Patents

Literature

103 results about "Linked protein" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

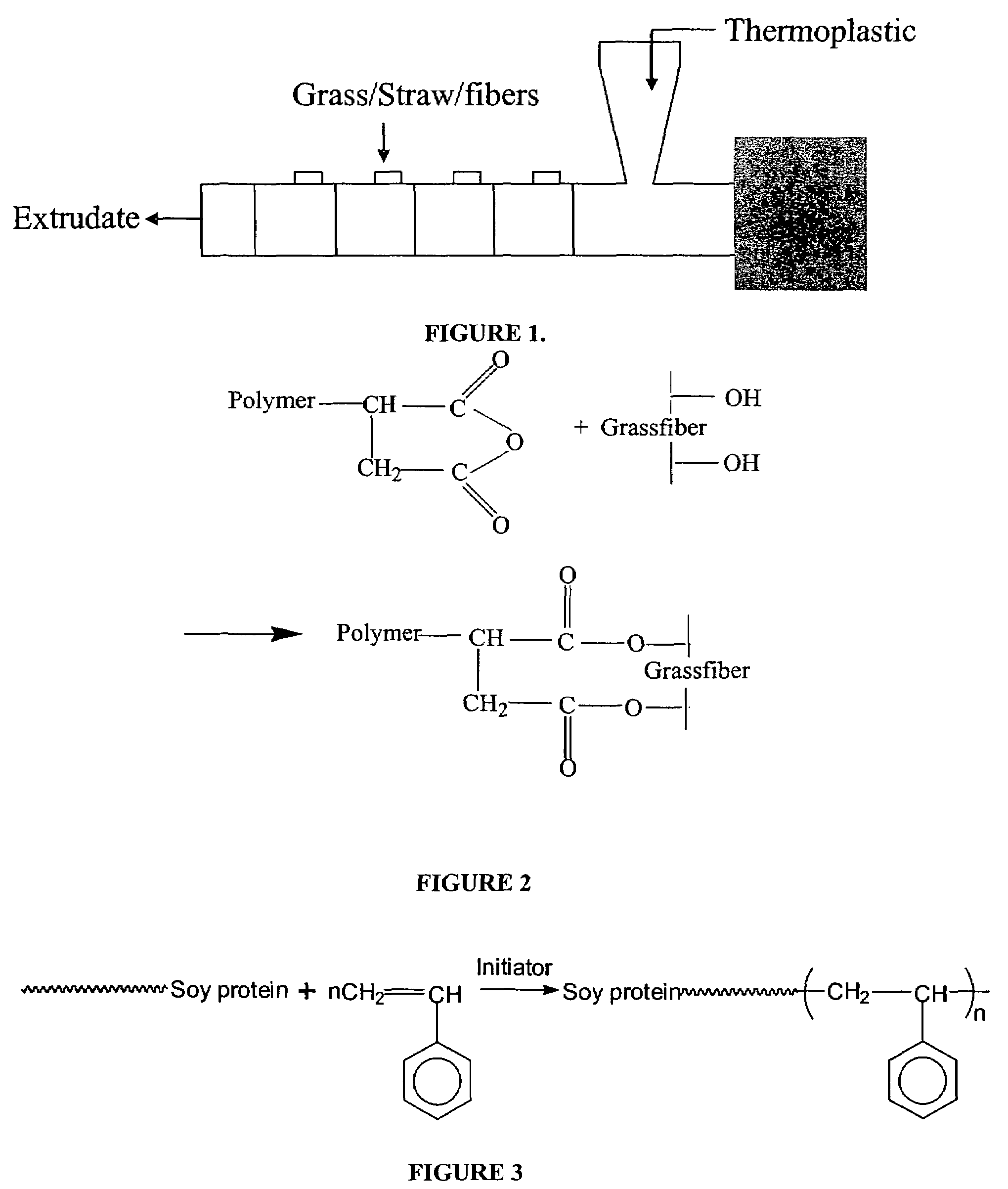

Cellulosic biomass soy flour based biocomposites and process for manufacturing thereof

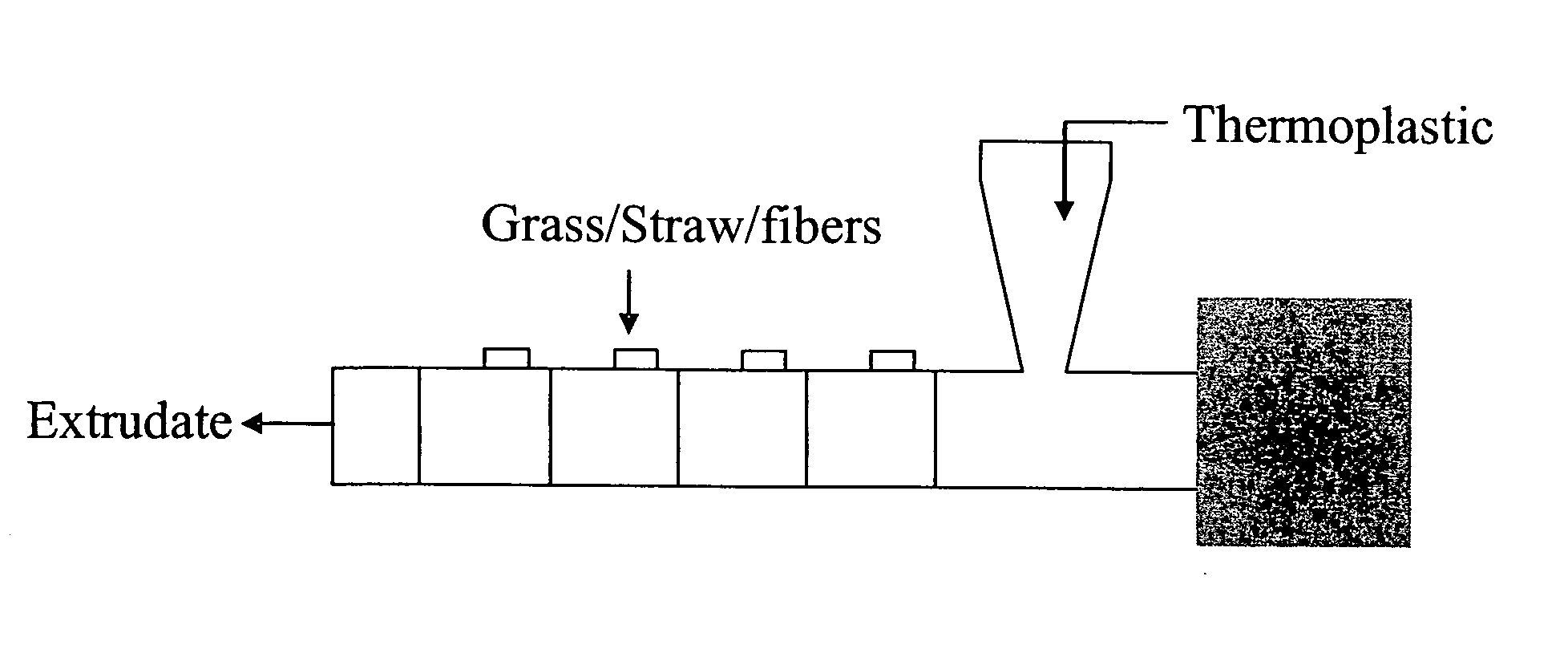

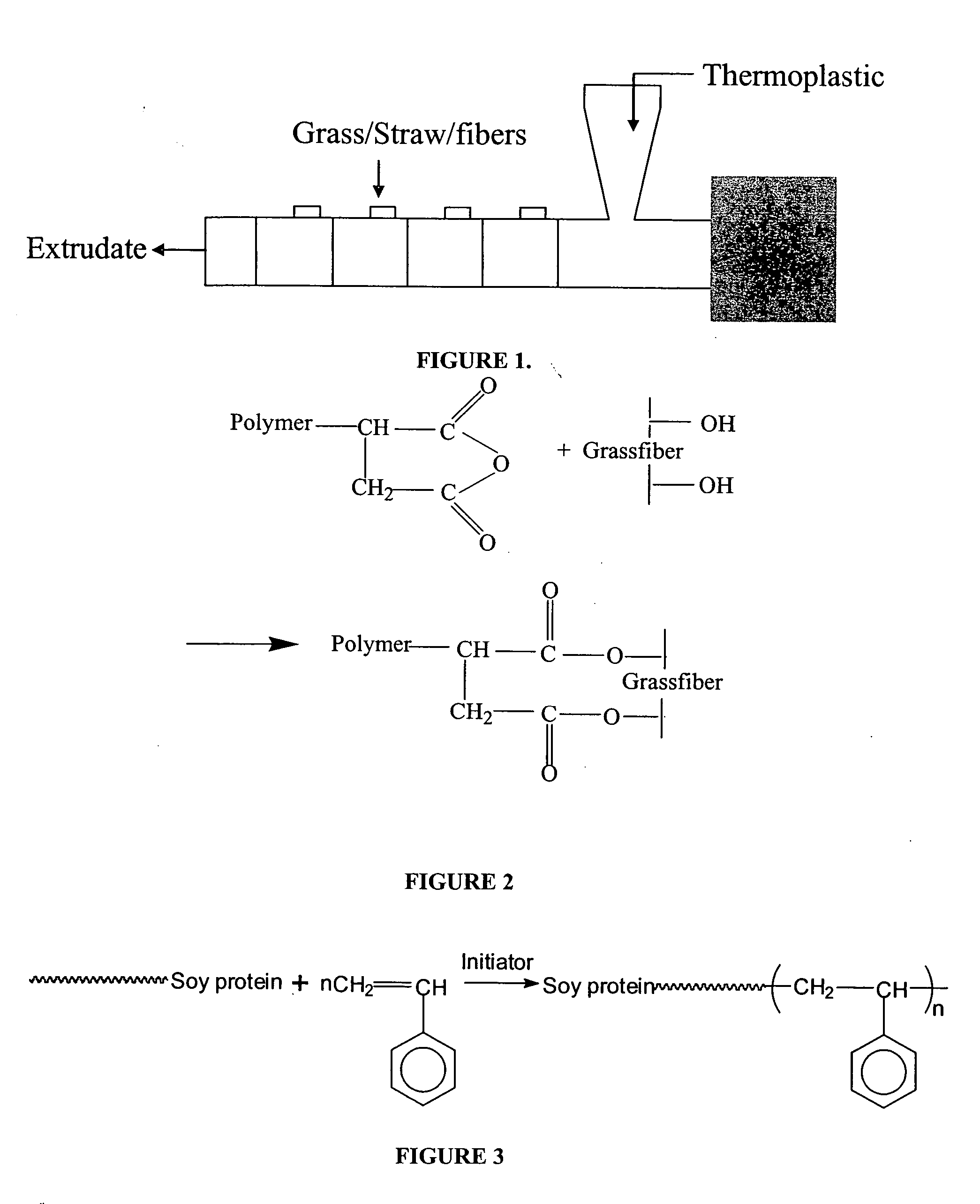

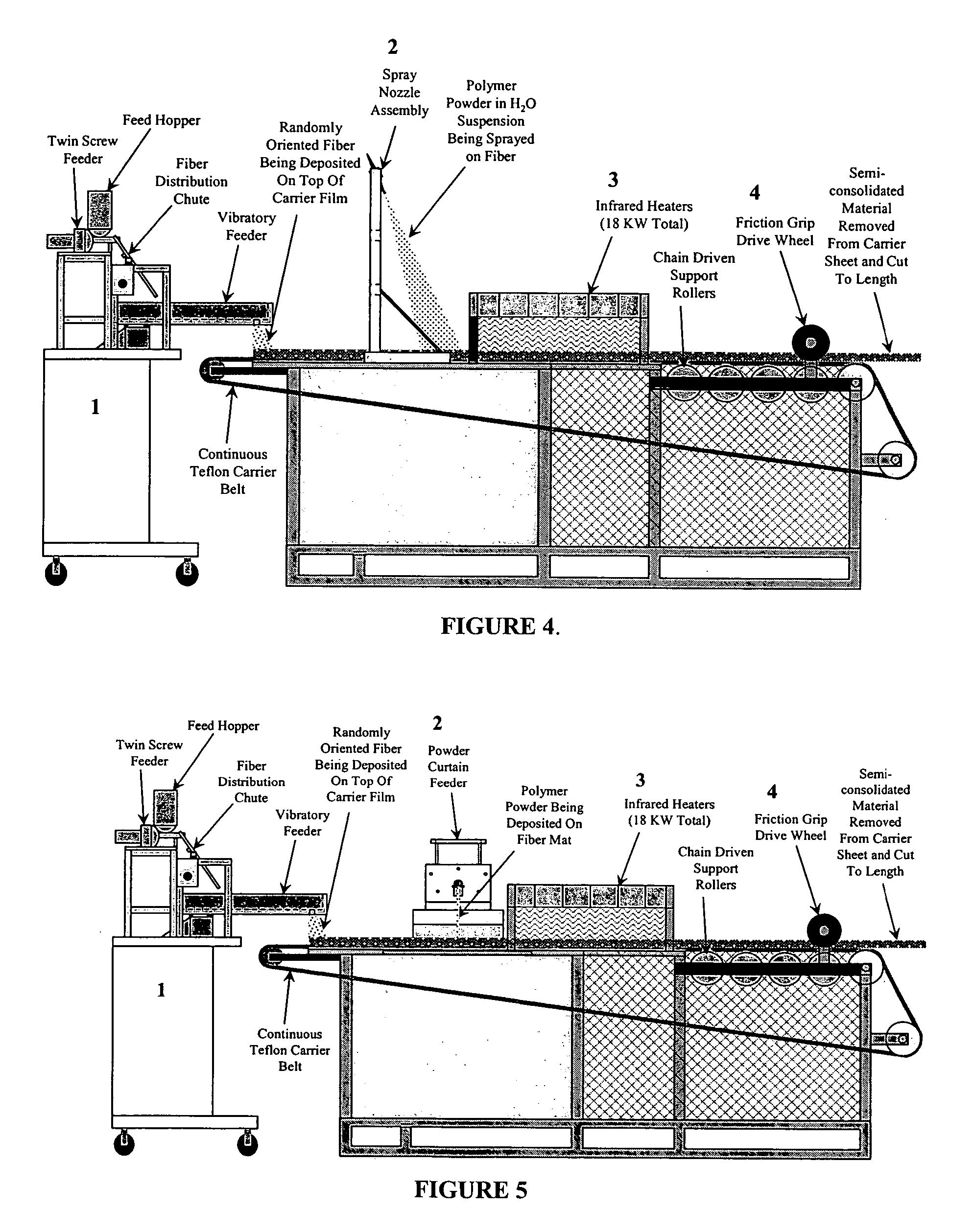

A process for the manufacture of natural fiber and polymer composites is described. Thermoplastically processed plasticized soy flour based plastics are used with thermoplastic polymers. Polymers of soy flour and an in situ polymerized polyvinyl polymer which links proteins and carbohydrates in the flour to form the polymer are used. The composites are useful in engineering materials.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

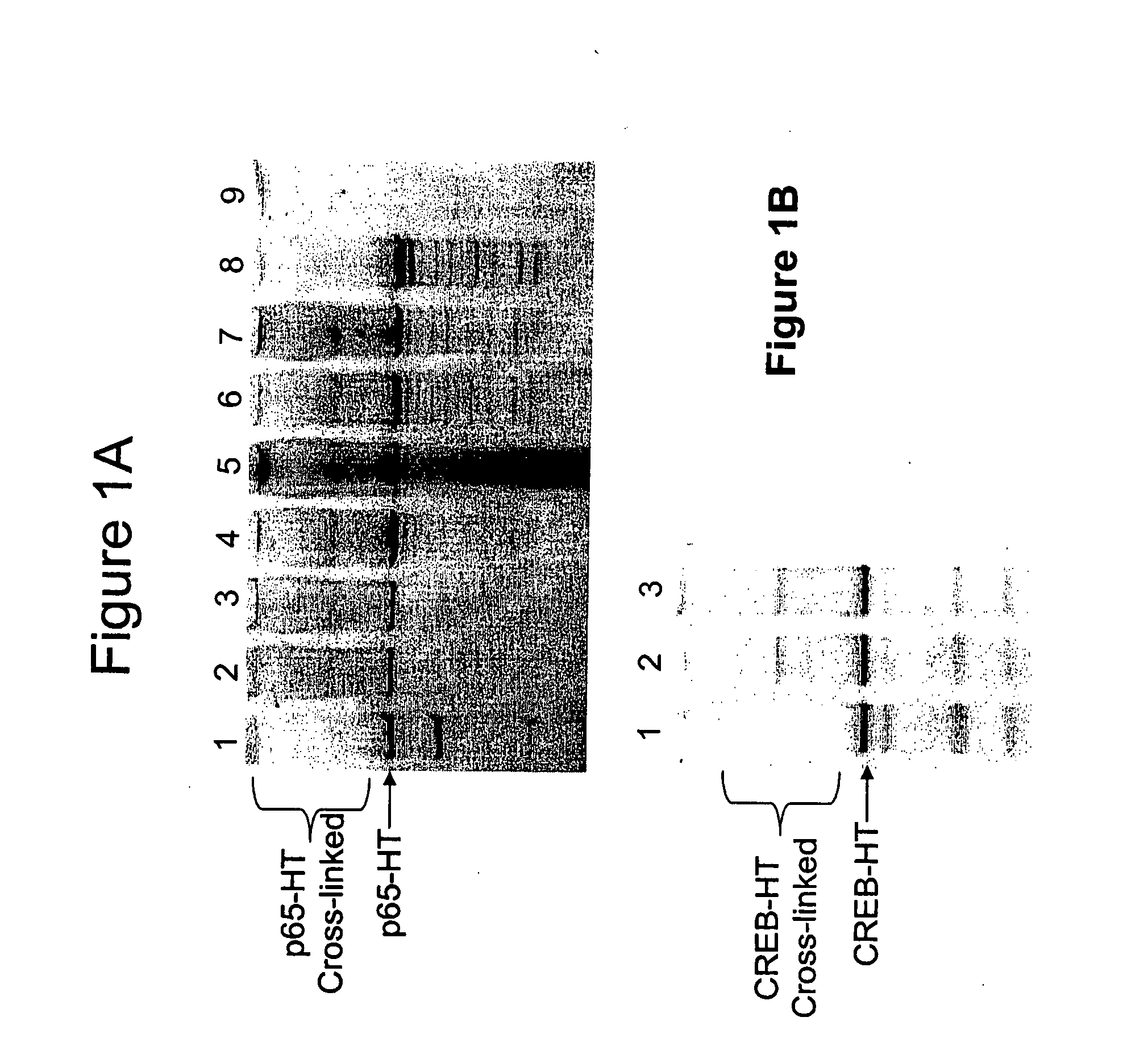

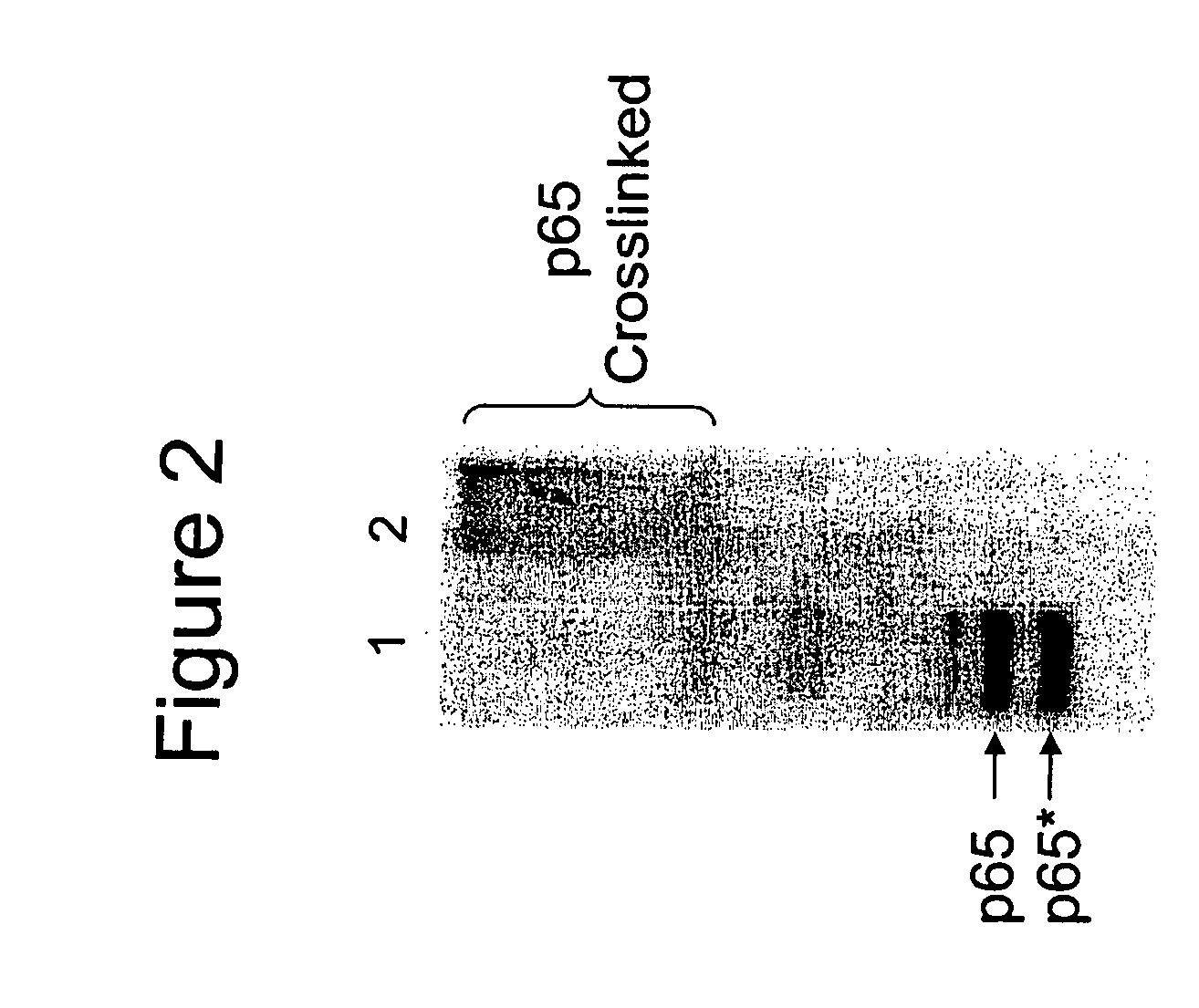

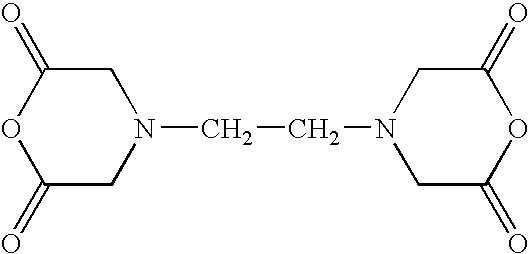

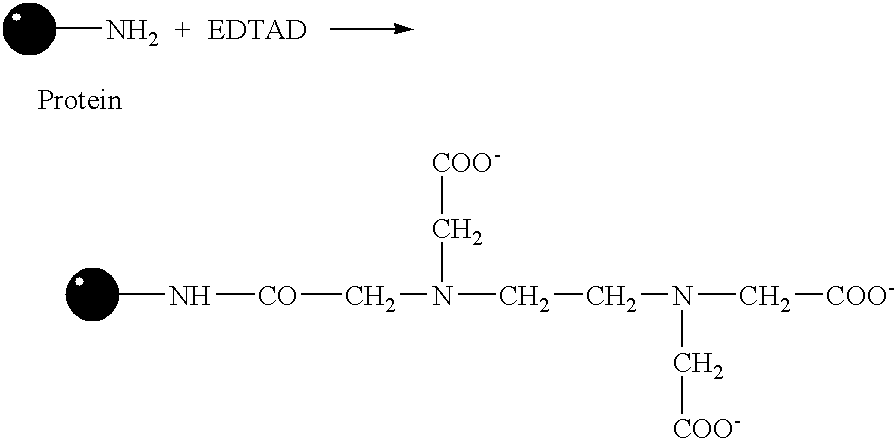

Compositions and methods for capturing and analyzing cross-linked biomolecules

InactiveUS20070224620A1Microbiological testing/measurementBiological testingCrystallographyCross-link

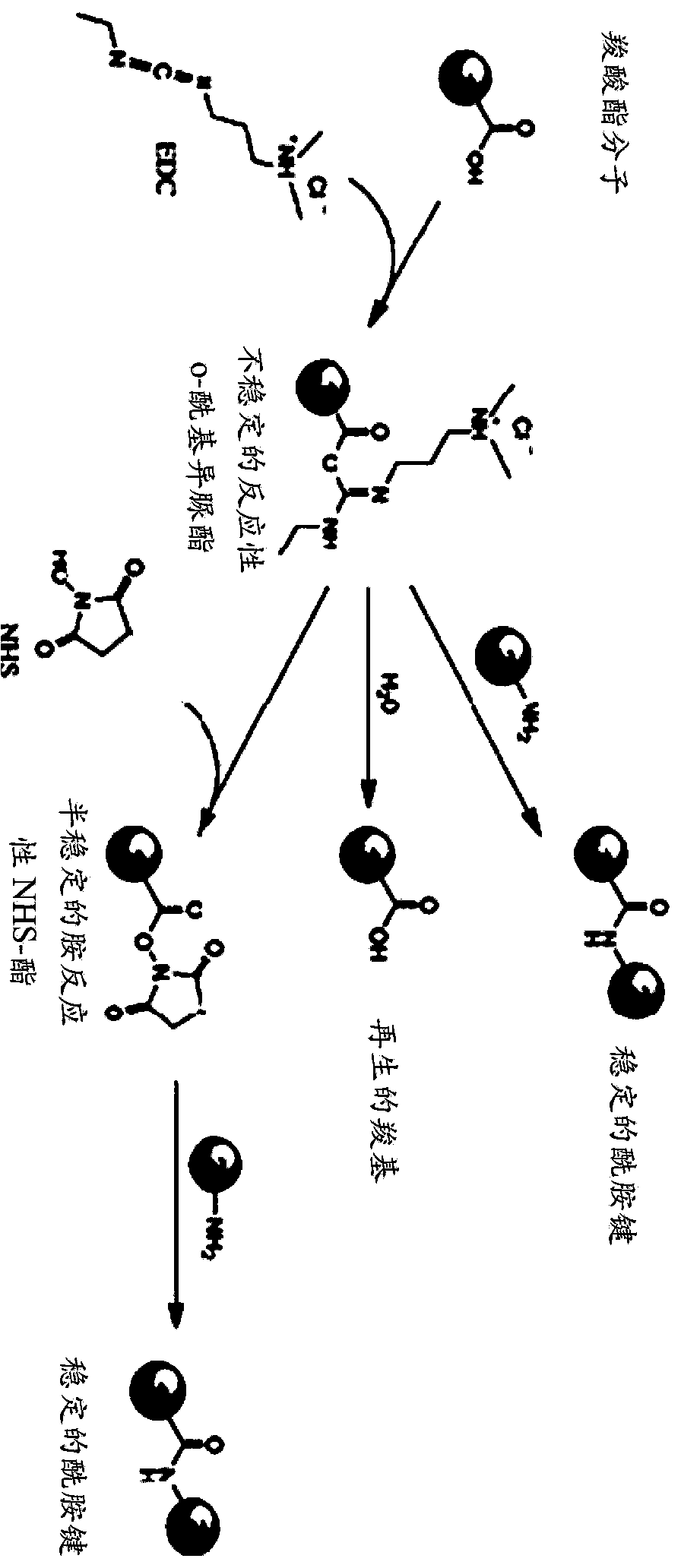

Methods, compositions and kits to capture cross-linked protein complexes to a support matrix in a stable, covalent bridge of attachment are provided.

