Special clamp for pneumatic type tire mold slideway

A tire mold and special fixture technology, applied in clamping, clamping devices, manufacturing tools, etc., can solve the problems of long processing time, long production cycle, low utilization rate, etc., to shorten the production preparation cycle, improve labor productivity, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further described below with reference to the accompanying drawings and embodiments.

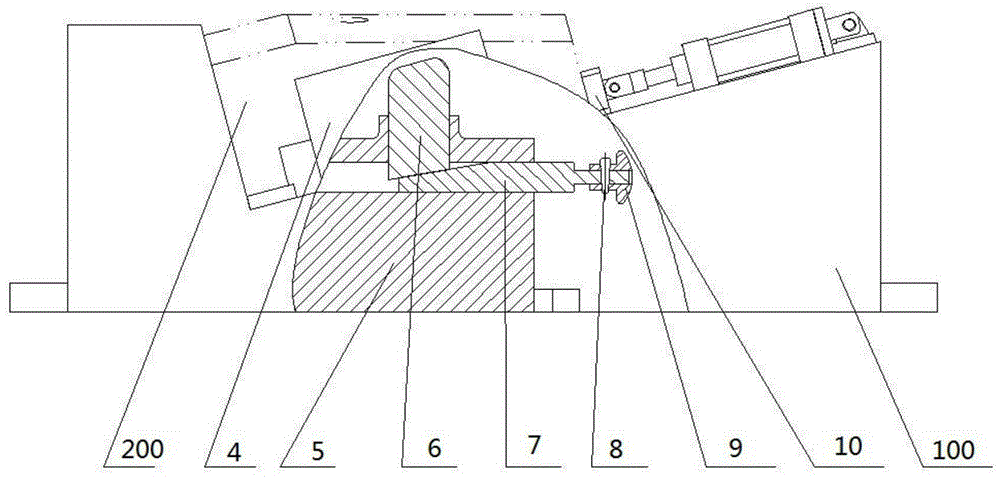

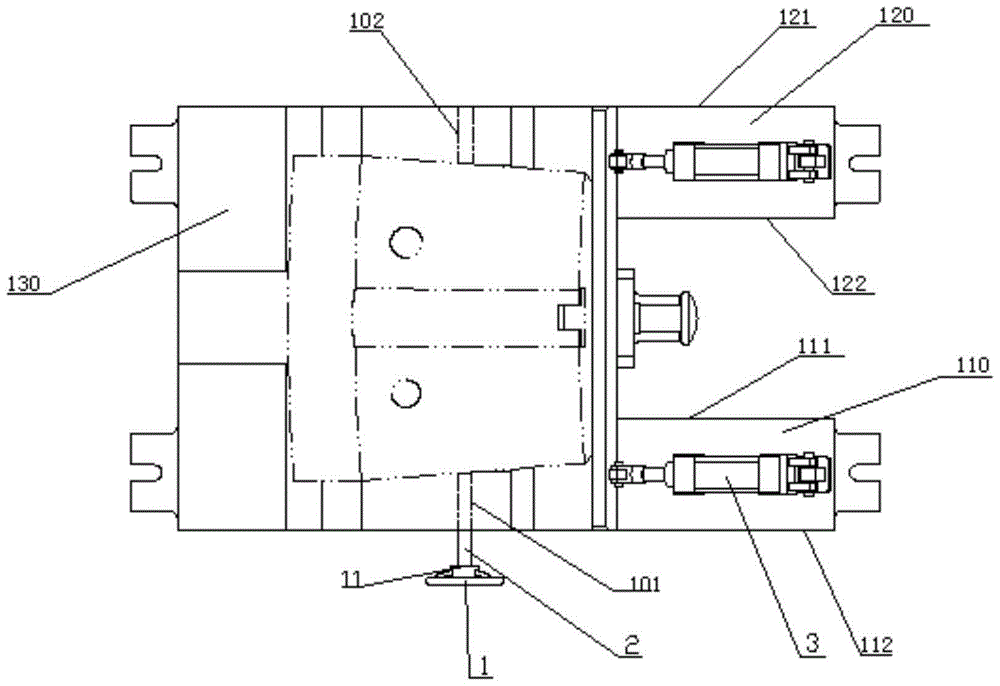

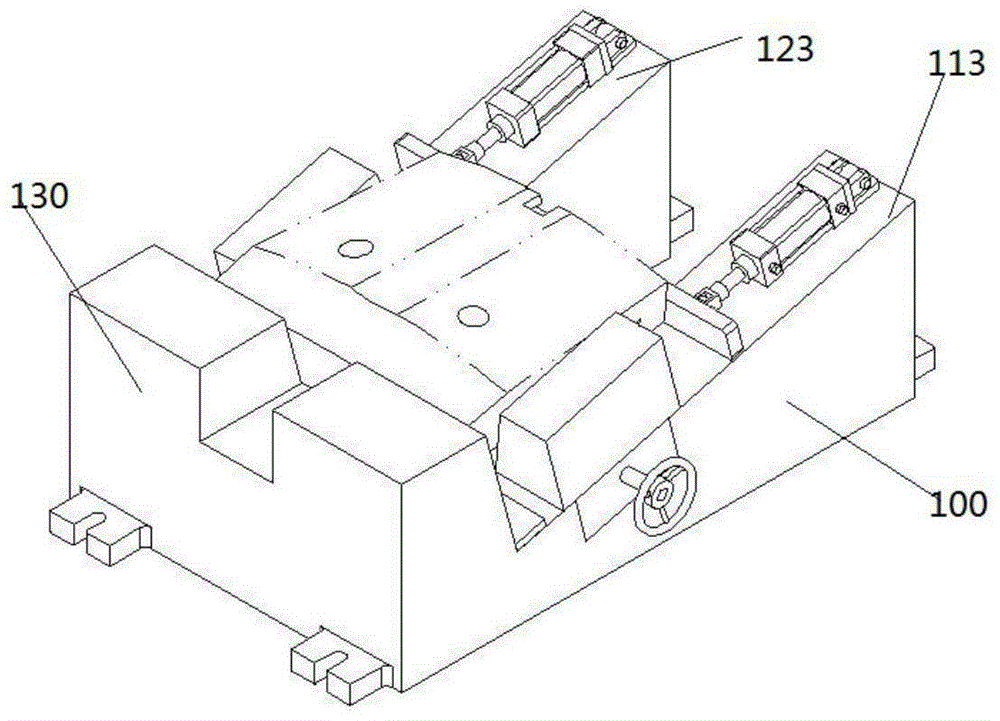

[0031] see Figure 1-7 , in a preferred embodiment of the present invention, a special clamp for pneumatic tire mold slideway includes a clamp body support 100, a tire mold 200, a hand wheel 1, a lead screw 2, a cylinder 3, two side blocks 4, The thrust auxiliary support seat 5, the support 6, the adjusting wedge 7, the conical pin 8, the handle 9 and the stopper 10.

[0032] The clip body support 100 includes a left convex rib 110, a right convex rib 120 and a convex rib connecting portion 130, the left convex rib 110 and the right convex rib 120 are fixedly connected by the convex rib connecting portion 130, and the left convex rib 110 includes a left convex rib 110. Linear groove 101, left convex rib inner surface 111, left convex rib outer surface 112, left convex rib cylinder connecting surface 113, left convex rib block 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com