Method for producing vitamin C by esterification reaction-infiltration evaporation barrier separation integral process

A technology of pervaporation membrane and methyl esterification reaction, which is applied in the application field of pervaporation membrane technology, can solve the problems that have not yet involved the esterification synthesis reaction of solid raw materials, long reaction time, and the combined membrane technology not involved in esterification reaction, etc., reaching The effect of stable reaction, small membrane area and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

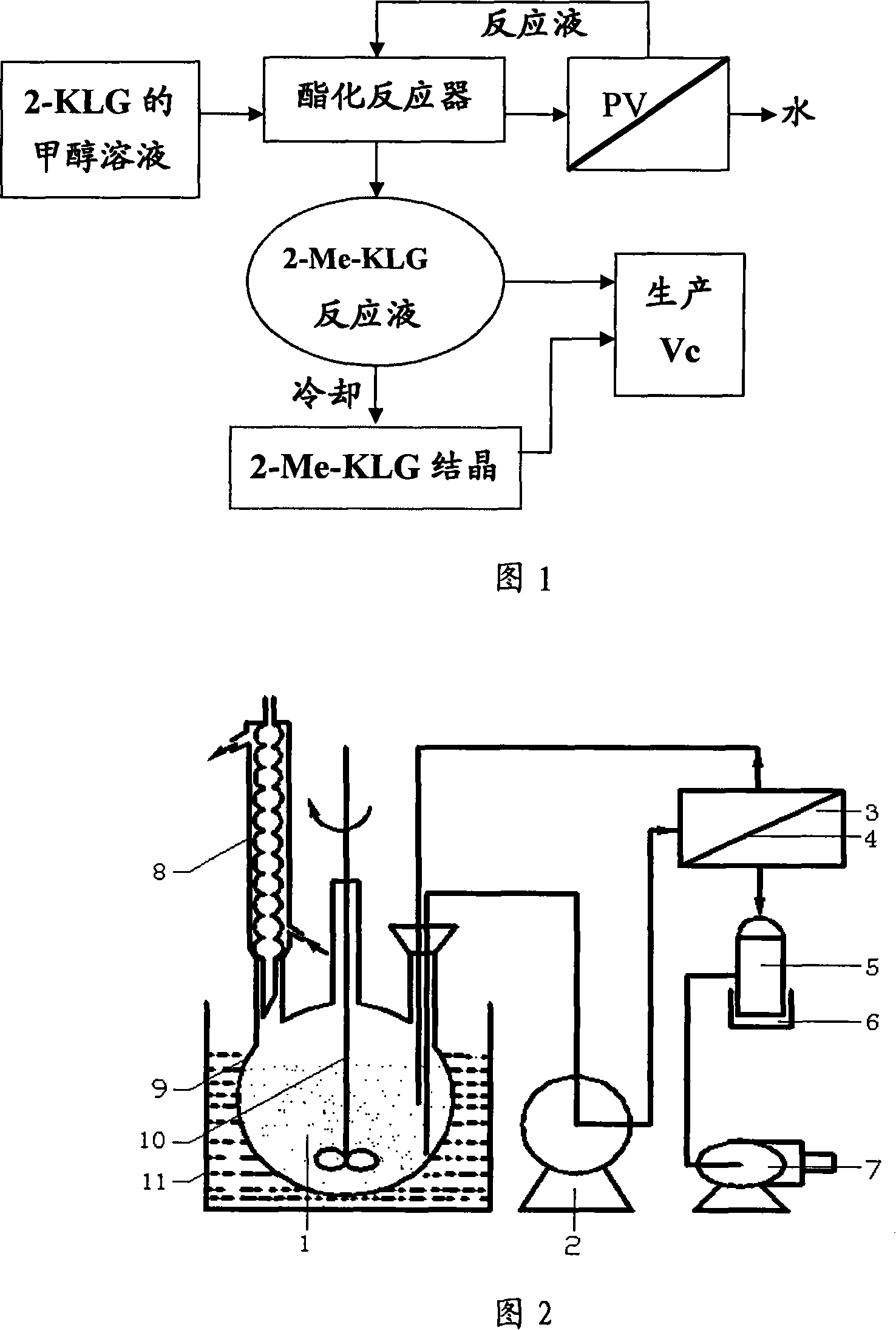

[0027] See Figure 1. The integrated process flow of 2-KLG methyl esterification reaction-pervaporation membrane separation is as follows:

[0028] Preparation of binary reaction solution of 2-KLG and methanol → esterification reaction-pervaporation membrane separation → termination of methyl esterification reaction. The inventive method starts from 2-KLG raw material, through esterification reaction-pervaporation membrane separation integration process, finally obtains for V C Production of highly pure 2-keto-L-gulonic acid methyl ester liquid.