Owner:PROMEGA

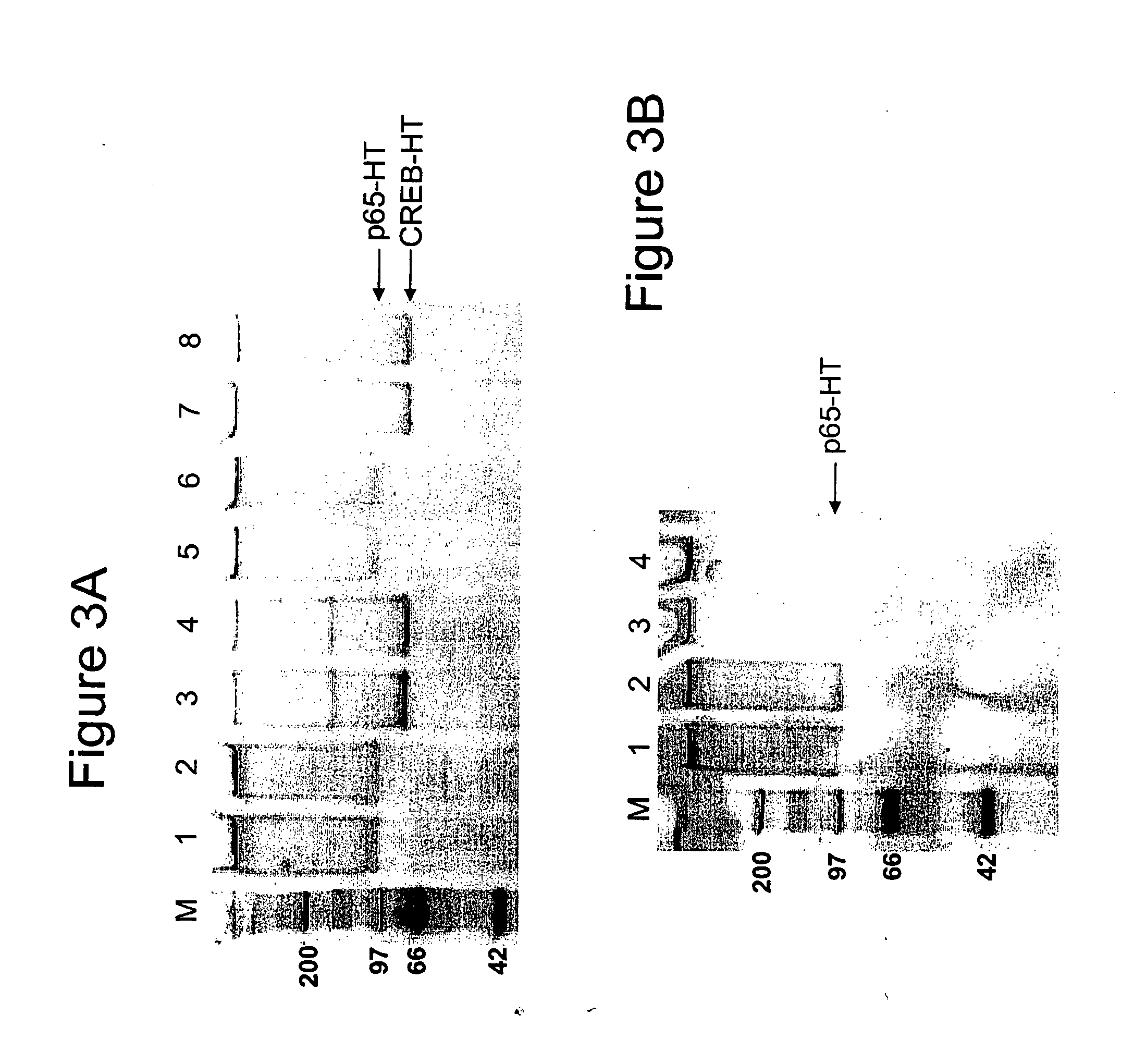

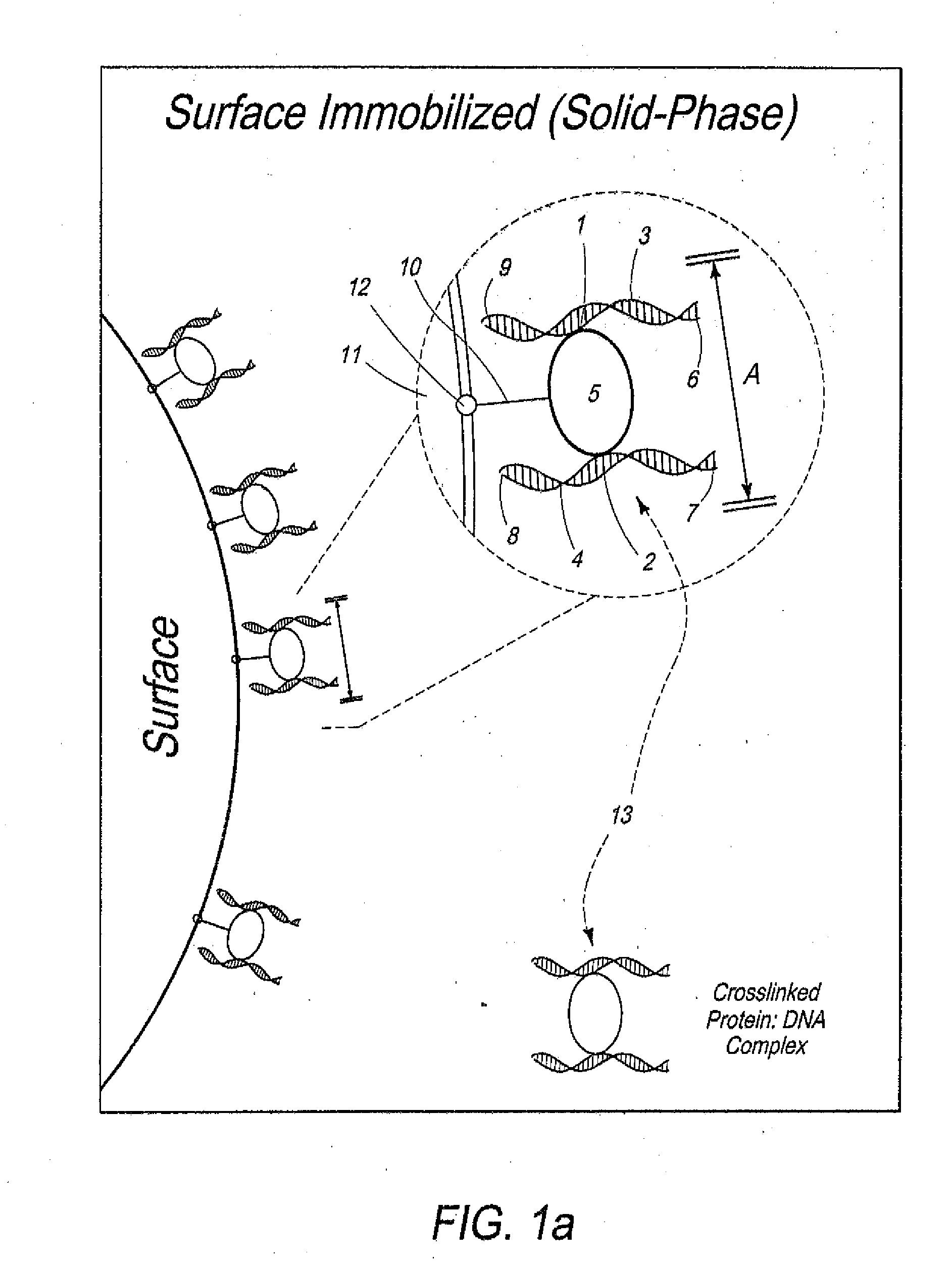

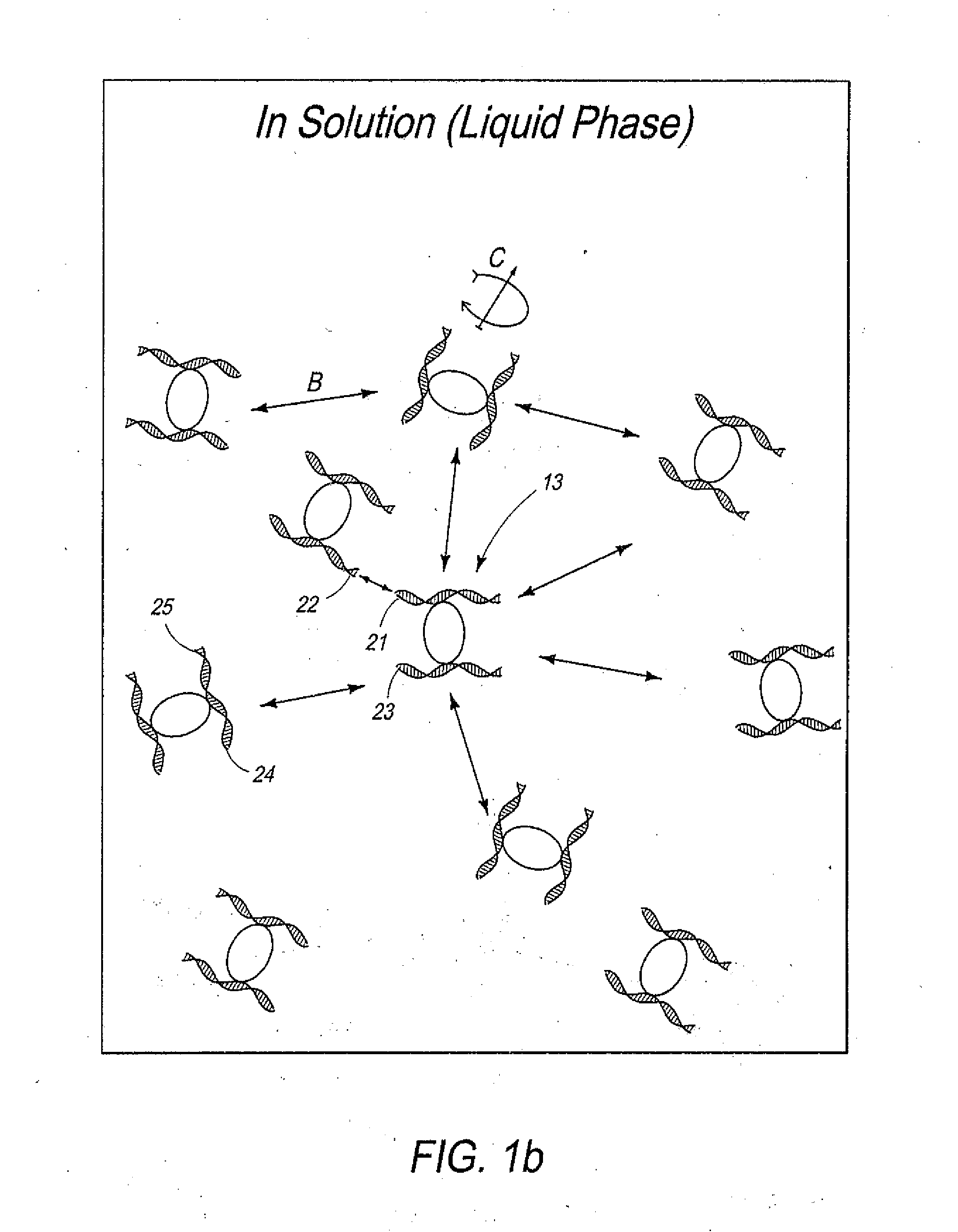

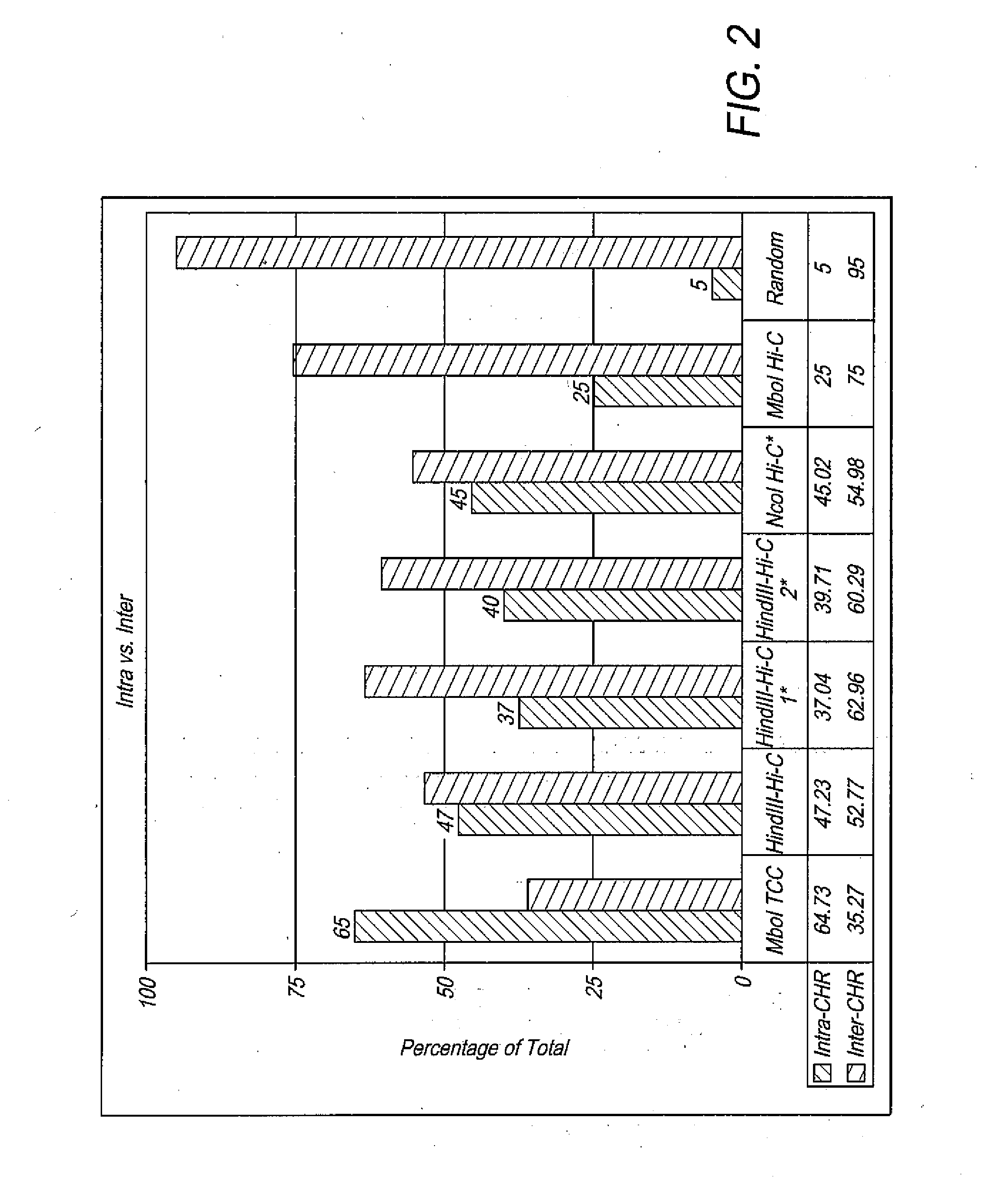

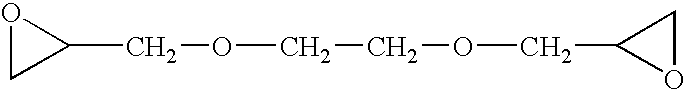

Tethered Conformation Capture

InactiveUS20110287947A1High resolutionReduce noiseMicrobiological testing/measurementLibrary screeningCross-linkEnzyme

Disclosed are methods and systems for determining the three-dimensional structure of chromatin in eukaryotic cells. More specifically, disclosed are methods and systems for obtaining chromatin structural information by surface immobilization, i.e tethering crosslinked protein:DNA complexes and / or ligated DNA complexes to media such as beads, gels, and or matrices during the conformation capture assay. In general, the method includes contacting a cell with a cross-linking reagent to cross-link DNA and protein in the cell; lysing the cell, producing cross-linked protein:DNA complexes by cutting the chromatin using a chemical, physical or enzymatic method, substantially immobilizing the cross-linked protein:DNA complexes, ligating the cross-linked protein:DNA complexes intramolecularly such that the ligated protein:DNA complexes represent structural organization of the chromatin; characterizing the ligated DNA by sequencing or other methods; and identifying any structural organization of the chromatin. The structural organization preferably includes information relating to interacting loci of the chromatin.

Owner:UNIV OF SOUTHERN CALIFORNIA

Protein-polysaccharide hybrid hydrogels

InactiveUS6821331B2Improve featuresIncrease contentProtein waste adhesivesOther chemical processesCross-linkHybrid protein

Disclosed is a hybrid protein-polysaccharide superabsorbent hydrogel. The hydrogel includes two interpenetrating matrices: a first matrix which is an acylated, cross-linked protein matrix, and a second matrix which is an anionic polysaccharidc matrix. The two matrices can be non-cross-linked, or the hydrogel can further include bridging moieties that covalently cross-linking the acylated, cross-linked protein matrix to the anionic polysaccharide matrix.

Owner:WISCONSIN ALUMNI RES FOUND

Stabilized proteins

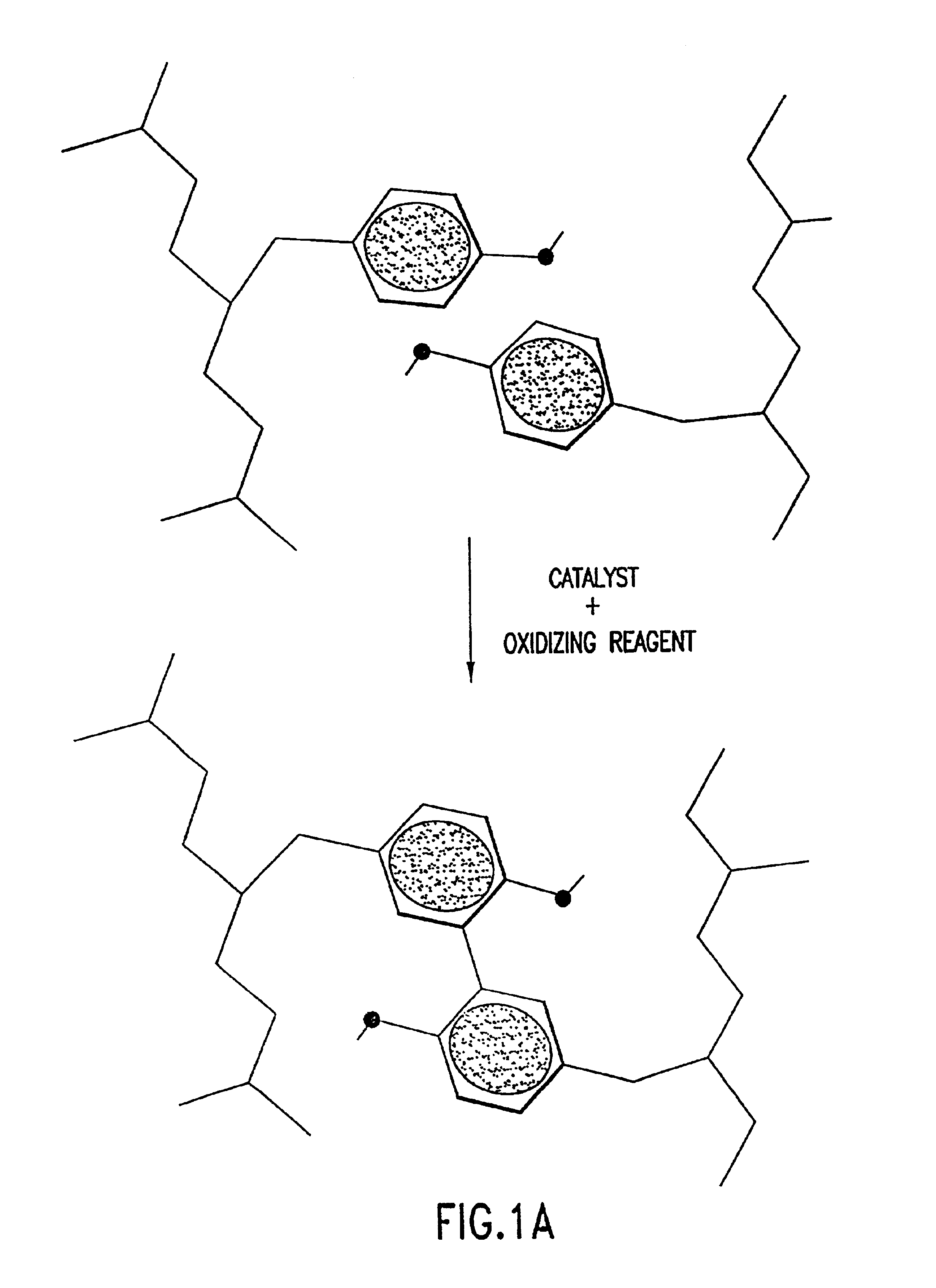

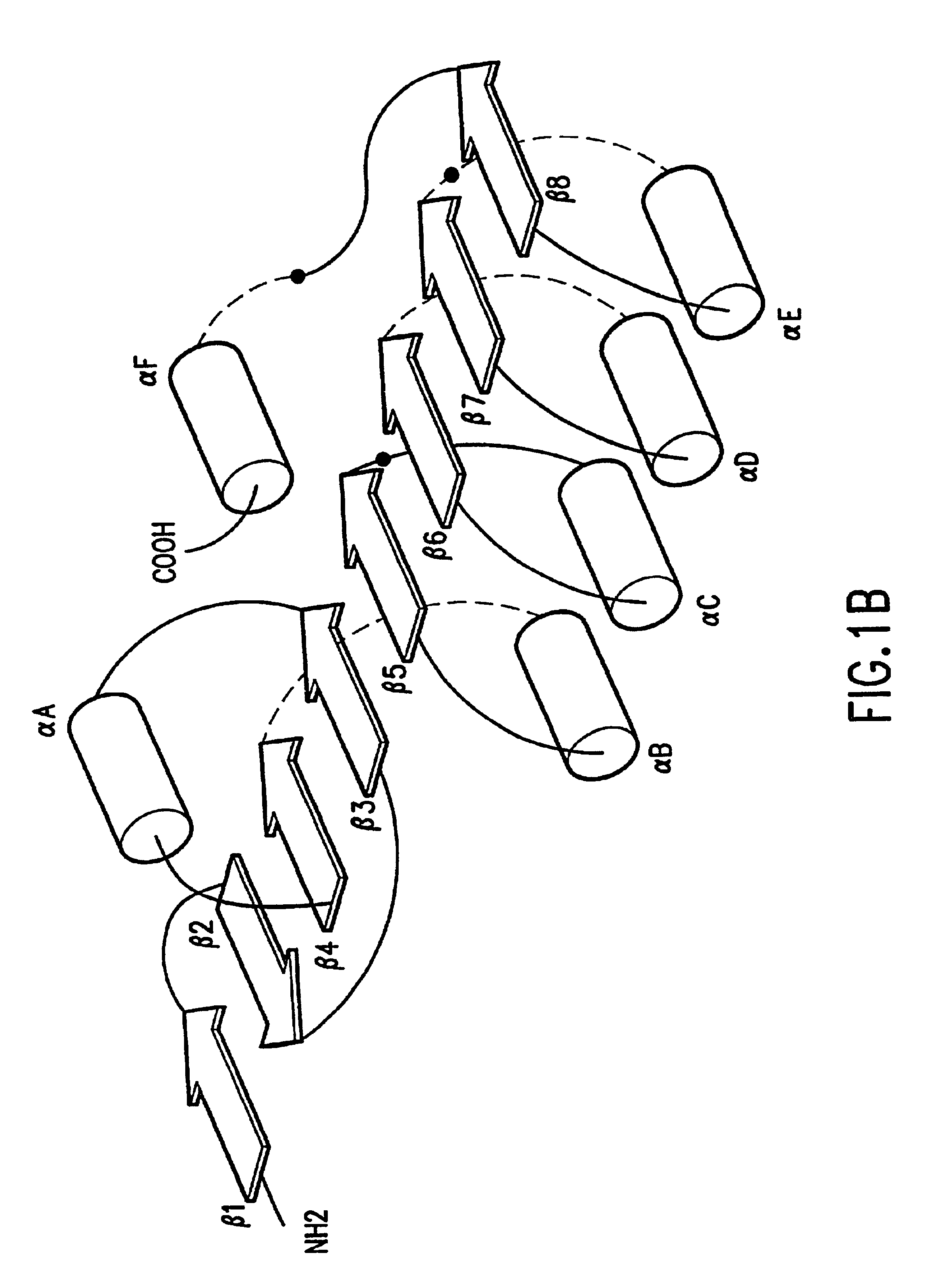

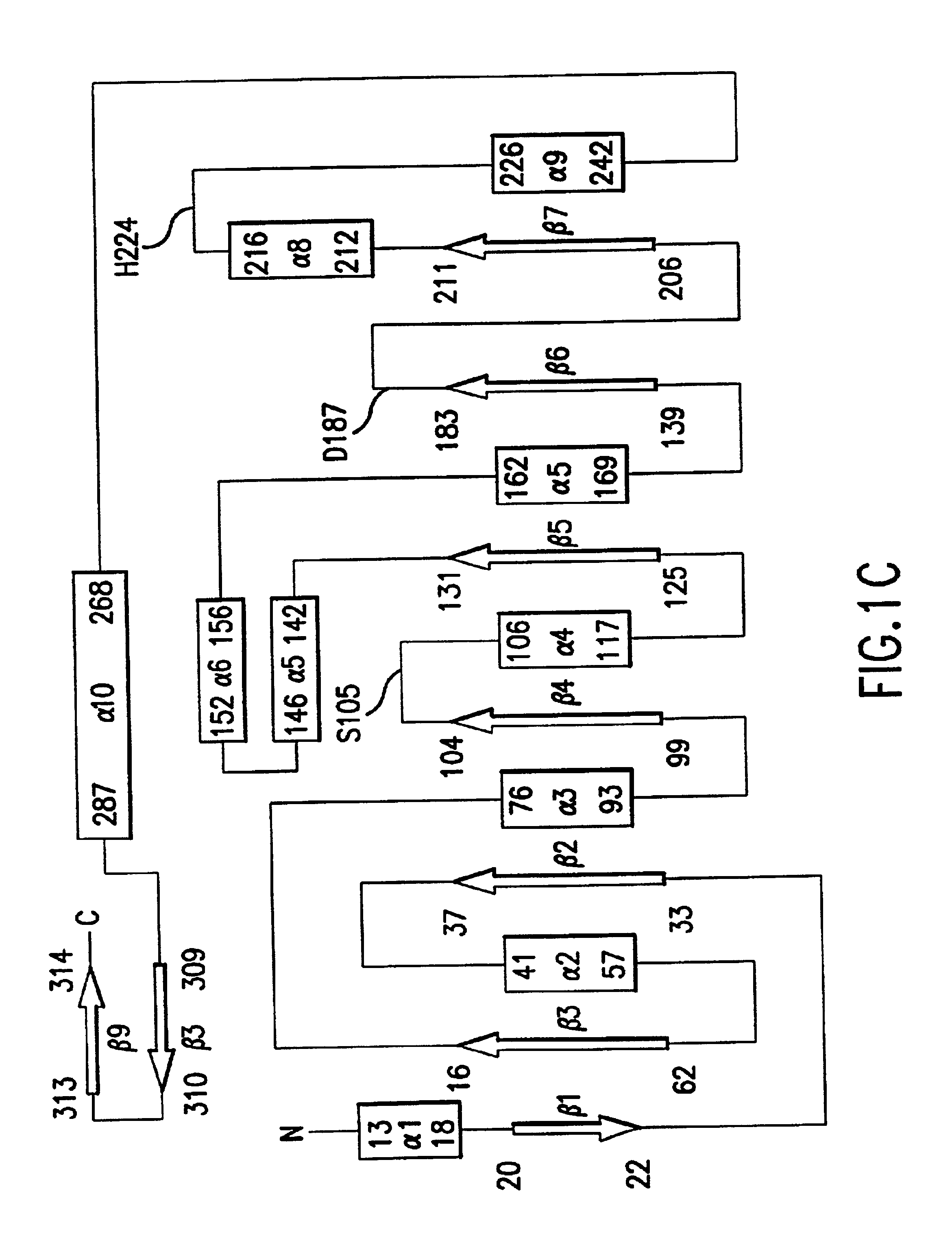

InactiveUS7037894B2Prevent undesired cross-linkControl cross-link reactionHormone peptidesPeptide/protein ingredientsTyrosineProtein retention

Isolated polypeptides or polypeptide chains are modified by di-tyrosine cross-linking such that the retain at least one functional activity. In one embodiment, the isolated polypeptide or polypeptide chains comprise at least one di-tyrosine cross-link, wherein at least one tyrosine of the di-tyrosine cross-link originates from a point mutation to tyrosine, and wherein the di-tyrosine cross-linked protein retains at least one function displayed by the protein in the absence of di-tyrosine cross-linking. In another embodiment, the di-tyrosine cross-linked polypeptide or polypeptide chain has enhanced stability compared to the same polypeptide or polypeptide chain in the absence of di-tyrosine cross-linking. A method for stabilization of a polypeptide or polypeptide complex, by the introduction of intra-polypeptide and / or inter-polypeptide di-tyrosine bonds, which simultaneously maintains the structure and function of the polypeptide or polypeptide complex is also described.

