Patents

Literature

107results about How to "Easy to put into production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminum alloy material and production method of cast-rolling stock of decorative strip of same

The invention relates to a 3004 aluminum alloy material and a production method of a cast-rolling stock of a decorative strip of the 3004 aluminum alloy material. The compositions of the aluminum alloy material comprise smaller than or equal to 0.25 percent of Si, 0.20 to 0.60 percent of Fe, 0.10 to 0.15 percent of Cu, 1.0 to 1.20 percent of Mn, 0.85 to 1.25 percent of Mg, smaller than or equal to 0.05 percent of Ti, and the remaining amount of Al. The production method comprises the steps of smelting, refining, on-line degassing, grain refinement, filtration, cast rolling, and the like; during the smelting, 50 percent to 60 percent of electrolytic aluminum liquid and the rest of aluminum alloy waste materials are mixed and smelted; the compositions except Mg are added to the mixture; and after the steps of powder injection refining, slag skimming, magnesium ingot adding, furnace turning-down and refining are conducted, the stock of the strip is cast-rolled. A product of the production method has even and steady chemical compositions and can satisfy the mechanical property requirements of subsequent rolling, so that the yield of subsequent rolling is increased; by using the aluminum alloy waste materials as raw materials, the raw materials are saved; by directly adding the electrolytic aluminum liquid, gas loss in the melting process is reduced, and burning loss in the waste material melting process can also be decreased; and by using a cast-rolling manner to replace a hot-rolling manner, the process is simplified and the production cost is greatly reduced.

Owner:沁阳市鼎建建设发展有限公司

Method for spinning high-grade knitting yarns by using long flax fibers

InactiveCN102704095ASoft textureImproved drying uniformityFibre treatmentYarnYarnPulp and paper industry

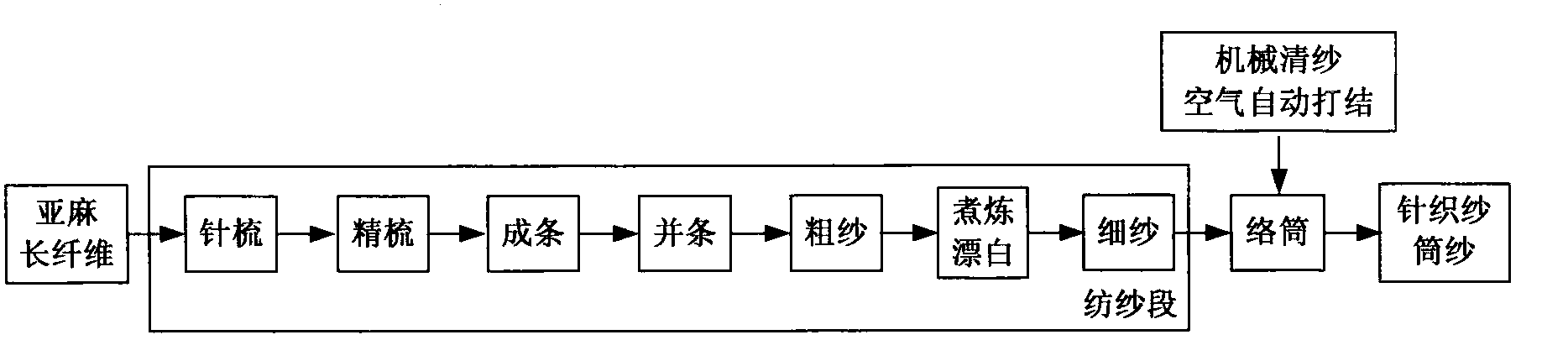

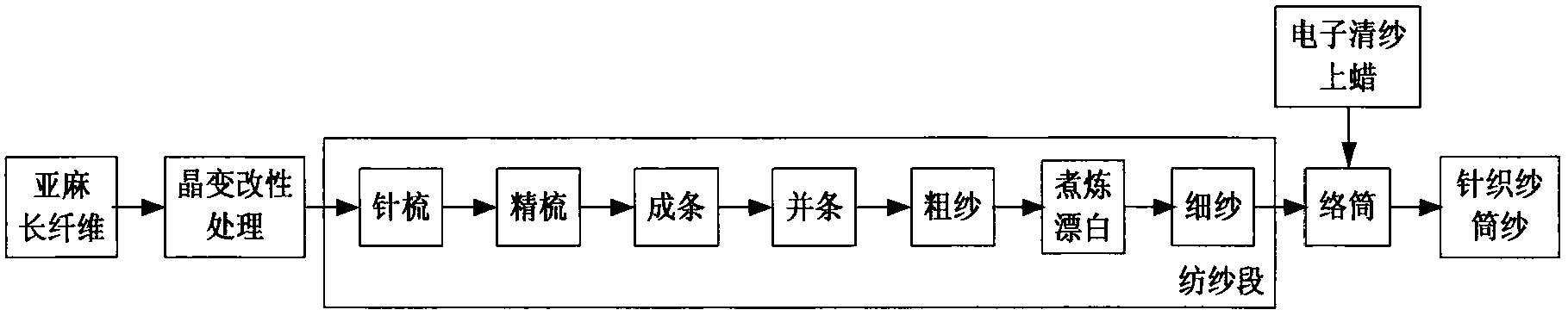

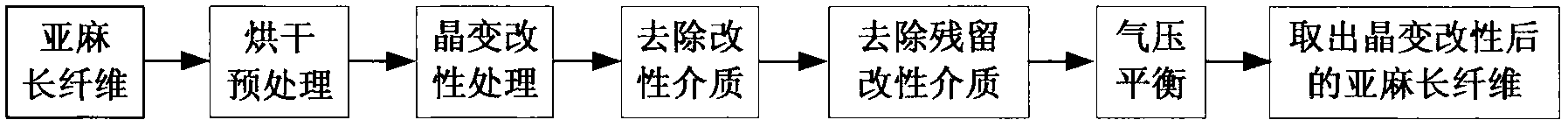

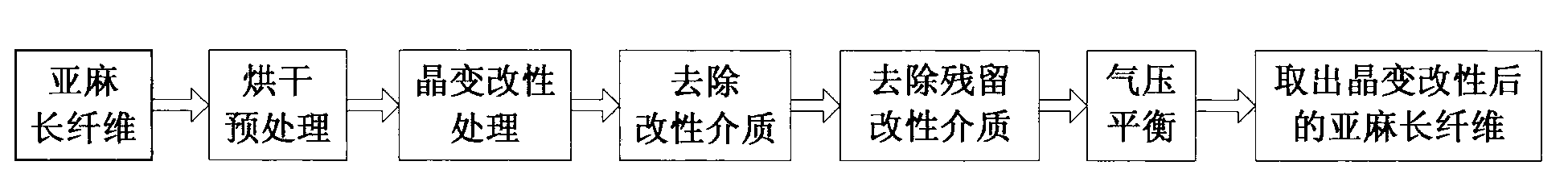

The invention provides a method for spinning high-grade knitting yarns by using long flax fibers. The method comprises the steps of: carrying out crystallization modification treatment on the long flax fibers, carrying out gilling, combing, slivering, drawing, roving, boiling-off, bleaching and spinning operations sequentially, and carrying out electronic yarn clearing and waxing simultaneously in a spooling process, thereby forming the knitting yarns. According to the method provided by the invention, the crystallization modification treatment is carried out on the long flax fibers, so that the fibers are soft in texture and have an improved uniformity for dry adjustment, therefore a foundation for spinning the high-grade knitting yarns is laid; and electronic yarn clearing and waxing operations are simultaneously carried out in the spooling process owing to the facts that the fibers are soft in texture and have an improved uniformity for dry adjustment after the crystallization modification treatment is carried out on the long flax fibers, therefore the spinning efficiency is improved, and the knitting yarn quality is improved.

Owner:DONGHUA UNIV +1

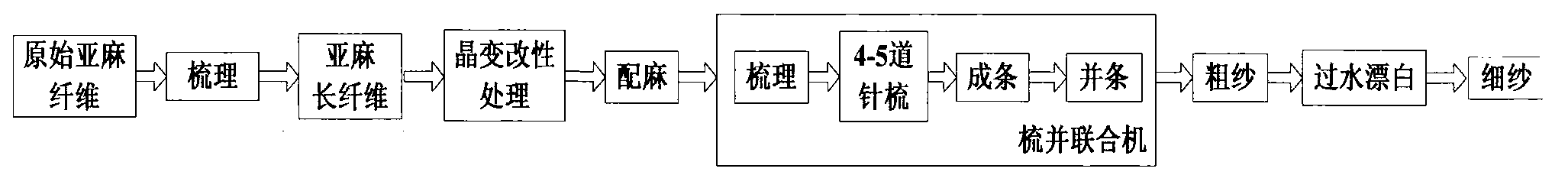

Wet spinning method of low-proportion high-spun flax macrofiber

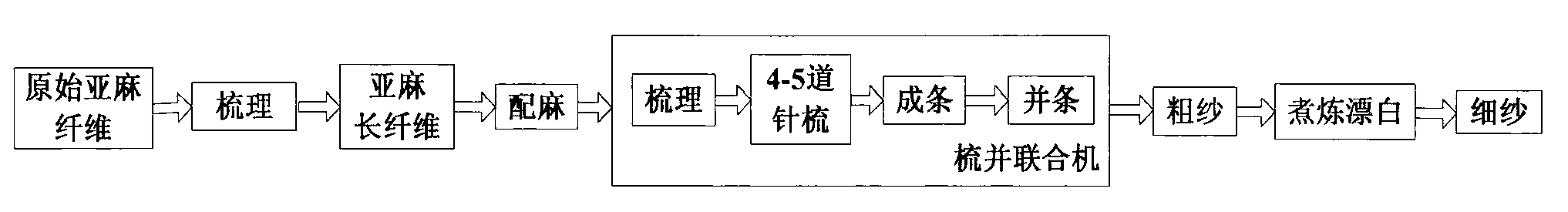

The invention provides a wet spinning method of low-proportion high-spun flax macrofiber, which comprises the steps of: a first step, combing original flax fiber to obtain flax macrofiber; a third step, carrying out hemp proportioning on the flax macrofiber obtained after crystal transition modification in a former step, gilling, paralleling and spinning by a roving process to obtain flax roving; and a fifth step, carrying out wet spinning on the flax roving obtained after water blanching in a former step by a wet spinning frame to obtain the flax yarn. The wet spinning method is characterized in that a second step of carrying out crystal transition modification treatment on the flax macrofiber is performed between the first step and the third step, and a fourth step of carrying out water blanching on the flax roving is performed between the third step and the fifth step. The method has the advantages that the utilization ratio of the flax macrofiber is greatly improved and reaches more than 70%, and the material resources are saved; high-count linen yarn can be spun according to the fiber proportion of the traditional wet spinning method; and the water blanching replaces the scouring blanching in the traditional wet spinning method, so that the process is simplified, the energy sources are saved and the cost is lowered.

Owner:DONGHUA UNIV +1

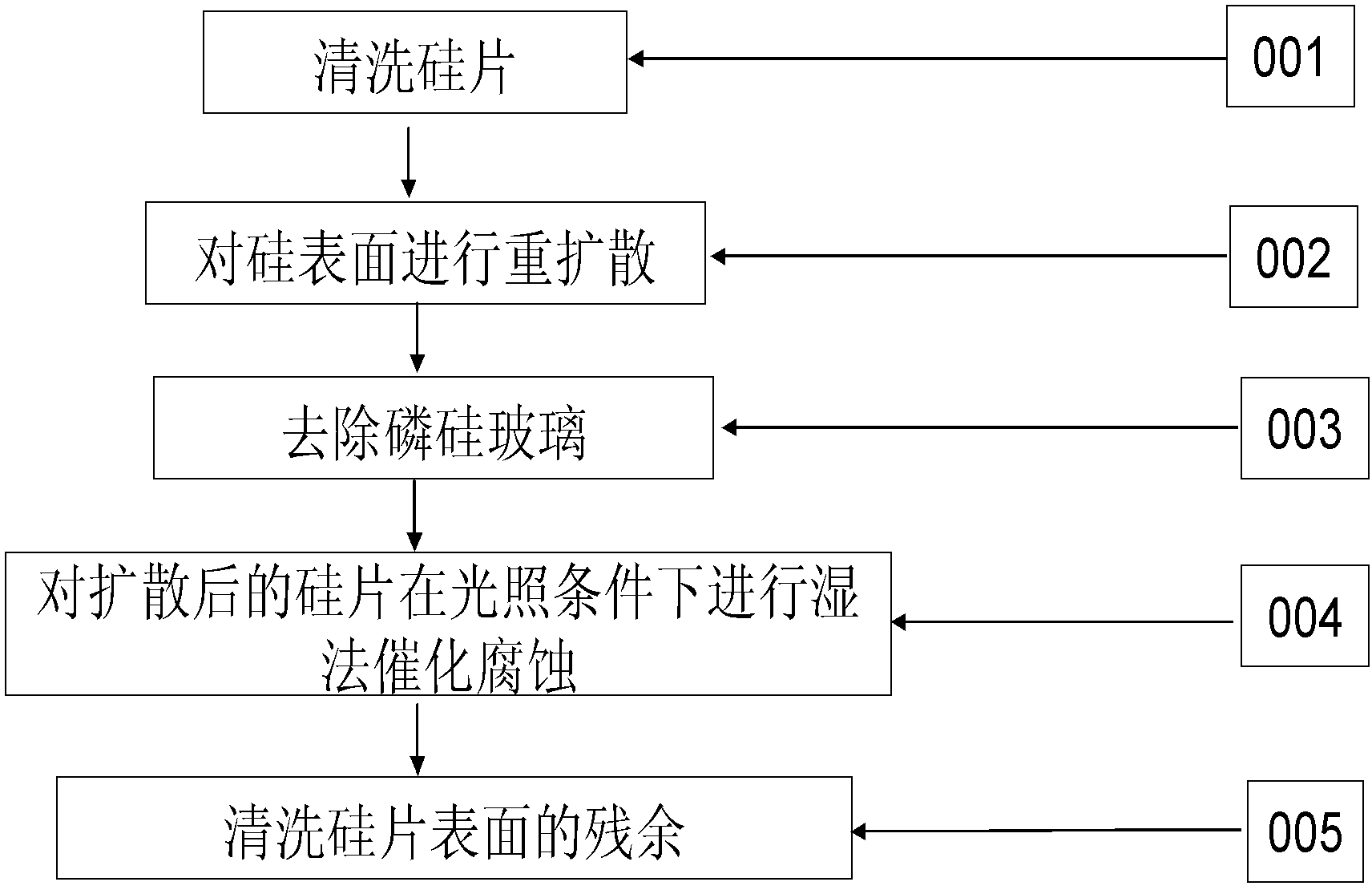

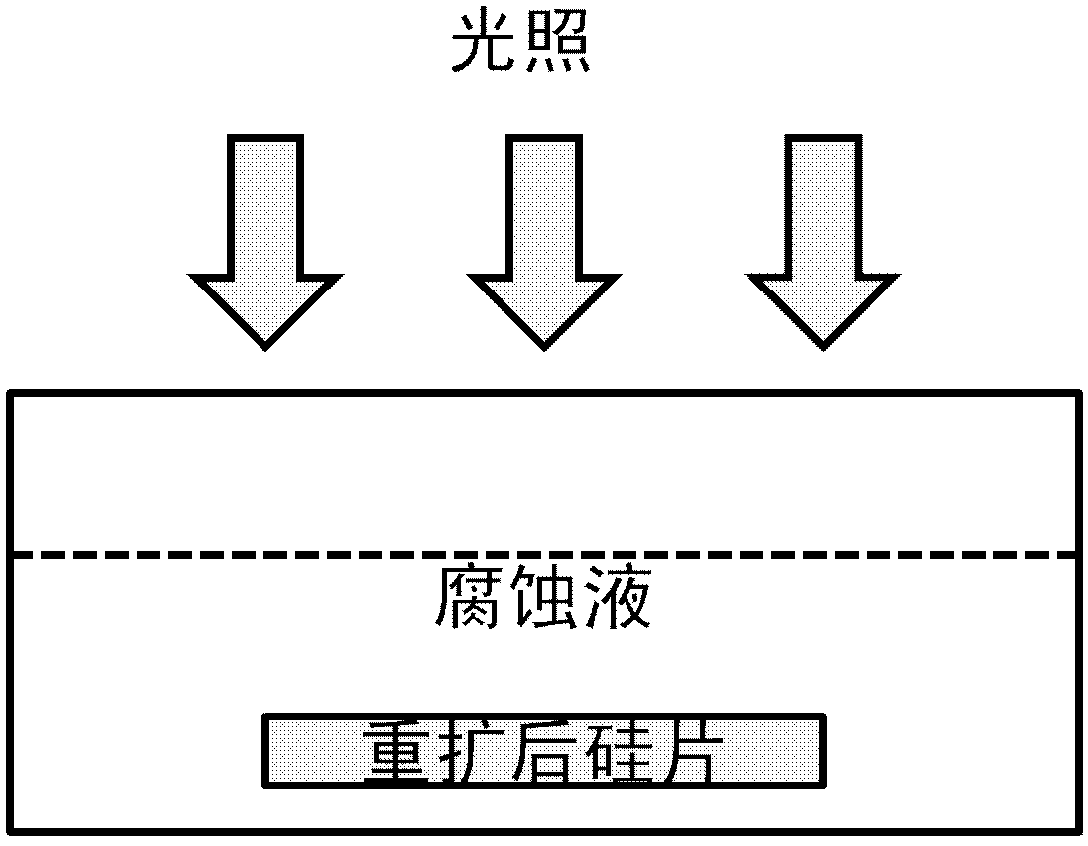

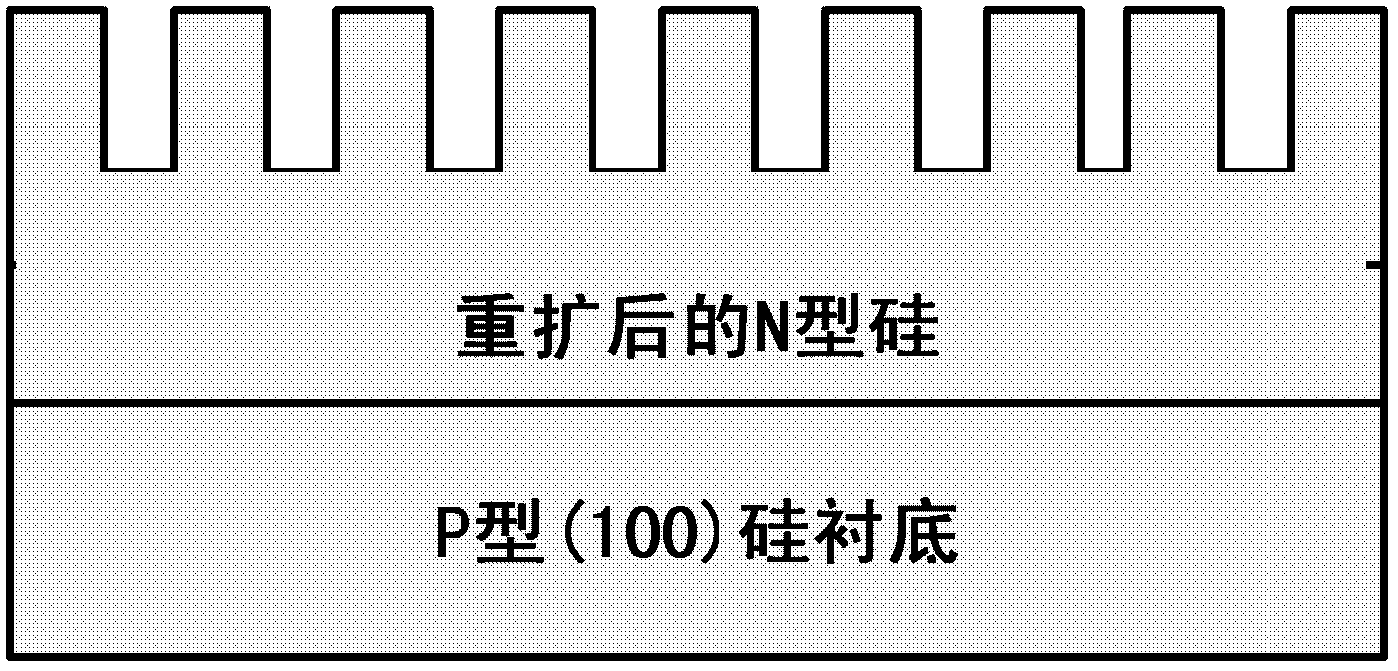

Method for realizing high-trapping-light nanostructure single-face texture surface making

