Novel process for improving grade of sulfate cinder iron

A technology of sulfuric acid slag and iron grade, applied in solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of inability to obtain economic benefits, low iron recovery rate, difficult to treat waste liquid, etc. The effect of increasing ore volume, recovery rate and reducing grinding cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The raw material is sulfuric acid slag produced by an acid factory in Guangxi. The raw material contains about 44% iron grade and about 80% +0.15mm particle size. Using shaker gravity separation, when the grinding fineness is -0.074mm 90%, the iron grade is 61%, and the recovery rate is 51%. After adopting the new process of the invention, when the iron grade is 61%, the recovery rate can reach 58%, which is 7 percentage points higher than the recovery rate of the traditional process.

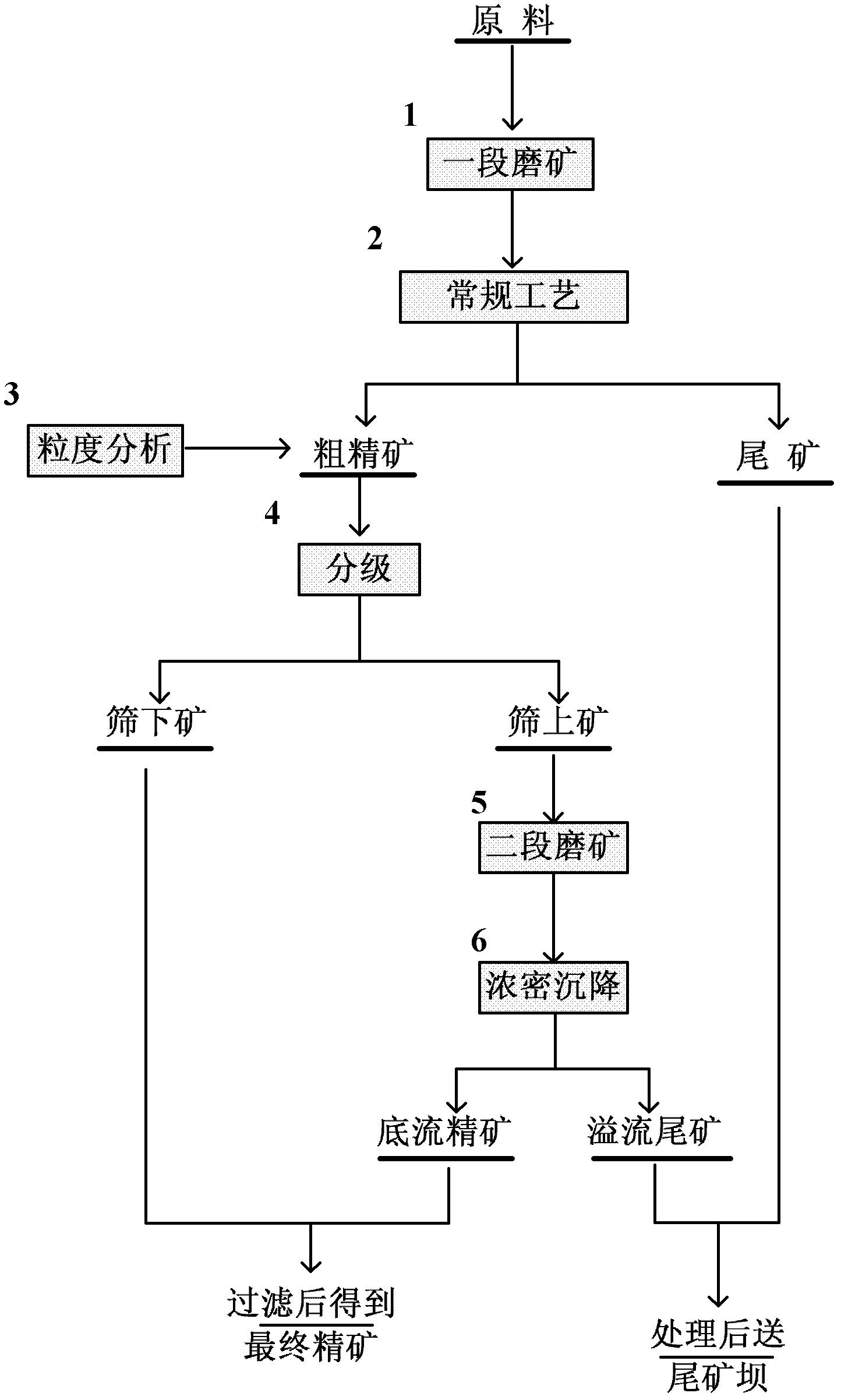

[0021] use as figure 1 Shown technological process, concrete operation is as follows:

[0022] (1) The raw material enters the grinding system, so that the fineness of the material reaches -0.074mm 60%, and the iron is initially dissociated;

[0023] (2) Obtain coarse concentrate and tailings through shaker gravity separation;