Owner:CALDER BIOSCI INC

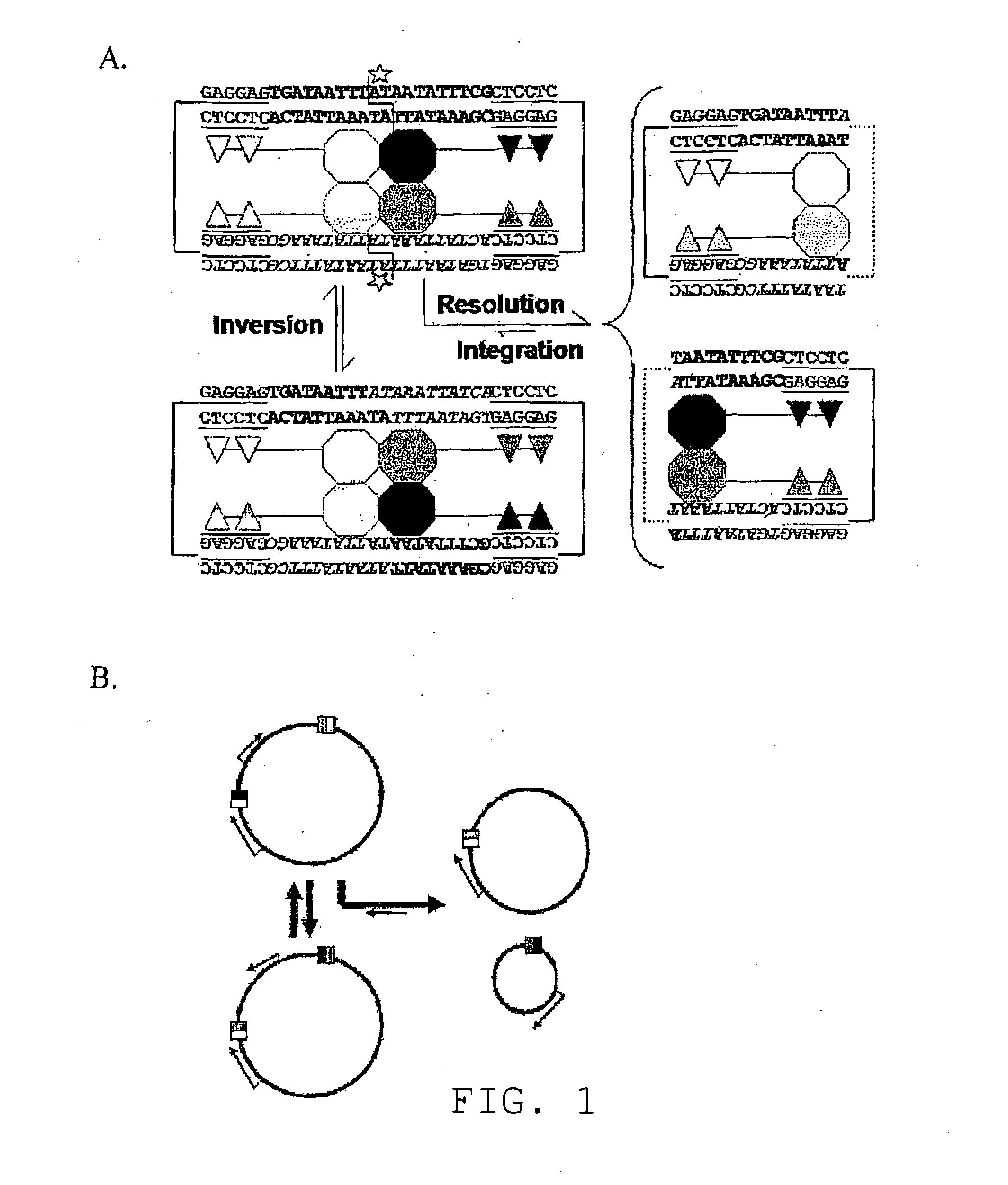

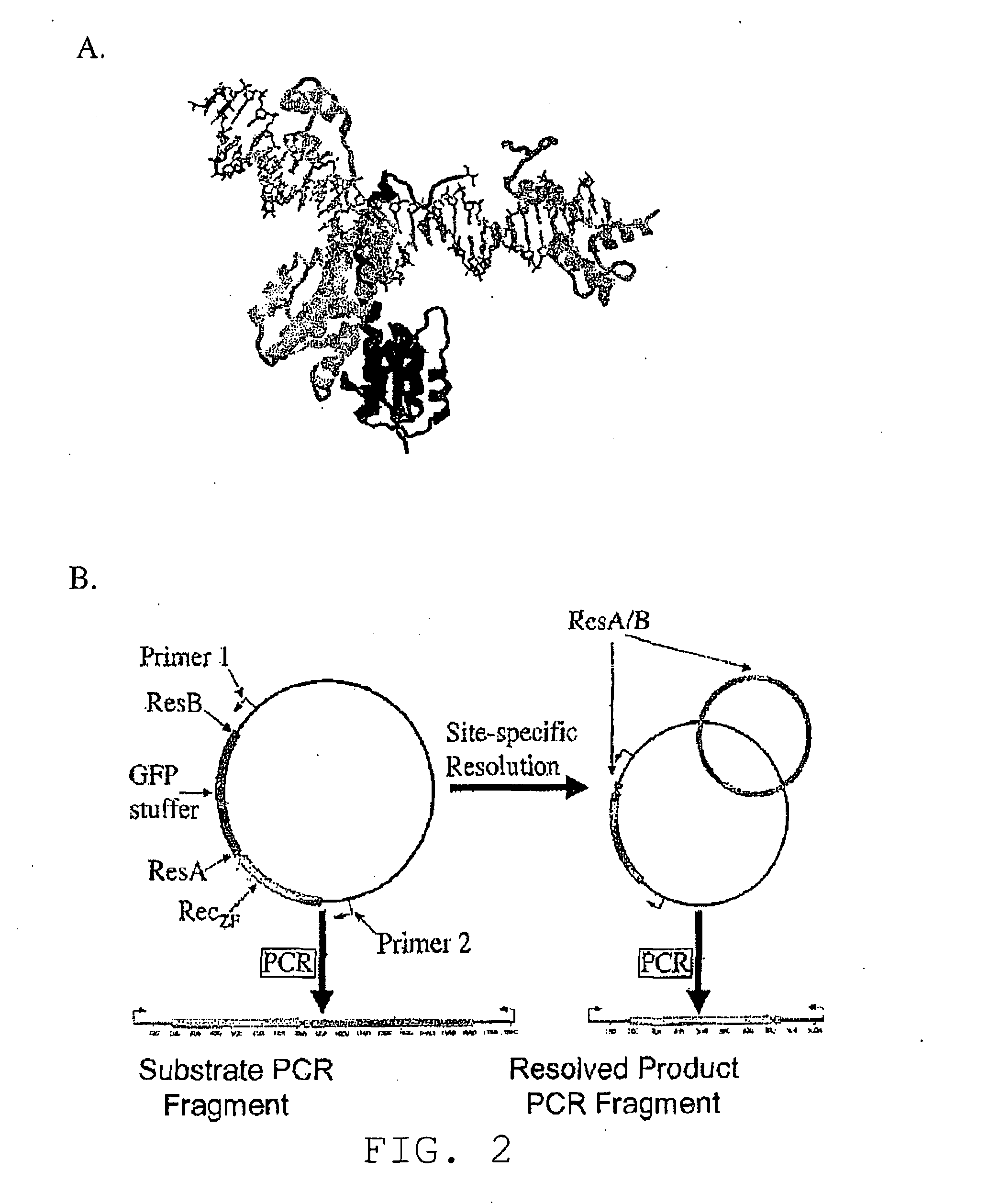

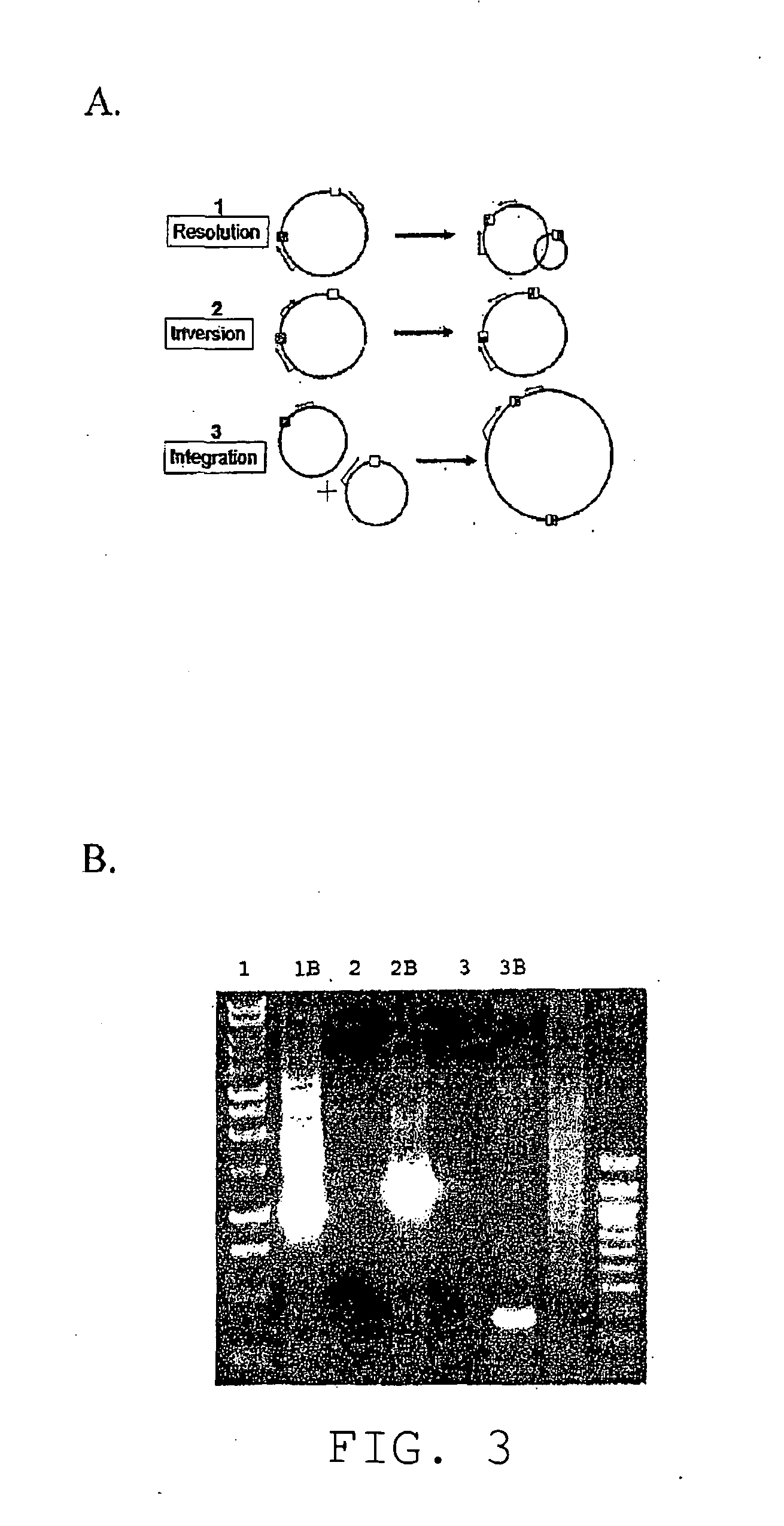

Chimeric zinc finger recombinases optimized for catalysis by directed evolution

InactiveUS20100086532A1Improved growth profileReduce nutritionFusion with DNA-binding domainBacteriaLinked proteinProtein evolution

The present invention is directed to chimeric recombinases comprising a serine recombinase operatively linked to a zinc finger nucleotide binding domain such that the chimeric recombinase protein catalyzes site-specific recombination at a DNA site specifically bound by the zinc finger nucleotide binding domain. The serine recombinase can be one of several naturally occurring serine recombinases. The invention also includes nucleic acids encoding the chimeric recombinases, vectors including the nucleic acids, host cells transformed or transfected with the vectors, methods of using the chimeric recombinases to carry out recombination, methods of using substrate-linked protein evolution to generate additional chimeric recombinases, methods of using the chimeric recombinases for gene therapy, and pharmaceutical compositions.

Owner:THE SCRIPPS RES INST

Plants with modified growth

InactiveUS6559358B1Improve the level ofModulating level of expression and activityClimate change adaptationOther foreign material introduction processesCell divisionPlant cell

A process is provided for modifying growth or architecture of plants by altering the level or the functional level of a cell division controlling protein, preferably a cell-division controlling protein that binds phosphorylates retinoblasoma-link proteins, more preferably a cyclin, particularly a D-type cyclin within cells of a plant. Also provided are chimeric genes comprising a transcribed DNA region encoding an RNA or a protein, which when expressed either increases or decreases the level or functional level of a cell-division controlling protein, and plant cells and plants expressing such chimeric genes.

Owner:CAMBRIDGE UNIV TECH SERVICES LTD

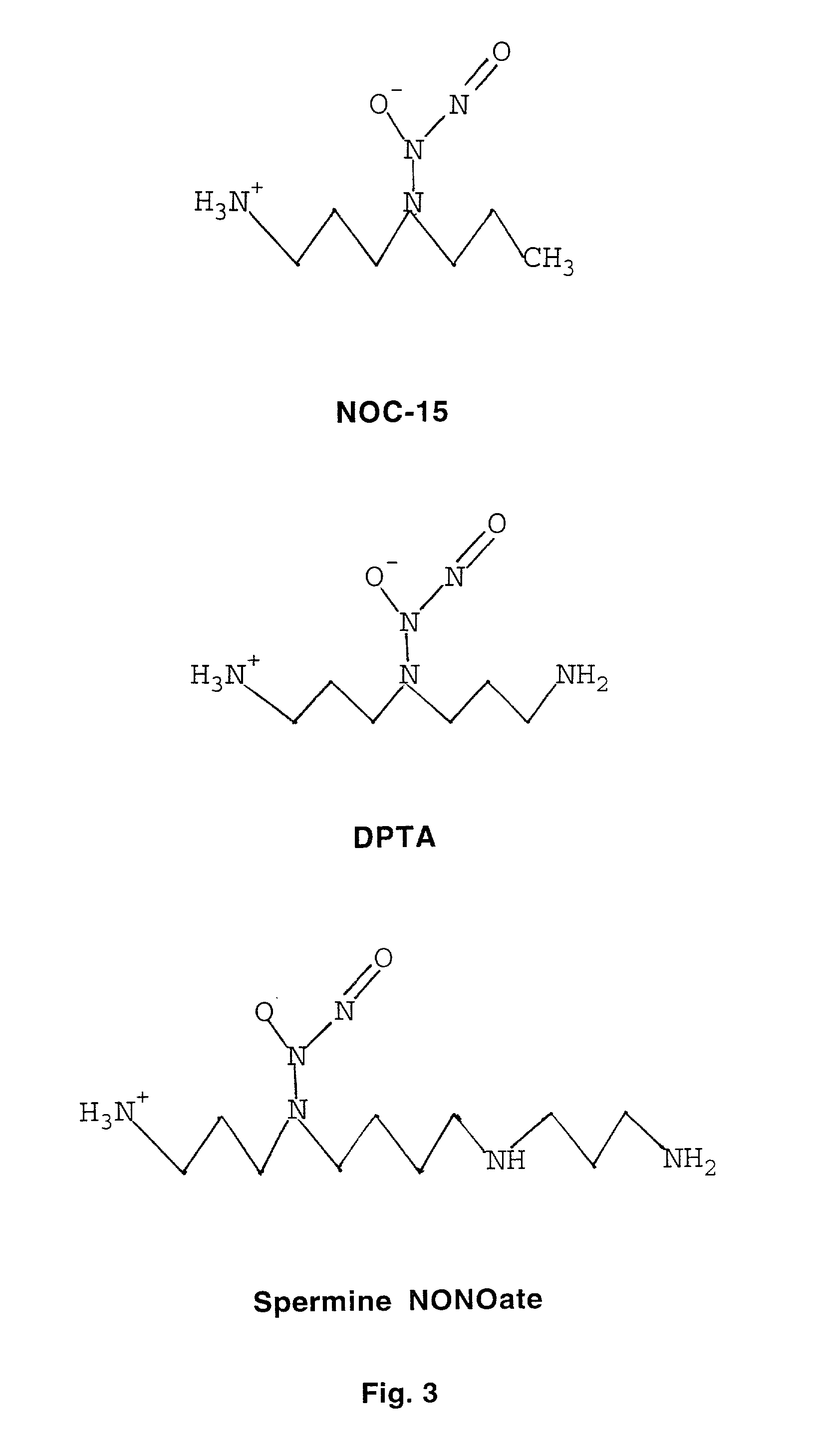

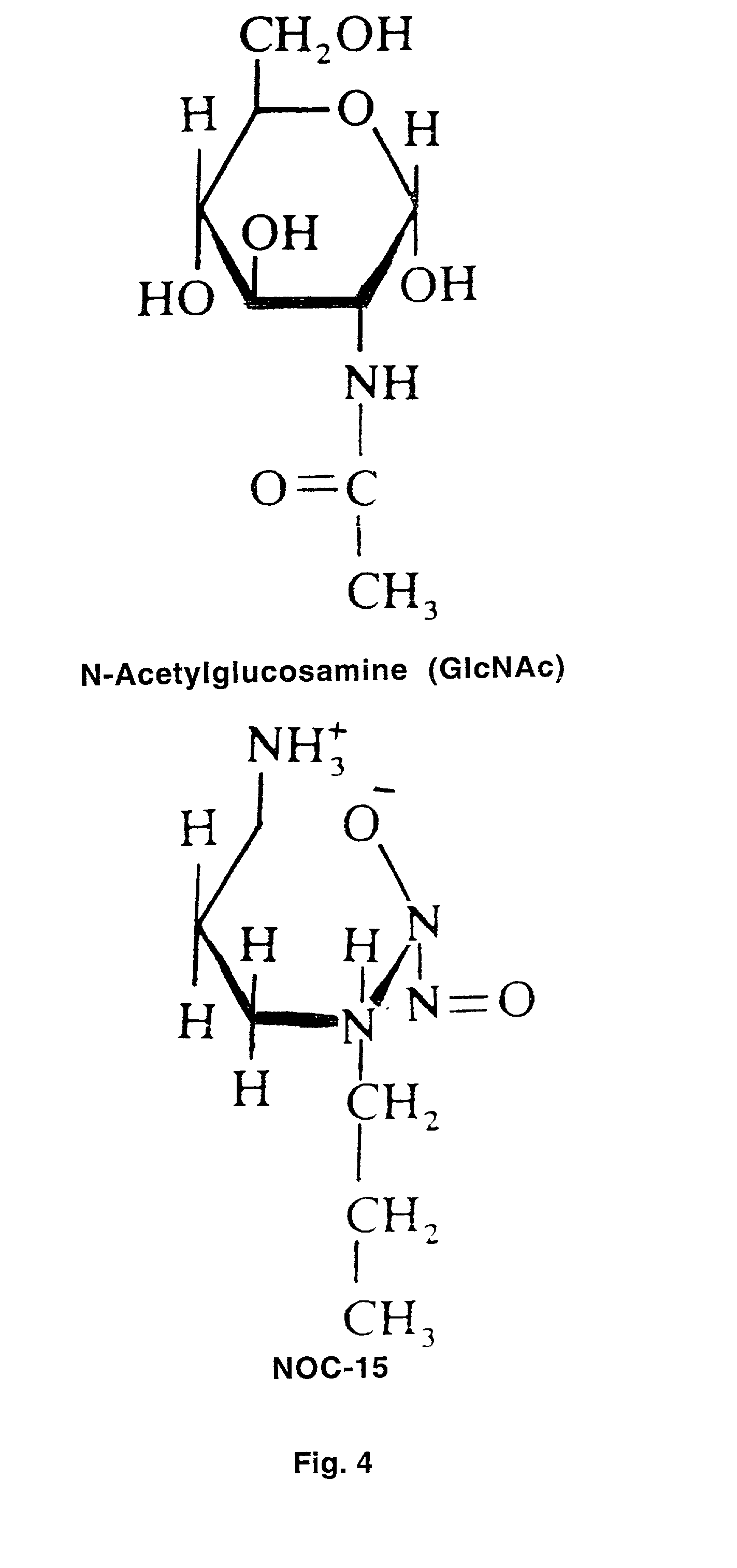

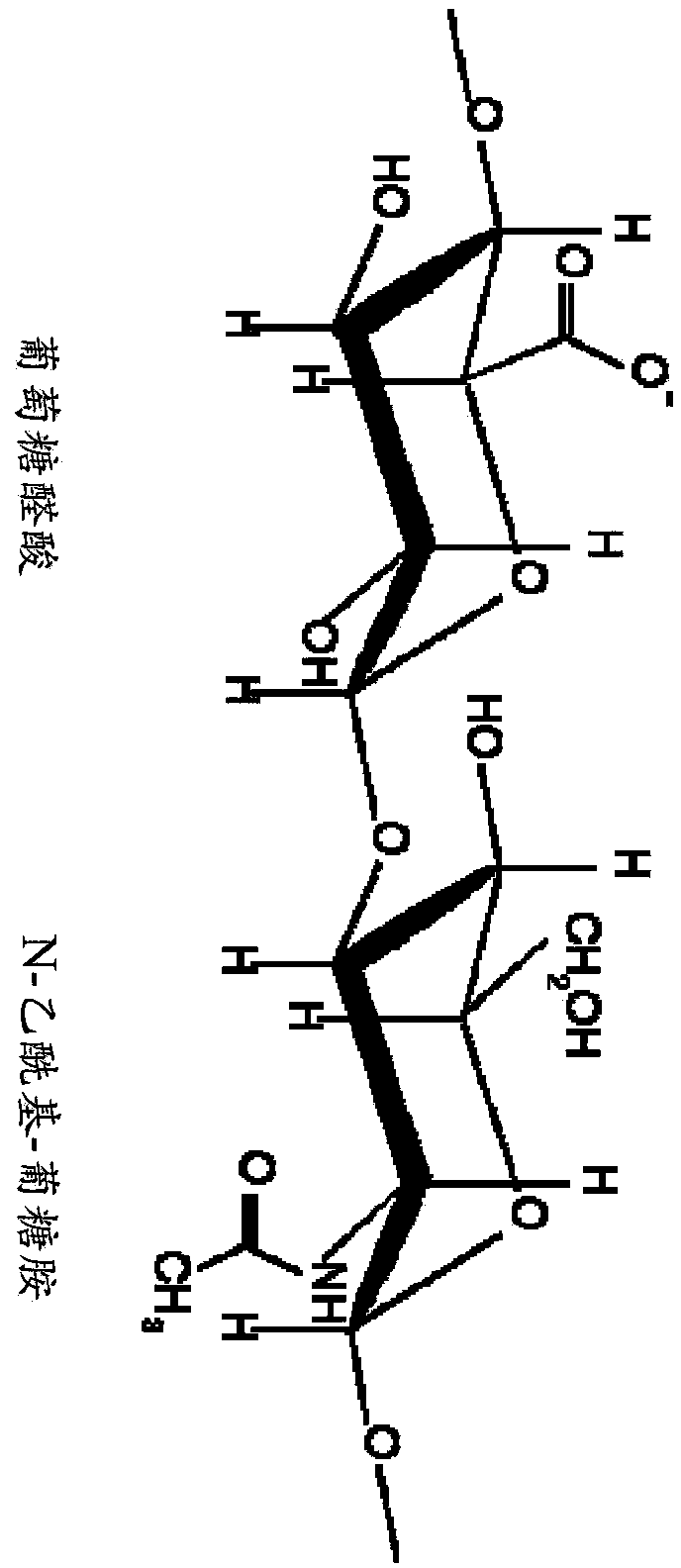

Prevention and/or treatment of diabetes mellitus by pharmacologically inhibiting pancreatic beta-cell O-linked protein glycosylation and/or pancreatic beta-cell p135 O-glycosylation

The present invention demonstrates a method for inhibiting O-linked protein glycosylation in a tissue or cell, comprising the step of contacting said tissue or cell with (Z)-1-[N-(3-Ammoniopropyl)-N-(n-propy- l)amino] diazen-ium-1,2-diolate or a derivative thereof. The present invention is also directed to a method of treating or inhibiting the onset of diabetes mellitis in an individual in need of such treatment, comprising the step of admininstering to said individual a pharmacological dose of a compound which inhibiting O-linked protein glycosylation in a tissue or cell of said individual. Further, the present invention provides a pharmaceutical composition, comprising (Z)-1-[N-(3-Ammoniopropyl)-N-(n-propyl)amino] diazen-ium-1,2-diolate and a pharmaceutically acceptable carrier or a derivative thereof.

