Production technique of xanthochromia-resisting and illumination-resisting two-layer leather

A production process, the technology of split leather, applied in the field of leather, can solve the problems of high product cost, general quality, and affecting the use effect of leather, achieve good yellowing resistance and light resistance, simple and easy production method, good resistance The effect of friction fading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

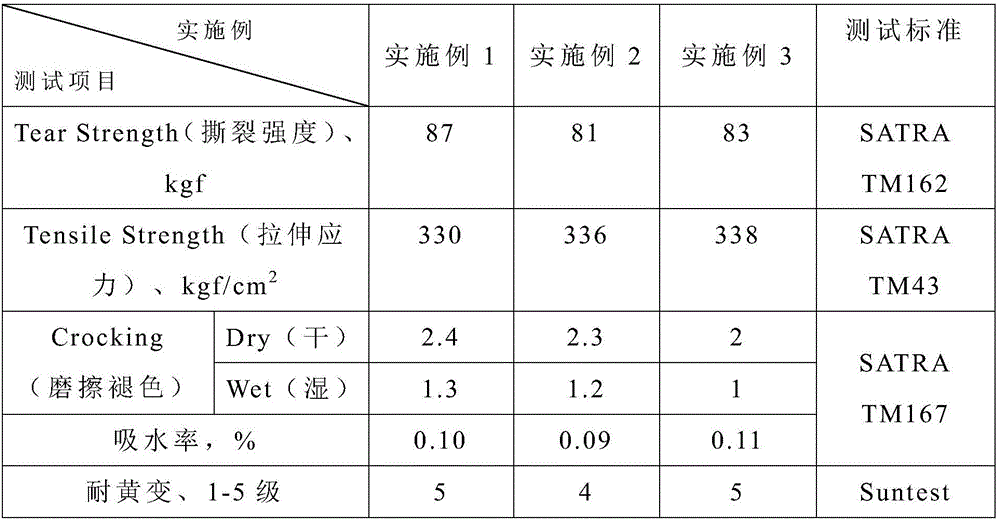

Examples

Embodiment 1

[0043] A production process for anti-yellowing and light-resistant split leather, comprising the steps of:

[0044] Step 1, rehumidification: take the second layer of leather and put it in the drum, add 200% of 45°C water and 0.5% of Eusapon OC degreasing agent according to the weight of the leather to the drum, rotate for 40 minutes, and then add 0.5% Oxalic acid, rotate for 60 minutes, drain the drum, then add water to wash and drain twice;

[0045] Step 2, retanning: add 100% water at 25°C and 0.3% formic acid according to the weight of the leather to the drum, rotate for 30 minutes, then add 1.5% TJ-706 fatty aldehyde, rotate for 40 minutes, then add 2% aluminum Tannin, turn for 60 minutes;

[0046] Step 3, alkali extraction: add 50% water and 1% sodium formate according to the weight of the leather to the drum, rotate for 20 minutes, then add 0.5% sodium bicarbonate, rotate for 30 minutes, drain the drum, and then add water to carry out wash and drain;

[0047] Step 4,...

Embodiment 2

[0054] A production process for anti-yellowing and light-resistant split leather, comprising the steps of:

[0055] Step 1, rehumidification: take the second layer of leather and put it in the drum, add 150% of 40°C water and 0.3% of Eusapon OC degreasing agent according to the weight of the leather to the drum, rotate for 60min, and then add 0.3% Oxalic acid, rotate for 80 minutes, drain the drum, then add water to wash and drain twice;

[0056] Step 2, retanning: add 50% water at 20°C and 0.1% formic acid according to the weight of the leather to the drum, rotate for 40 minutes, then add 1% TJ-706 fatty aldehyde, rotate for 50 minutes, then add 1% aluminum Tannin, turn for 80 minutes;

[0057] Step 3, alkali extraction: add 40% water and 0.6% sodium formate according to the weight of the leather to the drum, rotate for 30 minutes, then add 0.2% sodium bicarbonate, rotate for 40 minutes, drain the drum, and then add water to carry out wash and drain;

[0058] Step 4, neutr...

Embodiment 3

[0065] A production process for anti-yellowing and light-resistant split leather, comprising the steps of:

[0066] Step 1, rehumidification: take the second layer of leather and put it in the drum, add 300% of 50°C water and 1% of Eusapon OC degreasing agent according to the weight of the leather to the drum, rotate for 30min, and then add 1% Oxalic acid, rotate for 50 minutes, drain the drum, then add water to wash and drain twice;

[0067] Step 2, retanning: add 180% of 30°C water and 0.8% formic acid according to the weight of the leather to the drum, rotate for 20 minutes, then add 3% TJ-706 fatty aldehyde, rotate for 30 minutes, then add 5% aluminum Tannin, turn for 50 minutes;

[0068] Step 3, alkali extraction: add 80% water and 2% sodium formate according to the weight of the leather to the drum, rotate for 10 minutes, then add 0.8% sodium bicarbonate, rotate for 20 minutes, drain the drum, and then add water to carry out wash and drain;

[0069] Step 4, neutraliza...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com