Leather retanning method and crust leather prepared by using leather retanning method

A technology for leather and wet blue leather, applied in the field of leather retanning, which can solve problems such as environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

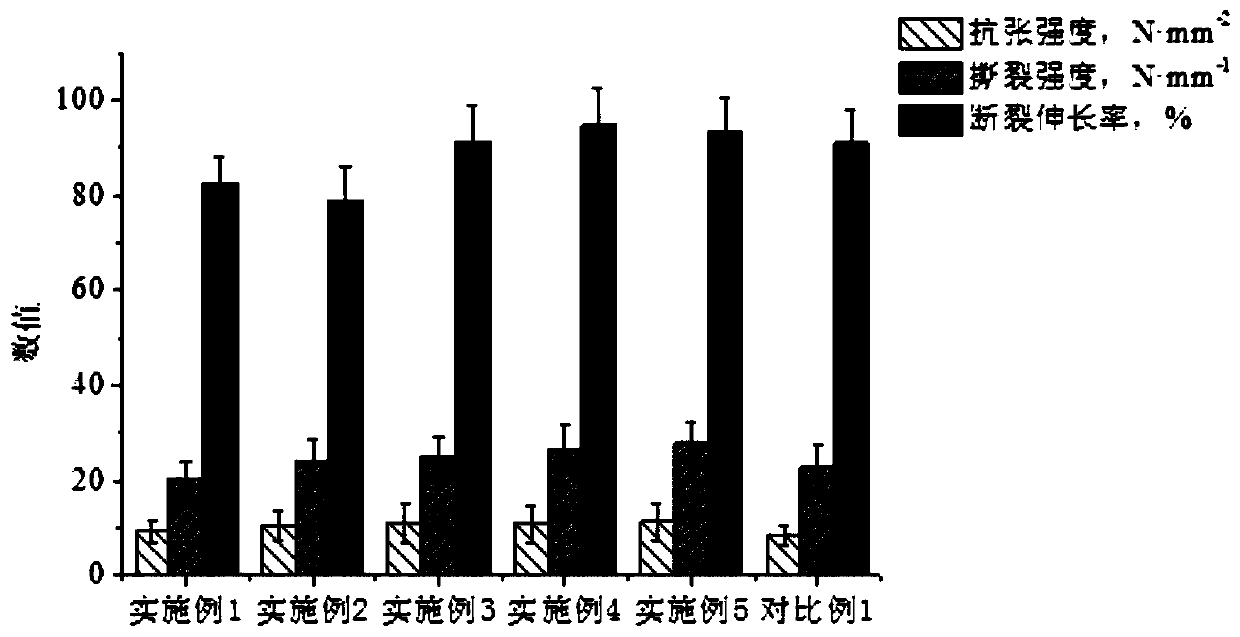

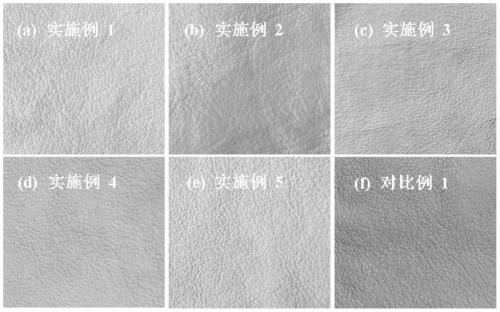

Examples

Embodiment 1

[0043] The leather retanning method of the present invention specifically includes the following steps:

[0044] (1) Material: Weigh the wet blue leather of sheep apparel, and the amount of reagent in the subsequent steps is expressed as a percentage of the weight.

[0045] (2) Backwater: Put the wet blue leather in a rotating drum, add 200wt% water, 1wt% degreasing agent DT, adjust the temperature to 25°C, and drain the liquid after rotating for 30 minutes.

[0046] (3) Water washing: Add 200wt% of water to the drum, adjust the temperature to 25°C, and drain the liquid after rotating for 10 minutes.

[0047] (4) Neutralization: Add 100wt% of water to the drum, then add 1wt% of neutralizer NT and 0.5wt% of baking soda to adjust the pH to 5.5, adjust the temperature to 25°C, and rotate the liquid for 150 minutes. discharge.

[0048] (5) Water washing: Add 200wt% water to the drum, adjust the temperature to 25°C, and discharge the liquid after rotating for 10 minutes.

[0049] (6) Retanni...

Embodiment 2

[0057] The leather retanning method of the present invention specifically includes the following steps:

[0058] (1) Material: Weigh the wet blue leather of sheep apparel, and the amount of reagent in the subsequent steps is expressed as a percentage of the weight.

[0059] (2) Backwater: Put the wet blue leather in a rotating drum, add 300wt% water, 1.5wt% degreasing agent DT, adjust the temperature to 35°C, and drain the liquid after rotating for 40 minutes.

[0060] (3) Water washing: 300wt% water is added to the drum, the temperature is adjusted to 35°C, and the liquid is discharged after rotating for 30 minutes.

[0061] (4) Neutralization: Add 200wt% of water to the drum, then add 2wt% of neutralizer NT and 1wt% of sodium formate to adjust the pH to 5.8, adjust the temperature to 40°C, and discharge the liquid after rotating for 180 minutes.

[0062] (5) Water washing: Add 300wt% water to the drum, adjust the temperature to 40°C, and discharge the liquid after rotating for 20 minu...

Embodiment 3

[0071] The leather retanning method of the present invention specifically includes the following steps:

[0072] (1) Weighing: Weigh the wet blue leather of sheep apparel, and the amount of reagent in the subsequent steps is expressed as a percentage of the weight.

[0073] (2) Backwater: Put the wet blue leather in a rotating drum, add 150wt% water, 0.5wt% degreasing agent DT, adjust the temperature to 20°C, and drain the liquid after rotating for 20 minutes.

[0074] (3) Water washing: add 350wt% water into the drum, adjust the temperature to 20°C, and drain the liquid after rotating for 20 minutes.

[0075] (4) Neutralization: Add 150wt% of water to the drum, then add 3wt% of neutralizer NT and 2wt% of sodium formate to adjust the pH to 5, adjust the temperature to 30°C, and discharge the liquid after rotating for 200 minutes.

[0076] (5) Water washing: Add 250wt% water into the drum, adjust the temperature to 30°C, and drain the liquid after rotating for 15 minutes.

[0077] (6) Ret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com