InactiveCN103219427AObvious advantagesGood effectAfter-treatment detailsFinal product manufactureEtchingTrapping

The invention discloses a method for realizing high-trapping-light nanostructure single-face texture surface making. The method comprises the steps: cleaning a silicon wafer; conducting re-spreading to the surface of the silicon wafer; removing residues on the surface of the silicon wafer which is re-spread; coating TiO2 of a nanostructure on the surface of the silicon wafer or depositing Ti on the surface of the silicon wafer, and rapidly annealing; conducting wet etching on the silicon wafer to form the nanostructure; and removing oxide and titanium ions which are not completely reacted on the surface of the silicon wafer. Compared with the prior art, the method is adopted to prepare the high-trapping-light nanostructure, only technology sequence is changed, and under the premise that key equipment is not increased, only one light source needs to be added or only sun light needs to be led in so that the purpose of single-face texture surface making can be achieved. The nanostructure has a good light trapping effect. Besides, the method is simple in process step, and suitable for mass production.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

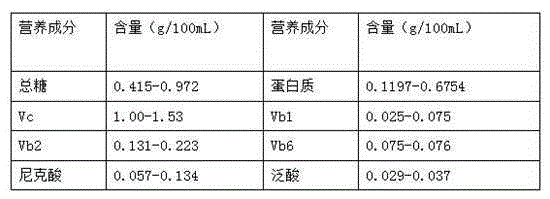

Production method of fermented fruit and vegetable juice and Chinese rice wine composited function beverage

ActiveCN105249100ALong flavorFlavor substances, these flavors lastAlcoholic beverage preparationFood ingredient functionsBiotechnologyNutrition

The invention discloses a production method of a fermented fruit and vegetable juice and Chinese rice wine composited function beverage. The production method comprises steps as follows: fermented fruit and vegetable juice and fermented fruit and vegetable Chinese rice wine are prepared; the fermented fruit and vegetable Chinese rice wine, the fermented fruit and vegetable juice and water are mixed in a volume ratio being (7-10): (3-6): (1-1.5); degassing, sterilizing and filling are performed after mixing, and a finished product is obtained. The fermented fruit and vegetable juice and Chinese rice wine composited function beverage produced with the method can overcome defects of uncomprehensive nutrition and absence of a healthcare function of the fermented fruit and vegetable Chinese rice wine as well as low content of vitamin B of the fermented fruit and vegetable juice, produces unique fermentation flavor, has more comprehensive and more balanced nutrition and gastrointestinal healthcare efficacy, is suitable for people of all ages and is a novel nourishing beverage.

Owner:广西轻工业科学技术研究院有限公司

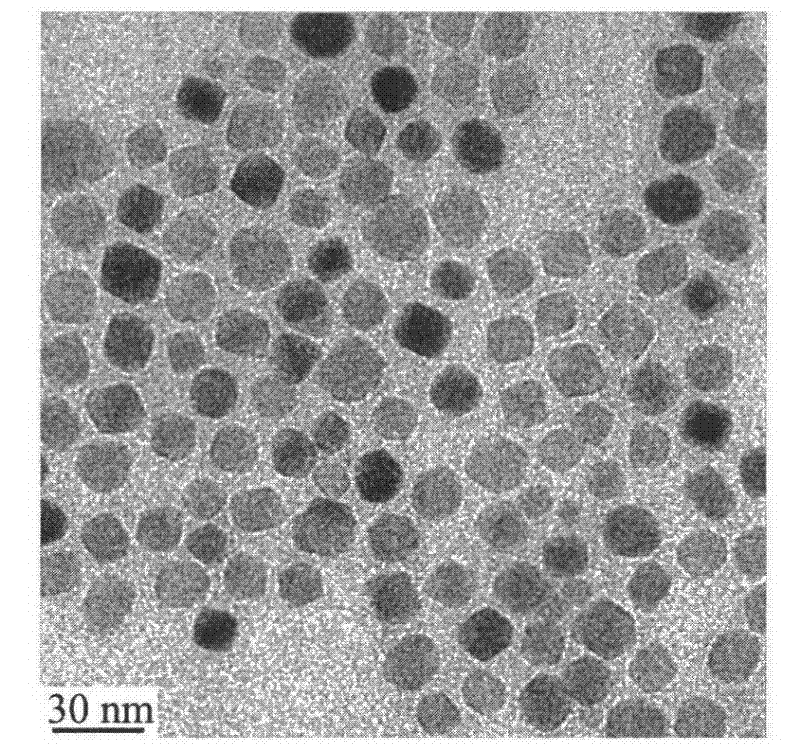

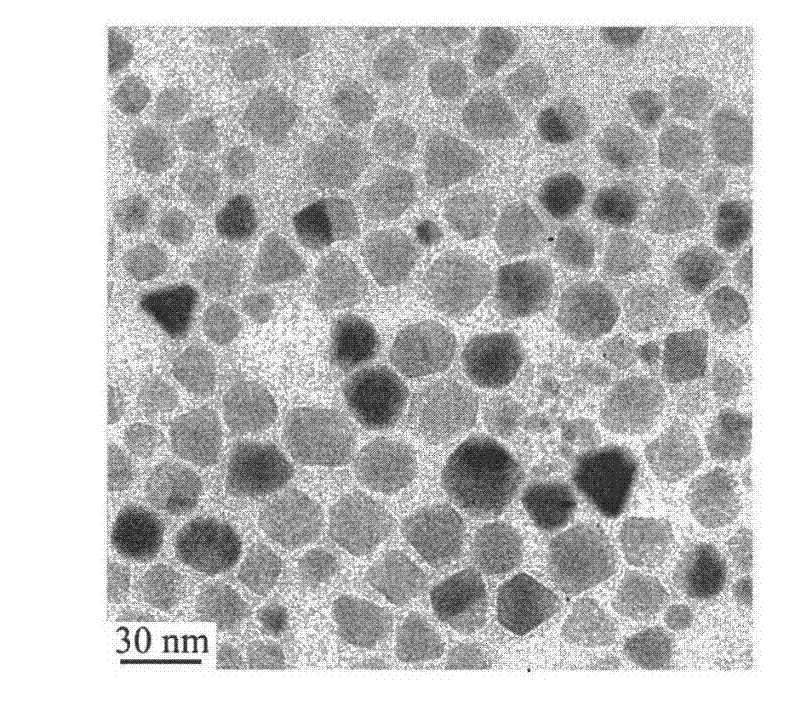

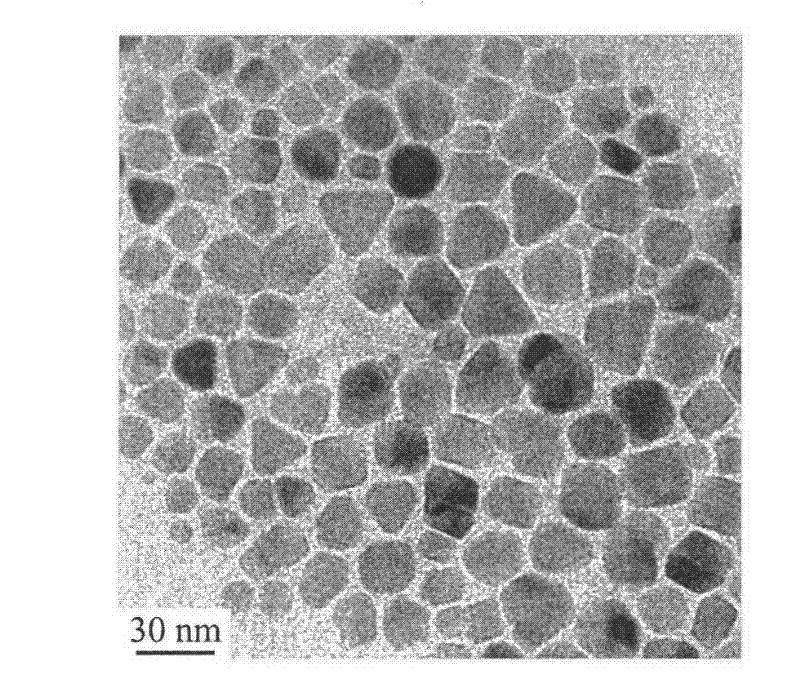

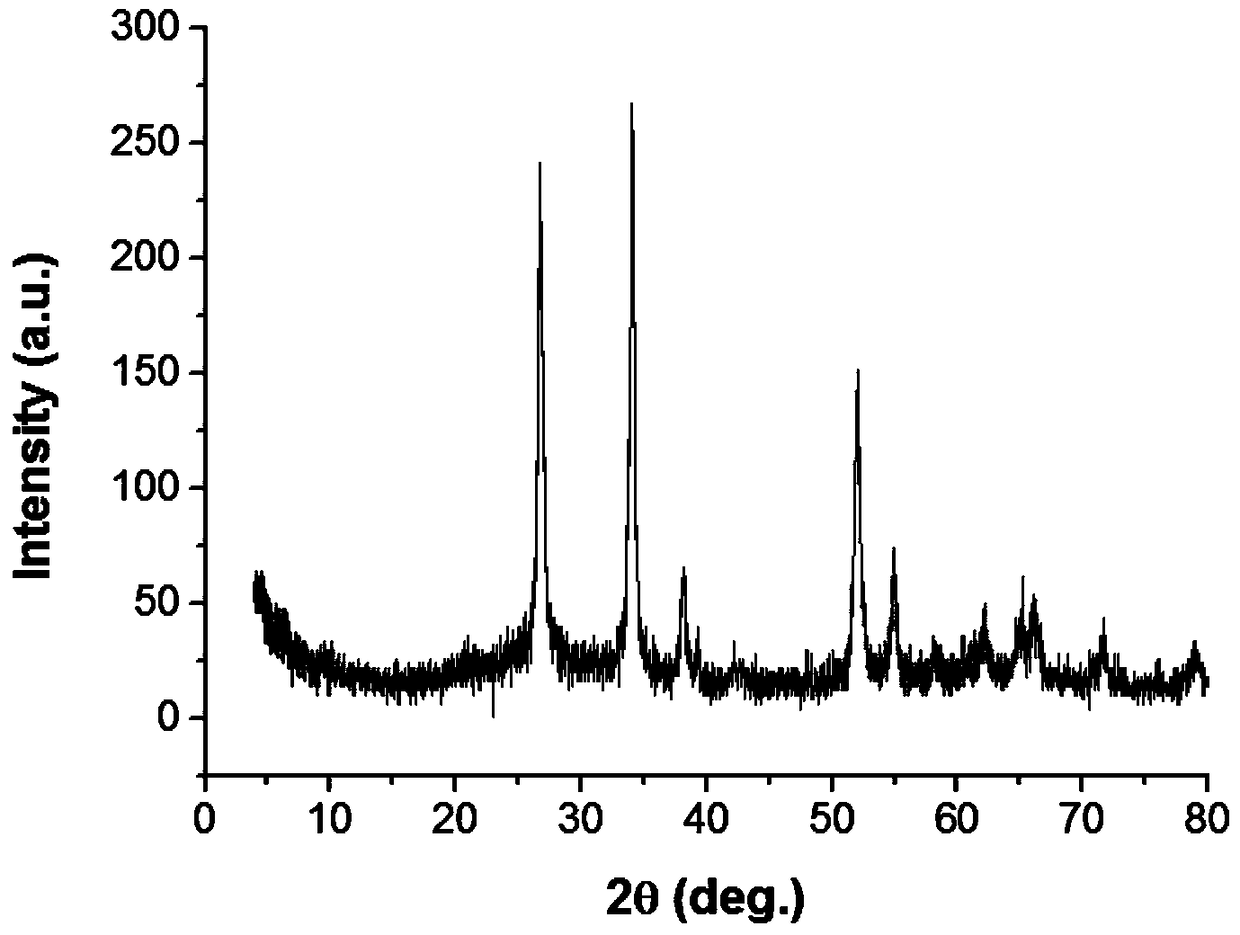

Preparation method of magnetic iron oxide nanoparticle capable of stably dispersing in water

InactiveCN102515283AReaction is easy to controlEasy to put into productionFerroso-ferric oxidesNanotechnologyPolyethylene glycolPolyethylene glycol monomethyl ether

The invention discloses a preparation method of a magnetic iron oxide nanoparticle capable of stably dispersing in water. The preparation method provided by the invention comprises the following steps of weighing 10 to 30g of triethylene glycol or polyethylene glycol having molecular weight of 600 to 20000 or polyethylene glycol monomethyl ether having molecular weight of 600 to 20000, adding 0.15 to 3g of an additive into the 10 to 30g of triethylene glycol or polyethylene glycol having molecular weight of 600 to 20000 or polyethylene glycol monomethyl ether having molecular weight of 600 to 20000, putting the mixture into a three-neck flask, putting the three-neck flask with the mixture on a temperature-control magnetic stirrer, heating the mixture to a temperature of 70 to 90 DEG C, adding 0.1 to 3g of analytically pure iron acetylacetonate into the mixture, stirring for 5 to 15 minutes by a magnetic stir bar, wherein in heating, flowing argon is fed into the three-neck flask for protection, heating to a temperature of 150 to 320 DEG C, keeping the temperature for 20 to 600 minutes by heating, cooling to a temperature below 60 DEG C, adding 50 to 70ml of analytically pure toluene or acetone into the three-neck flask, carrying out magnet adsorption, washing by analytically pure acetone twice, and dissolving precipitates obtained by the previous step in water to obtain the magnetic iron oxide nanoparticles having sizes of 3 to 50nm. The preparation method provided by the invention has simple processes and is conducive to production. The magnetic iron oxide nanoparticle obtained by the preparation method can be utilized for the fields of biotechnology, medicine, catalysis and mechanical lubrication.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

