Preparation method of gold absorbent based on waste eggshell membrane biomaterial

A technology of biological materials and biomass materials, applied in the field of resource recovery, can solve problems such as optimization of the adsorption capacity of egg membrane adsorbents, failure to describe the adsorption behavior of precious metal gold, and unsatisfactory adsorbents, so as to achieve controllable product particle size and facilitate sustainable The effect of continuous growth, volume and uniformity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

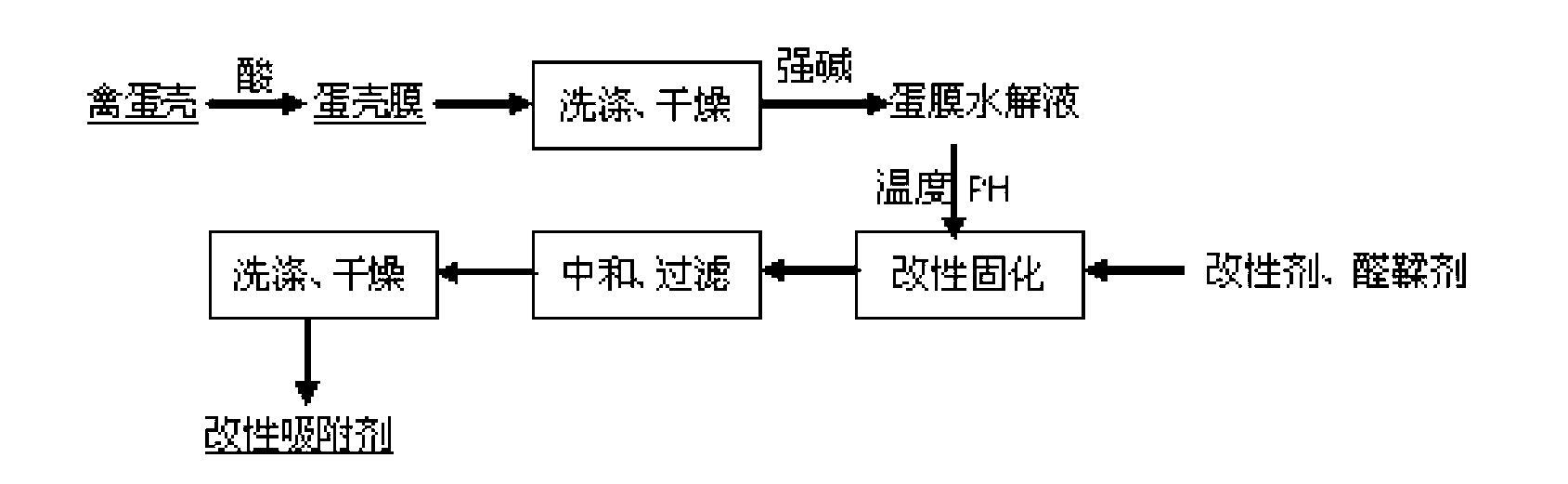

Method used

Image

Examples

Embodiment 1

[0038] (1) Acidic pretreatment: The raw materials used are poultry eggshells, glacial acetic acid with a concentration of 99%, and deionized water. First, wash the poultry eggshells and dry them at 40°C, then prepare an acetic acid solution with a concentration of 10%, and control the solid-liquid ratio to 1:2. Mix and react for 2 hours. In order to prevent the egg shell from floating out of the liquid surface and affect the reaction, regular stirring is required during the reaction process. Finally, the egg membrane is taken out, washed with deionized water and dried at 50°C.

[0039] (2) Strong alkali hydrolysis: first prepare a NaOH solution with a concentration of 7%, mix the dried egg film obtained in (1) with NaOH, heat in a 50°C water bath in a reaction vessel, and control the solid-to-liquid ratio of the egg film and NaOH solution to 1:80, take out the reaction dish after 10 minutes, and cool to room temperature.

[0040] (3) Solidification and precipitation: Add thio...

Embodiment 2

[0043] (1) Acidic pretreatment: The raw materials used are poultry eggshells, hydrochloric acid with a concentration of 36-38%, and deionized water. First, wash the poultry eggshells and dry them at 40°C, then prepare a hydrochloric acid solution with a concentration of 2%, and control the solid-liquid ratio to 1:10. Mix and react for 4 hours. In order to prevent the egg shell from floating out of the liquid surface and affect the reaction, regular stirring is required during the reaction process. Finally, the egg membrane is taken out, washed with deionized water and dried at 25°C.

[0044] (2) Strong alkali hydrolysis: first prepare a KOH solution with a concentration of 5%, mix the dried egg film obtained in (1) with KOH, heat in a water bath at 80°C in a reaction vessel, and control the solid-to-liquid ratio of the egg film and KOH solution to 1:120, take out the reaction dish after 20 minutes, and cool to room temperature.

[0045] (3) Solidification and precipitation: A...

Embodiment 3

[0048] (1) Acidic pretreatment: The raw materials used are poultry eggshells, concentrated nitric acid with a concentration of 69%, and deionized water. First, wash the poultry eggshells and dry them at 40°C, then prepare an acetic acid solution with a concentration of 5%, and control the solid-liquid ratio to 1:5. Mix and react for 6 hours. In order to prevent the eggshells from floating out of the liquid and affect the reaction, regular stirring is required during the reaction. Finally, the egg membranes are taken out, washed with deionized water and dried at 35°C.

[0049] (2) Strong alkali dissolution: first prepare a NaOH solution with a concentration of 3%, mix the dried egg film obtained in (1) with NaOH, heat in a water bath at 60°C in a reaction vessel, and control the solid-to-liquid ratio of the egg film to NaOH solution to 1:100, take out the reaction dish after 30min, and cool to room temperature.

[0050] (3) Solidification and precipitation: Add urea and formal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com