Hot cutting machine for plastic paper thin film

A technology of hot cutting machine and plastic paper, which is applied in the direction of metal processing, etc., can solve the problems of product quality competitiveness decline, production cost increase, plastic paper film tearing, etc., and achieve the effect of simple manufacture, extended service life and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

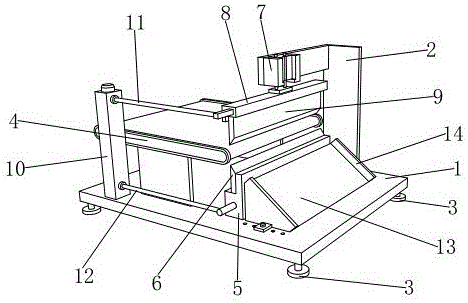

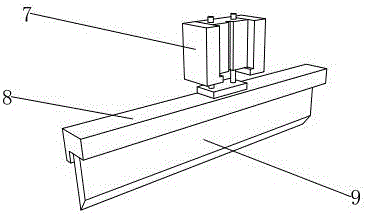

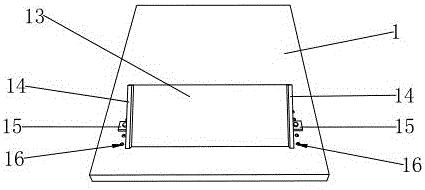

[0018] Such as Figure 1 to Figure 3 As shown, it is a plastic paper film cutting machine of the present invention, including a working platform 1 and a support frame 2, the support frame 2 is arranged on one side of the working platform 1, and supports are provided on the four corners of the bottom surface of the working platform 1 3. The support 3 raises the height of the working platform 1, so that the working platform 1 is separated from the ground without direct contact with the ground. The friction is replaced by the support 3, which prolongs the service life of the working platform 1. The manufacture of the support 3 is simple ,low cost. The working platform 1 is respectively provided with a conveying mechanism 4 and a hot-cutting die holder 5. The conveying mechanism 4 is used to convey the plastic paper film, and the hot-cutting die holder 5 is located on one side of the conveying mechanism 4. The frame 2 is provided with a driving cylinder 7, the driving cylinder 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com