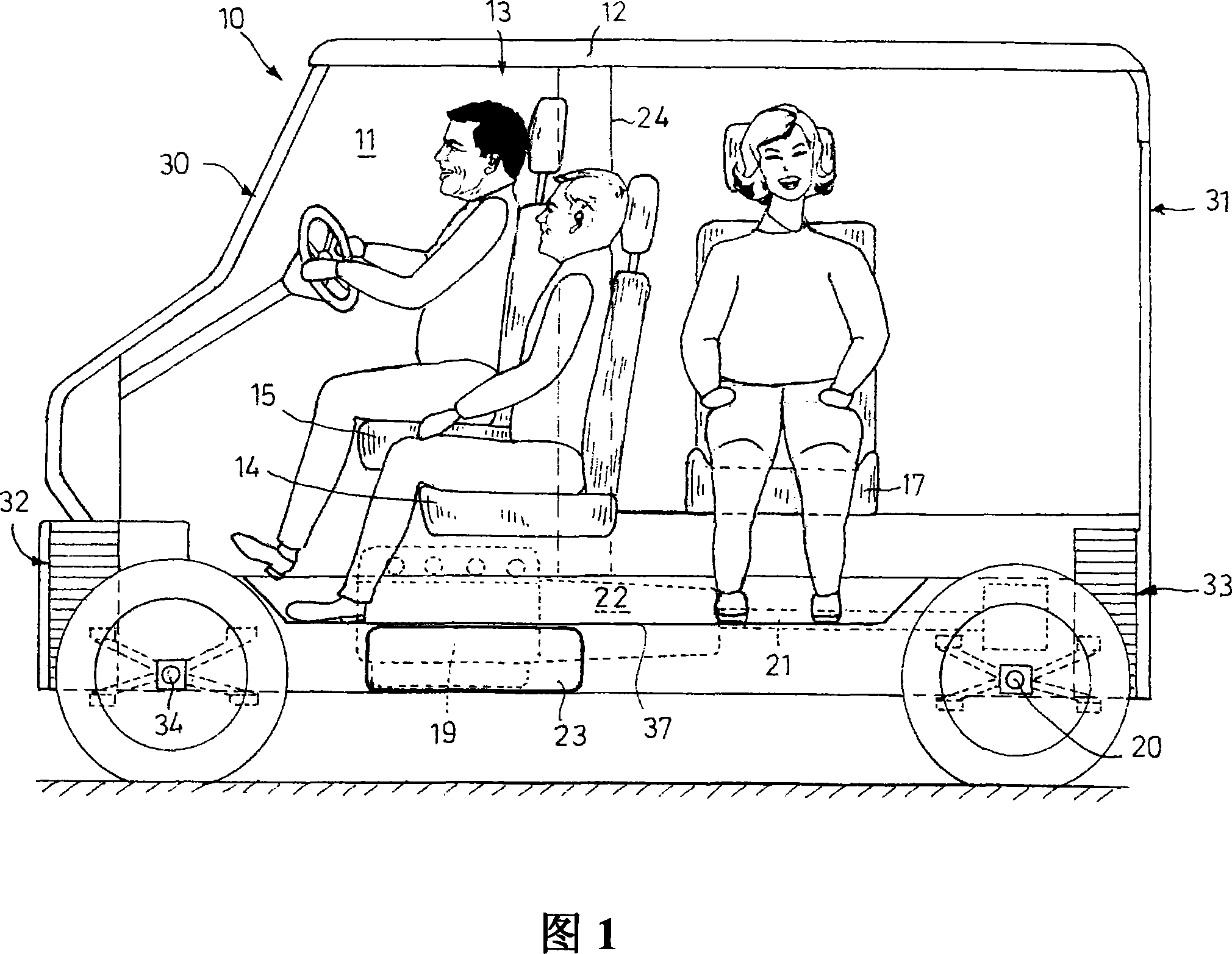

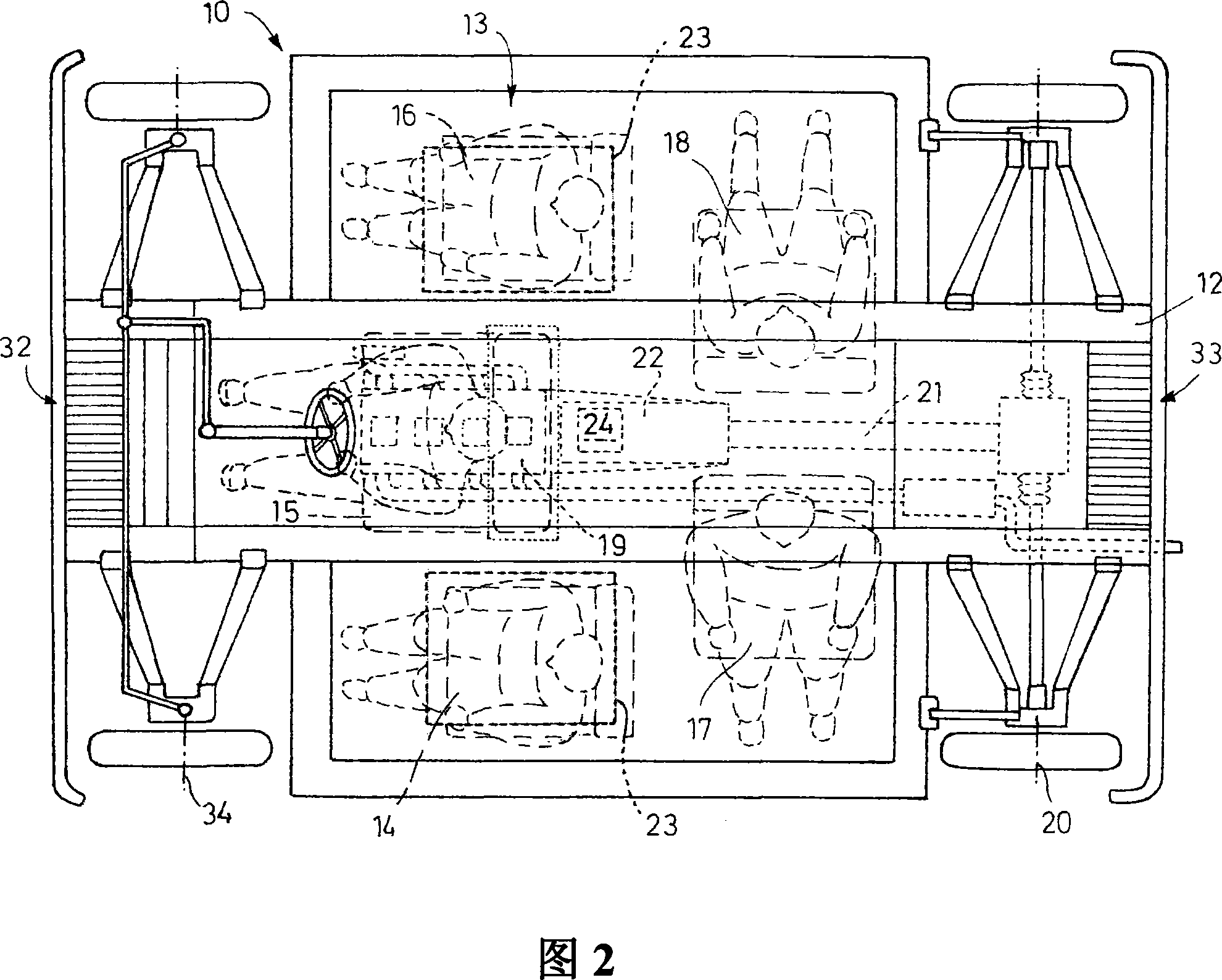

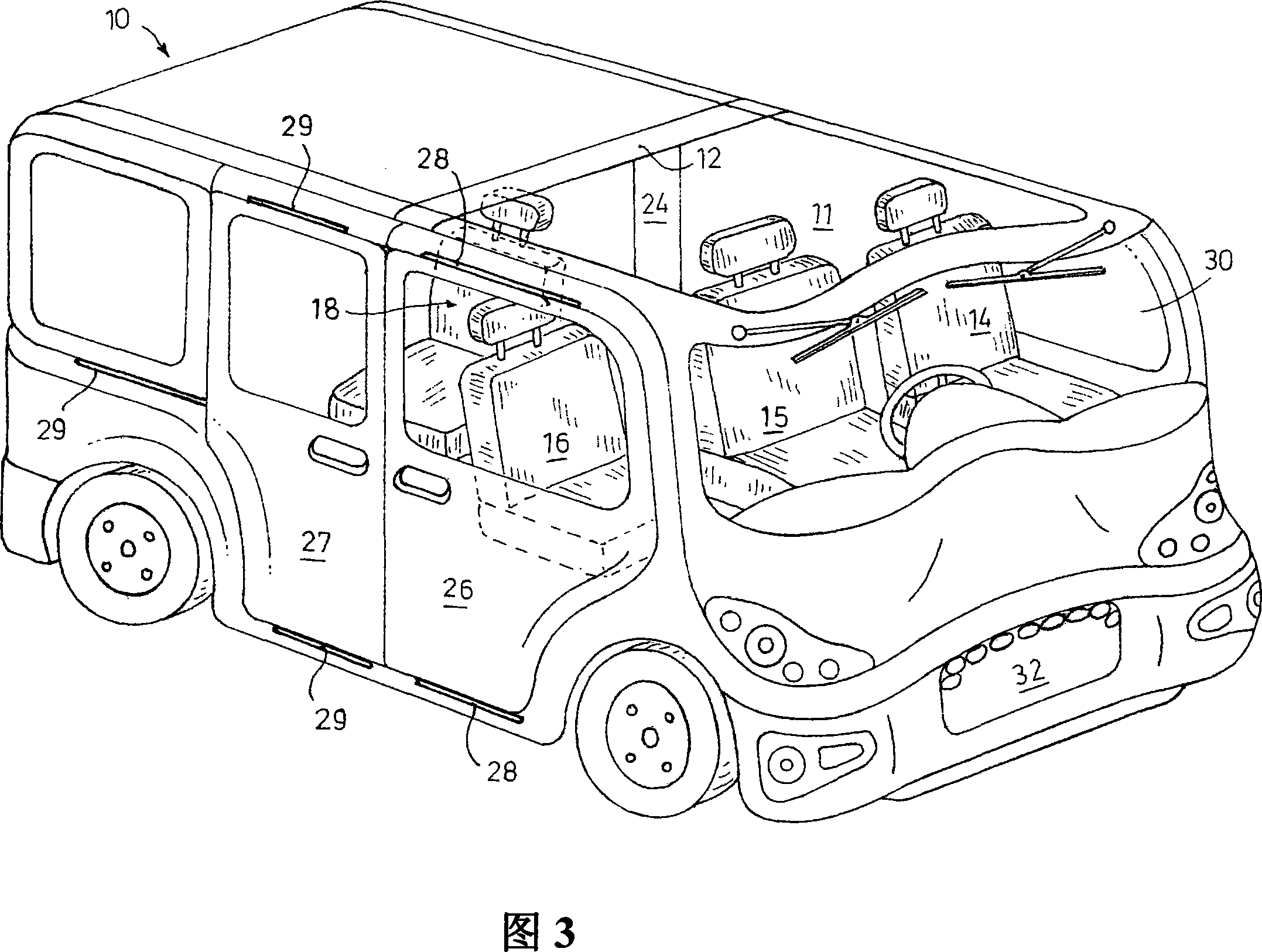

Traffic tool, especially optimization vehicle with compact structure

InactiveCN101190655AEasy to operateLess dead zoneVehicle seatsJet propulsion mountingVehicle frameDrive shaft

The vehicle (10) has a vehicle frame accommodating a utilization area (11), and a central carrying frame support with a seat row (13) having 3 seats including a centrally arranged driver seat (15) and with two rear seats (17) that are arranged at the support. The rear seats rest against each other at a rear side and are provided below the seat row. A longitudinally running force transmission device (21) is arranged at the center and acts on a rear axis (20). A central motor (19) is arranged below the seat row in an area of the driver seat that is arranged below the centre.