Owner:UAB RES FOUND

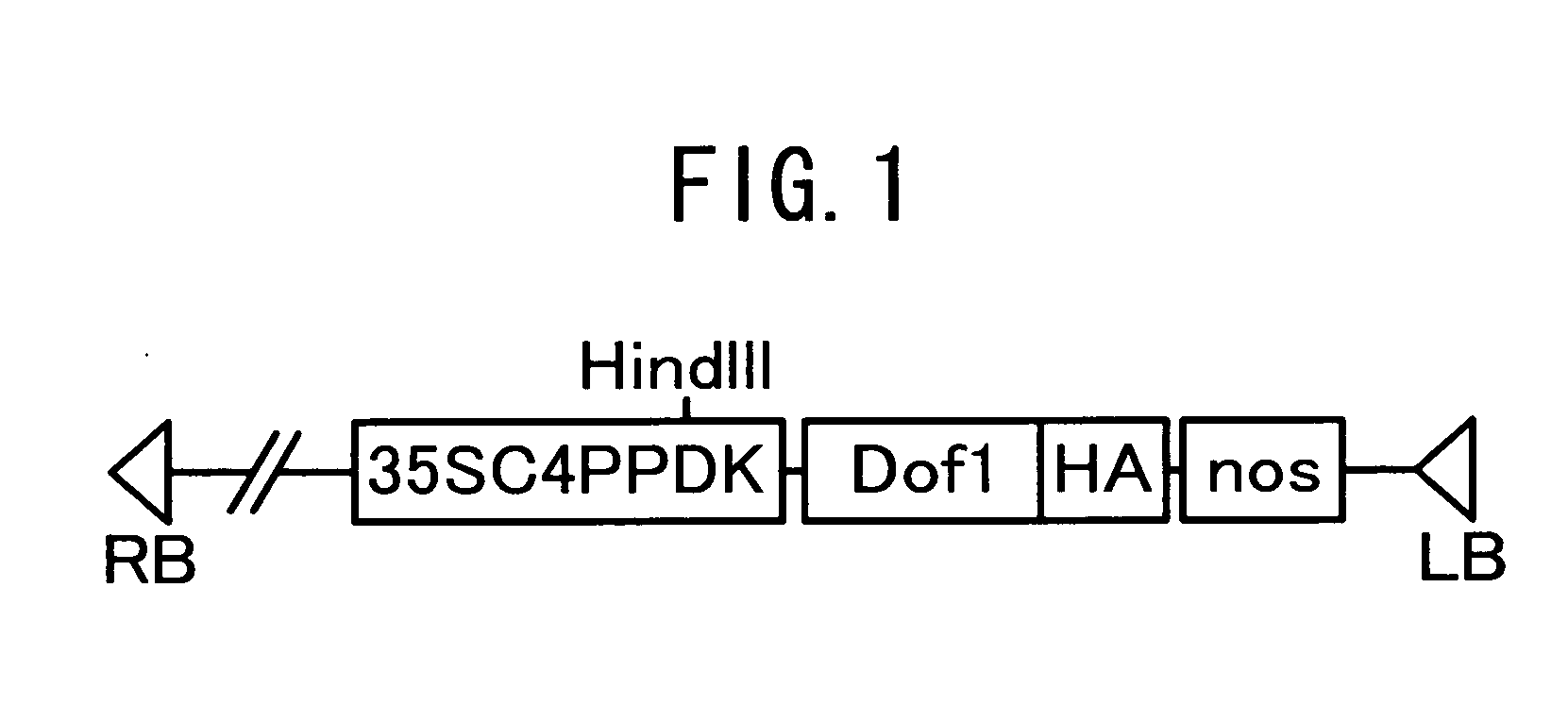

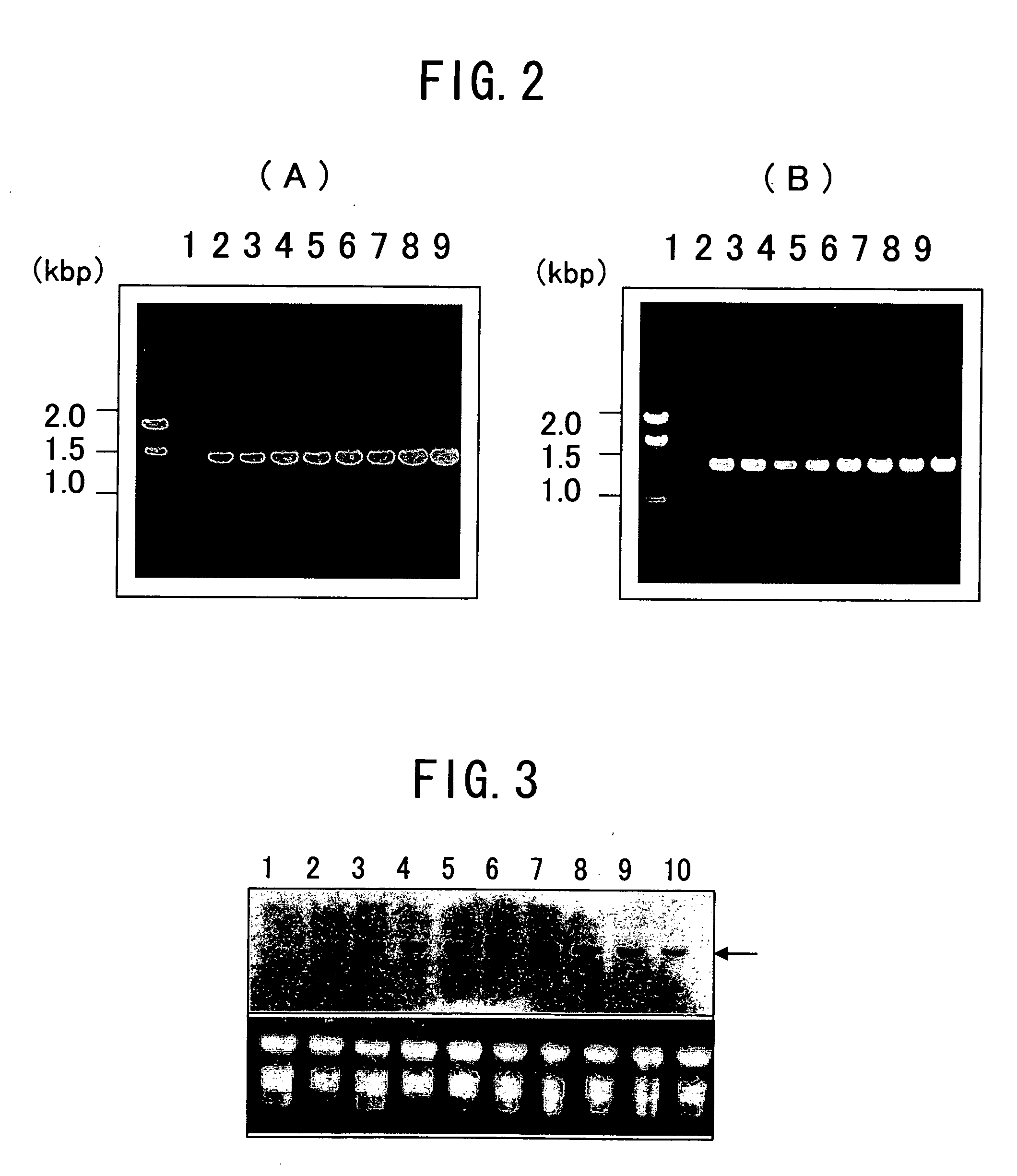

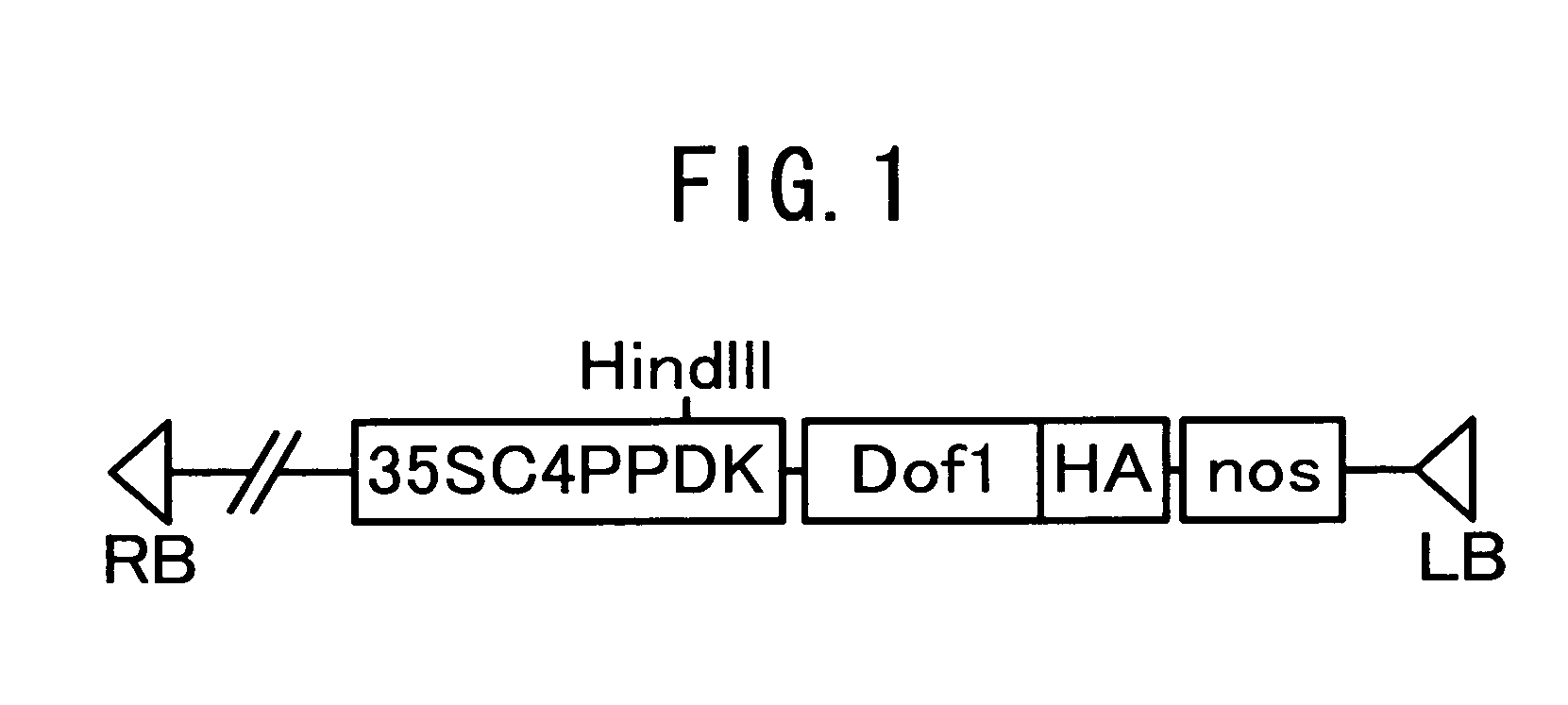

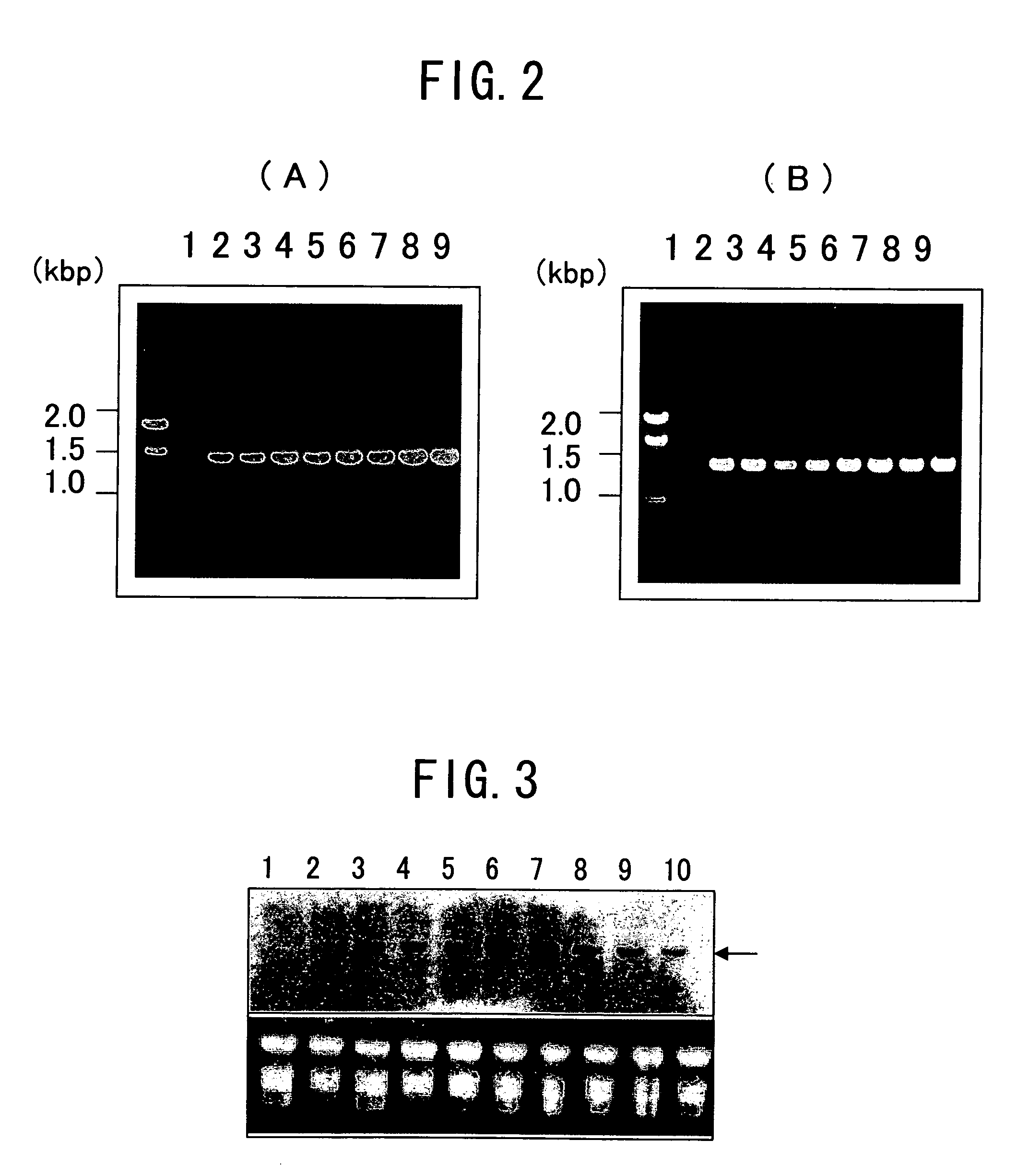

Potatoes having an increased yield of starch per plant body and method for producing the same

The present invention provides potatoes having a tuber yield of potatoes per plant higher than that of non-transformed potatoes cultivated under the same conditions, wherein a gene encoding DNA linking protein belonging to Dof family is introduced in the potatoes. The present invention also provides a method for producing potatoes having a tuber yield of potatoes per plant body higher than that of non-transformed potatoes cultivated under the same conditions, comprising introducing a gene encoding a DNA linking protein belonging to Dof family into the potatoes, and expressing said gene in the potatoes.

Owner:AJINOMOTO CO INC

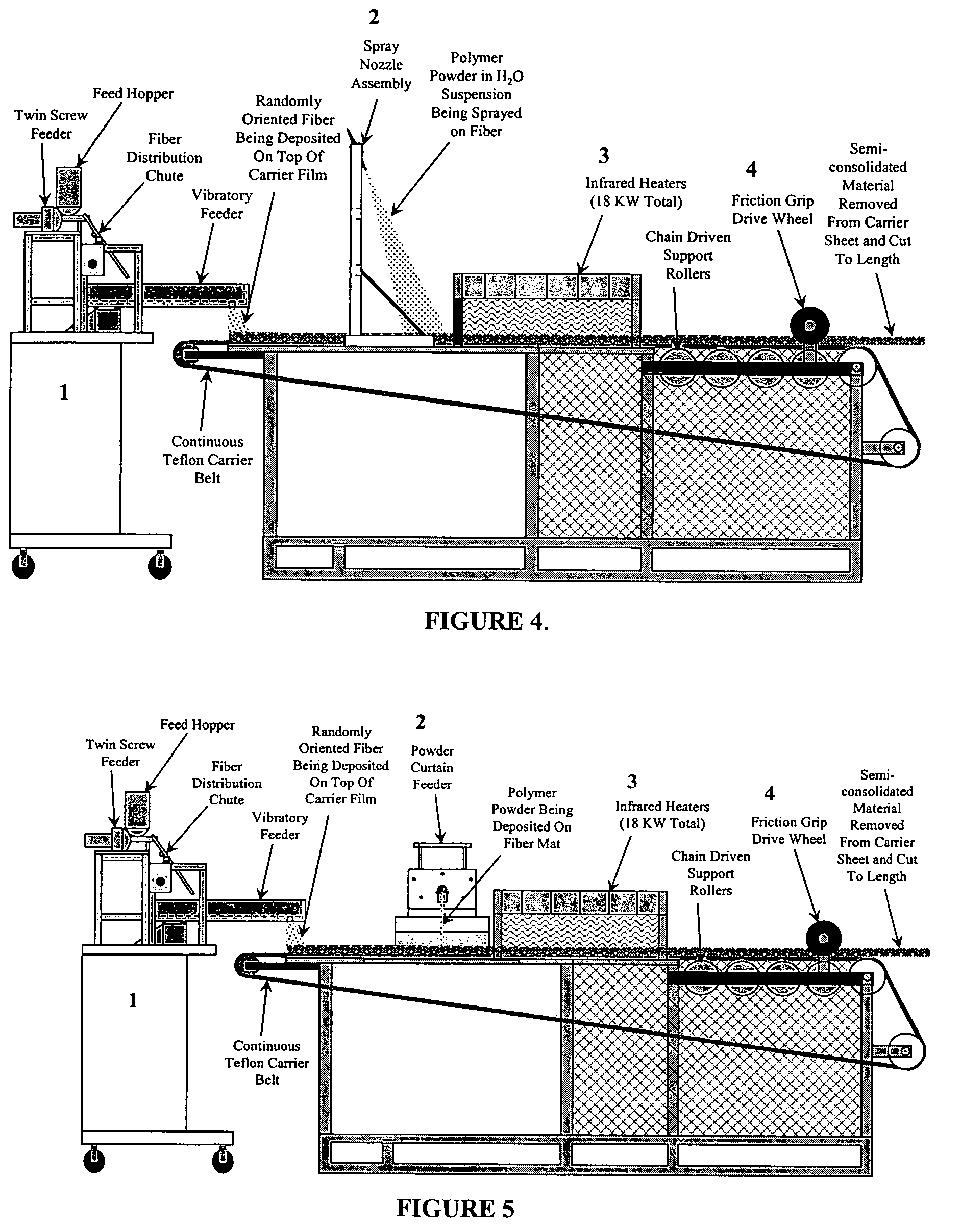

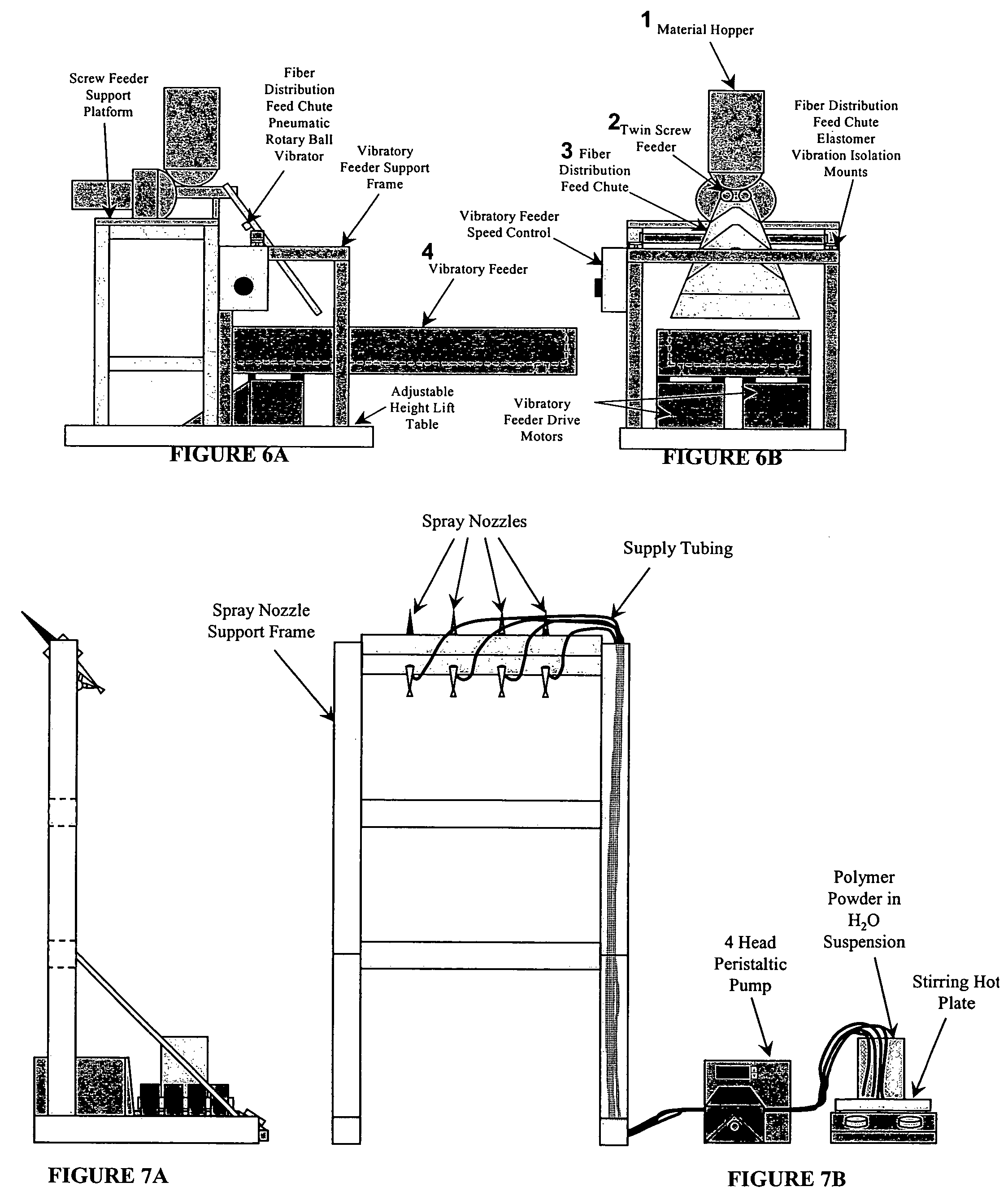

Cellulosic biomass soy flour based biocomposites and process for manufacturing thereof

A process for the manufacture of natural fiber and polymer composites is described. Thermoplastically processed plasticized soy flour based plastics are used with thermoplastic polymers. Polymers of soy flour and an in situ polymerized polyvinyl polymer which links proteins and carbohydrates in the flour to form the polymer are used. The composites are useful in engineering materials.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

Process for preparing white cross-linked protein powder from silkworm pupa

InactiveCN1397192AImprove protectionImprove product qualityProtein composition from waste materialsProtein composition from vegetable materialsCross-linkLinked protein

Owner:CHONGQING UNIV

Potatoes having an increased yield of starch per plant body and method for producing the same

The present invention provides potatoes having a tuber yield of potatoes per plant higher than that of non-transformed potatoes cultivated under the same conditions, wherein a gene encoding DNA linking protein belonging to Dof family is introduced in the potatoes. The present invention also provides a method for producing potatoes having a tuber yield of potatoes per plant body higher than that of non-transformed potatoes cultivated under the same conditions, comprising introducing a gene encoding a DNA linking protein belonging to Dof family into the potatoes, and expressing said gene in the potatoes.

Owner:AJINOMOTO CO INC

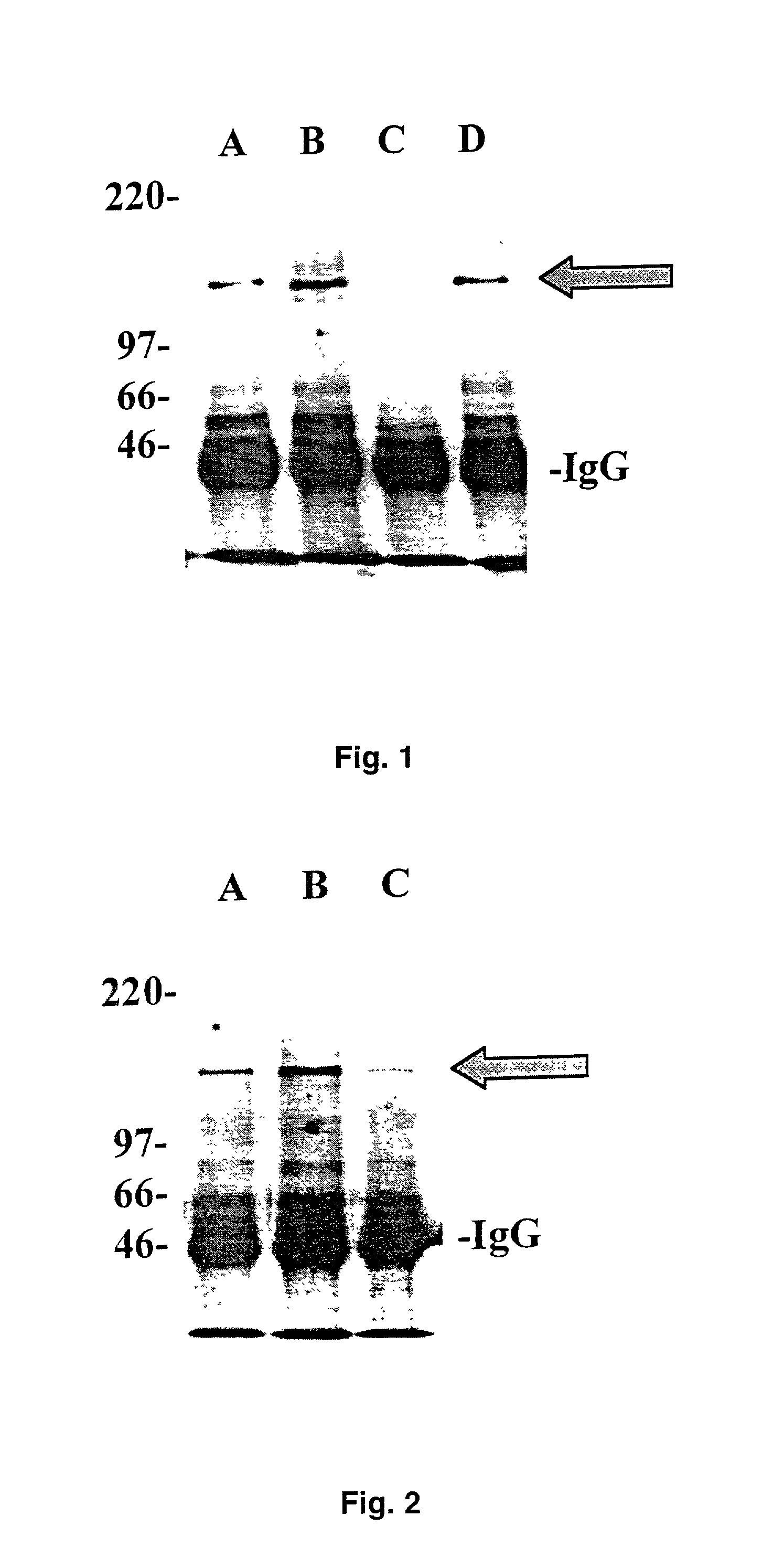

Fusion or linked proteins with extended half life

InactiveUS20110045007A1Reduce capacityImproved profileAntibacterial agentsFungiImmunoglobulin FragmentsHalf-life

The present invention provides fusion proteins comprising a first molecule, and a second molecule which is a monovalent immunoglobulin or a fragment of a monovalent immunoglobulin with a long half-life when administered in vivo, methods of making such fusion proteins, pharmaceutical compositions comprising such fusion proteins, and uses thereof.

