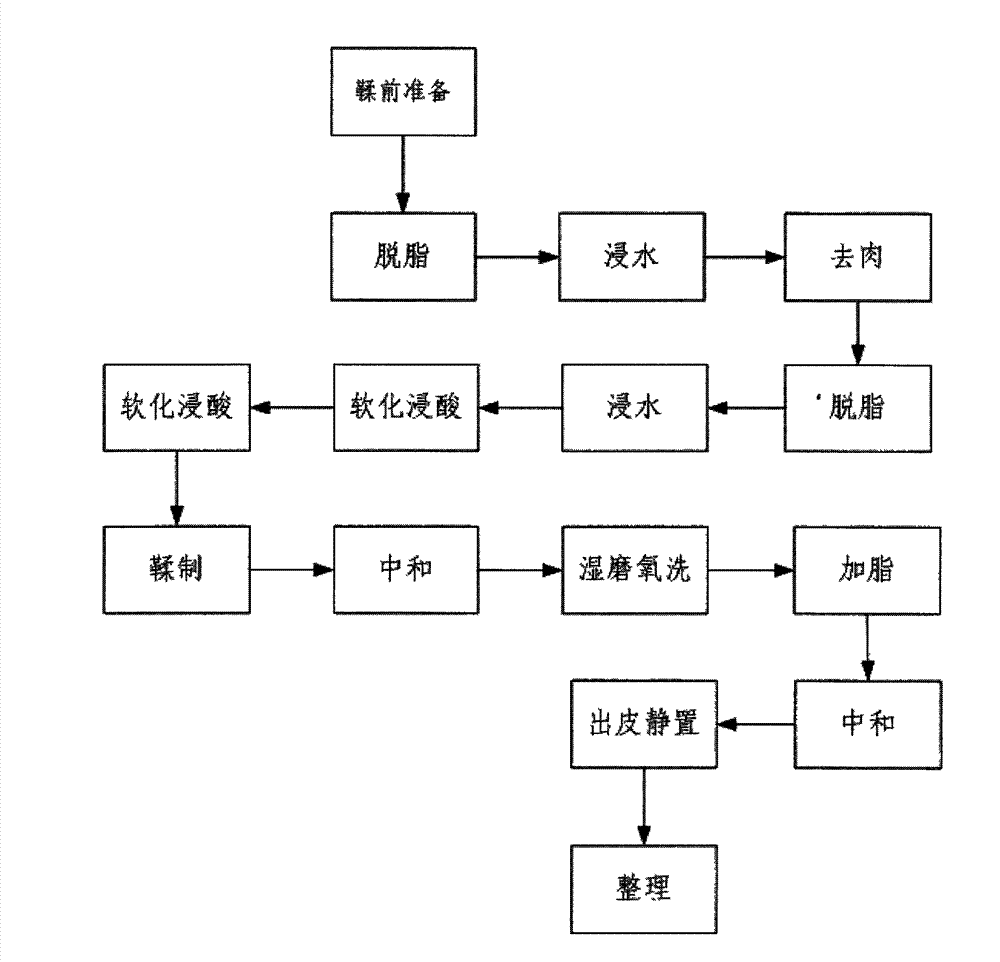

[0016] Please also see figure 1 , a clean production method for ecological tanning of Tan sheepskin, comprising the following steps: preparation before tanning → degreasing → soaking in water → flesh removal → degreasing → soaking in water → softening and pickling → tanning → neutralization → wet grinding oxygen washing → fatliquoring → neutralization → peeling Standing → tidying up.

[0017] Wherein, the softening pickling step is specifically:

[0018] Mix edible salt, formic acid and water to obtain a first mixed solution, and let it stand for 60 minutes to ensure that the temperature of the first mixed solution is 38°C;

[0019] Add fur fatliquor and softening enzyme to the first mixed solution and stir evenly to obtain a softened pickling solution, and after standing for 4 hours, the temperature is raised to 48°C, wherein the concentration of edible salt is 60g / L, the concentration of formic acid is 2g / L, The concentration of fur fatliquoring agent is 2g / L, and the conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com