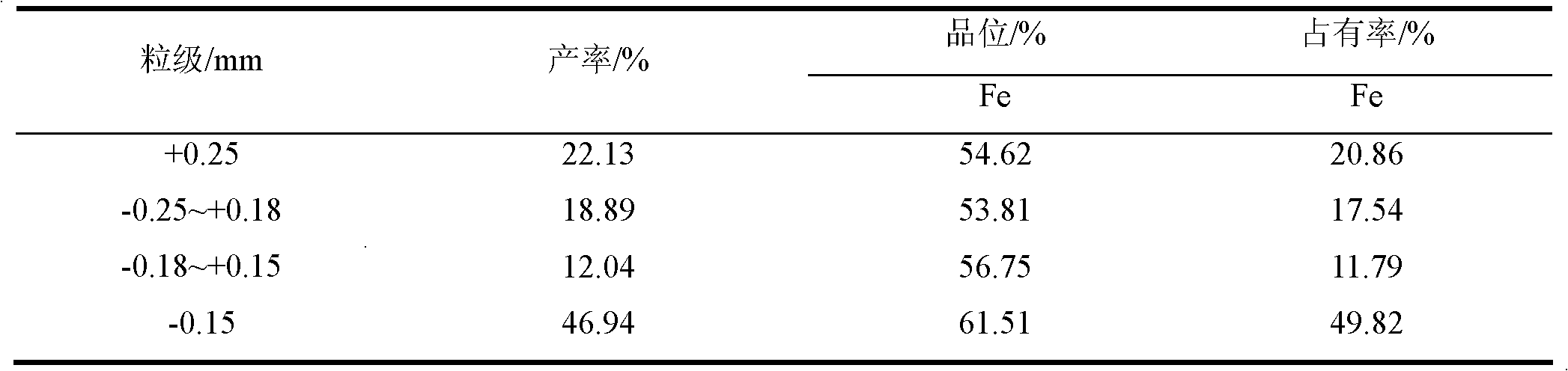

[0024] (3) Use 0.15mm, 0.18mm, 0.25mm sieves to sieve 1000g of crude concentrate samples for particle size sieving, and analyze the iron grade distribution o...

Embodiment 2

[0032] The sulfuric acid slag from an acid factory in Hebei has a raw material iron grade of about 38% and a particle size of +0.15mm of about 70%. Using shaker gravity separation, when the grinding fineness is -0.074mm 85%, the iron grade is 60%, and the recovery rate is only 37%. After adopting the new process of the invention, when the iron grade is 60%, the recovery rate reaches 43%, which is 6 percentage points higher than the recovery rate of the traditional process.

[0033] use as figure 1 Shown technological process, concrete operation is as follows:

[0034] (1) The raw material enters the grinding system, so that the fineness of the material reaches -0.074mm 50%, and the iron is initially dissociated;

[0035] (2) Obtain coarse concentrate and tailings through shaker gravity separation;

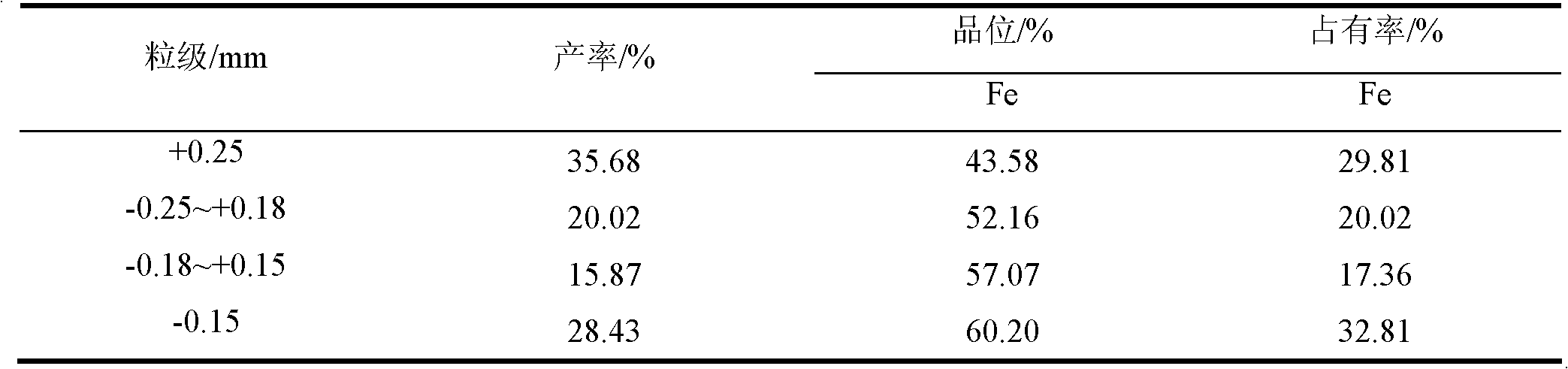

[0036] (3) Use 0.15mm, 0.18mm, 0.25mm sieves to sieve 1000g of crude concentrate samples for particle size sieving, and analyze the iron grade distribution of each particle size...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com