Owner:GENMAB AS

Double-functional fusion protein based on antibacterial peptide, preparation method and applicaitoin thereof

InactiveCN101698682ASmall molecular weightHigh molecular weightPeptide/protein ingredientsMicroorganism based processesDiseaseLink protein

The invention discloses a double-functional fusion protein based on an antibacterial peptide, a preparation method and an application thereof. The double-functional fusion protein based on the antibacterial peptide is a fusion protein based on a cecropins B protein sequence and a human epidermal growth factor; the linking protein is especially designed to be a locus which can be identified by thrombin; and a purified His tag is constructed on the fusion protein. In the invention, the biological preparation for the fusion protein is realized by using a prokaryotic expression system and the purified fusion protein is obtained. A bacteriostasis test and a verification for realizing live animals are performed by the purified fusion protein to indicate that the fusion protein can be applied to preparing a medicine for treating epidermal wound, can be applied to diseases such as epidermal wound, abrade, burn and scald, etc., and can prevent wound from being infected.

Owner:MICROBIOLOGY INST OF SHAANXI

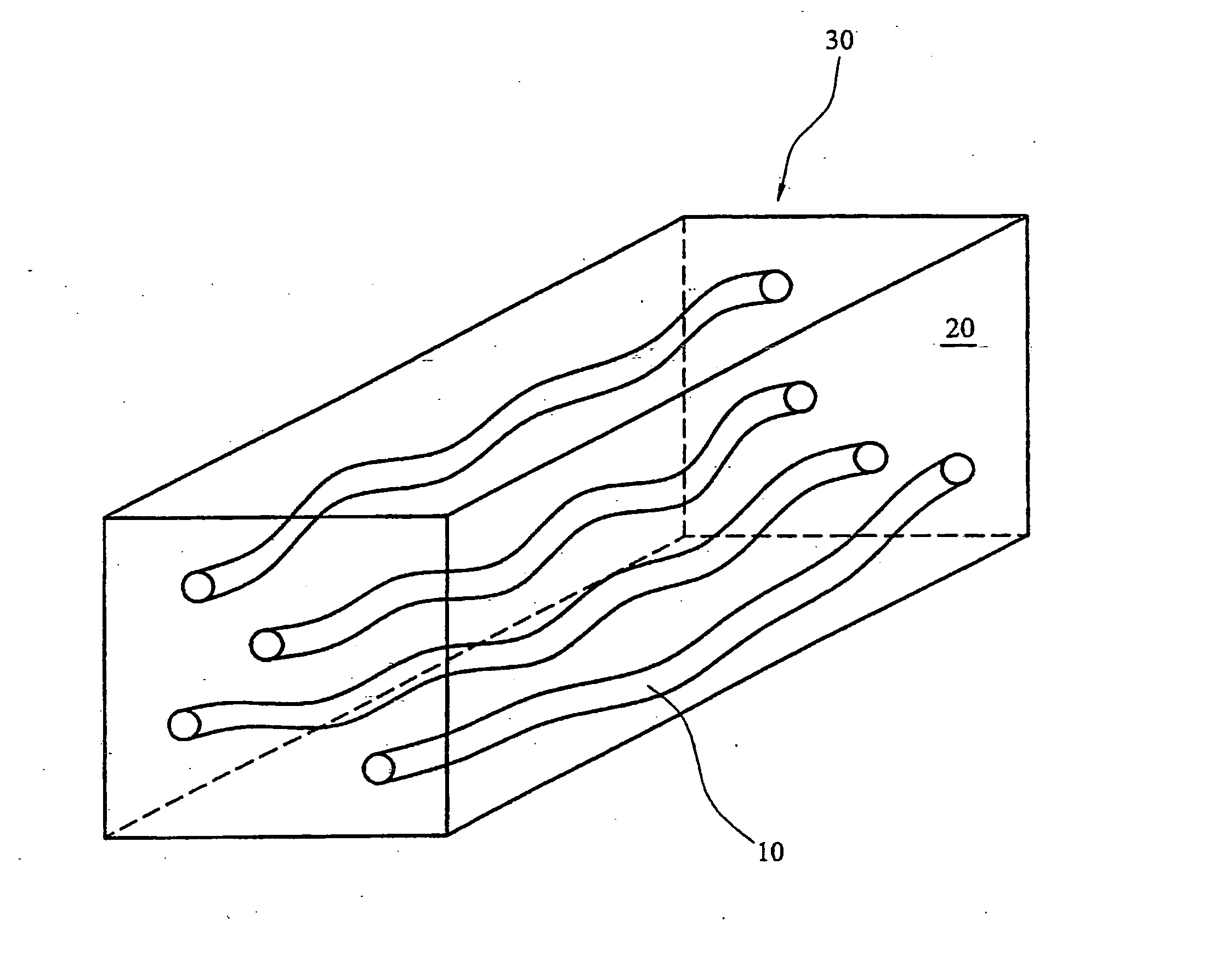

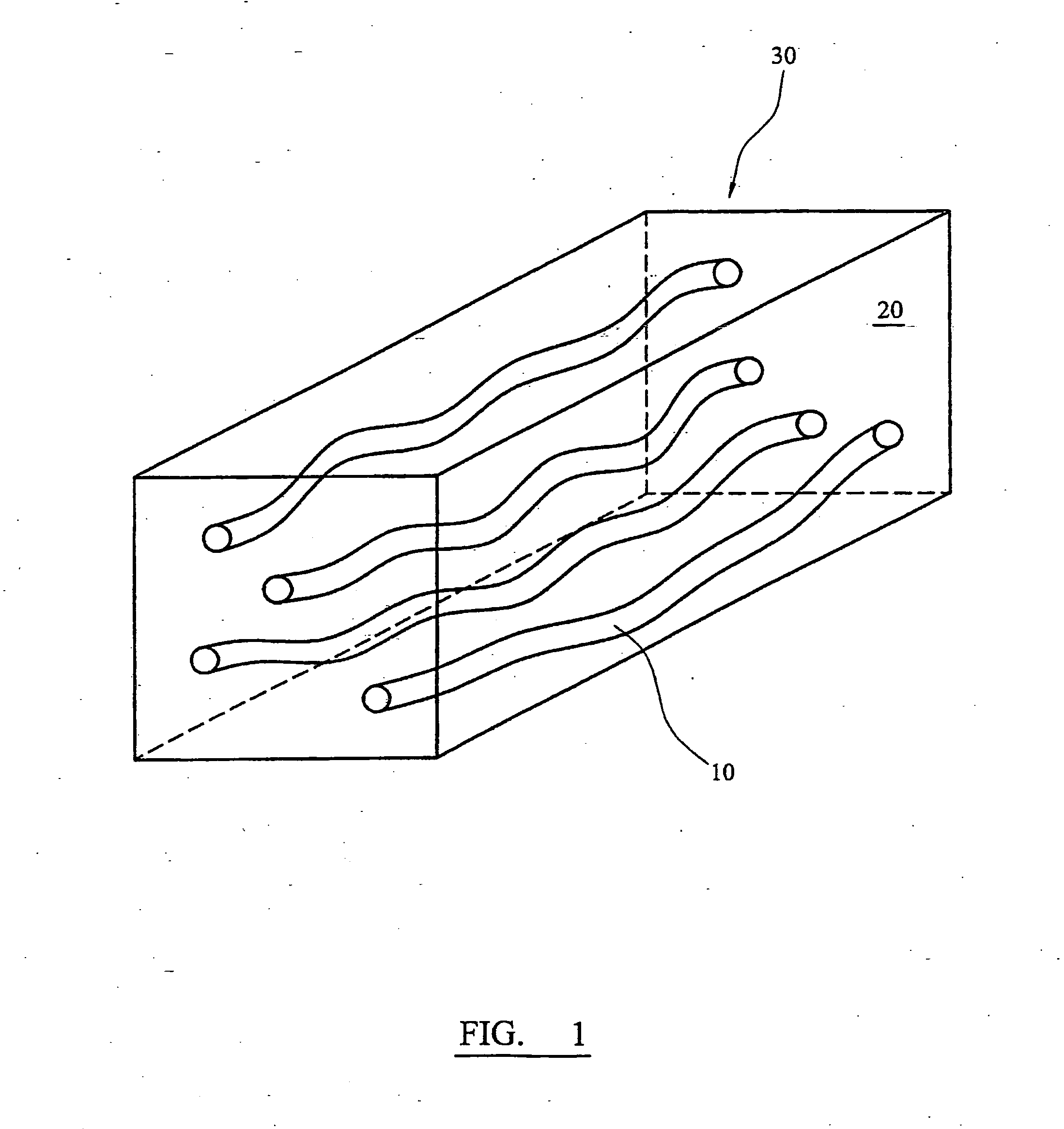

Composite materials

InactiveUS20070113355A1Good biocompatibilityEasy to moveAnthropod material medical ingredientsFibre treatmentCross-linkSurgical implant

This application discloses a composite material comprising one or more silk elements in an acrylic or cross-linked protein matrix. The silk elements are made from the group of silk elements consisting of domestic silkworm silk, wild silkworm silk, spider dragline silk, and filaments spun from recombinant silk protein or protein analogues. The composite material is particularly useful for use in-surgical-implants.