Owner:FORD GLOBAL TECH LLC

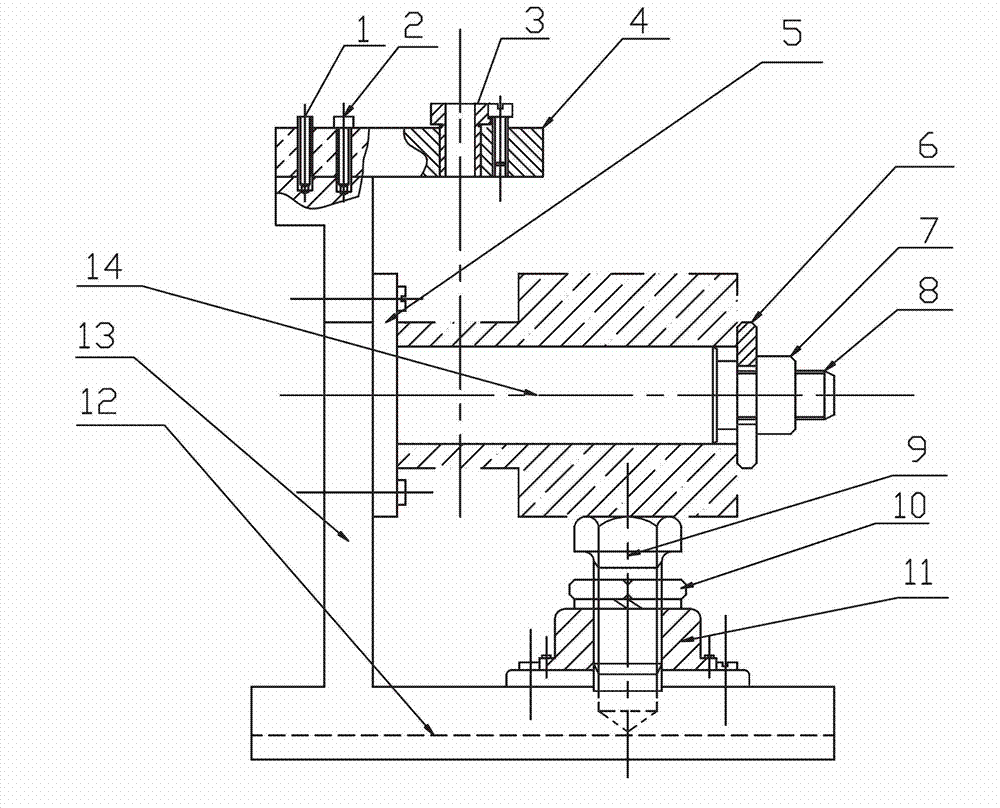

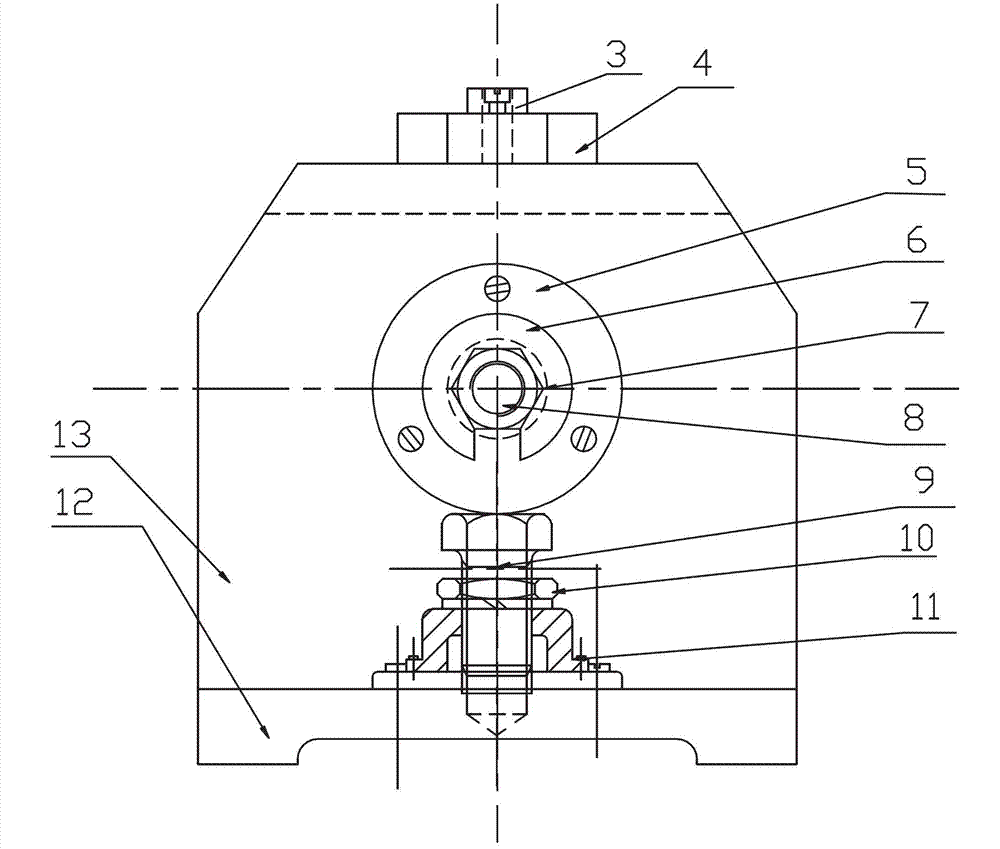

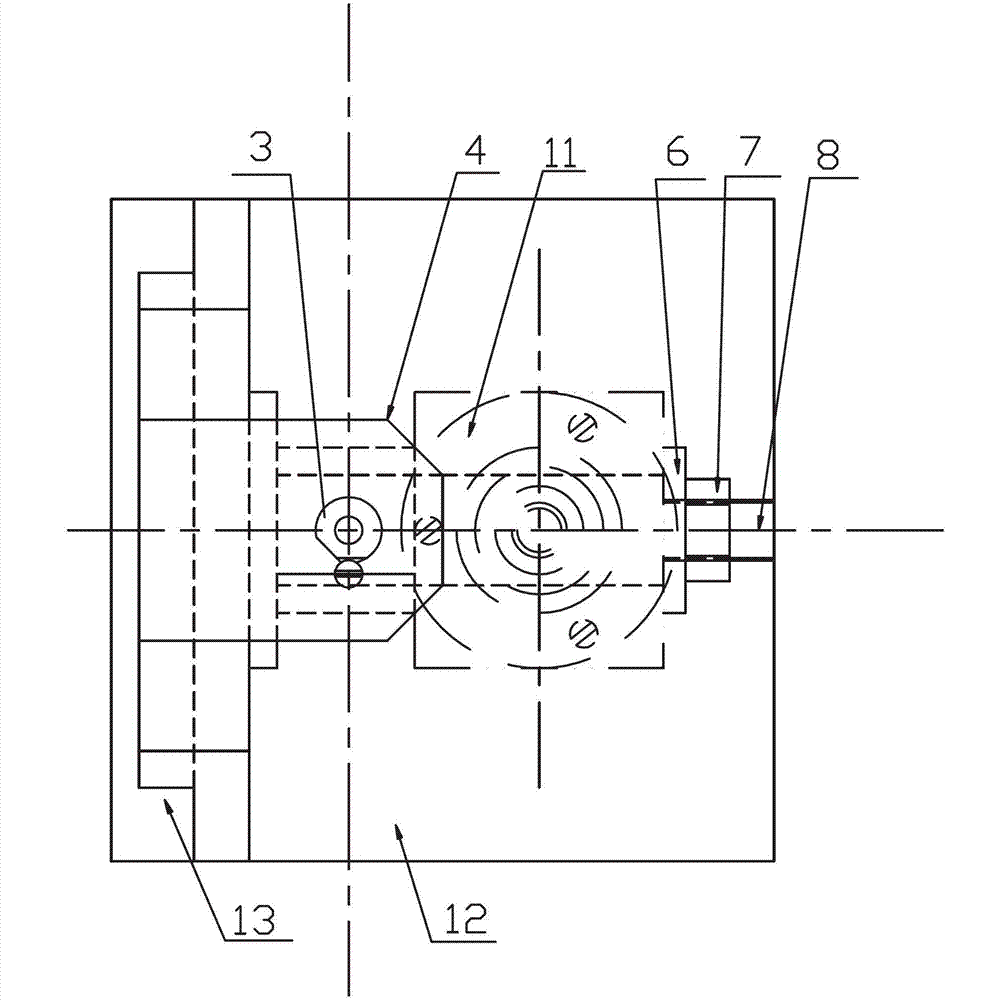

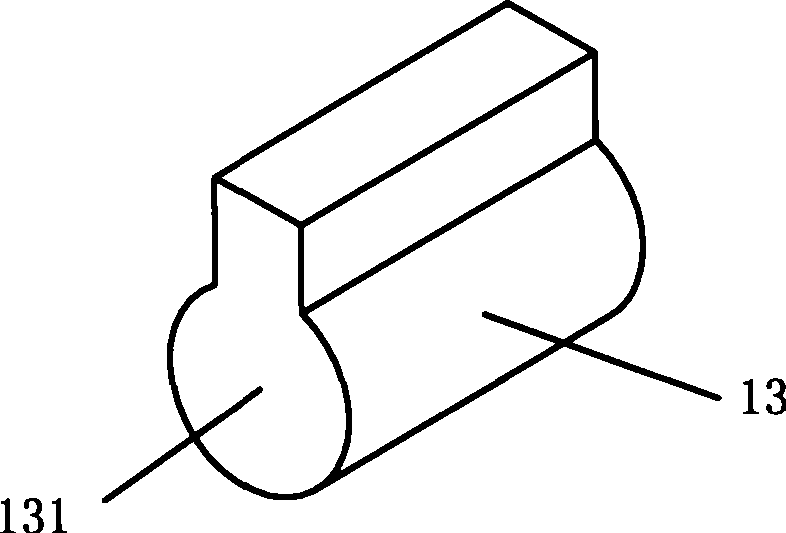

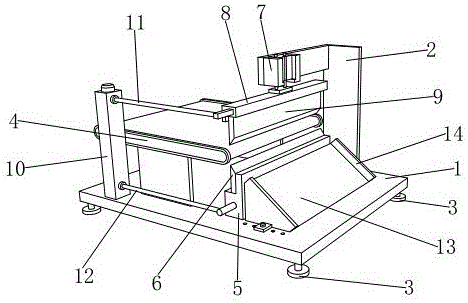

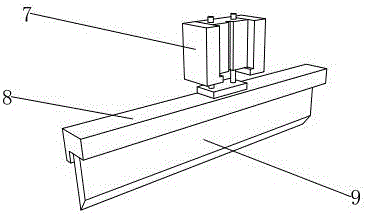

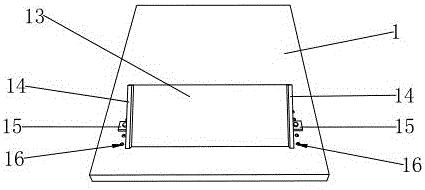

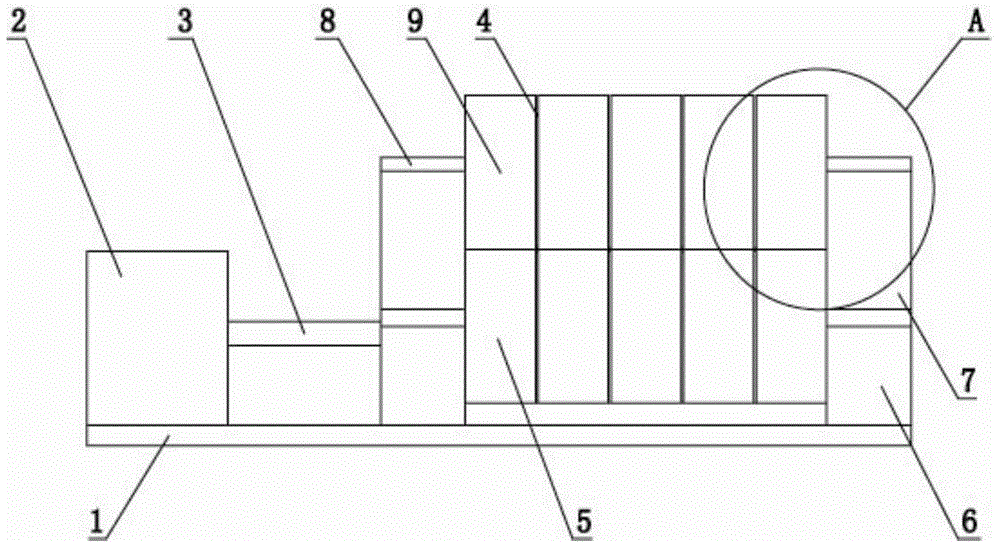

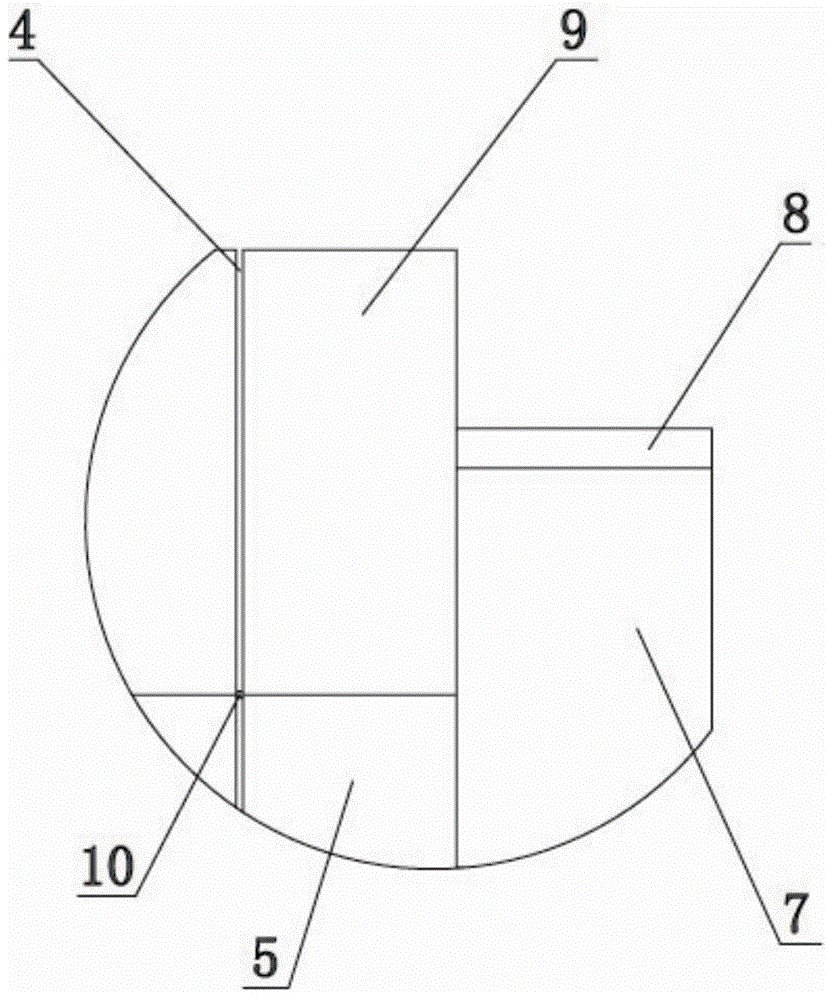

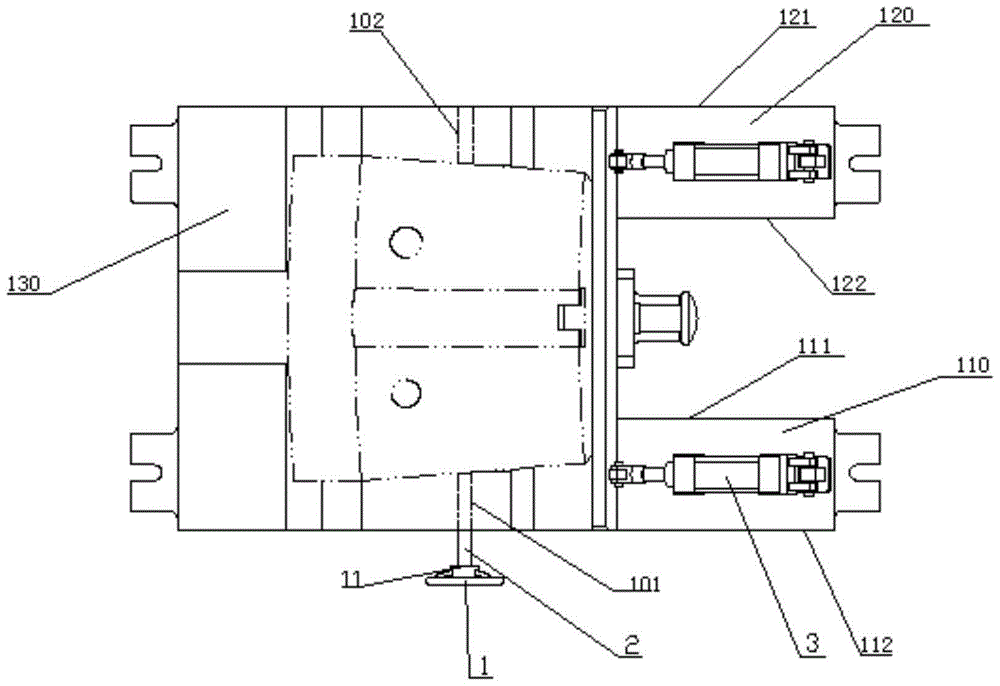

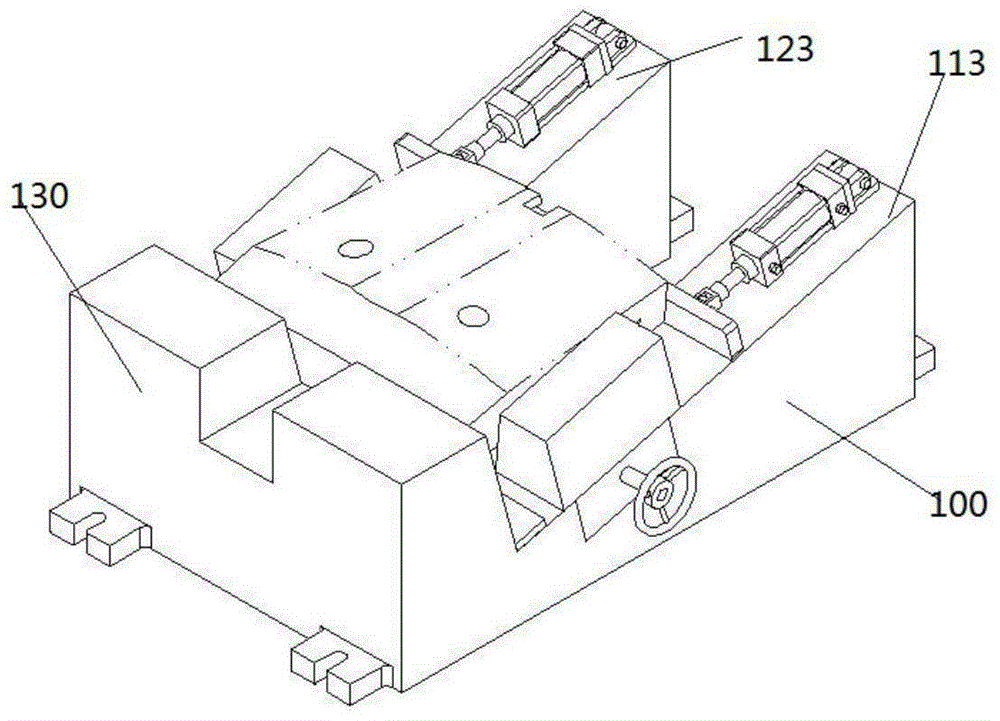

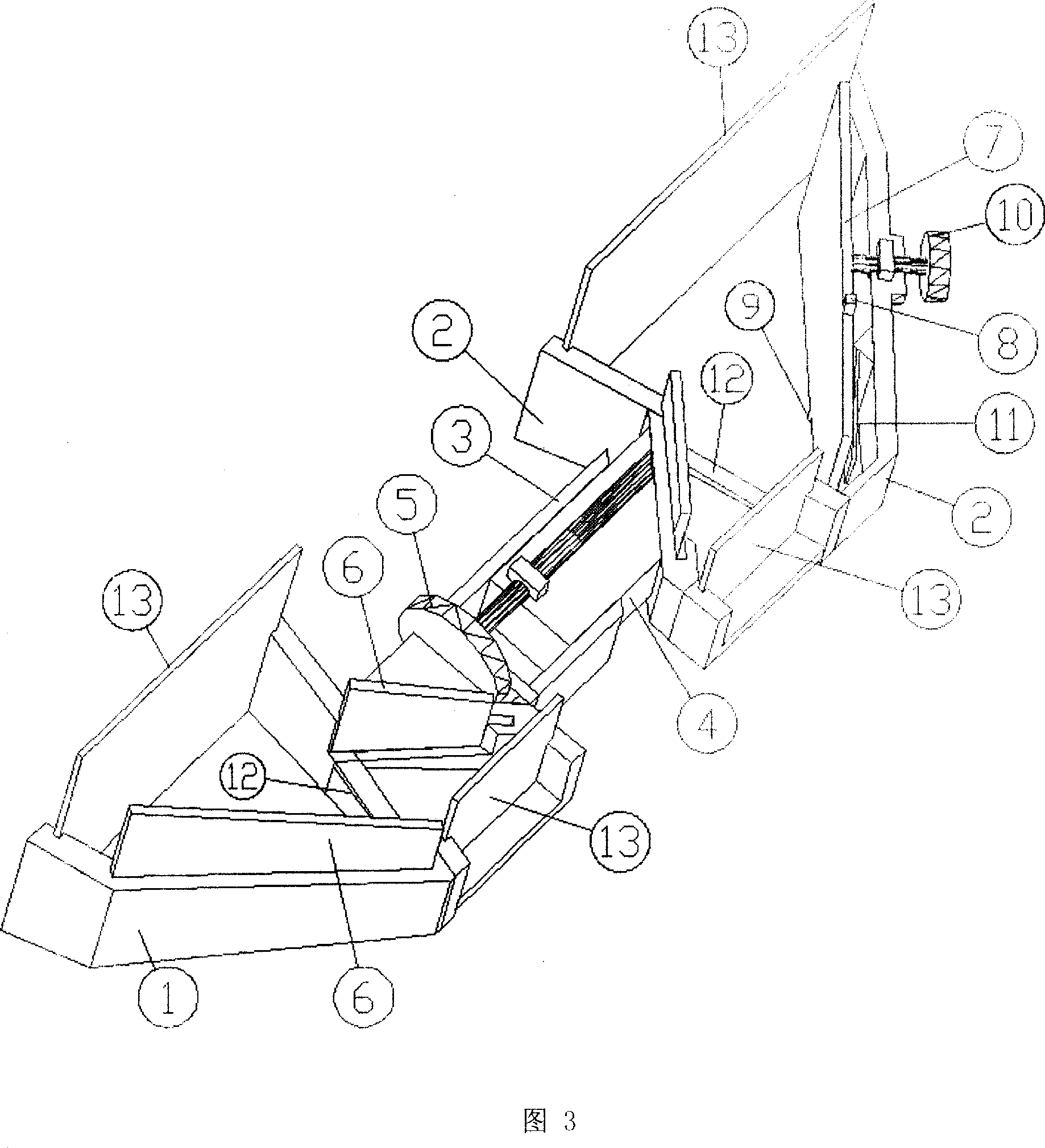

Novel radial hole joint fixture suitable for multi-model number drills

InactiveCN102896506AReduce auxiliary man-hoursReduce labor intensityPositioning apparatusDrill jigsEngineeringSupport plane

The invention discloses a novel radial hole joint fixture suitable for multi-model number drills. The fixture comprises a pedestal, a supporting frame and a fixture body used for clamping a workpiece to be processed, wherein the supporting frame is fixed on the pedestal, and a drill plate is fixed on the top end of the supporting frame through a screw and a locating pin; and the fixture body comprises an axial fixture and a radial telescopic fixture, the axial fixture is arranged on the supporting frame, and the radial telescopic fixture is arranged on the pedestal. By means of the mode, the novel radial hole joint fixture disclosed by the invention can reduce the technical demand on workers, reduce the labor intensity of the workers, guarantee safe production and improve the labor productivity; and the novel radial hole joint fixture can be quickly and conveniently used for producing new products to shorten the production preparation period and reduce the production cost.

Owner:SUZHOU VOCATIONAL UNIV

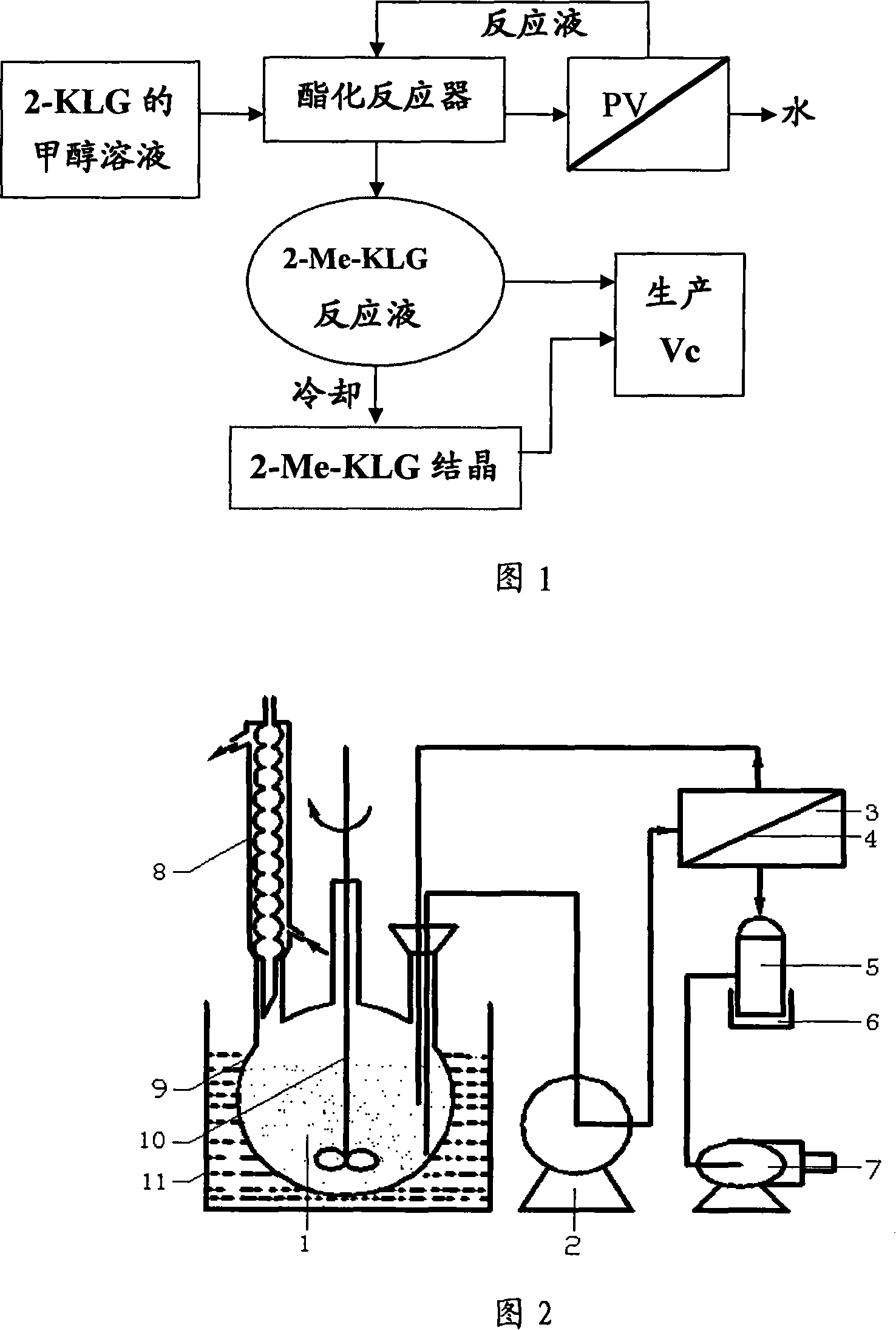

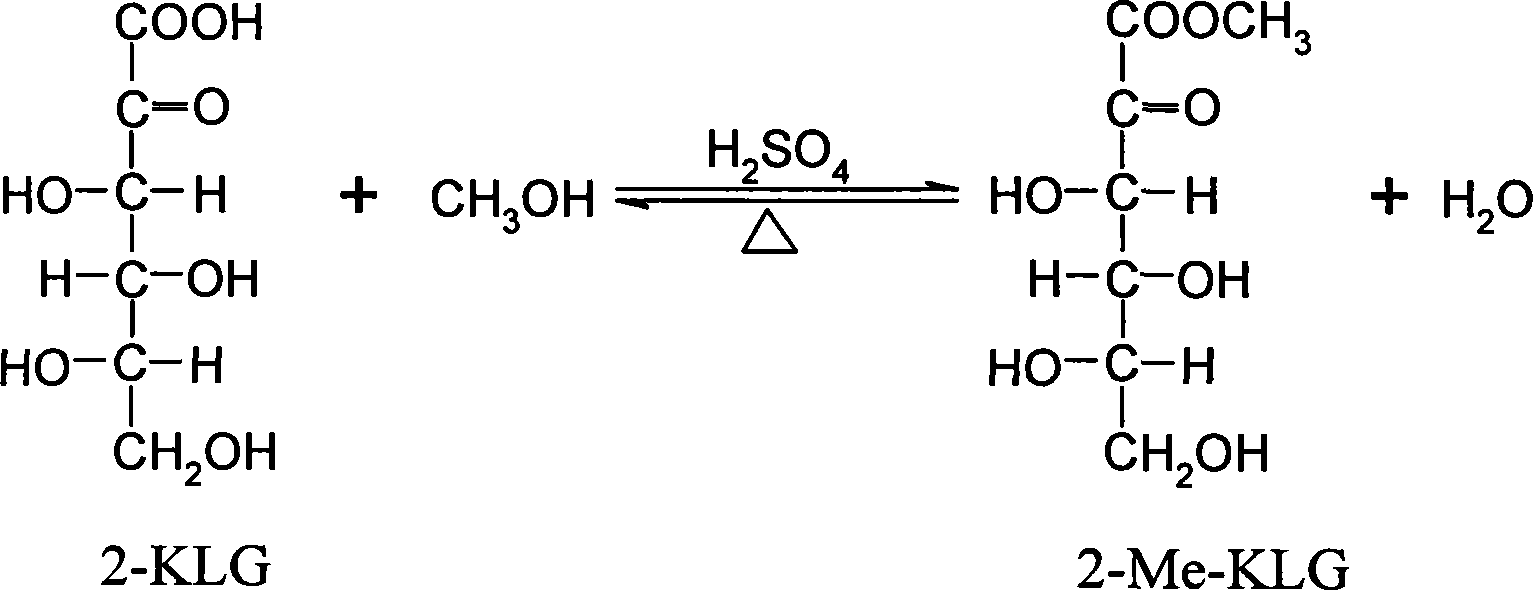

Method for producing vitamin C by esterification reaction-infiltration evaporation barrier separation integral process

