A kind of production process of anti-yellowing and anti-light split leather

A production process, the technology of two-layer leather, which is applied in the fields of leather/skin/leather/raw hide chemical treatment equipment, leather softening, leather impregnation, etc. The effect of yellowing resistance and light resistance, good abrasion and fading resistance, and simple and easy production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

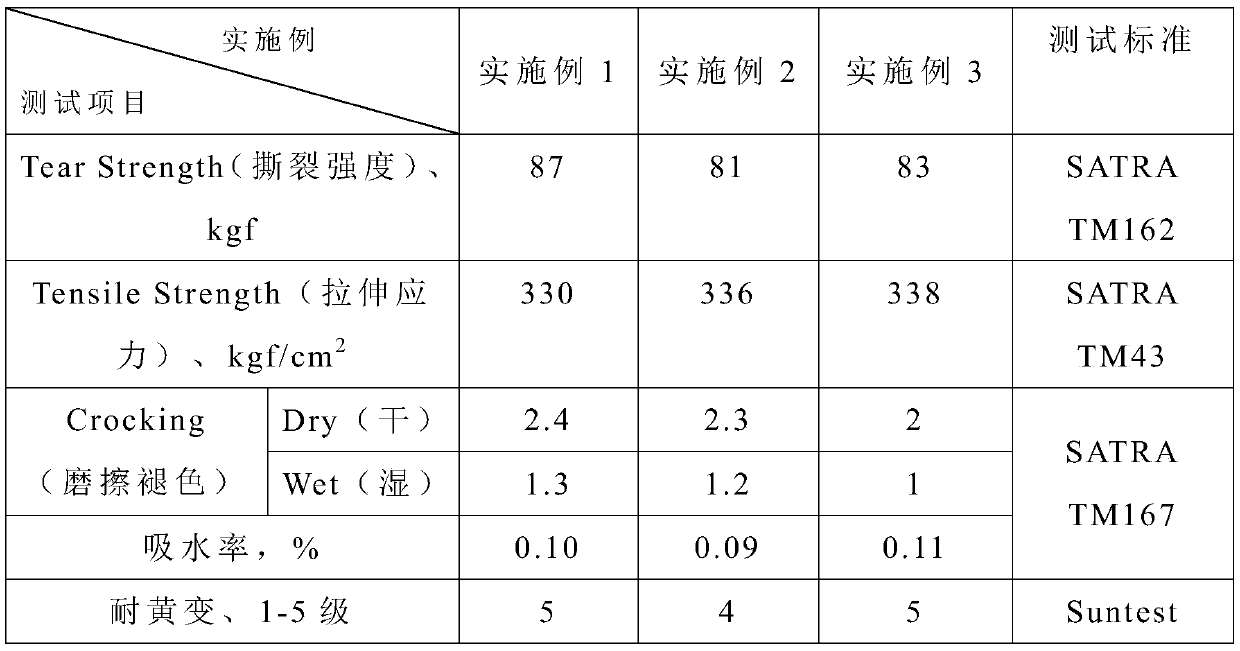

Examples

Embodiment 1

[0043] A production process for anti-yellowing and light-resistant split leather, comprising the steps of:

[0044] Step 1, rehumidification: take the second layer of leather and put it in the drum, add 200% of 45°C water and 0.5% of Eusapon OC degreasing agent according to the weight of the leather to the drum, rotate for 40 minutes, and then add 0.5% Oxalic acid, rotate for 60 minutes, drain the drum, then add water to wash and drain twice;

[0045] Step 2, retanning: add 100% water at 25°C and 0.3% formic acid according to the weight of the leather to the drum, rotate for 30 minutes, then add 1.5% TJ-706 fatty aldehyde, rotate for 40 minutes, then add 2% aluminum Tannin, turn for 60 minutes;

[0046] Step 3, alkali extraction: add 50% water and 1% sodium formate according to the weight of the leather to the drum, rotate for 20 minutes, then add 0.5% sodium bicarbonate, rotate for 30 minutes, drain the drum, and then add water to carry out wash and drain;

[0047] Step 4,...

Embodiment 2

[0054] A production process for anti-yellowing and light-resistant split leather, comprising the steps of:

[0055] Step 1, rehumidification: take the second layer of leather and put it in the drum, add 150% of 40°C water and 0.3% of Eusapon OC degreasing agent according to the weight of the leather to the drum, rotate for 60min, and then add 0.3% Oxalic acid, rotate for 80 minutes, drain the drum, then add water to wash and drain twice;

[0056] Step 2, retanning: add 50% water at 20°C and 0.1% formic acid according to the weight of the leather to the drum, rotate for 40 minutes, then add 1% TJ-706 fatty aldehyde, rotate for 50 minutes, then add 1% aluminum Tannin, turn for 80 minutes;

[0057] Step 3, alkali extraction: add 40% water and 0.6% sodium formate according to the weight of the leather to the drum, rotate for 30 minutes, then add 0.2% sodium bicarbonate, rotate for 40 minutes, drain the drum, and then add water to carry out wash and drain;

[0058] Step 4, neutr...

Embodiment 3

[0065] A production process for anti-yellowing and light-resistant split leather, comprising the steps of:

[0066] Step 1, rehumidification: take the second layer of leather and put it in the drum, add 300% of 50°C water and 1% of Eusapon OC degreasing agent according to the weight of the leather to the drum, rotate for 30min, and then add 1% Oxalic acid, rotate for 50 minutes, drain the drum, then add water to wash and drain twice;

[0067] Step 2, retanning: add 180% of 30°C water and 0.8% formic acid according to the weight of the leather to the drum, rotate for 20 minutes, then add 3% TJ-706 fatty aldehyde, rotate for 30 minutes, then add 5% aluminum Tannin, turn for 50 minutes;

[0068] Step 3, alkali extraction: add 80% water and 2% sodium formate according to the weight of the leather to the drum, rotate for 10 minutes, then add 0.8% sodium bicarbonate, rotate for 20 minutes, drain the drum, and then add water to carry out wash and drain;

[0069] Step 4, neutraliza...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com