Owner:OXFORD BIOMATERIALS LTD

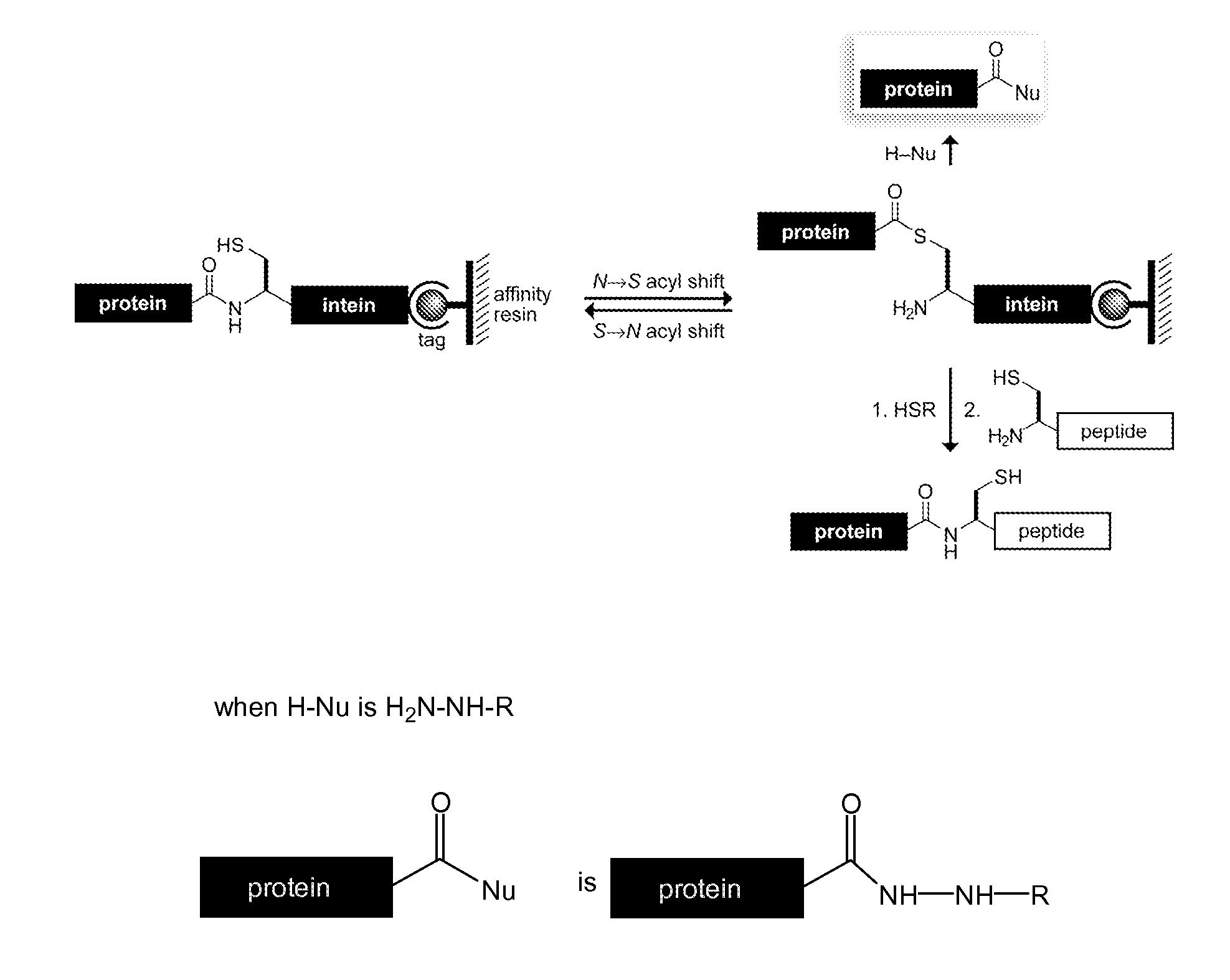

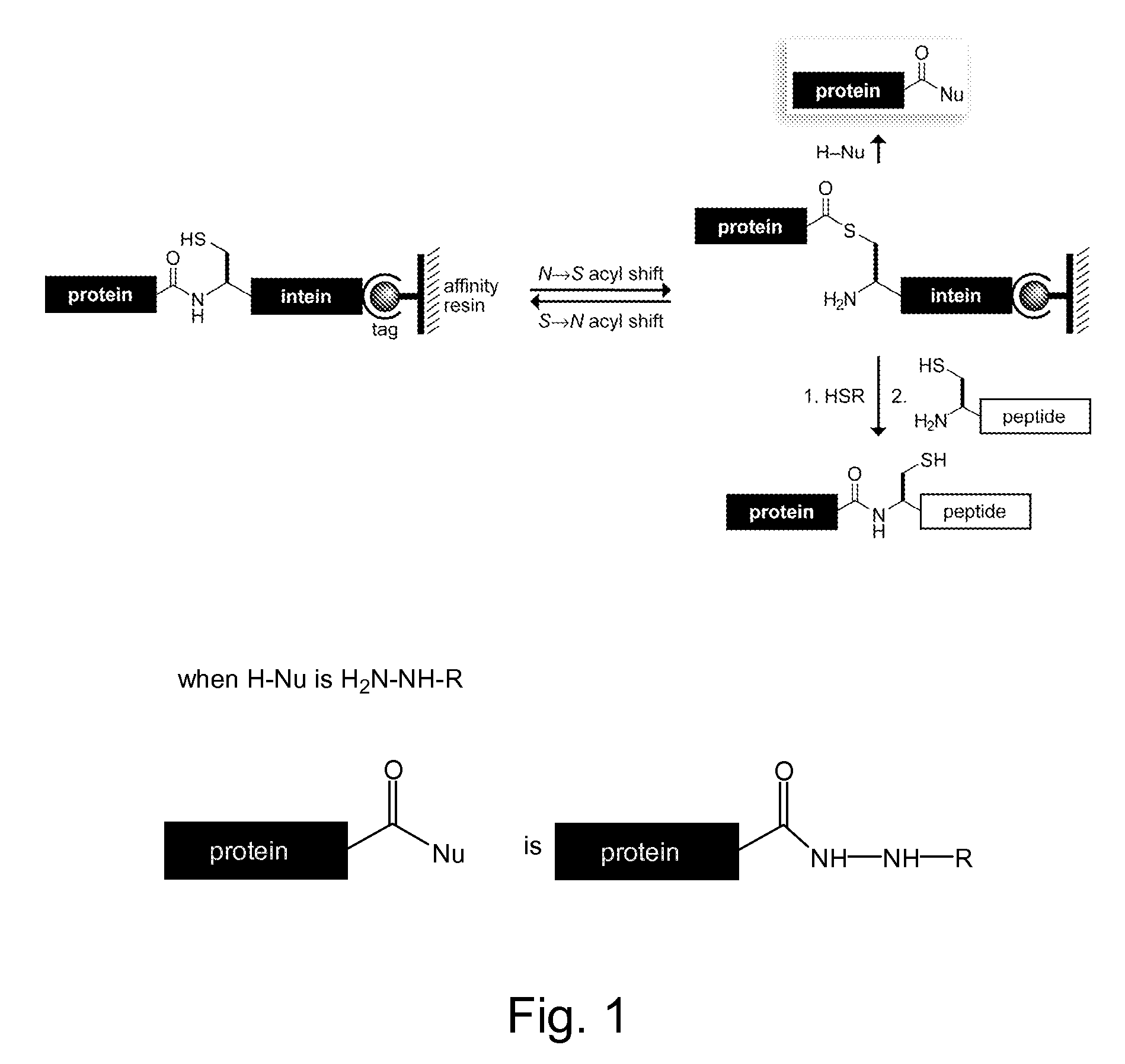

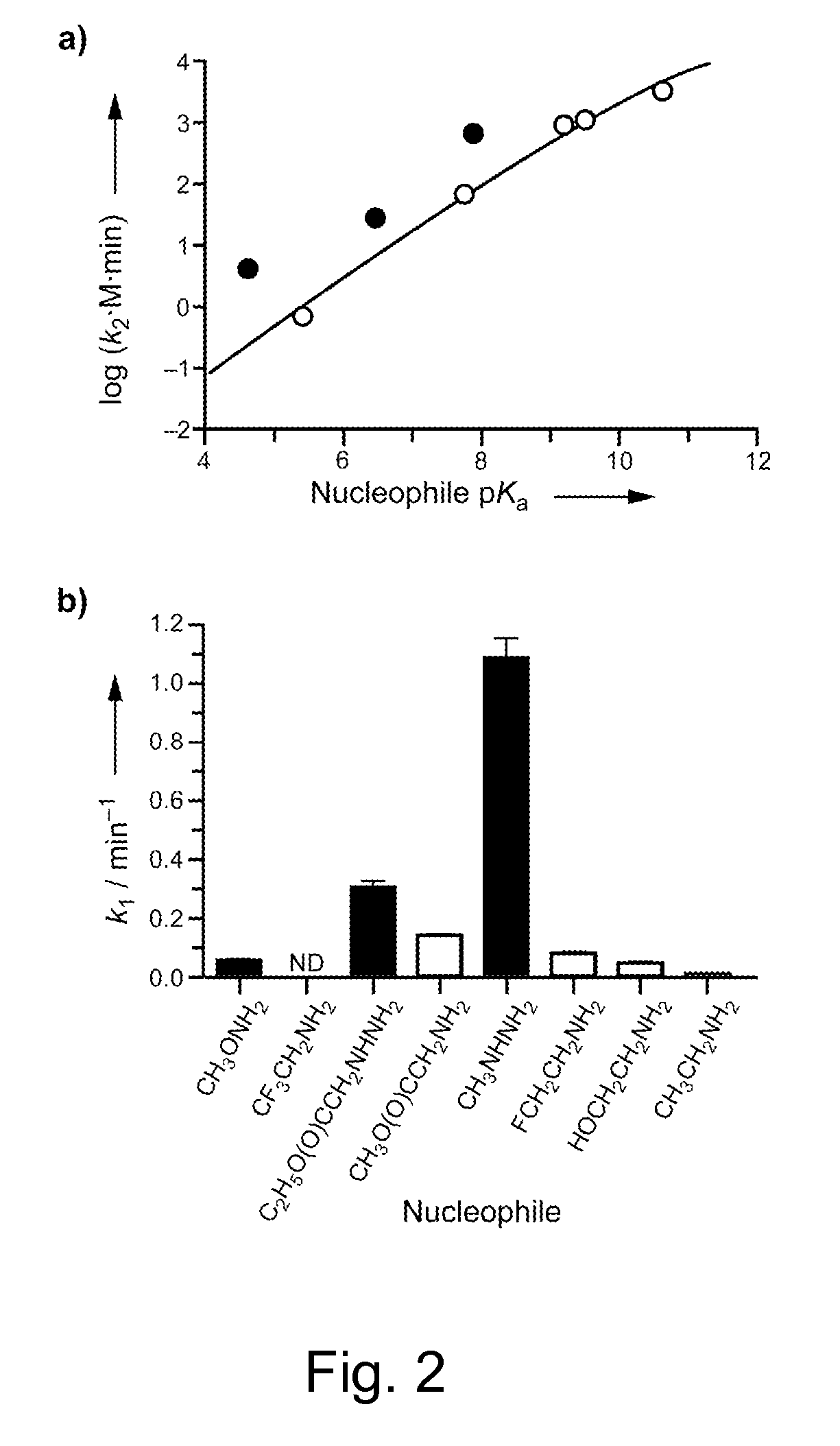

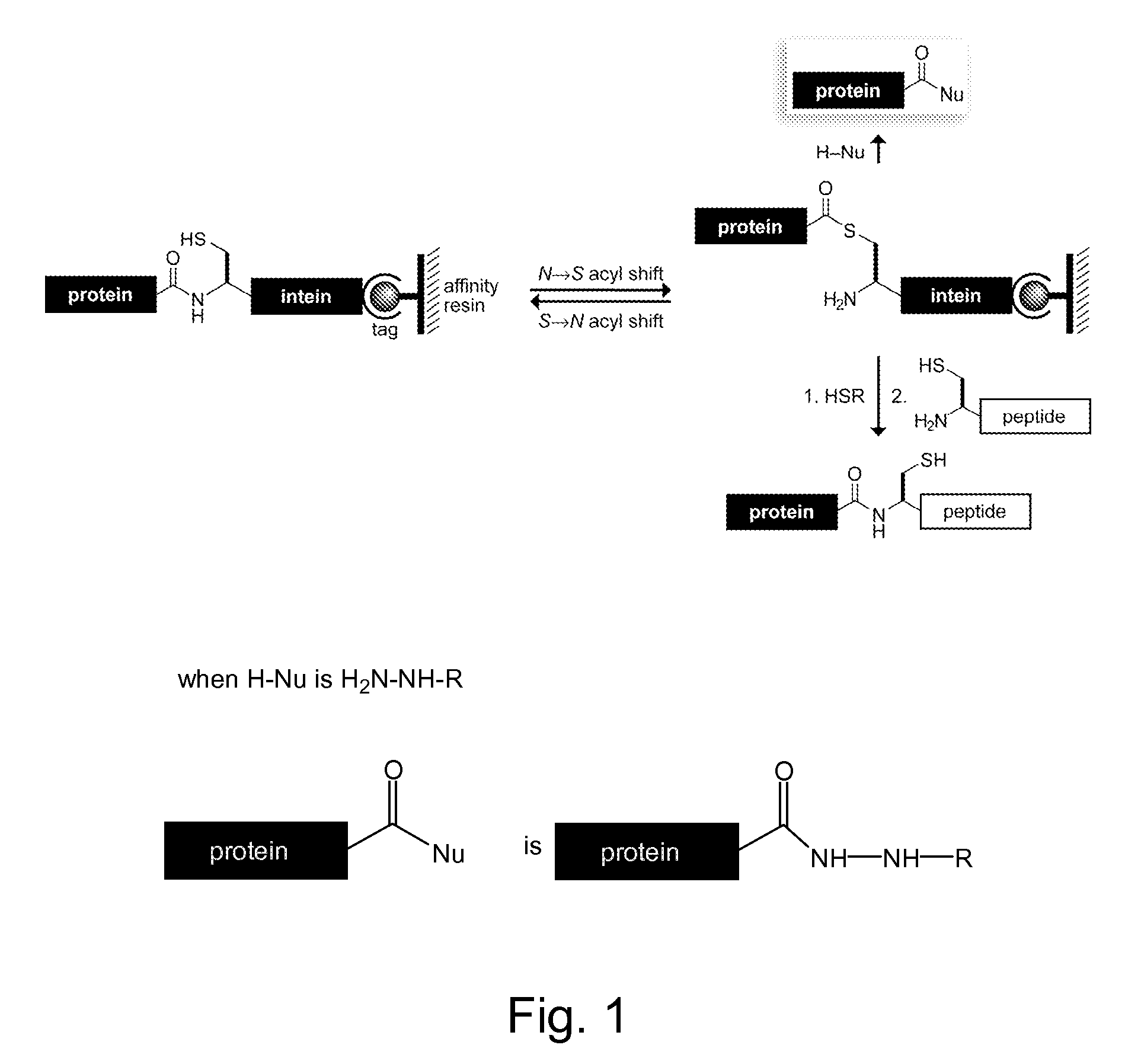

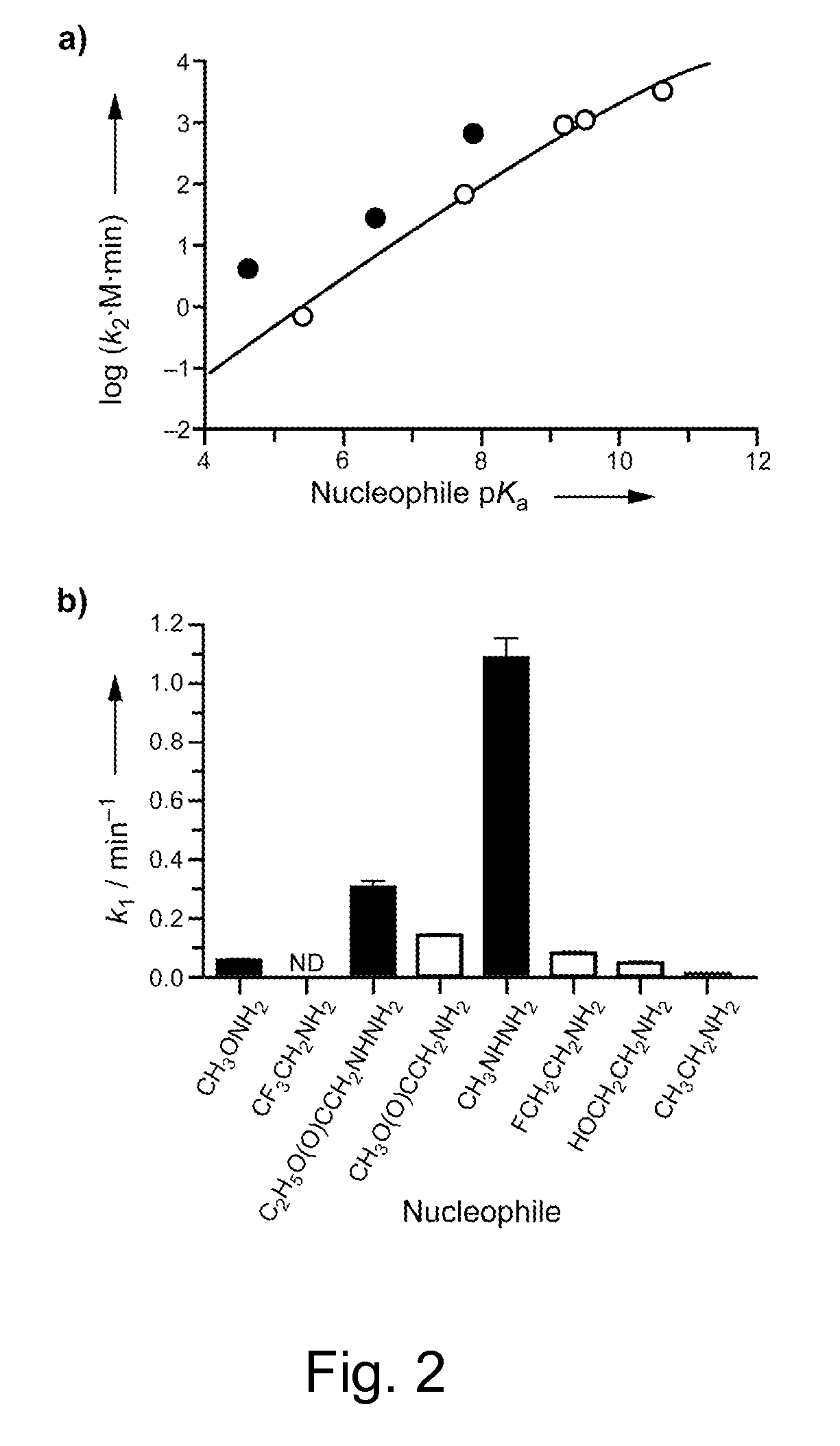

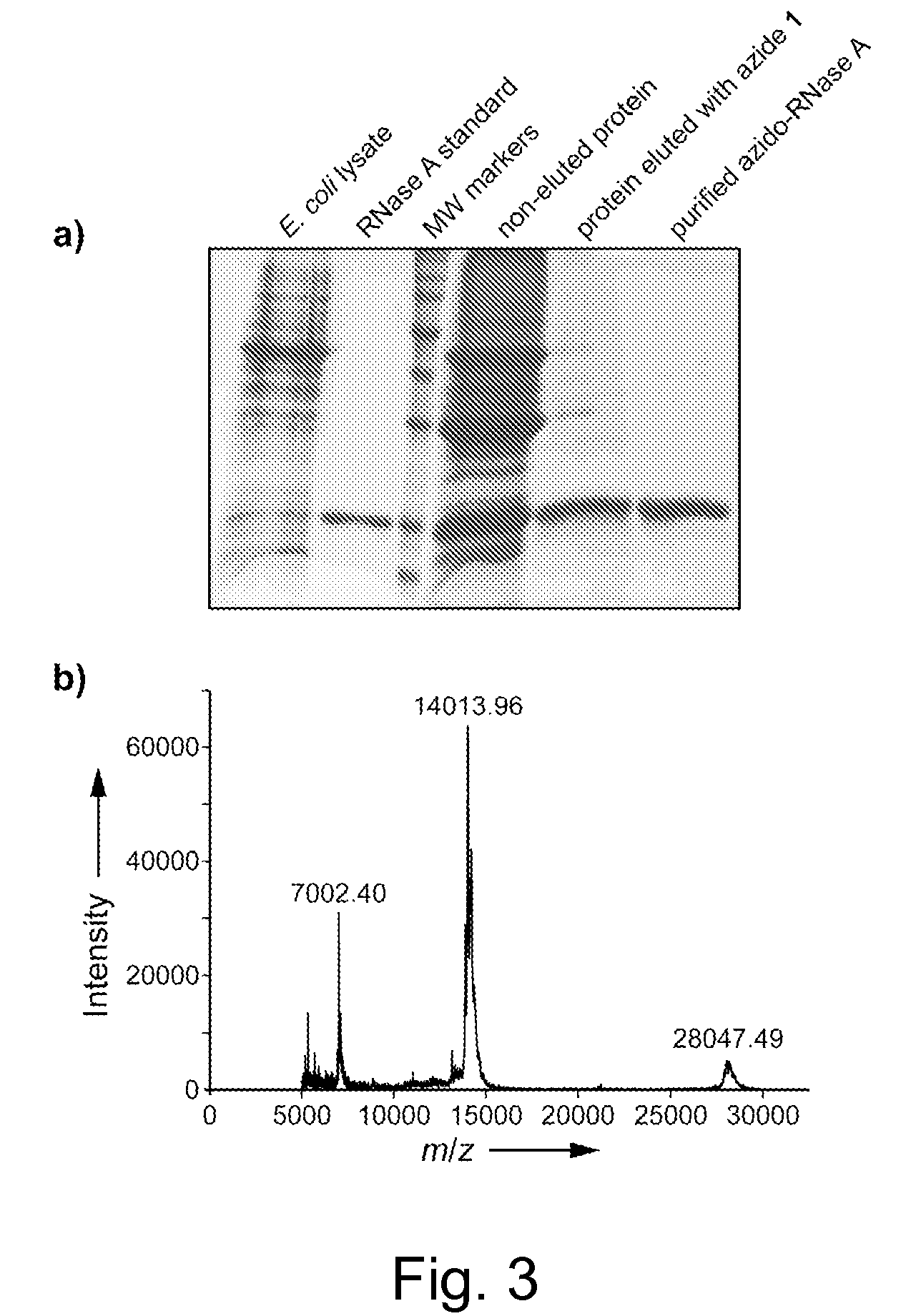

Reagents and Methods for Appending Functional Groups to Proteins

ActiveUS20080020942A1Minimizes and avoids inactivationMaintain biological activityPeptide librariesPeptide/protein ingredientsInteinLink protein

Methods and reagents for site-selective functionalization of peptides and proteins. The methods most generally involve the reaction of a thioester with hydrazine. Reagents include bifunctional reagents of formula:H2N—NH—CH2-M-L-FGand salts thereof where M is a single bond or a chemical group carrying a non-bonding electron pair, such as —C(O)NR′—, where R′ is H, or an alkyl or aryl group; L is an optional linker group as described above; and FG is a functional group having reactivity that is orthongonal to that of the hydrazine group. FG can, among others, be an azide, alkenyl, alkynyl, nitrile (—CN) or triazole group and is preferably an azide group (—N3). Methods and reagents can, for example, be combined with intein-mediated protein splicing to link proteins or fragments thereof to various chemical species or to a surface. Surface immobilization of proteins via the methods herein results in immobilized proteins which substantially retain biological activity and is thus useful for the generation of peptide or protein microarrays. Kits for functionalization and / or immobilization of peptides and proteins are provided as well as microarrays of peptides, proteins or both.

Owner:WISCONSIN ALUMNI RES FOUND

Processing technology of cowhide leather

InactiveCN107858458AGood removal effectNot perishableTanning treatmentPre-tanning chemical treatmentCross-linkRemoving hair

The invention discloses a processing technology of cowhide leather. The technology comprises the steps of: cleaning, degreasing, hair removal, alkali dipping, deashing, softening, acid dipping and tanning. According to the invention, the ester removal agent used in degreasing treatment can remove the residual ester well, is beneficial to intracutaneous penetration of tanning agent molecules and combination with collagen molecule active groups in a follow-up tanning process, formation of a cross-linked protein fiber three-dimensional network, and improvement of the stability and chemical resistance, and the prepared leather does not rot or deteriorate easily. Through the treatment of alkali dipping, deashing, softening and other steps, mesenchymal protein fiber in cortex can be dissolved, the softness of finished leather can be improved, and the handfeel is comfortable.

Owner:ANHUI DINGHENG LEATHER PROD

Reagents and methods for appending functional groups to proteins

ActiveUS8242058B2Minimizes and avoids inactivationMaintain biological activityPeptide librariesSugar derivativesInteinHydrazine compound

Methods and reagents for site-selective functionalization of peptides and proteins. The methods most generally involve the reaction of a thioester with hydrazine. Reagents include bifunctional reagents of formula:H2N—NH—CH2-M-L-FGand salts thereof where M is a single bond or a chemical group carrying a non-bonding electron pair, such as —C(O)NR′—, where R′ is H, or an alkyl or aryl group; L is an optional linker group as described above; and FG is a functional group having reactivity that is orthongonal to that of the hydrazine group. FG can, among others, be an azide, alkenyl, alkynyl, nitrile (—CN) or triazole group and is preferably an azide group (—N3). Methods and reagents can, for example, be combined with intein-mediated protein splicing to link proteins or fragments thereof to various chemical species or to a surface. Surface immobilization of proteins via the methods herein results in immobilized proteins which substantially retain biological activity and is thus useful for the generation of peptide or protein microarrays. Kits for functionalization and / or immobilization of peptides and proteins are provided as well as microarrays of peptides, proteins or both.

Owner:WISCONSIN ALUMNI RES FOUND

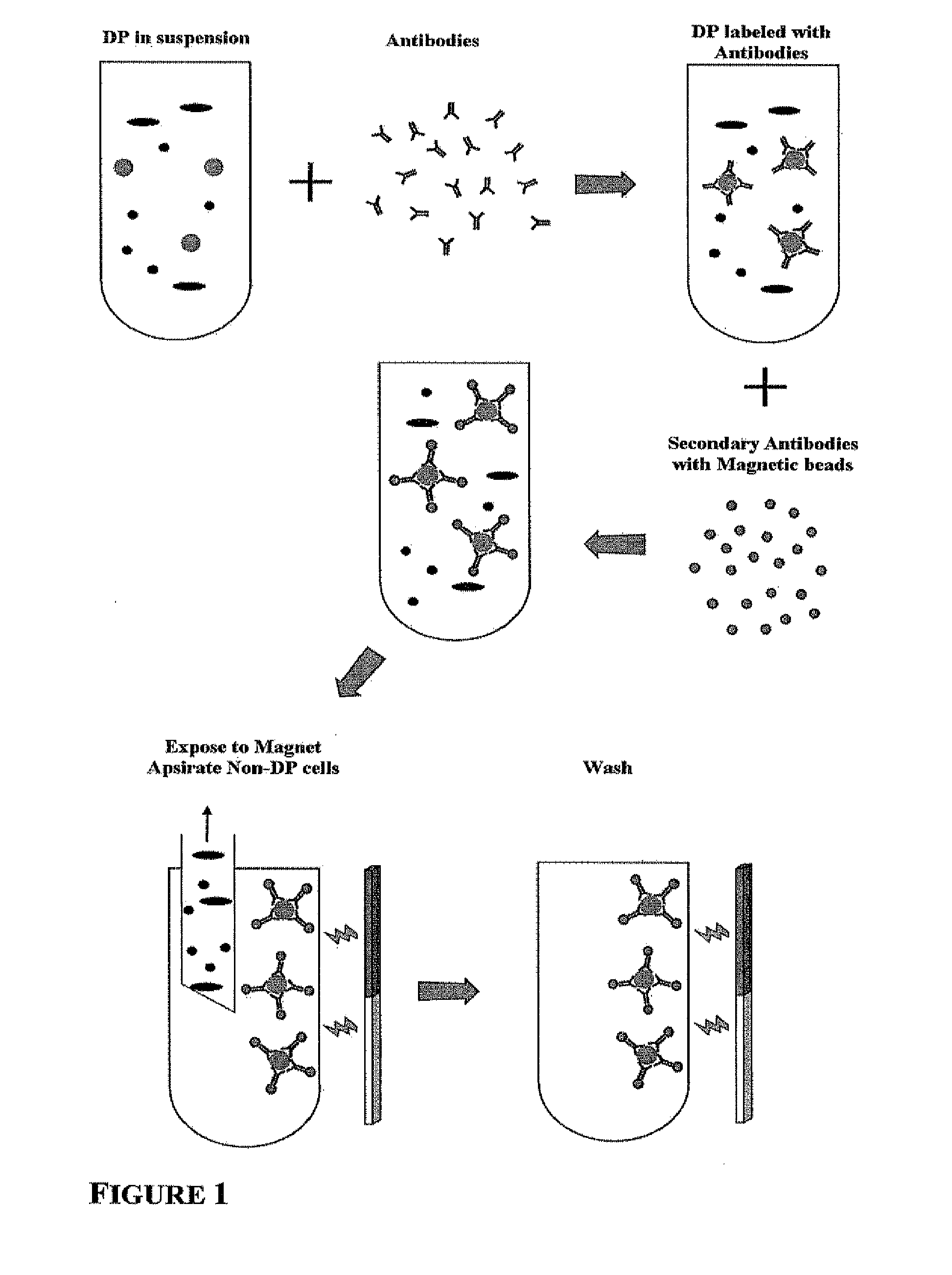

Identity markers

InactiveUS20120128632A1Reduce needReduce laborBiocideEpidermal cells/skin cellsDermal papillaeTransmembrane domain

Methods for identifying trichogenic dermal cells, including dermal papilla cells and dermal sheath cells, capable of inducing hair follicle formation when injected into skin are provided. It has been discovered that EGF latrophilin and seven transmembrane domain-containing protein 1 (ELTD1). Transmembrane Protein 108 (TMEM1 08), Hyaluronan and proteoglycan link protein 1 (HAPLN1) are biomarkers that can be used to detect, identify, and distinguish trichogenic dermal cells, i.e., that are able to induce hair follicle formation, from other skin cells. Populations of skin cells enriched with trichogenic dermal cells can be produced by selecting for and enriching for dermal cells that express ELTD1, TMEM1 08, HAPLN1, or a combination thereof.