InactiveCN101139290AStable production processSimple production processOrganic compound preparationCarboxylic acid esters preparationProduction lineVitamin C

The present invention provides a method of synthesizing the vitamin C (V C ) through the esterification, the pervaporation (PV) membrane separation and integration technology, comprising the process of the methyl esterification between the methanol and the 2-ketone-L-gulonic acid (2-KLG) to produce the 2-ketone-L-gulonic methyl ester (2-Me-KLG). The process comprises the following steps: (1) the solid or liquid 2-KLG is dissolved in the methanol; the temperature is then raised and the catalyst is added; (2) the reaction solution prepared in the first step is pumped into the PV membrane separation device; the reaction solution after the membrane dehydration circulates into the esterification reactor; (3) the product 2-Me-KLG or the reaction solution is directly provided for the later production of the VC. In the method of the present invention, the area of the used membrane is small; the ratio between the alcohol and acid of the raw material liquid and the reaction temperature are relatively low; the invention greatly improves the purity and collection rate of the 2-Me-KLG; the technology is simple and the process is stable; the present invention is suitable for the industrial production-line.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

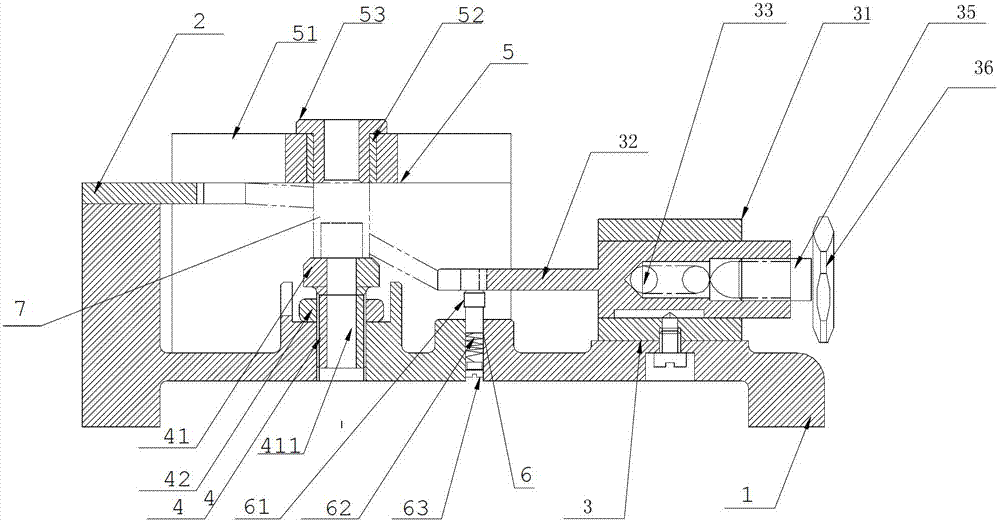

Adjustable lever drilling die clamp

ActiveCN102729064ALow technical requirementsReduce labor intensityDrilling/boring measurement devicesPositioning apparatusEngineering

Owner:SUZHOU VOCATIONAL UNIV

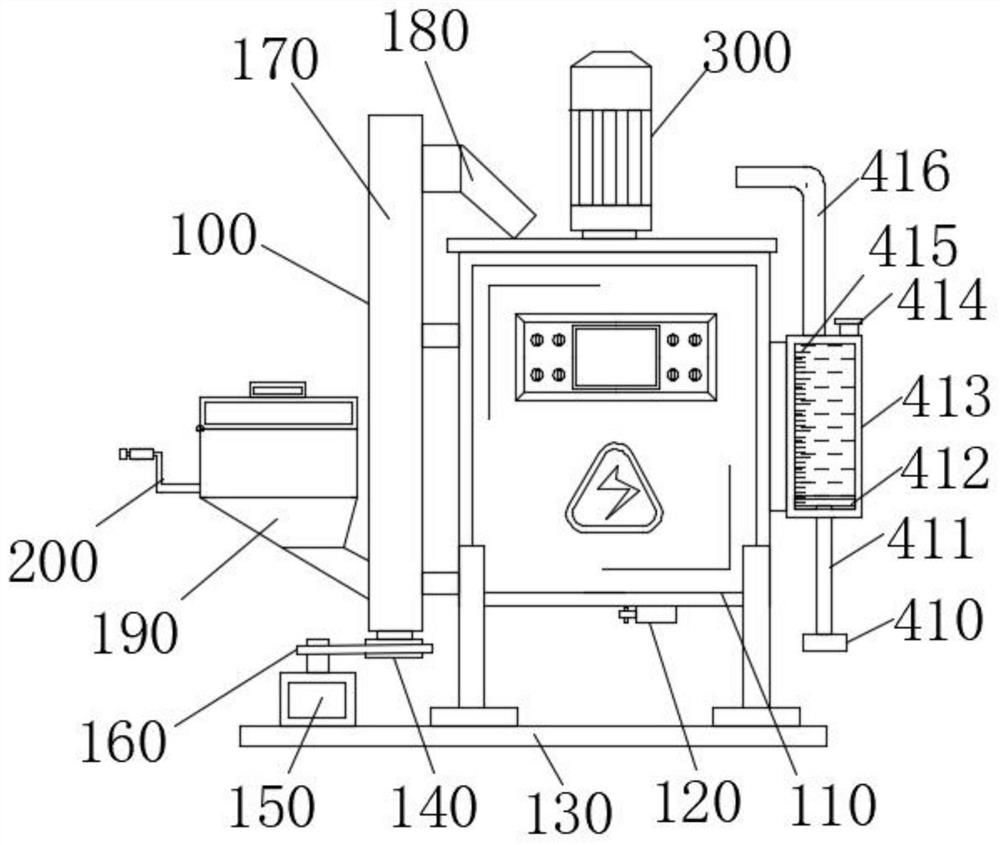

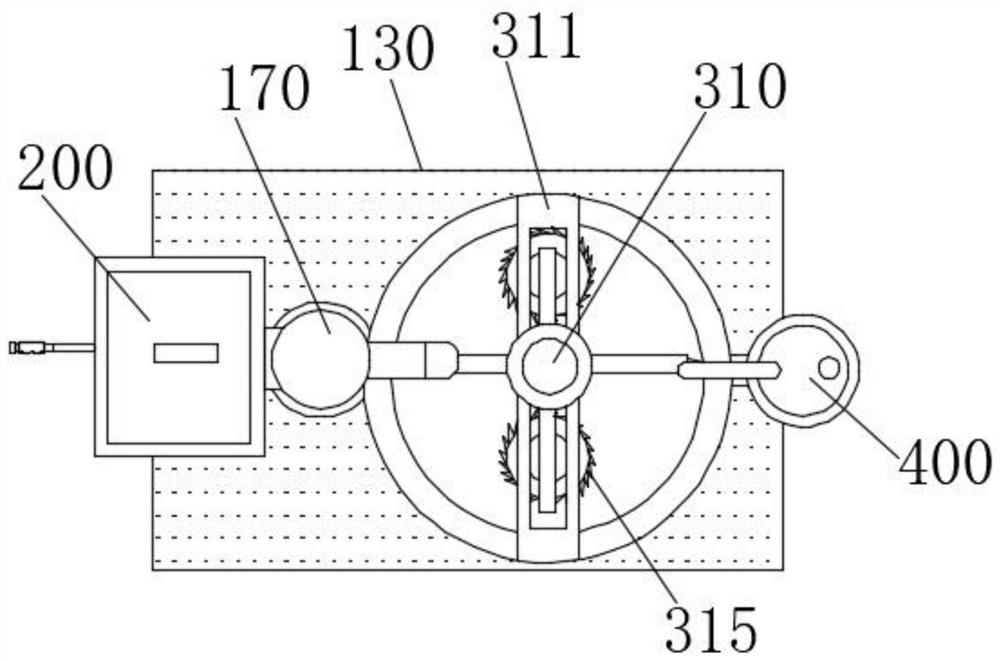

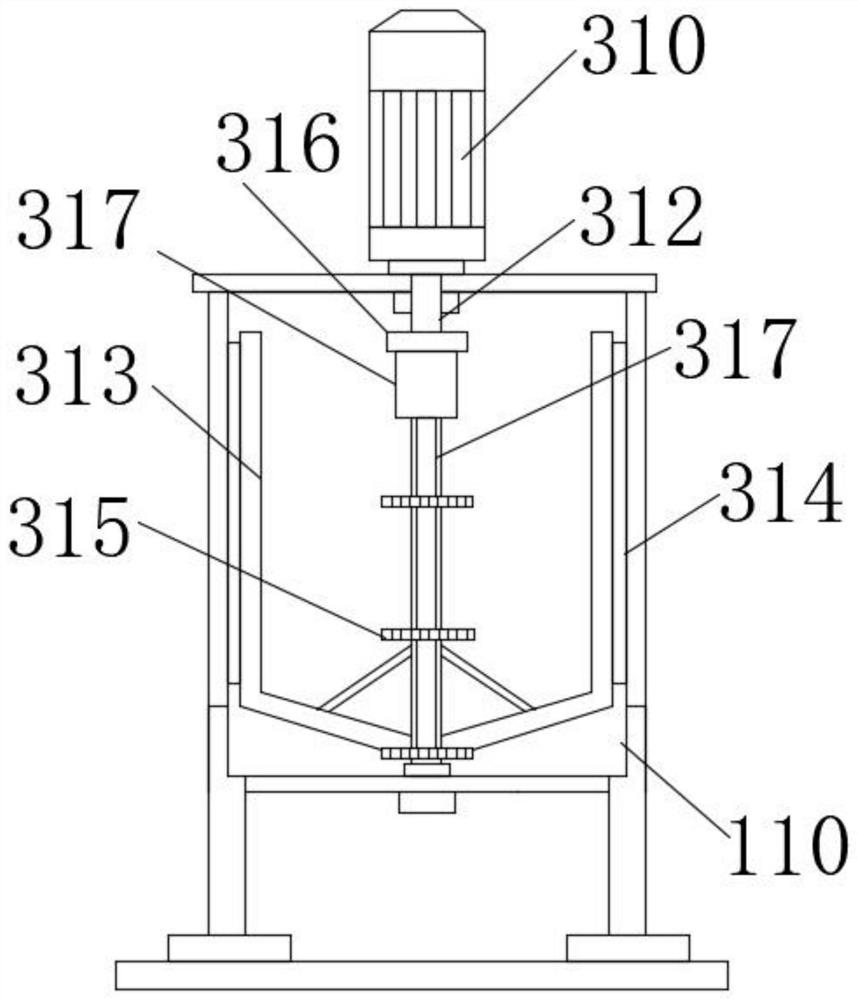

Iron oxide pigment production equipment capable of being used for removing particle impurities

ActiveCN112473413ASimple structureEasy to operateTransportation and packagingMixer accessoriesBrown iron oxideReciprocating motion

The invention relates to the technical field of iron oxide pigment production equipment, in particular to iron oxide pigment production equipment capable of being used for removing particle impurities. The equipment comprises an iron oxide pigment production equipment main body, wherein the iron oxide pigment production equipment main body comprises a processing mixing box main body, a bottom plate, a conveying box, a second servo motor, a third servo motor, a first servo motor and a raw material feeding box main body, the processing mixing box main body is fixedly mounted at the top end of the bottom plate, and a discharging opening is fixedly formed in the bottom end of the processing mixing box main body; and a control valve is fixedly mounted in the discharge port. By arranging the screening mechanism, through the shape characteristics of the rotary arc cam and the arc cam, the threaded spring can be driven to do reciprocating motion up and down, raw materials can be rapidly filtered, the structure is simple, operation is convenient, meanwhile, impurity particles are easy to clean and convenient to put into production, and rectangular grooves in the two sides of the filtering screen plate body slide up and down on sliding blocks; the stability of the filter sieve plate main body in the vertical vibration process is ensured.

Owner:正太新材料科技有限责任公司

Nano-PVC modifier and producing method thereof

ActiveCN101429317AHigh melting pointNot easy to decomposeHeat deflection temperatureCompound (substance)

The invention discloses a nanometer PVC modifier and a method for producing the same. The nanometer PVC modifier comprises the following components in weight percentage: 50 to 70 percent of silicon whisker, 5 to 20 percent of dioctylphthalate, 5 to 20 percent of coupling agent, 5 to 20 percent of dispersing agent, and 5 to 20 percent of PVC resin. The method comprises the following steps: the raw materials are stirred at high speed in a high-speed mixer until the temperature of the materials is raised to between 110 and 140 DEG C, the materials are transferred into a cooling mixer, and the materials are discharged when the temperature is dropped to between 40 and 70 DEG C; the materials are mixed and granulated at a temperature of between 150 and 180 DEG C; and then the materials are ground to obtain the nanometer PVC modifier. The PVC modifier has the advantages of high strength, stable chemical performance, high temperature resistance, good insulativity and low oil absorbing rate, thus the modifier is a functionality-enhanced plasticizing material; and the PVC modifier has high melting point, and the refractoriness of the PVC modifier reaches 1,720 DEG C. The fire resistance and the heat distortion temperature of the PVC product are improved, and the cost of raw materials is lower; and the preparation method has the advantages of simple process, easy operation, less investment, and easy production.

Owner:LUOHE KELAIBAO TECH CO LTD

Method and module for building basic furniture component

InactiveCN101498331AImprove efficiencyExtended service lifeFurniture joiningThree-dimensional spaceMechanical engineering

Owner:LONGYAN UNIV

Deodorizing boorganic fertilizer and its production method

InactiveCN1470480ASolve intractableNo pollution in the processClimate change adaptationExcrement fertilisersFecesHigh pressure

The production method of biological organic fertilizer by using chicken manure includes the following steps: a. treating chicken manure for 15-20 min. under the condition of that the temp. is 121-132deg.C and pressure is 12-14 kg / sq.cm, b. cooling chicken manure to 50-60 deg.C, then making fermentation for 10-20 days in fermentation chamber; and c. drying, granulating and packaging according to conventional method. In the production method of the described deodorized biological organic fertilizer the high-temp. high-pressure decomposed chicken manure can be directly puffed and sprayed out from pressure container, then naturally cooled to 50-60 deg.c and fermented.

Owner:赵春乱 +2

Hot cutting machine for plastic paper thin film

InactiveCN106493789AIncrease heightExtended service lifeMetal working apparatusAutomationEngineering

The invention discloses a hot cutting machine for a plastic paper thin film. The hot cutting machine comprises a working platform and a support frame, wherein the support frame is arranged on one side of the working table, a conveying mechanism and a hot cutting die holder are respectively on the working table, the hot cutting die holder is located on one side of the conveying mechanism, a breaking blade is arranged on the hot cutting die holder, a driving cylinder is arranged on the support frame, a hot cutting die head is arranged on the driving cylinder, a cutting blade is arranged on the hot cutting die head, the cutting blade and the breaking blade are oppositely arranged, a heating device is arranged on the working table, a first heating pipe and a second heating pipe are respectively arranged on the heating device, the first heating pipe is connected with the hot cutting die head, and the second heating pipe is connected with the hot cutting die holder. The hot cutting machine disclosed by the invention has the advantages that the structure is simple, an automation operation is realized, the labor cost is saved, cutting is ordered, the cutting efficiency is high, the cutting effect is good, and the practicability is strong.