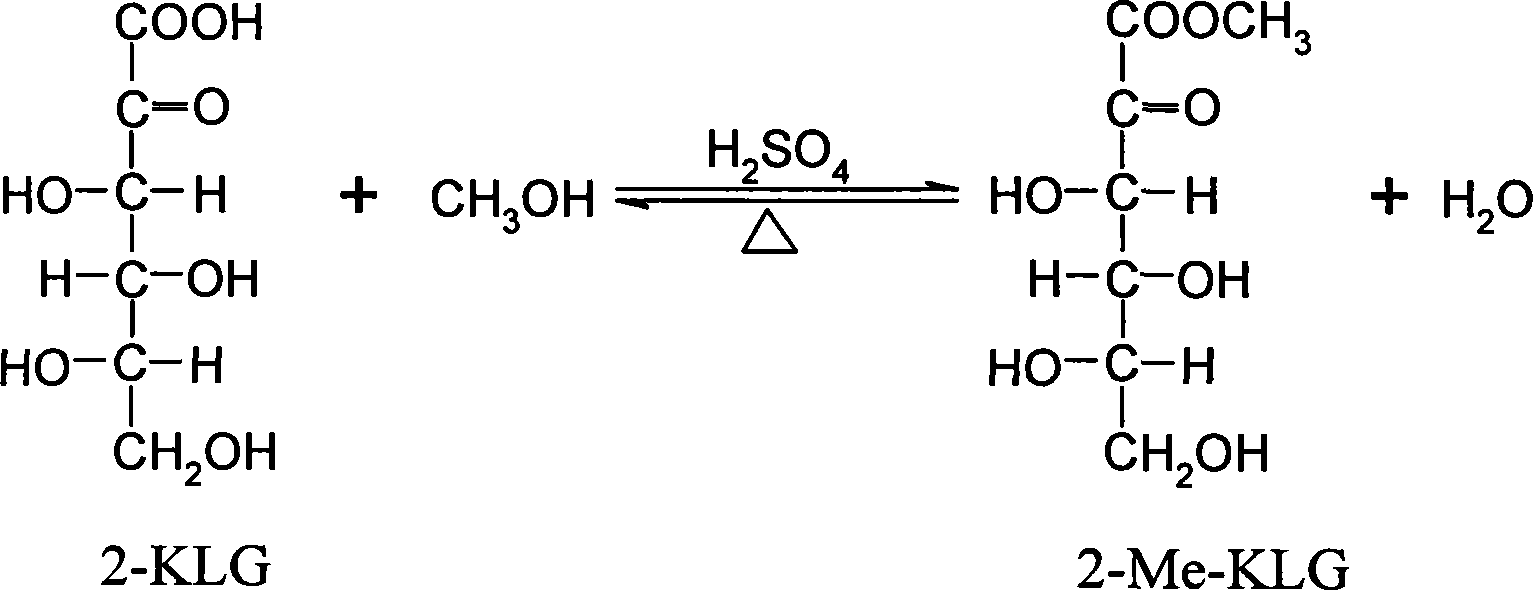

[0029] The esterification reaction-pervaporation membrane separation was carried out in the experimental setup of the integrated process shown in Figure 2. Get 400mL methanol (density 0.792g / mL), inject in the there-necked flask that has stirrer, reflux condenser, open stirrer, then inject 120.43g purity and be 91% 2-KLG (methanol and 2-KLG mass ratio are 2.89), the temperature of the reaction solution was kept constant at 50°C, aft...

Embodiment 2

[0034] According to the operation of embodiment 1, wherein, only changing the ratio of the effective membrane area of the pervaporation membrane to the volume of the reaction solution is 0.083cm -1 , the vacuum on the downstream side of the membrane was 600Pa, and at the end of the methyl esterification reaction, HPLC analysis showed that 93.86% of 2-KLG in the reaction solution was converted into 2-Me-KLG, and 479 mL of light yellow 2-keto-L-cologne was obtained methyl ester solution.

Embodiment 3

[0036] According to the operation of Example 1, wherein only the mass ratio of methanol to 2-KLG is changed to 1.74, the vacuum on the downstream side of the membrane is 670Pa, HPLC analysis shows that 98.17% of the 2-KLG in the reaction solution is converted into 2-Me-KLG , Obtain 516mL light yellow 2-keto-L-gulonic acid methyl ester liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com