Owner:ADERANS RES INST

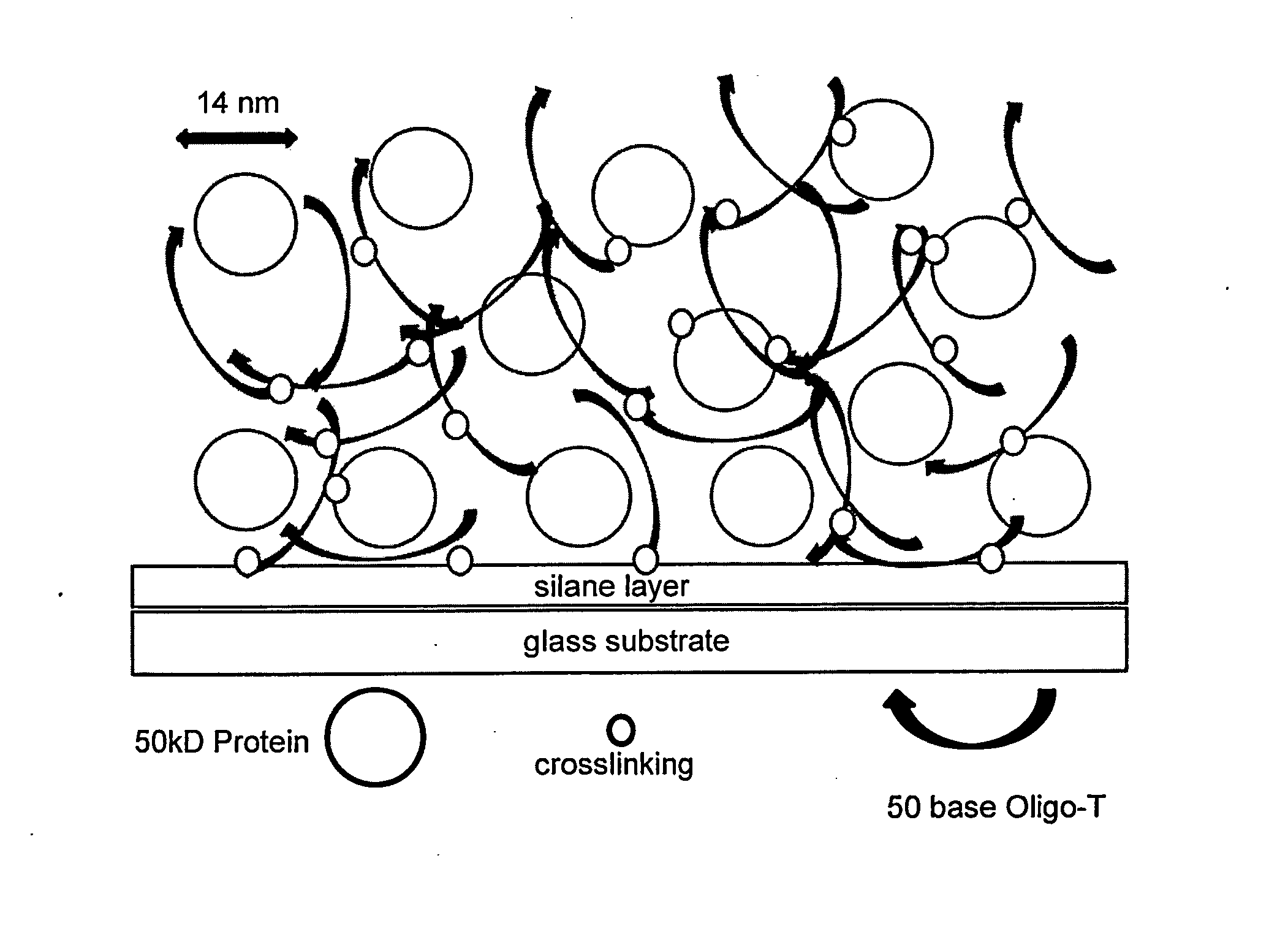

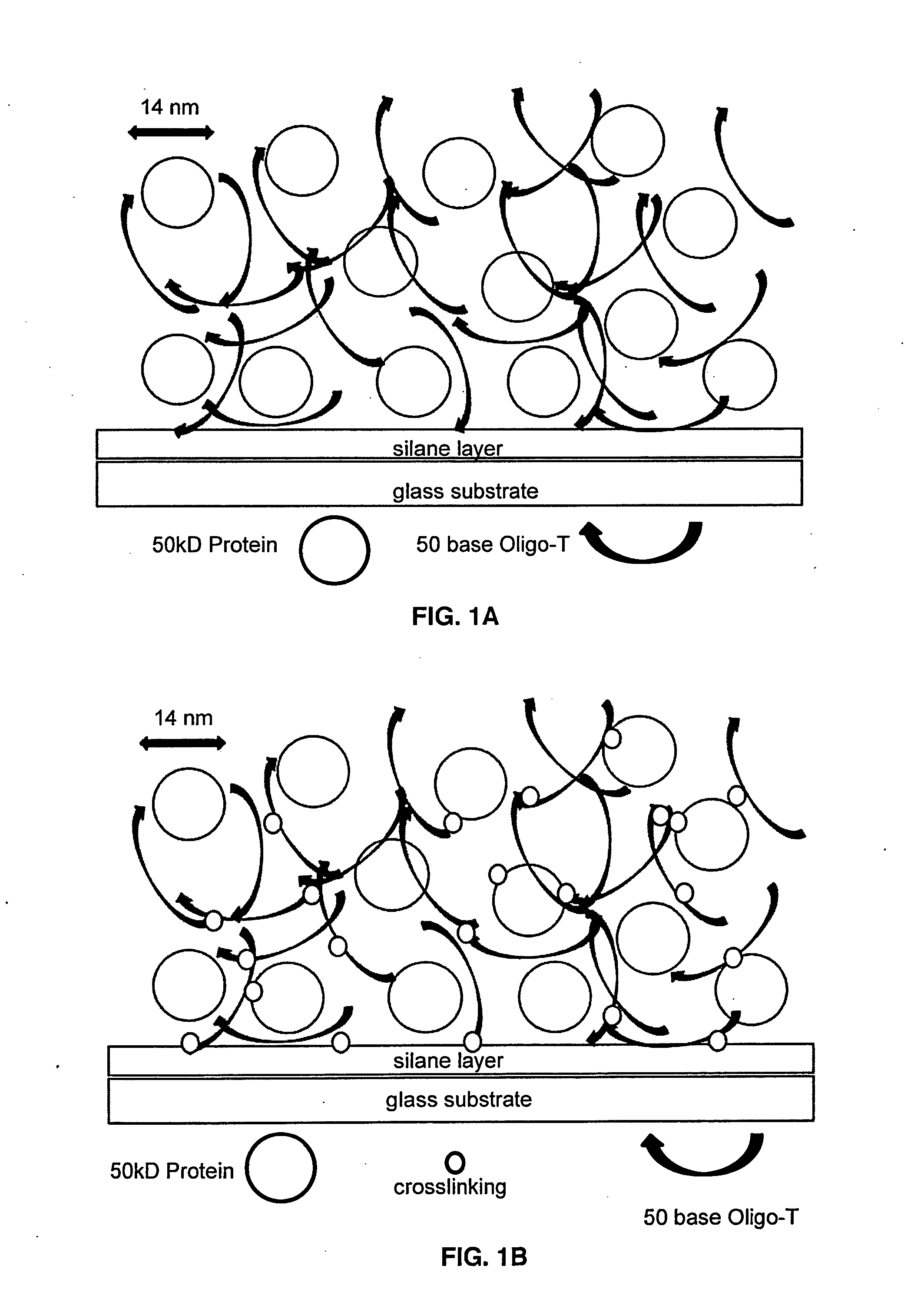

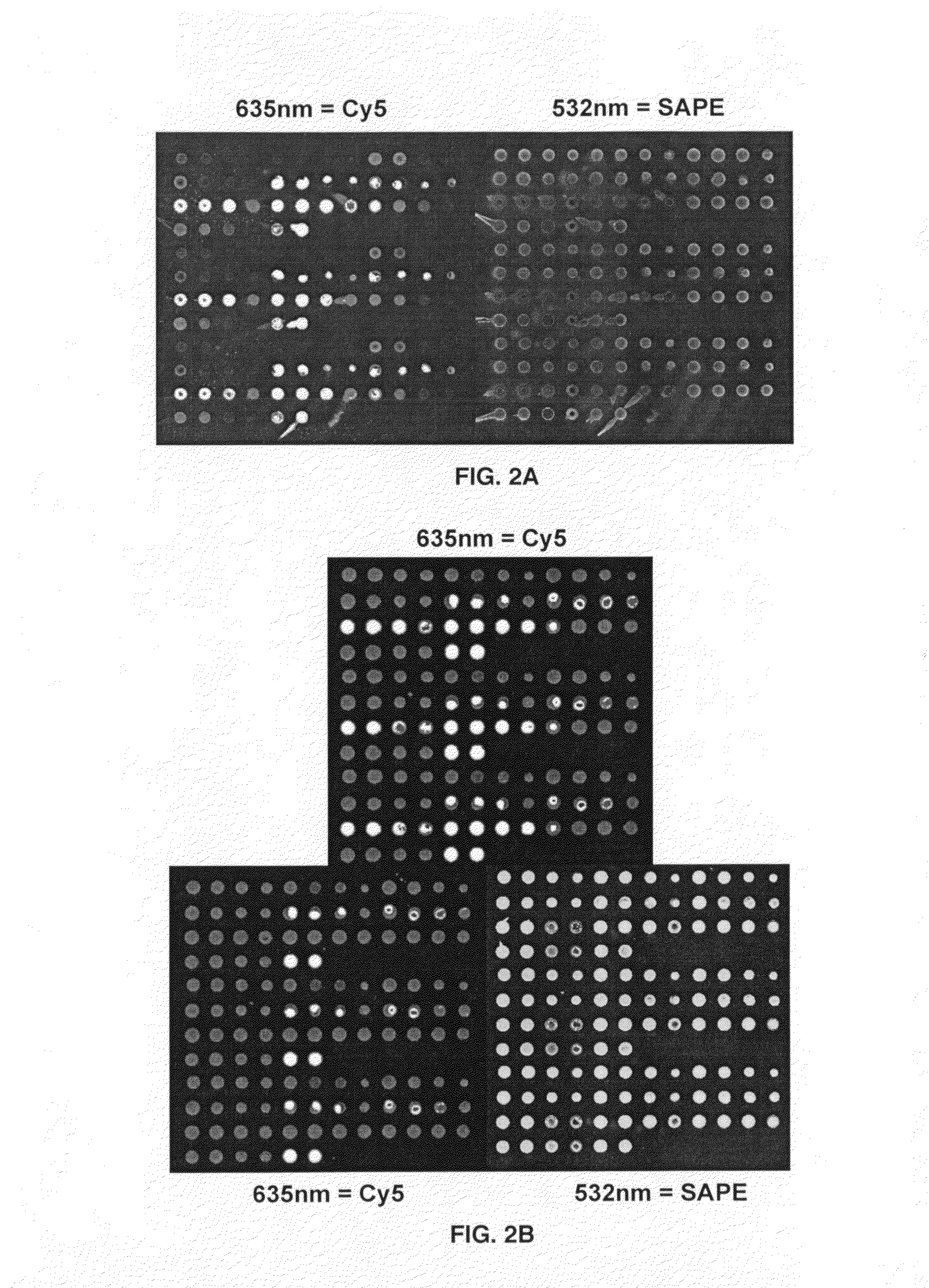

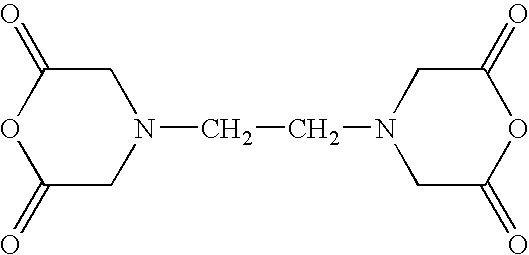

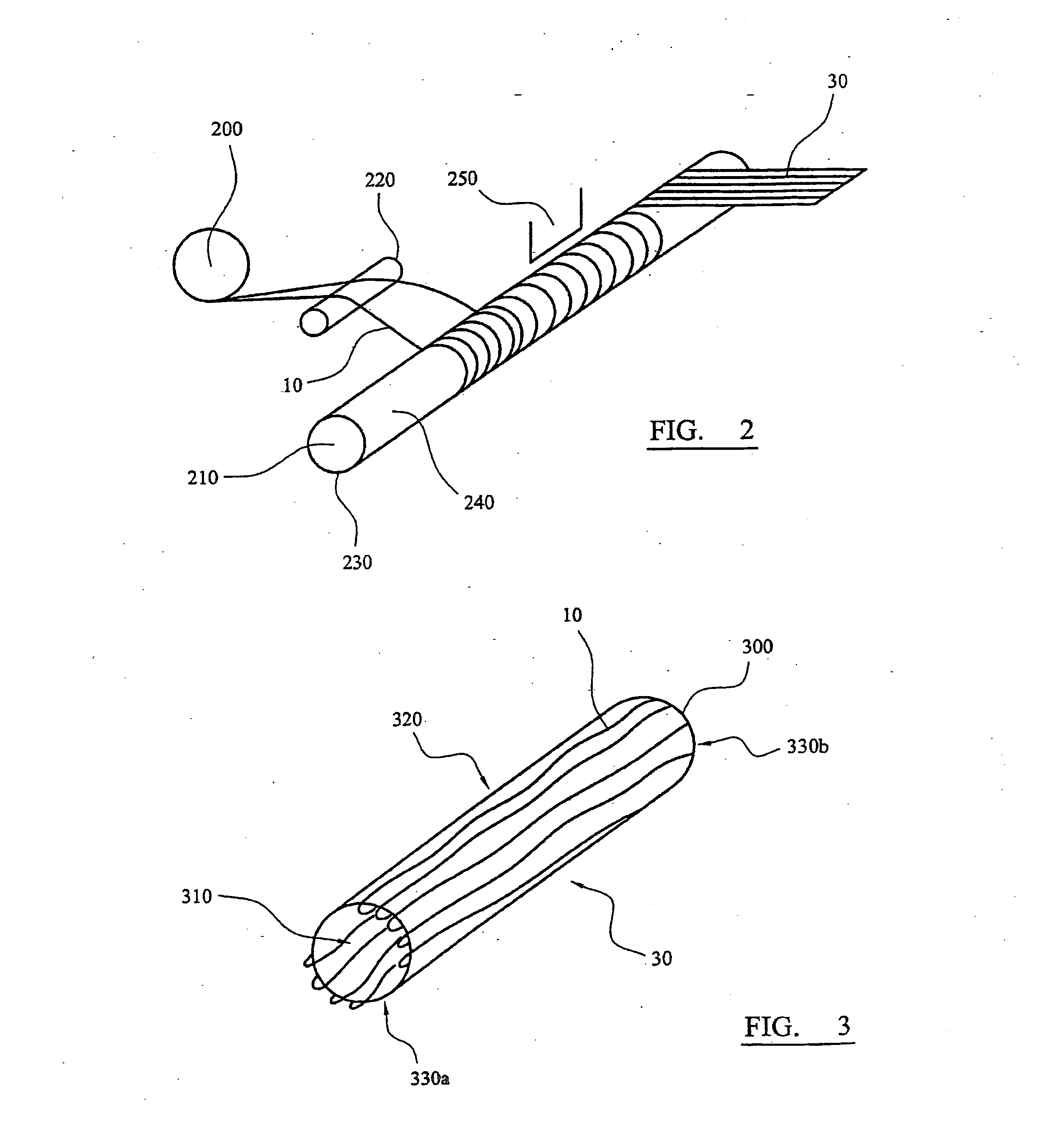

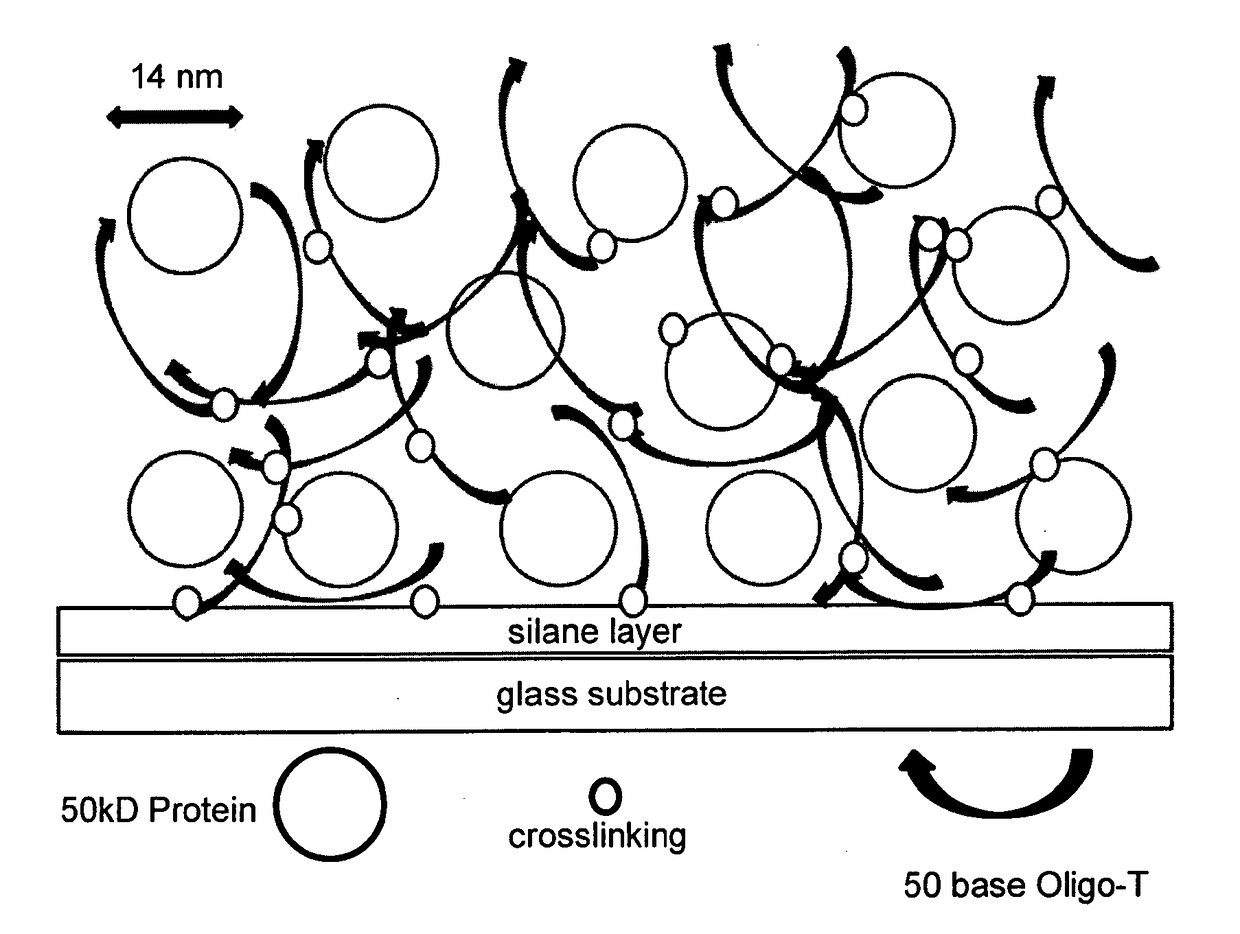

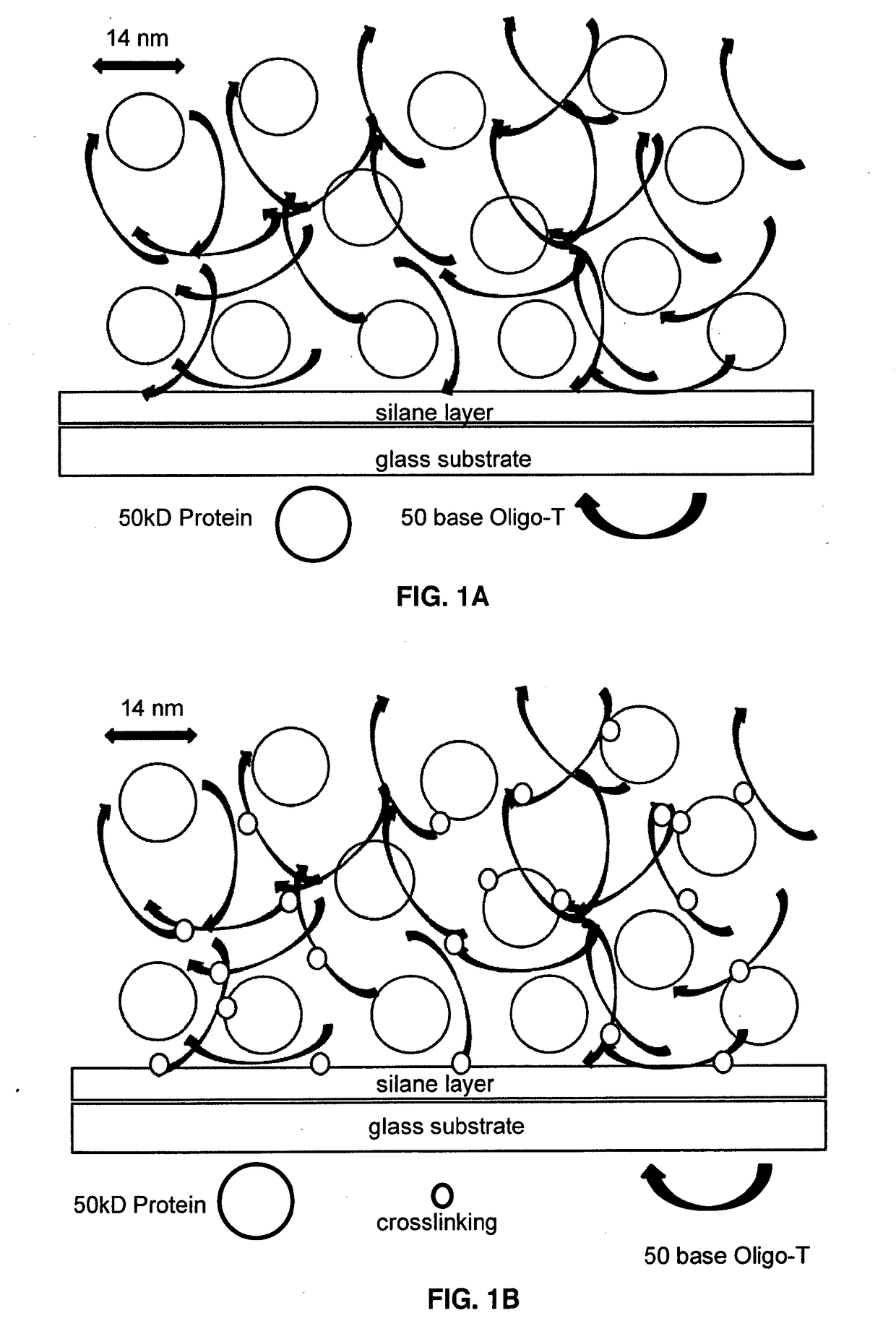

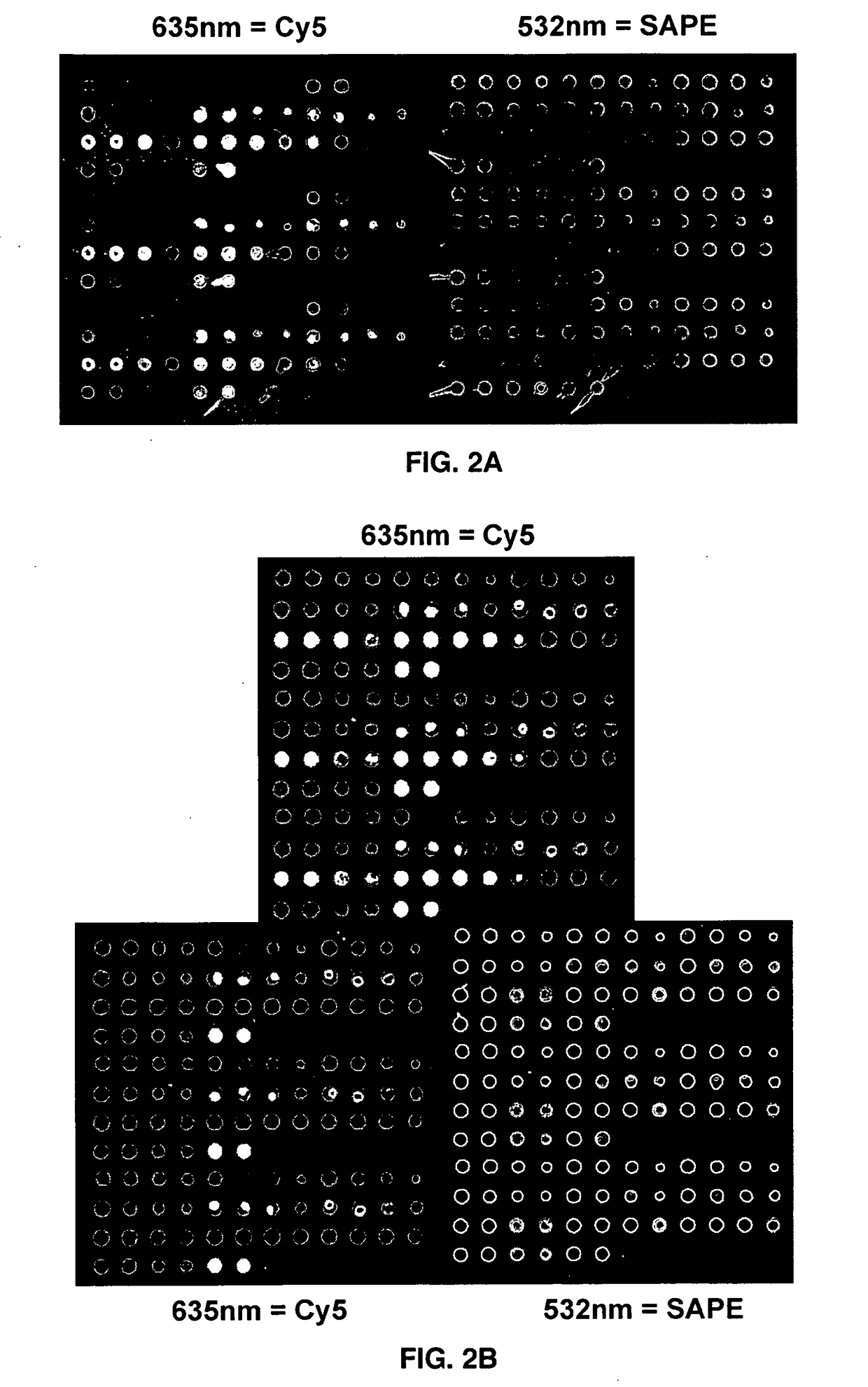

Compositions and methods for entrapping protein on a surface

The present invention provides a formulation to link protein to a solid support that comprises one or more proteins, Oligo-dT and one or more non-volatile, water-soluble protein solvents, solutes or combination thereof in an aqueous solution. Further provided is a method of attaching a protein to a surface of a substrate. The formulations provided herein are contacted onto the substrate surface, printed thereon and air dried. The substrate surface is irradiated with UV light to induce thymidine photochemical crosslinking via the thymidine moieties of the Oligo-dT.

Owner:PURE TRANSPLANT SOLUTIONS L L C

Protein-polysaccharide hybrid hydrogels

InactiveUS20040200386A1Improve featuresIncrease contentProtein waste adhesivesOther chemical processesCross-linkHybrid protein

Disclosed is a hybrid protein-polysaccharide superabsorbent hydrogel. The hydrogel includes two interpenetrating matrices: a first matrix which is an acylated, cross-linked protein matrix, and a second matrix which is an anionic polysaccharide matrix. The two matrices can be non-cross-linked, or the hydrogel can further include bridging moieties that covalently cross-linking the acylated, cross-linked protein matrix to the anionic polysaccharide matrix.

Owner:WISCONSIN ALUMNI RES FOUND

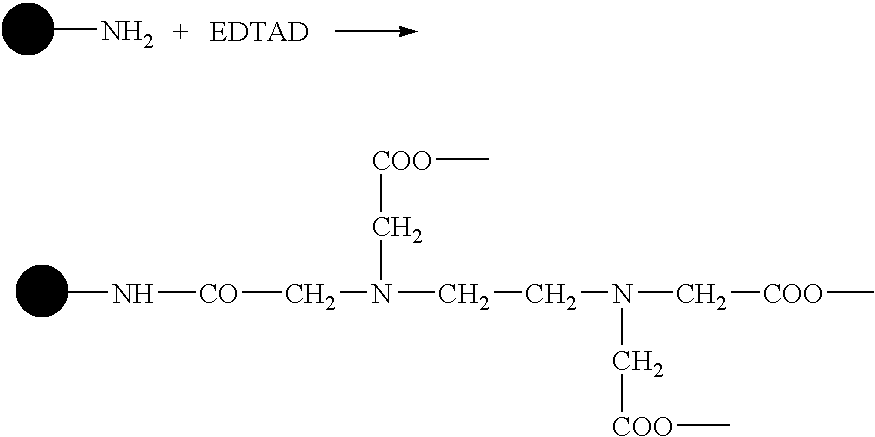

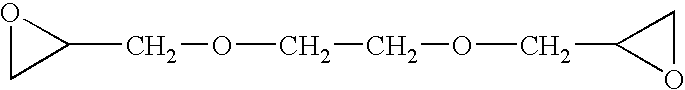

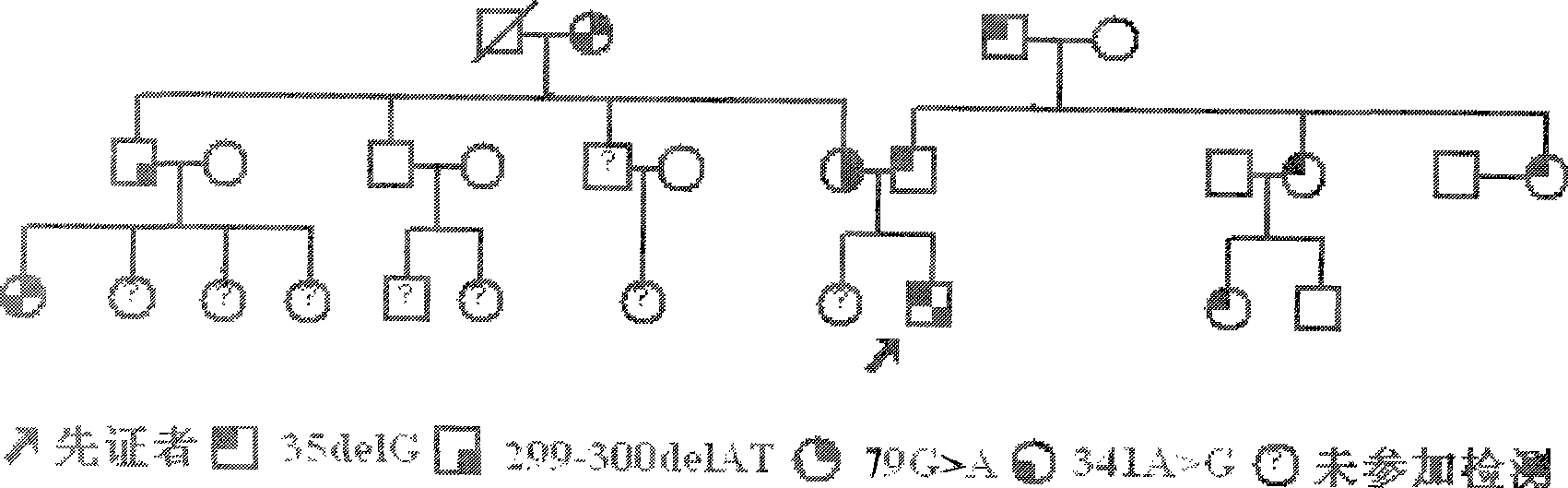

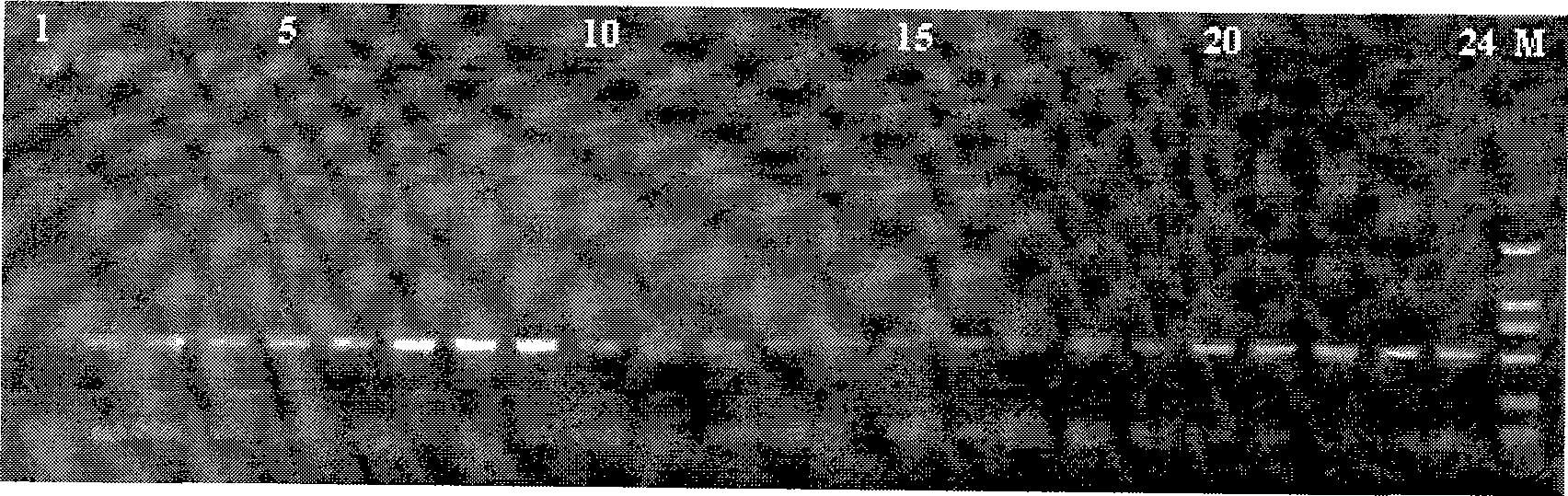

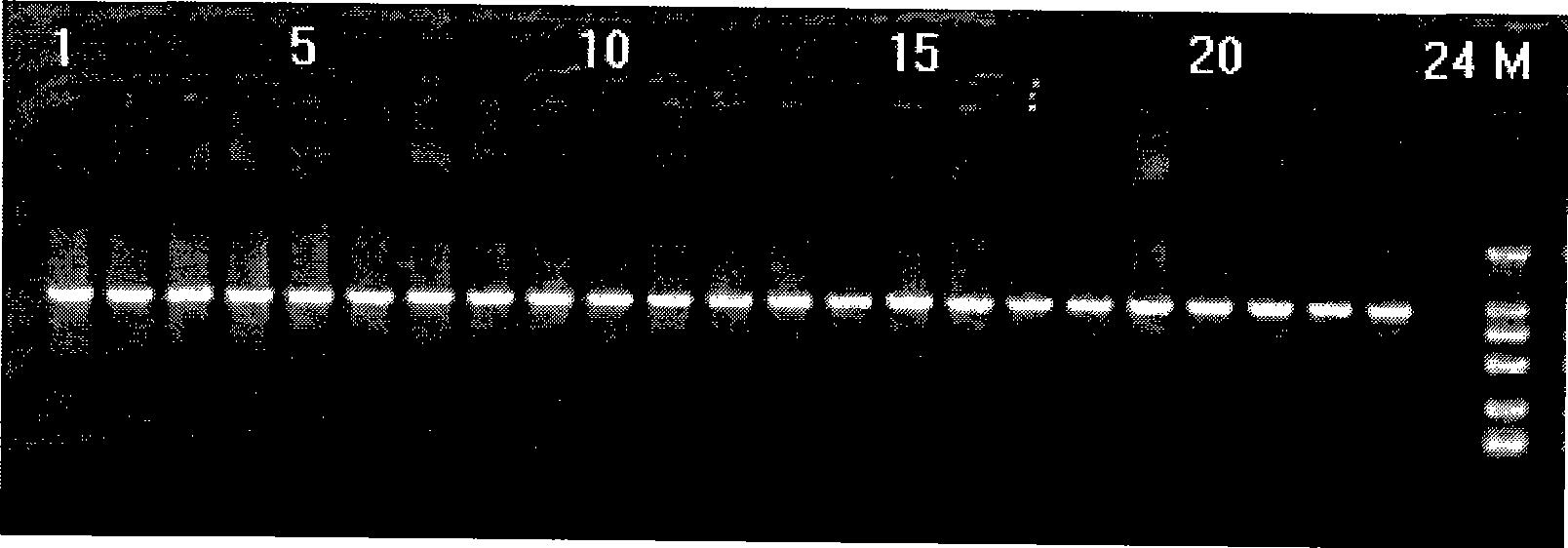

Method for detecting hereditary hearing loss relative connexin 26 gene GJB2 mutation and kit for detection

InactiveCN101363054AImprove diagnosis rateEasy diagnosisMicrobiological testing/measurementLink proteinExon

The invention relates to a method for testing gap linking protein 26 gene GJB2 mutation related to hereditary hearing impairment, which completely enlarges GJB2 gene base boot sector, exon 1, exon 2 and shear zone by polymerase chain reaction; and then, DNA sequence is measured to detect whether GJB2 genetic mutation exists; the method of the invention can completely cover all the genetic mutation of the GJB2 gene base boot sector, the exon 1, the exon 2 and the shear zone, so that detectable rate of the GJB2 genetic mutation and diagnosis rate of hereditary hearing impairment related to the GJB2 gene are improved; compared with that sequence measurement is separately carried out on a GJB2 code area, the method is more comprehensive and reliable, so as to be beneficial to the diagnosis of hereditary hearing impairment.