Owner:王丽春

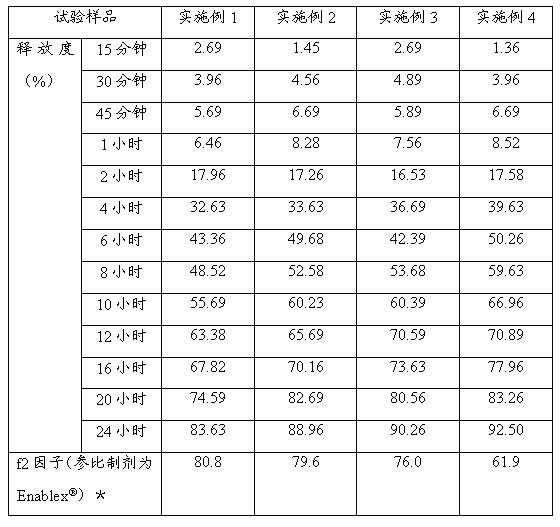

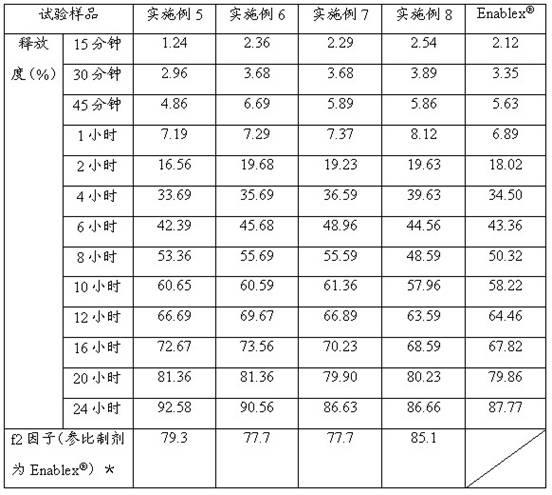

Darifenacin hydrobromide sustained-release tablet and preparation method

ActiveCN102048706AReduce dosageReduce manufacturing costOrganic active ingredientsPharmaceutical delivery mechanismDarifenacin hydrobromideProlonged-release tablet

The invention belongs to the field of new medicament technologies, and in particular relates to a darifenacin hydrobromide sustained-release tablet and a preparation method. The darifenacin hydrobromide sustained-release tablet adopts carbomer as a new retardant, and the dosage of the carbomer is 1-5% by weight of the preparation and can reach considerable vitro release and bioavailability compared with the dosage of the retardant in the prior art, which is more than half of the dosage of a prescription. The dosage of the retardant in the new method is greatly reduced so that the consumption of materials can be greatly reduced, the process is simpler, the controllability is better, the efficiency is improved, and the production cost is greatly reduced.

Owner:SHANDONG CHUANGXIN PHARMA RES & DEV

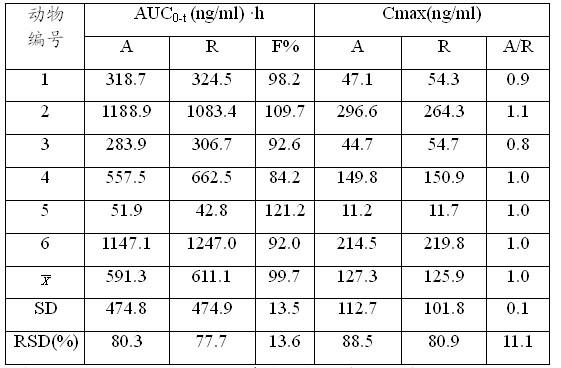

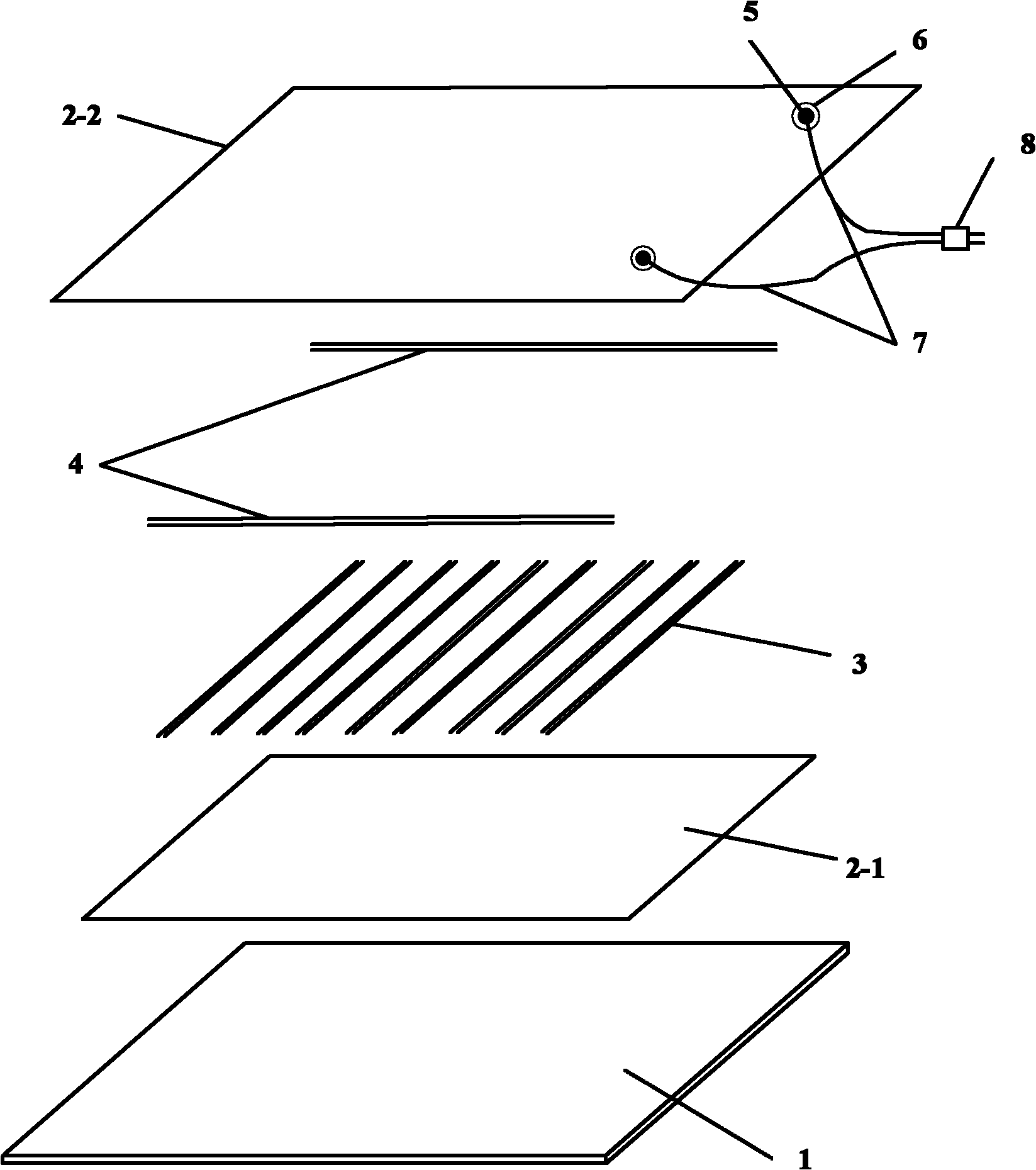

Far infrared heating plate and manufacturing method thereof

ActiveCN102104999AImprove cooling effectImprove high temperature resistanceOhmic-resistance electrodesSustainable buildingsAdhesiveConduction band

The invention discloses a far infrared heating plate and a manufacturing method thereof. The far infrared heating plate comprises an aluminium substrate, a first polyimide thin film layer, infrared slurry, a copper foil conduction band, a second polyimide thin film layer and the like. The method provided by the method comprises the following steps of: firstly, coating the first high-temperature resistant polyimide thin film layer on the aluminium substrate, printing the infrared slurry on the coated aluminium substrate, and pasting the copper foil conduction band pasted with conductive dual-sided adhesive on the infrared slurry of the aluminium substrate; secondly, coating the second polyimide thin film layer with good insulation performance; finally drilling a welding hole for welding a lead, and pasting an insulation cap to obtain the far infrared heating plate. After the far infrared heating plate is electrified, the copper coil conduction band and the infrared slurry have uniform contact and good conductive effect and are safe and reliable. The heating plate has the advantages of rapidness for raising temperature, uniform heat conduction, long service life and simple structure. The manufacturing method for the far infrared heating plate has simple process, is easy to carry out and can be applied indoors in quantity as heating layers of wallboards and floors to achieve goodgreenhouse effect; furthermore, the far infrared heating plate can be widely applied to the apparatuses in a dry steam room.

Owner:ANHUI ZHONGKE BENYUAN INFORMATION TECH CO LTD

Superabsorbent fibers prepared from polyvinyl alcohol fibers and preparing method and application thereof

The invention relates to superabsorbent fibers prepared from polyvinyl alcohol fibers and a preparing method and application thereof. The preparing method of the superabsorbent fibers includes the steps that 11-15 g of water-soluble polyvinyl alcohol fibers are put into 85-95 g of organic solvent containing maleic anhydride and esterified by the maleic anhydride for 1-5 h at the temperature of 70 DEG C-95 DEG C; the esterified fibers are treated with an alkali solution, washed and dried. By selecting the appropriate amount of polyvinyl alcohol fibers, the appropriate amount of the maleic anhydride organic solution and appropriate reaction temperature, the polyvinyl alcohol superabsorbent fibers obtained through preparation have superhigh water absorption and can absorb deionized water with the weight 400 times larger than the own weight of superabsorbent fibers or normal saline with the weight 55 times larger than the own weight of superabsorbent fibers.

Owner:WUXI CHANGAN SHUGUANG GLOVE FACTORY

Environmentally-friendly interior and exterior wall coating and preparation method and construction method thereof

The invention relates to an environmentally-friendly interior and exterior wall coating and a preparation method and a construction method thereof. The coating is prepared from the following raw materials in part by mass: 40-80 parts of aqueous solution of polyvinyl alcohol with concentration of 8-10 percent (mass), 20-40 parts of 80-120 mesh waste stone dust, 1-8 parts of aqueous solution of boride with concentration of1-3 percent (mass) and 0.05 part of mildew preventive P803. The waste stone dust is obtained by grinding and screening a waste acrylic plate. Major ingredients of the waste acrylic plate include polymethyl methacrylate, aluminum hydroxide and calcium carbonate. The preparation method is simple. During construction, the coating is coated twice, and then a borax aqueous solution with concentration of 1-3 percent (mass) is sprayed.

Owner:ZHUHAI SHENGXIYUAN MECHANICAL & ELECTRICAL EQUIP CO LTD

Raisin tree seed wine and production method thereof

InactiveCN106398973AFull of nutritionGood curative effectAlcoholic beverage preparationYeastTremella

The invention discloses raisin tree seed wine and a production method thereof. The raisin tree seed wine is produced from the following raw materials in parts by weight: 50-80 parts of raisin tree seed, 5-10 parts of barbary wolfberry fruit, 3-5 parts of tremella, 5-10 parts of citruslimon slice, 15-25 parts of crystal sugar and 4-8 parts of activated yeast. The invention provides a brewing method of the raisin tree seed wine which is rich in nutrition, rich in taste and mellow in fruit flavor, has effect of expelling wind-damp, has good treatment effect for rheumatoid arthritis, and also has effects of sobering up, soothing the nerves, relieving thirst and restlessness, resisting oxidation, lowering blood pressure and the like.

Owner:黄文庆

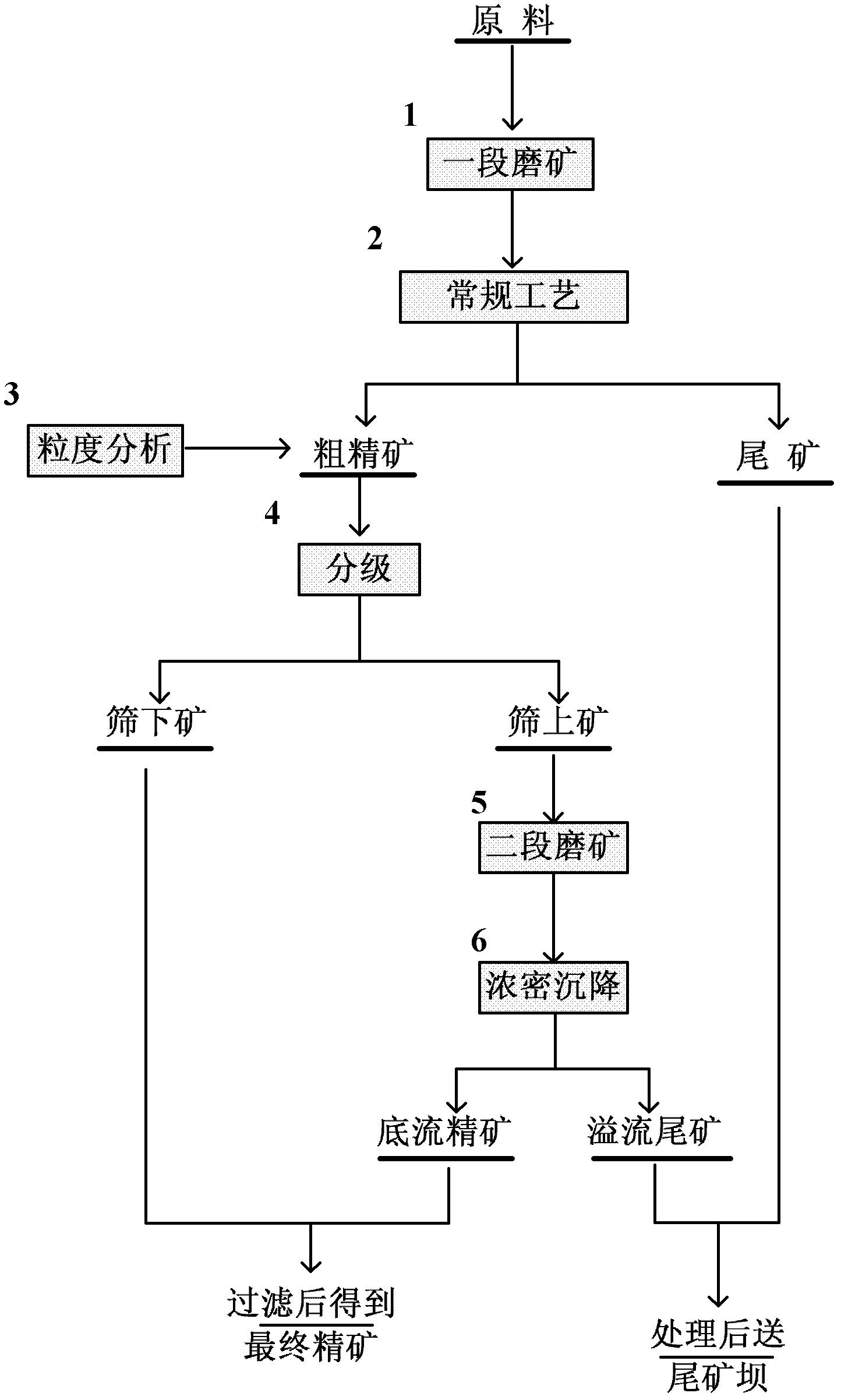

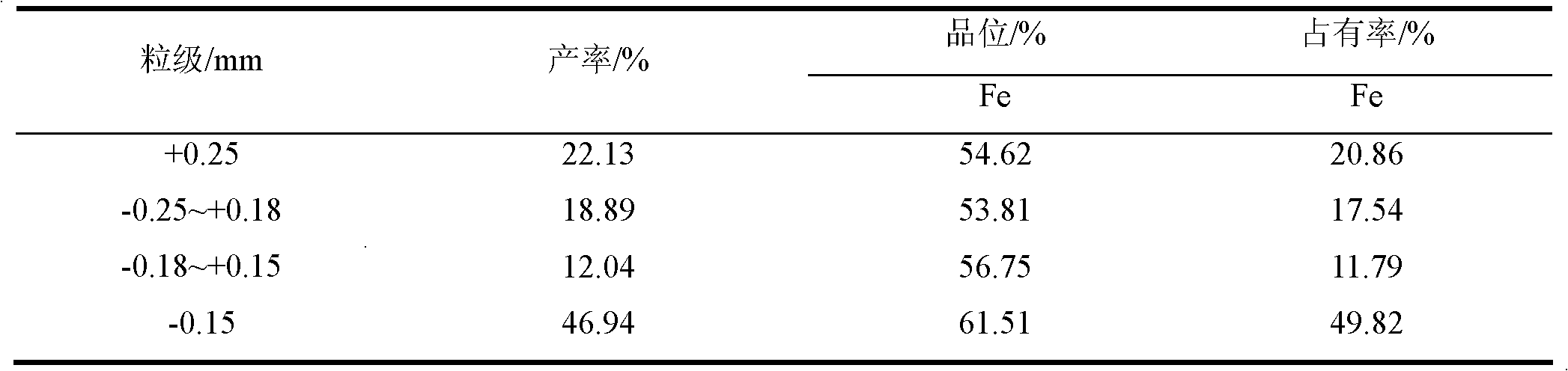

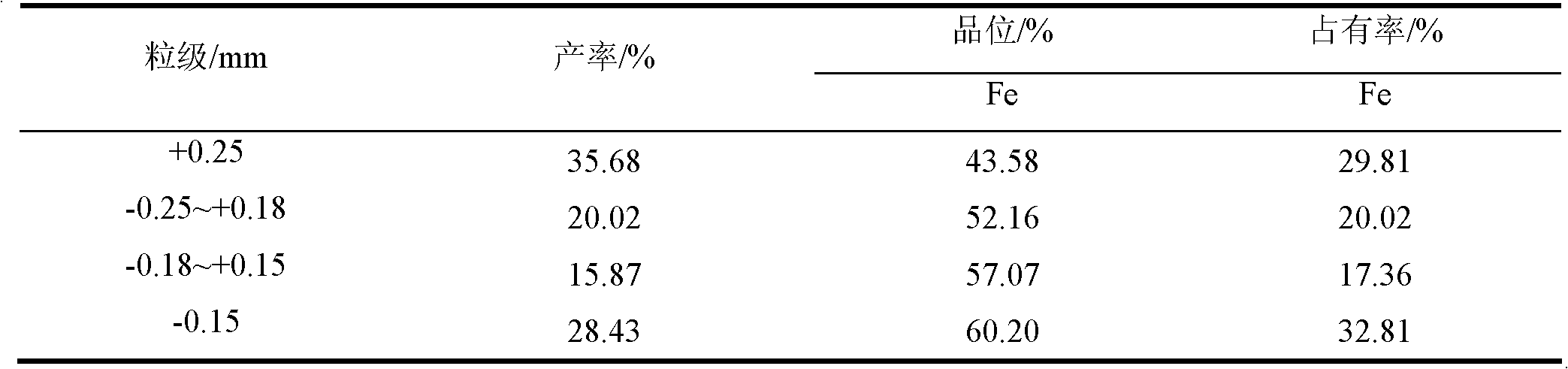

Novel process for improving grade of sulfate cinder iron

The invention relates to a novel process for improving the grade of sulfate cinder iron. After a sulfate cinder raw material is simply and crudely ground, a rough concentrate is obtained by using a conventional process, the rough concentrate is subjected to granularity sieving and grading, the selected ore is finely ground and quickly settles to obtain an underflow concentrate. And after the underflow concentrate is combined with the selected ore, the concentrate is obtained finally. The novel process is easy to construct and go into operation. After the process is improved, the ore grinding amount is reduced, the ore grinding time is shortened, and the ore grinding cost is greatly reduced by 50 to 70 percent. Meanwhile, the newly added process and equipment belong to physical separation, so energy consumption is low and pollution is not caused.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG +1

