Production process of automobile interior decorative leather with ultralow total carbon emission

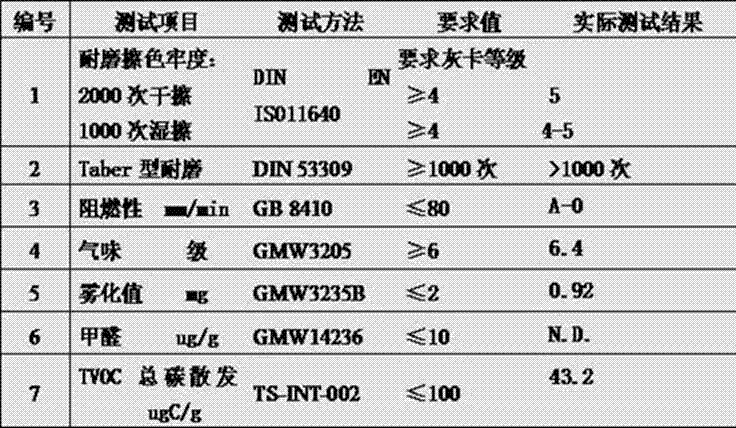

A technology for automotive interiors and production processes, applied in leather softening, leather drying, leather surface treatment, etc., can solve the problems of high atomization value, high total carbon emission, and the production process is not environmentally friendly, and achieves wear resistance and abrasion resistance. Good, stable quality, the effect of strengthening control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0015] A production process of ultra-low total carbon emission for automotive interior leather, comprising the following steps: a production process for ultra-low total carbon emission of automotive interior leather, comprising the following steps:

[0016] A. Hair preservation and depilation: After the cowhide is fleshed out, 2wt% sodium sulfide and 1.2wt% lime are used to pretreat the cowhide with a solid-to-liquid ratio of 1:3, so that the hair root falls off and the hair is filtered out.

[0017] B. Softening: Enzyme softening treatment was carried out on the depilated rawhide. The softening temperature was 30-32° C. and the softening time was 45 minutes. The enzyme preparation added in the enzyme softening treatment was pancreatin W, and its addition amount was 0.3wt%.

[0018] C, tanning: carry out the chrome tanning process on the softened bare leather to obtain leather.

[0019] D. Retanning / dyeing / fatliquoring: Put the tanned leather into the drum for rinsing once, ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com