Owner:ドングァン アオマイヤ ジェネティック テクノロジー カンパニー リミテッド

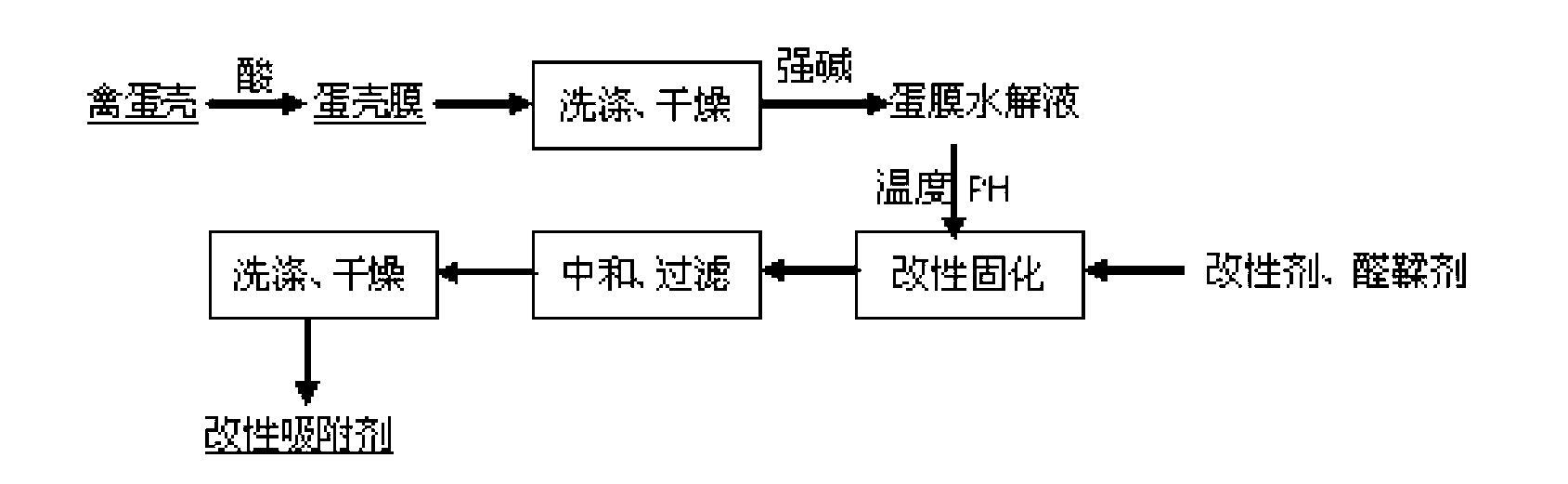

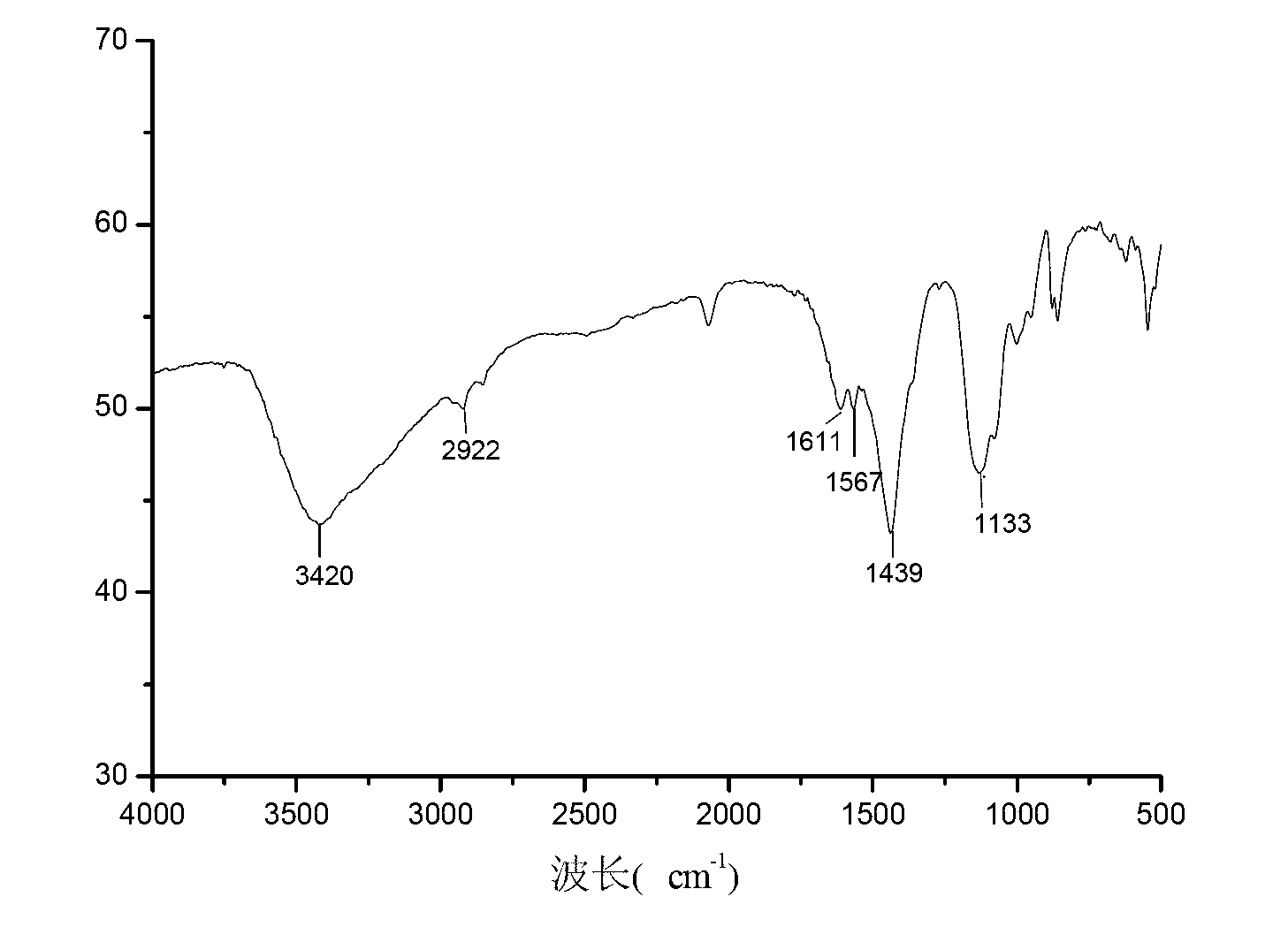

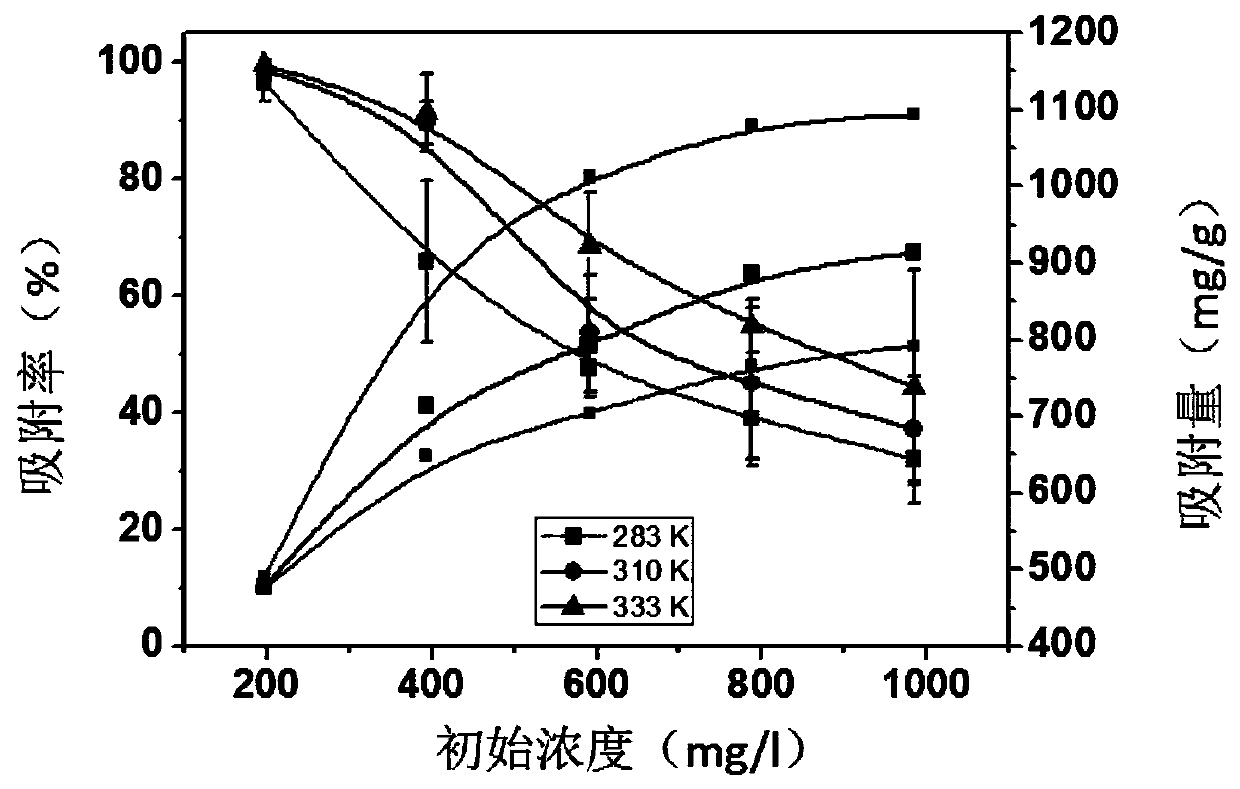

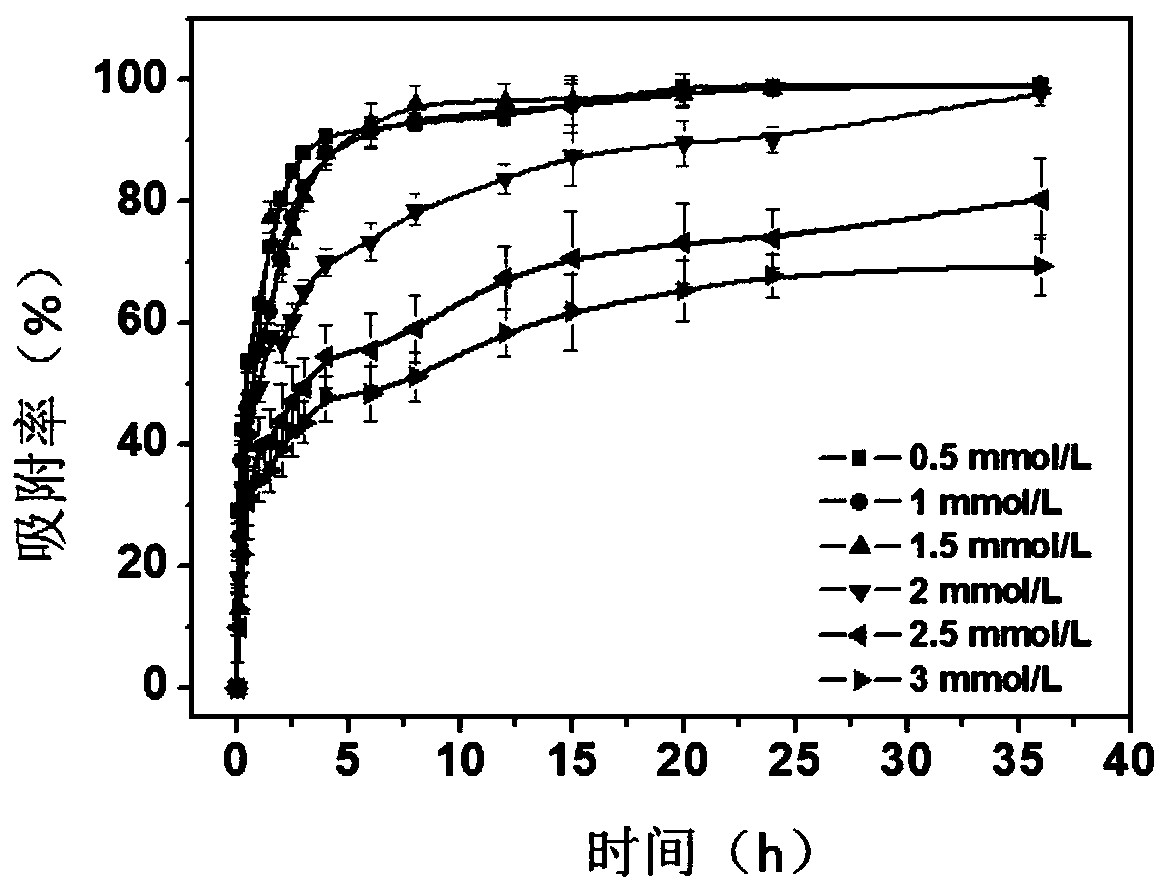

Preparation method of gold absorbent based on waste eggshell membrane biomaterial

ActiveCN103191701AImprove adsorption capacityIncrease the number ofOther chemical processesProcess efficiency improvementCross-linkSorbent

The invention relates to a preparation method of a gold absorbent based on a waste eggshell membrane biomaterial, and belongs to the technical field of resource recycling. Through the acid pretreatment, protein hydrolysis and modified curing of an eggshell, a modified biological protein composite absorbent can be obtained. The cross-linked protein is changed to a water-soluble substance through the hydrolysis of the protein, internal functional groups also can be exposed, the modified curing process is carried out in the water solution, and the reaction uniformity is improved. The prepared absorbent contains a great amount of specific reactive functional groups for adsorbing gold ions, thereby having a special selective adsorption property for the gold ions. The preparation material is sourced from the kitchen waste eggshell, so that no only can the surface of the adsorbent have a plurality of protein groups of the eggshell membrane, but also the functional property of a modifier can be integrated. The raw materials of the absorbent are abundant, the cost is low, the process is simple, and the operating time is short; and moreover, the kitchen waste is used for recycling the gold to treat the waste by utilizing the waste, and a high adsorption property and an excellent practicability can be realized.

Owner:BEIJING UNIV OF TECH

Preparation and/or formulation of proteins cross-linked with polysaccharides

Therapeutic compositions and / or formulations are provided, comprising: at least one cross-linked protein matrix, wherein the at least one cross-linked protein matrix comprises at least one protein residue and at least one saccharide-containing residue, and methods of producing the same. The cross-linked protein matrix may be derived from cross-linking a full length or substantially full length protein, such as tropoelastin, elastin, albumin, collagen, collagen monomers, immunoglobulins, insulin, and / or derivatives or combinations thereof, with a saccharide containing cross-linking agent, such as a polysaccharide cross-linking agent derived from, for example, hyaluronic acid or a cellulose derivative. The therapeutic compositions may be administered topically or by injection. The present disclosure also provides methods, systems, and / or kits for the preparation and / or formulation of the compositions disclosed herein.

Owner:APTALIS PHARMA

Composite materials

InactiveUS20120023677A9Easy to movePromote nerve regenerationAnthropod material medical ingredientsFibre treatmentCross-linkSurgical implant

This application discloses a composite material comprising one or more silk elements in an acrylic or cross-linked protein matrix. The silk elements are made from the group of silk elements consisting of domestic silkworm silk, wild silkworm silk, spider dragline silk, and filaments spun from recombinant silk protein or protein analogues. The composite material is particularly useful for use in-surgical-implants.

Owner:OXFORD BIOMATERIALS LTD

Compositions and methods for entrapping protein on a surface

ActiveUS20170327599A1Sequential/parallel process reactionsCarrier-bound/immobilised peptidesWater solubleLink protein

The present invention provides a formulation to link protein to a solid support that comprises one or more proteins, Oligo-dT and one or more non-volatile, water-soluble protein solvents, solutes or combination thereof in an aqueous solution. Further provided is a method of attaching a protein to a surface of a substrate. The formulations provided herein are contacted onto the substrate surface, printed thereon and air dried. The substrate surface is irradiated with UV light to induce thymidine photochemical crosslinking via the thymidine moieties of the Oligo-dT.

Owner:PURE TRANSPLANT SOLUTIONS L L C

Adsorbing material based on cross-linked protein, and applications of adsorbing material in recovery of precious metals

ActiveCN110975826AEasy to prepareLow costOther chemical processesProcess efficiency improvementBovine serum albuminAdsorption effect

Owner:SHAANXI NORMAL UNIV

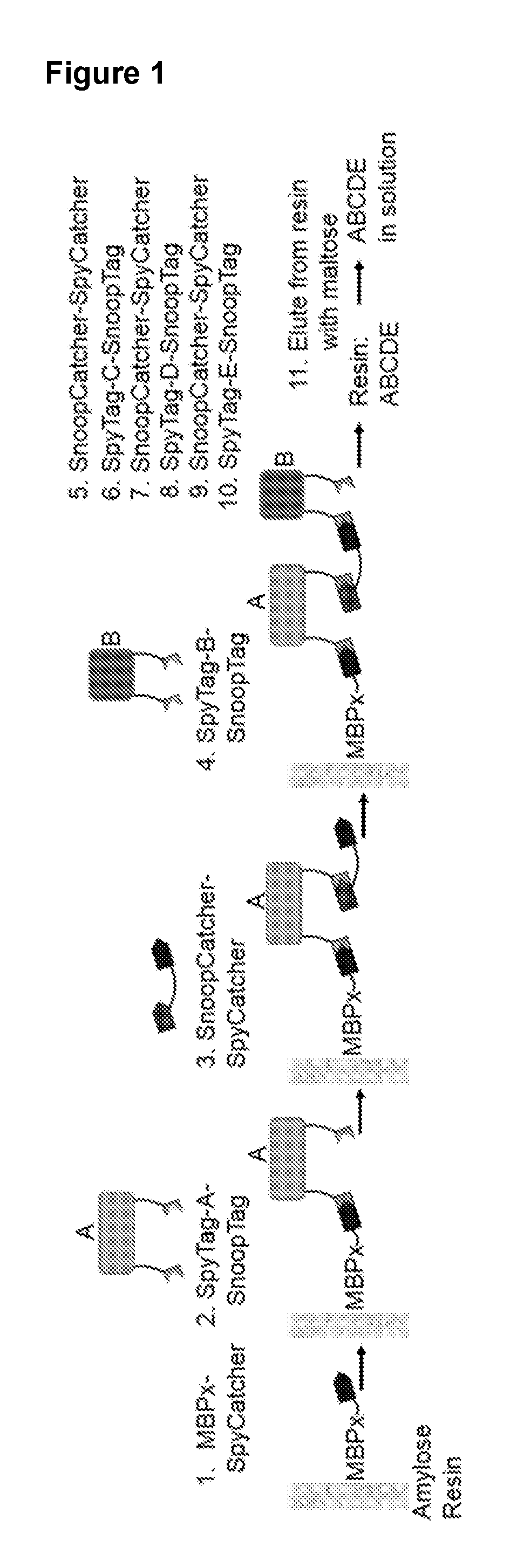

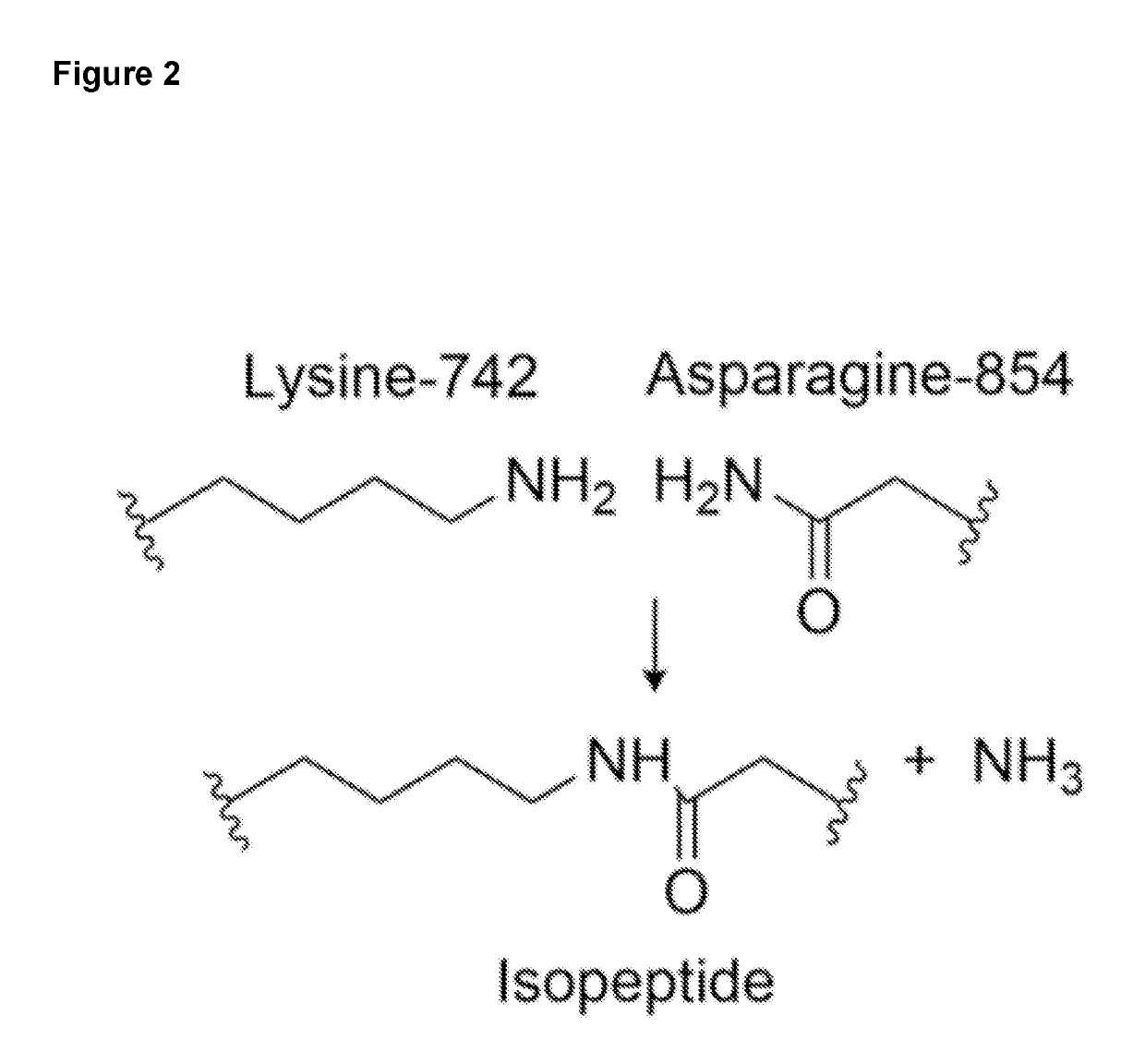

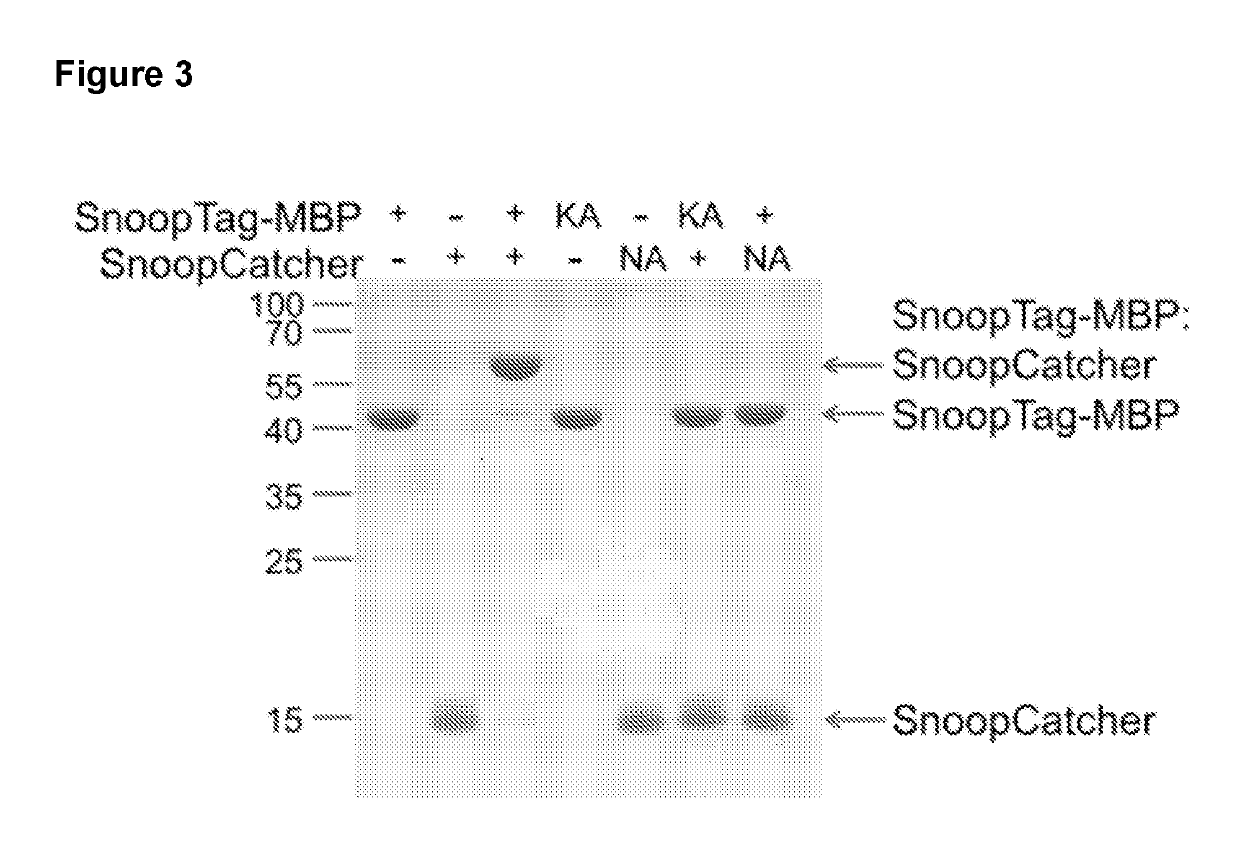

Methods and products for fusion protein synthesis

ActiveUS10526379B2Peptide librariesFusion with post-translational modification motifLink proteinTARP Protein

A method of producing a fusion protein is provided. The method includes: a) contacting a first protein with a second protein under conditions that enable the formation of an isopeptide bond between said proteins to form a linked protein; and b) contacting the linked protein from (a) with a third protein under conditions that enable the formation of an isopeptide bond between said third protein and said linked protein to form a fusion protein. Peptide linkers and the use of orthogonal pairs of said linkers in the synthesis of fusion proteins are also provided. Recombinant proteins comprising said linkers, nucleic acid molecules encoding said proteins and linkers, vectors comprising said nucleic acid molecules and host cells comprising said vectors and nucleic acid molecules are also contemplated.

Owner:OXFORD UNIV INNOVATION LTD

Production process for separating and purifying fiber linking proteins from pig blood

InactiveCN104945495AMeet the needs of large-scale productionIncrease profitPeptide preparation methodsAnimals/human peptidesFiberBlood plasma

The invention relates to a production process for separating and purifying fiber linking proteins from pig blood. The production process comprises the following steps: (1) separating blood plasma and blood cells from whole blood; (2) salting out: charging an acidic Na2HPO4-NaH2PO4 buffer solution into an upper layer of plasma, uniformly mixing, charging ammonium sulfate while stirring the solution so that the saturation degree reaches 20 percent, adjusting pH to be alkaline, placing the mixed solution into a refrigerator, refrigerating the mixed solution for 1.5 to 2.5 hours, sufficiently precipitating, finally centrifuging the solution, and obtaining a main precipitation component, i.e., fiber linking proteins; (3) dialyzing and desalting: dissolving precipitates in the step (2) into an acidic PBS buffer solution, putting the mixed solution into a dialysis bag, carrying out the dialysis and concentration, thereby obtaining a crude product of the fiber linking proteins; and (4) purifying: carrying out the affinity chromatography for an upper sample of the fiber linking protein crude product obtained in the step (3) by virtue of a gelatin sepharose-4B column, and eluting by virtue of a specific volume to obtain the purified fiber linking proteins. The production process is simple, low in requirement on needed equipment and suitable for industrialized production.

Owner:ANHUI BAODI MEAT FOODS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com