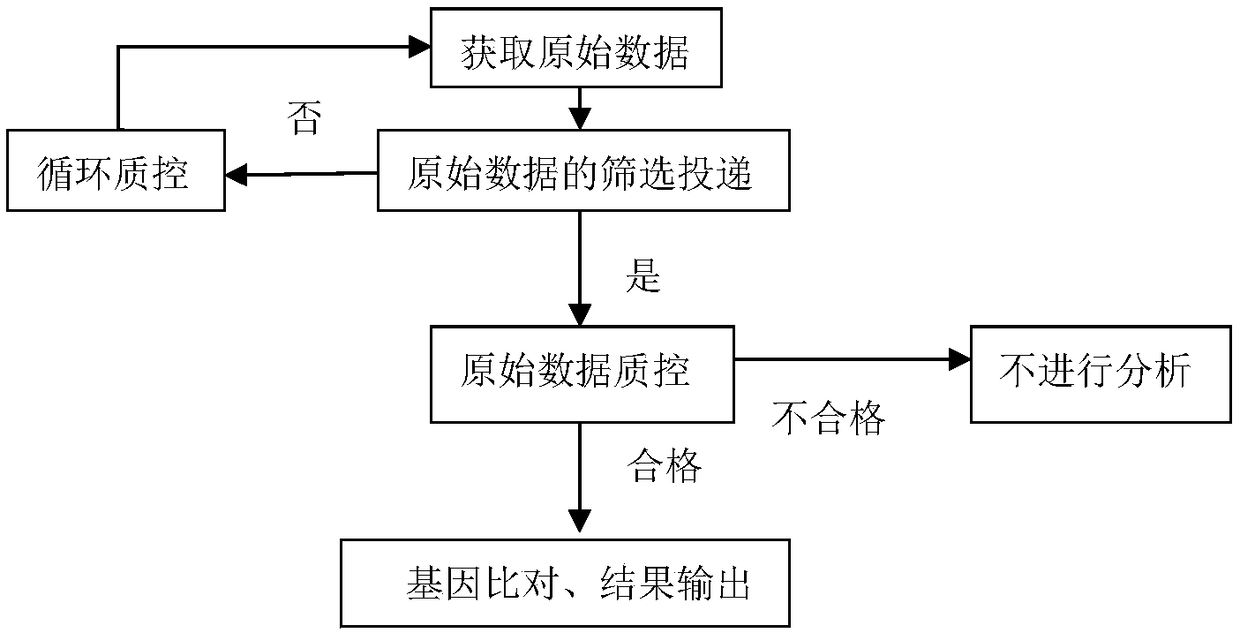

Noninvasive prenatal bioinformatics detection system and method as well as application

InactiveCN108388770AReduce complexityReduce mistakesSequence analysisHybridisationAutoanalysisOriginal data

The invention discloses a noninvasive prenatal bioinformatics detection system and method as well as application. The method comprises the following steps: 1) extracting cfDNA of peripheral blood of apregnant woman, and performing whole genome sequencing to obtain original offline data; 2) monitoring the original offline data by an automatic monitoring program, and automatically completing the delivery task of an analysis process; and 3) automatically completing the splitting task of the offline data, the quality control of fastq original data as well as the comparison and quality control ofreference genomes. The method disclosed by the invention can automatically complete the whole processes of data offline monitoring, automatic analysis and acquisition of detection results, and does not need personnel for operating so as to reduce the errors caused by human factors and reduce the complexity of data analysis, so that the method is more suitable for being put into production.

Owner:北京爱普益医学检验中心有限公司

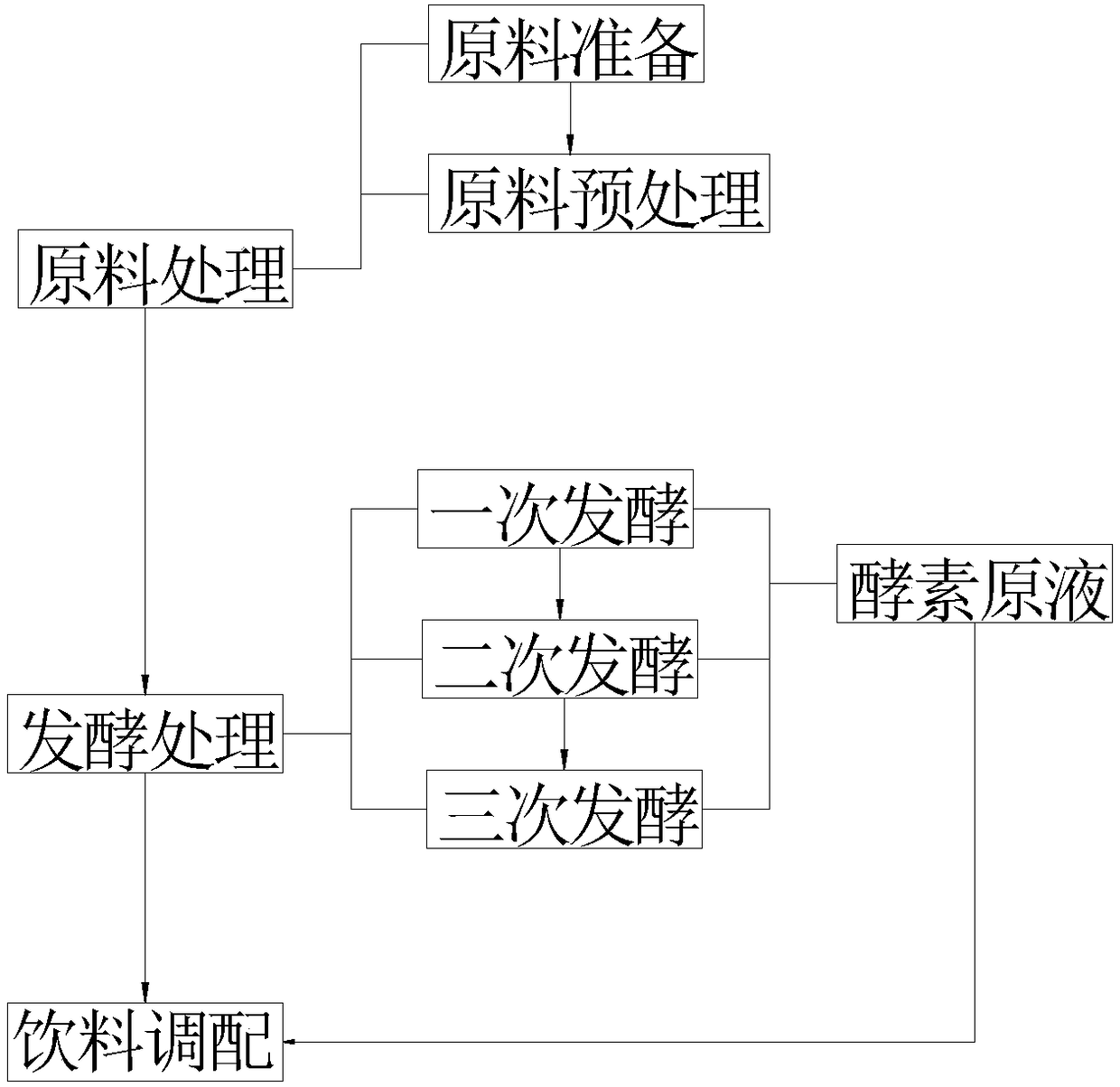

Pitaya enzyme beverage and preparation method thereof

InactiveCN109259011ARetained anthocyaninsReduce churnMilk preparationYeast food ingredientsFruit juicePhysical health

The invention discloses a pitaya enzyme beverage and a preparation method thereof. The objective of the invention is to provide the pitaya enzyme beverage and the preparation method thereof. The pitaya enzyme beverage is prepared by using pitaya, lemon, white granulated sugar, honey, rock candy, low-fat milk powder, lactobacillus, acetic acid bacteria, fruit juice, purified water and saccharomycete, the proportion of pitaya, lemon, white granulated sugar, rock candy, lactobacillus, acetic acid bacteria and saccharomycete in pitaya enzyme is 10 parts:2 parts:1 part:1 part:0.5 part:0.5 part:0.5part, and the blending proportions of fruit juice, honey, low-fat milk powder and pitaya enzyme in the pitaya enzyme beverage are 10:1, 4:1 and 2:1. By material processing and three times of fermentation, the pitaya enzyme beverage which has unique and rich taste is prepared, the anthocyanin of pitaya pericarp is kept to a great extent, the needed fermentation period is short, production is easy,the beverage is suitable for mass production, and moreover, the pitaya enzyme beverage can be used in a lot of ways, and is good for the physical health of people.

Owner:安徽古井健康科技有限公司

Line-pressing machine for absorbable medical suture lines and line-pressing method

ActiveCN104894721AEasy to operateEasy to useSuture equipmentsTextiles and paperDrive wheelEngineering

The invention relates to the technical field of medical operation and especially relates to a line-pressing machine for absorbable medical suture lines and a line-pressing method. The line-pressing machine for absorbable medical suture lines comprises a power system and a line-pressing system. A driving wheel and a driven wheel of the line-pressing system are correspondingly provided with one or multiple line-pressing grooves along the circumferential surface. The line-pressing grooves are semi-circular-arc-shaped. The line-pressing grooves of the driving wheel and the driven wheel are combined along the radial direction of the external circumference in order to form circular line-pressing holes used for pressing suture lines. The power system drives the driving wheel to rotate so that the driving wheel can drive the driven wheel to rotate relatively. The line-pressing method utilizes the line-pressing machine for absorbable medical suture lines to press the suture lines. The line-pressing machine for absorbable medical suture lines is easily operated and helps to effectively enhance production efficiency and utilization rate of material. The line-pressing method helps to effectively improve line bodies of suture lines. Regular line body structures help to greatly improve stitching and needle-threading efficiency in production and effectively increase utilization rate of suture lines during subsequent production and usage.

Owner:湖南然元医用高科技蛋白线有限公司

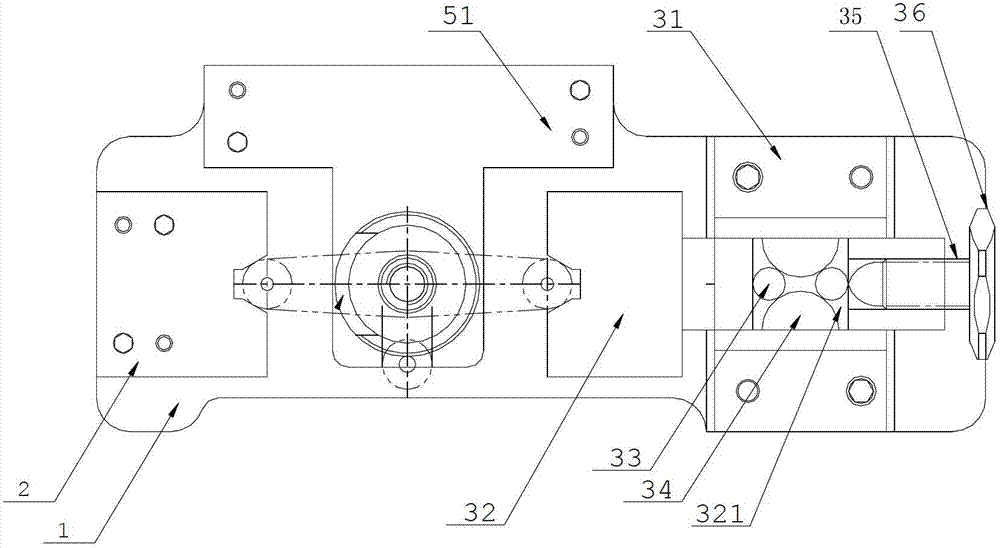

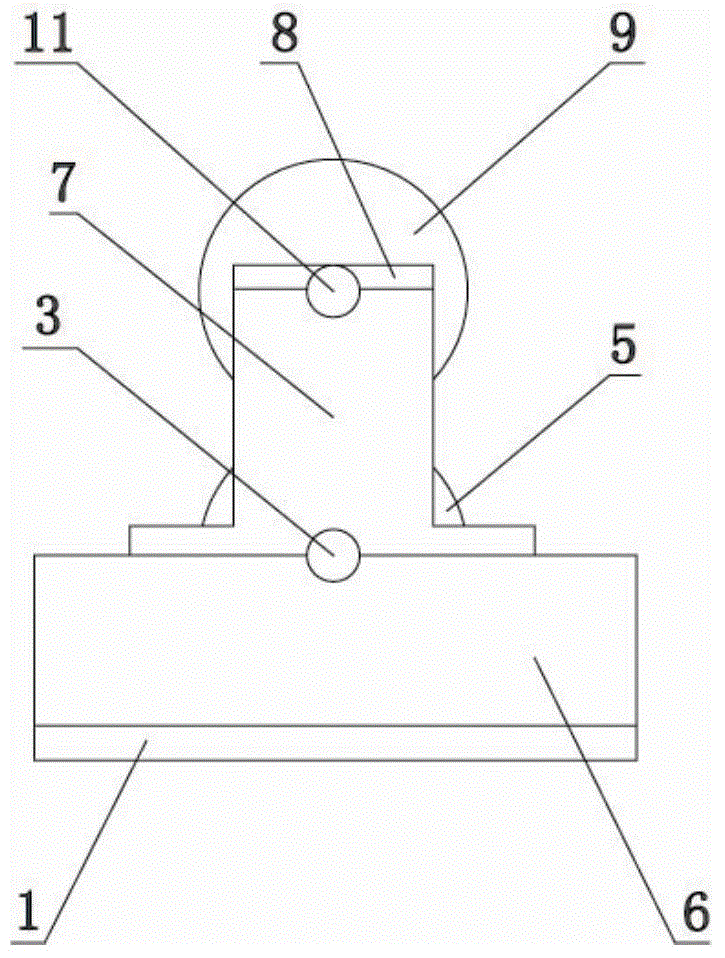

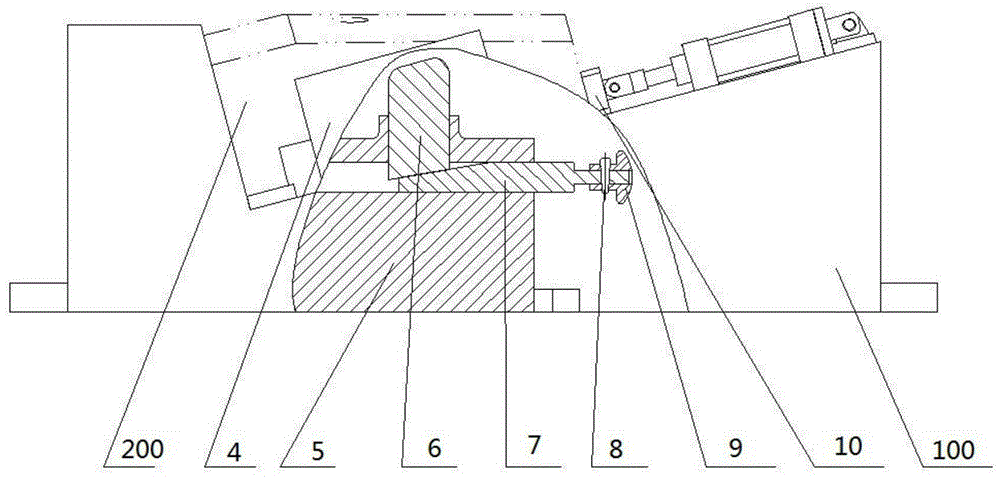

Special clamp for pneumatic type tire mold slideway

InactiveCN105234719AEasy to put into productionShorten production preparation cycleWork clamping meansPositioning apparatusEngineeringMachining process

The invention discloses a special clamp for a pneumatic type tire mold slideway. The research direction of the generalization design in a special range is determined according to the problem caused during clamping and processing of tire mold slideways. A slope type tire mold slideway clamp is disclosed and designed by taking an included angle between a T-shaped slideway and the horizontal plane as a fixed constant. The slope type tire mold slideway clamp comprises a hand wheel, a screw, a cylinder, a tire mold, a side barrier part, a thrust-assisted support, a baffle and a clamp body support seat and is characterized in that one end of the cylinder is rotationally connected with the clamp body support seat; the other end of the cylinder is connected with the baffle; the screw is arranged in a straight slot of the clamp body support seat; the thrust-assisted support is arranged at the interior of the clamp body support seat. The special clamp for the pneumatic type tire mold slideway is capable of locating and clamping the tire mold, avoiding deformation and compression in the processing process and implementing generalization of the special clamp in a certain range.

Owner:GUANGXI UNIV

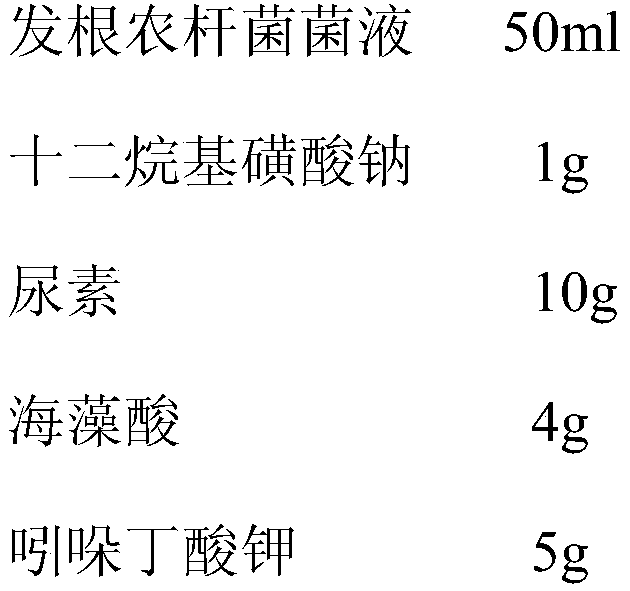

Microbial agent for improving growth of tomatoes and preparation method of same

PendingCN107828700AImprove qualityImprove survival rateBiocidePlant growth regulatorsMicrobial agentPotassium

The invention relates to a microbial agent for improving growth of tomatoes and a preparation method of same. The main raw materials in the microbial agent include agrobacterium rhizogenes A4, R1205,R1000, R1601, R1022, 15834, etc. In the invention, by means of the character that the agrobacterium rhizogenes can accelerate rooting and growth of crops, the microbial agent is prepared from the agrobacterium rhizogenes bacterial liquid, sodium dodecyl sulfonate, urea, alginic acid and potassium indolebutyrate according to certain ratio; when being applied to planting of tomatoes, the microbial agent is applied for one time every 20 days; due to a symbiotic relationship between the agrobacterium rhizogenes and tomatoes, growth of root system of the tomatoes is accelerated, and survival rate of the plants is ensured, growth of stems and leaves is accelerated, mature period of fruits is reduced, yield is increased and quality of tomatoes is greatly improved. The microbial agent overcomes problems of low fruit quality and yield during production of tomatoes, so that the microbial agent can be used for improving quality and increasing yield of crops in agriculture and has huge economic benefit.

Owner:JILIN NORMAL UNIV

Noble metal catalyst and preparation method and application thereof

ActiveCN108636403AHigh activityHigh catalytic activityIncinerator apparatusMetal/metal-oxides/metal-hydroxide catalystsPtru catalystLattice oxygen

The invention provides a noble metal catalyst, which employs noble metal as a first active component and stannic oxide as a second active component, and a methane combustion catalyst having high catalytic activity and sintering-resistant performance is obtained. The stannic oxide can protect the noble metal component from sintering, contains abundant and active surface oxygen vacancy, the latticeoxygen in a body phase has certain activity, at the same time, the surface of the stannic oxide has Lewis acid center, realizes effective catalysis, and is in favor of a catalytic combustion reactionof methane. A part of the noble metal is introduced into lattice of stannic oxide to substitute the divalent tin ions, and can increase the cavity concentration, so that the free electron concentration is reduced, adsorbed oxygen ions can be formed at the surface of the catalyst, the noble metal catalyst is in favor of generation of an oxidation reaction by the reductibility gas methane at the surface of the catalyst through oxygen ion adsorption, and the activity of the catalyst is increased.

Owner:吉林晟航科技发展有限公司

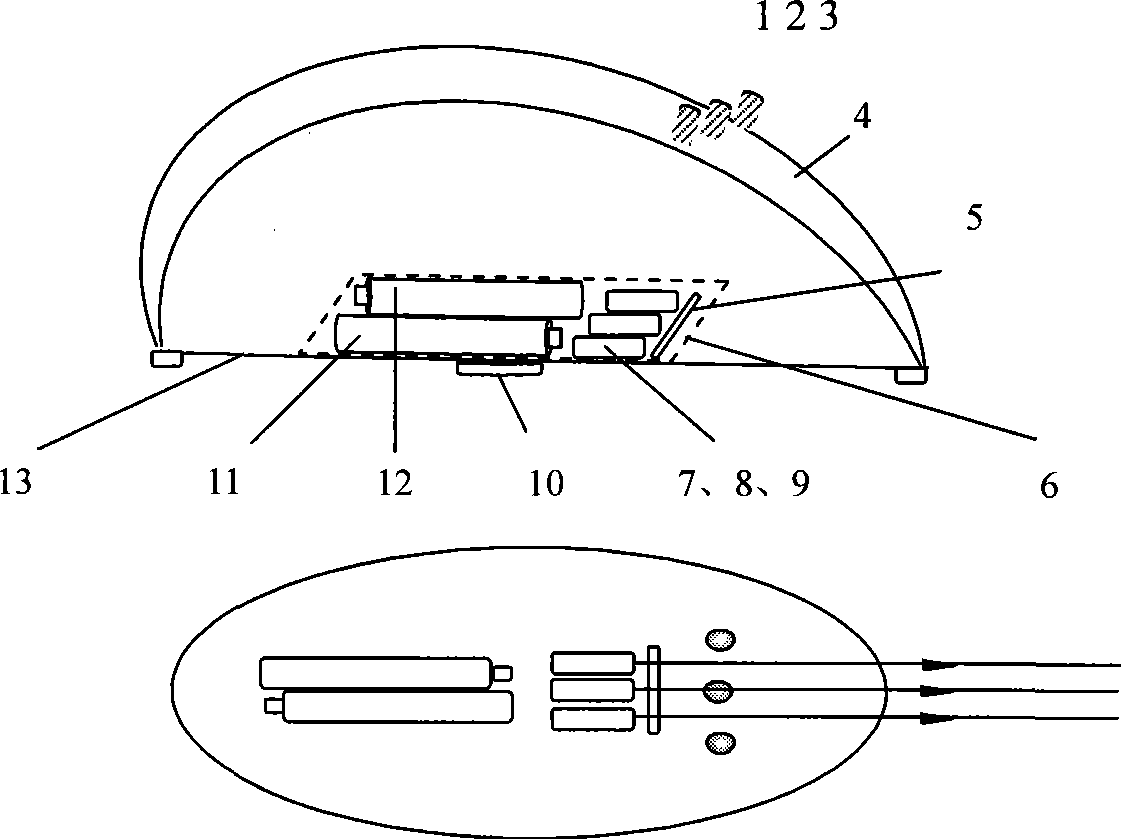

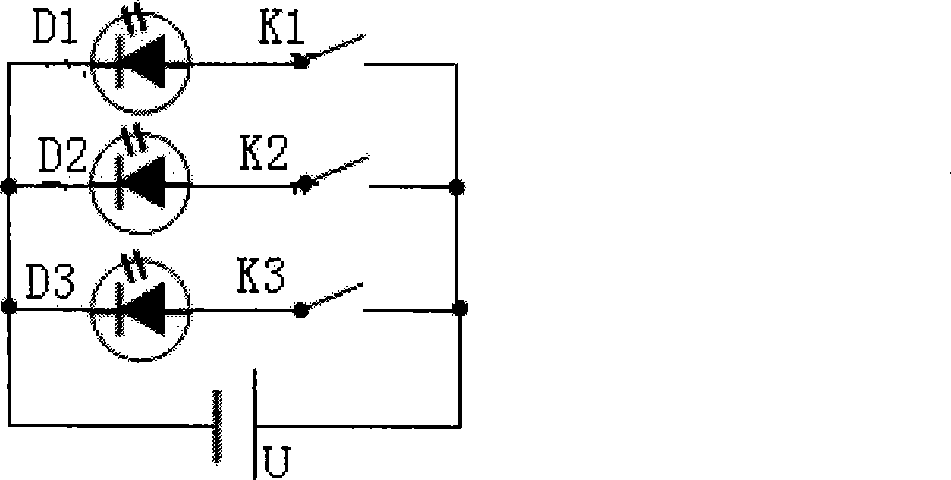

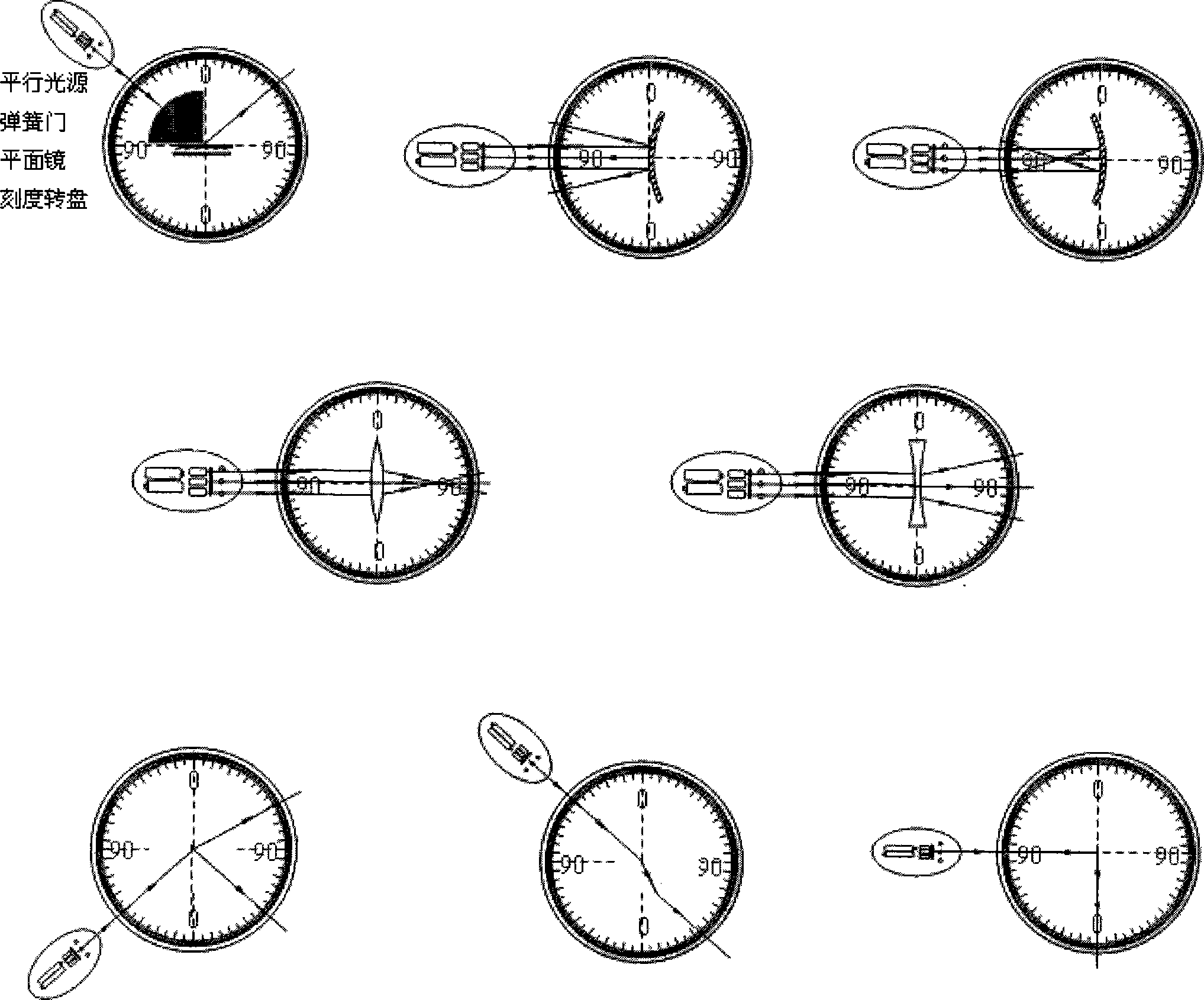

Low-voltage parallel beam source generation device

InactiveCN101368681AEasy to useSimple structureElectric circuit arrangementsWith built-in powerLow voltageOptoelectronics

The invention discloses a low-voltage parallel beam source generation device which mainly comprises a power switch, a plurality of light emitting diodes, a dc power supply, a light focus lens, a circuit board, a base and a mouse-shaped shell. The light emitting diodes are welded on the circuit board; the light focus lens is welded in front of the light emitting diodes. A dry battery is arranged on the electrode spring clamp on the corresponding position of the circuit board. The circuit board is fixed on the base through a screw. The power switch of the light emitting diodes is embedded in front of the top end of the mouse-shaped shell. The mouse-shaped shell is buckled with a bottom plate through a lock buckle. The low-voltage parallel beam source generation device has the advantages of simple structure, low cost, convenient machining and convenient production.

Owner:上海市罗星中学

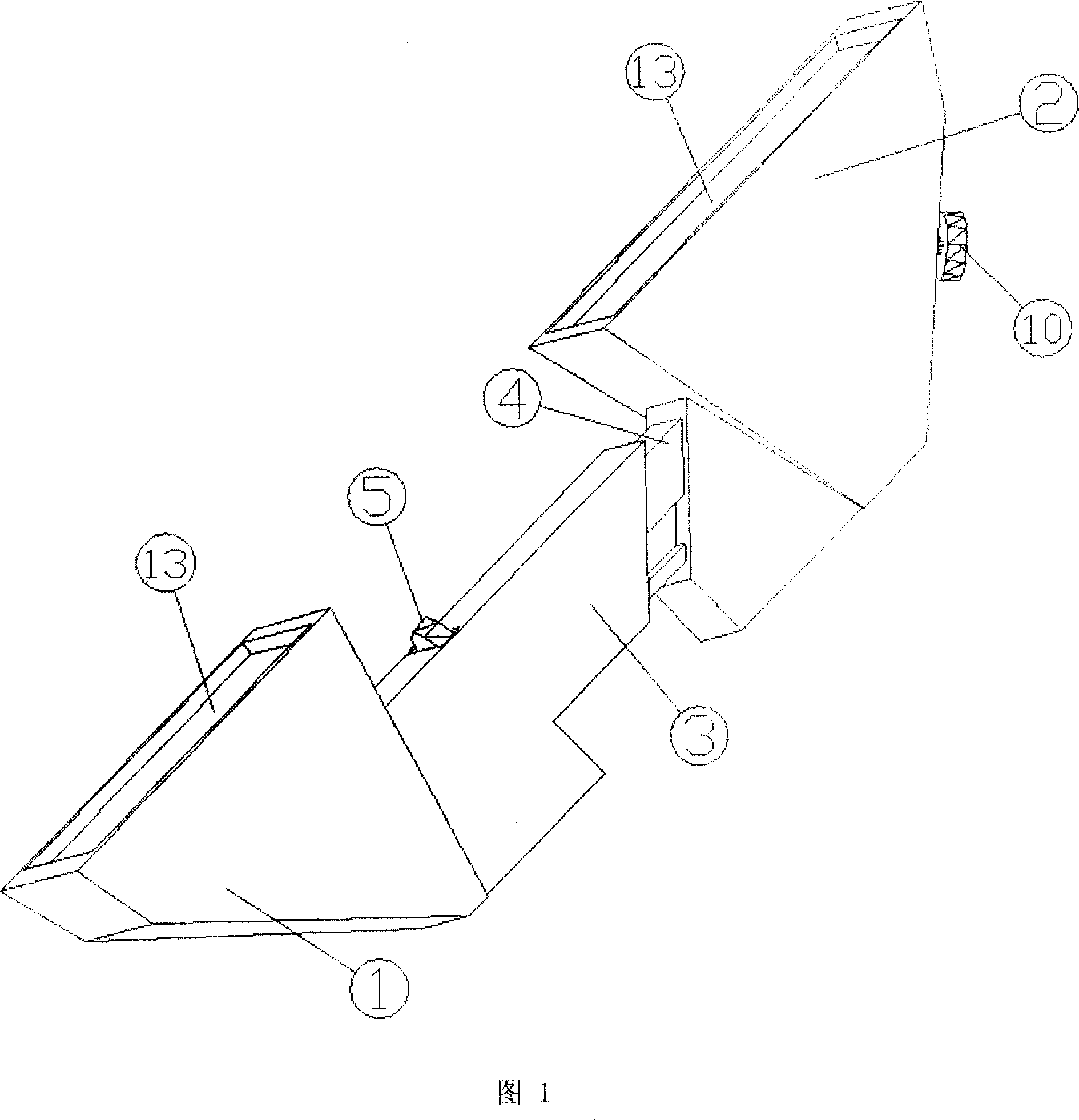

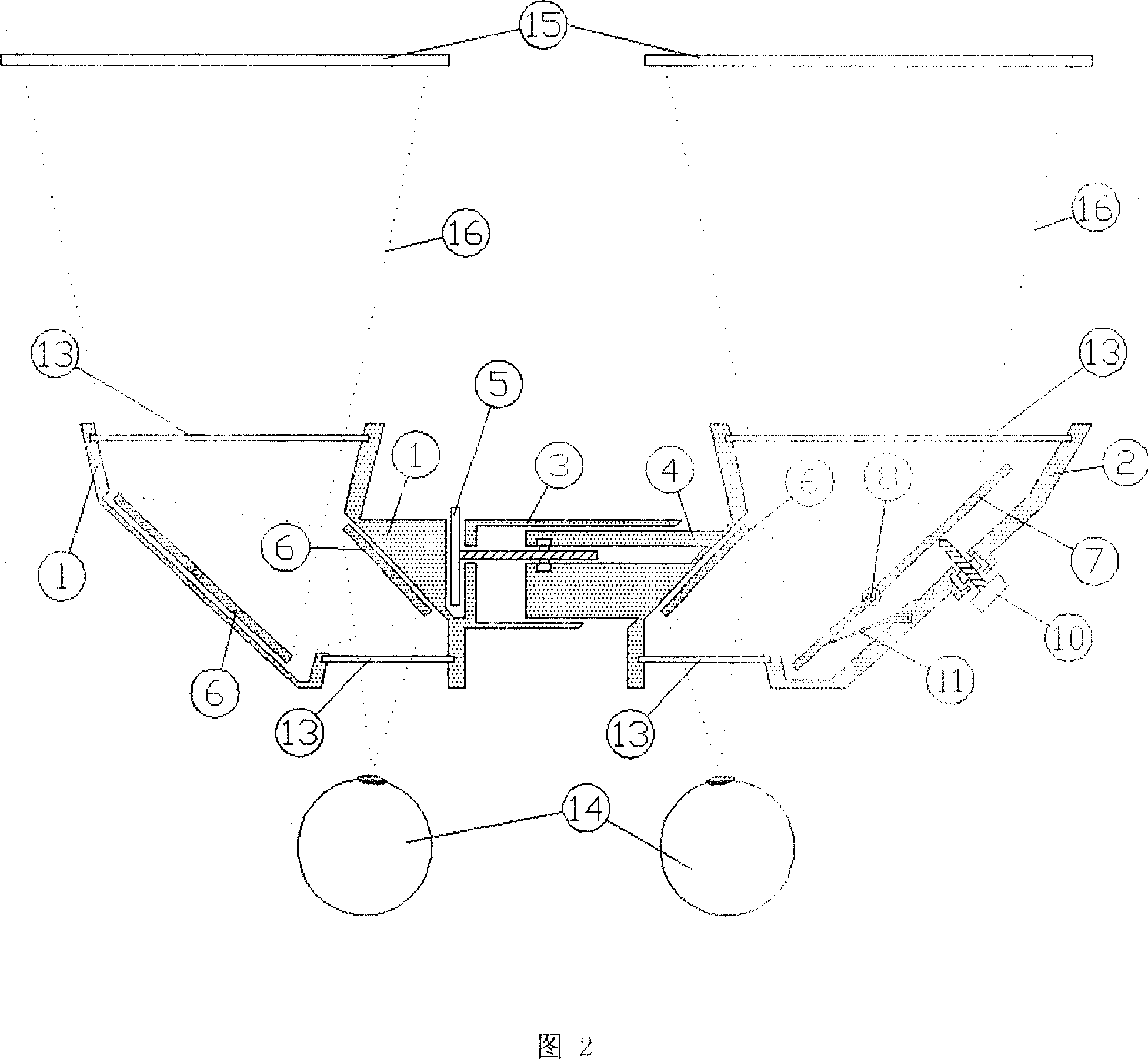

Reflection stereopicture spectroscope

An apparatus which is used for the filed of photograph, art and advertisement is disclosed. It solves the watching problems of stereopictures that the images on the display screen and printed can be viewed too. The optical path of eyes' sight line can be changed by the two groups of reflectors' secondary reflection which is mounted on the left and right lens cones. The children and adults whose pupil distance is different can be satisfied just by adjusting the telescoping device between the left and right lens cones. The included angle of the eyes' sight line can be changed by adjusting the included angle of reflectors. The apparatus is suitable for watching the stereopictures with different distance and size, and it also suitable for the conditions with different distance between the eyes and images. The stereoscopic effects can be seen easily. The optical path is designed according to the normal reading condition of the naked eyes. Using the trapeziform reflectors and the conical lens cones makes the shape smaller. Using the field range finishing holes can eliminate the disturbance of the irrelevant images to make people feel comfortable and vivid.

Owner:郗泉

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com