Composite materials

a technology of composite materials and materials, applied in the field of composite materials, can solve the problem of high biocompatibility of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

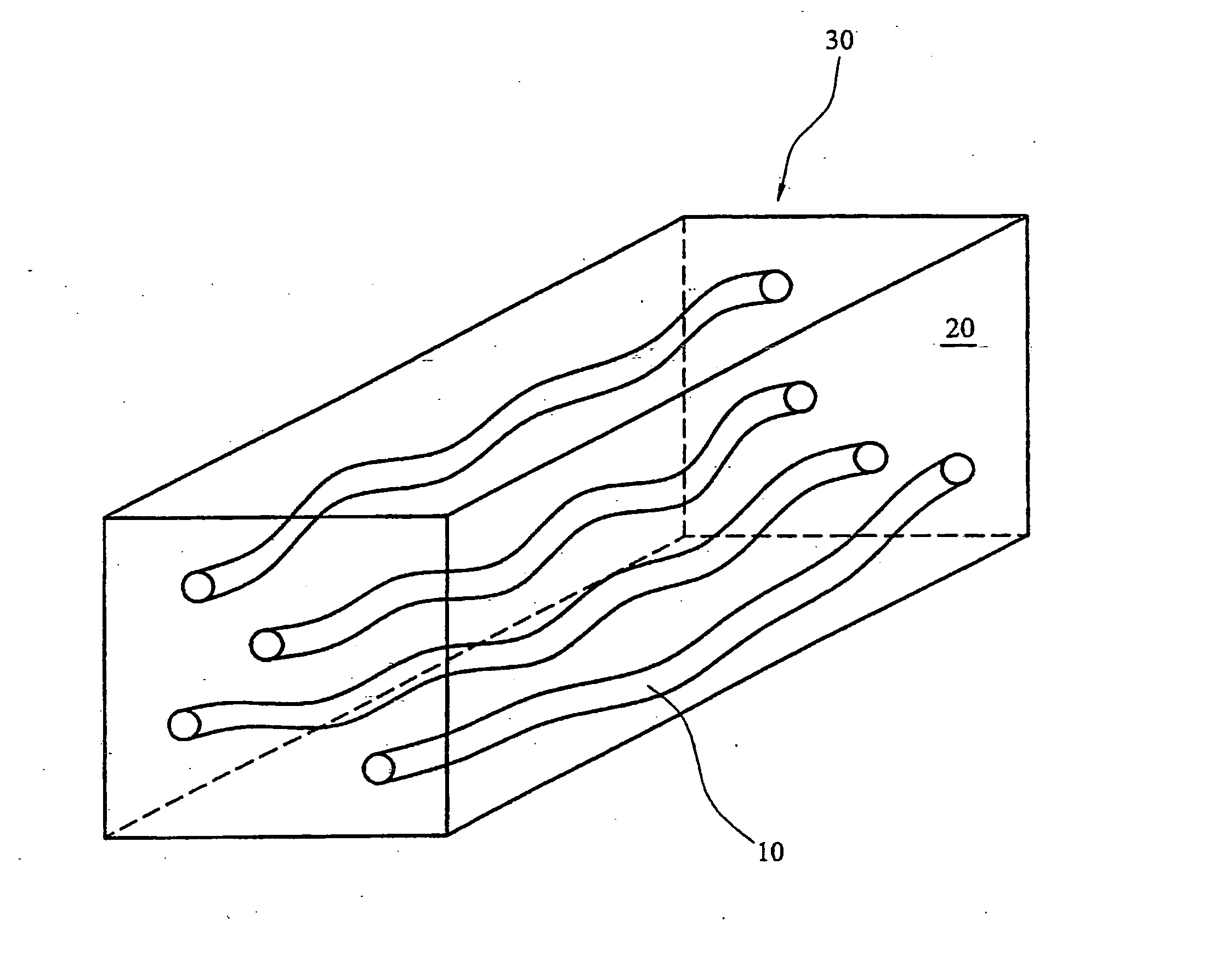

Preparation of Composite Materials from Carded Antheraea Pernyii Silk Filaments.

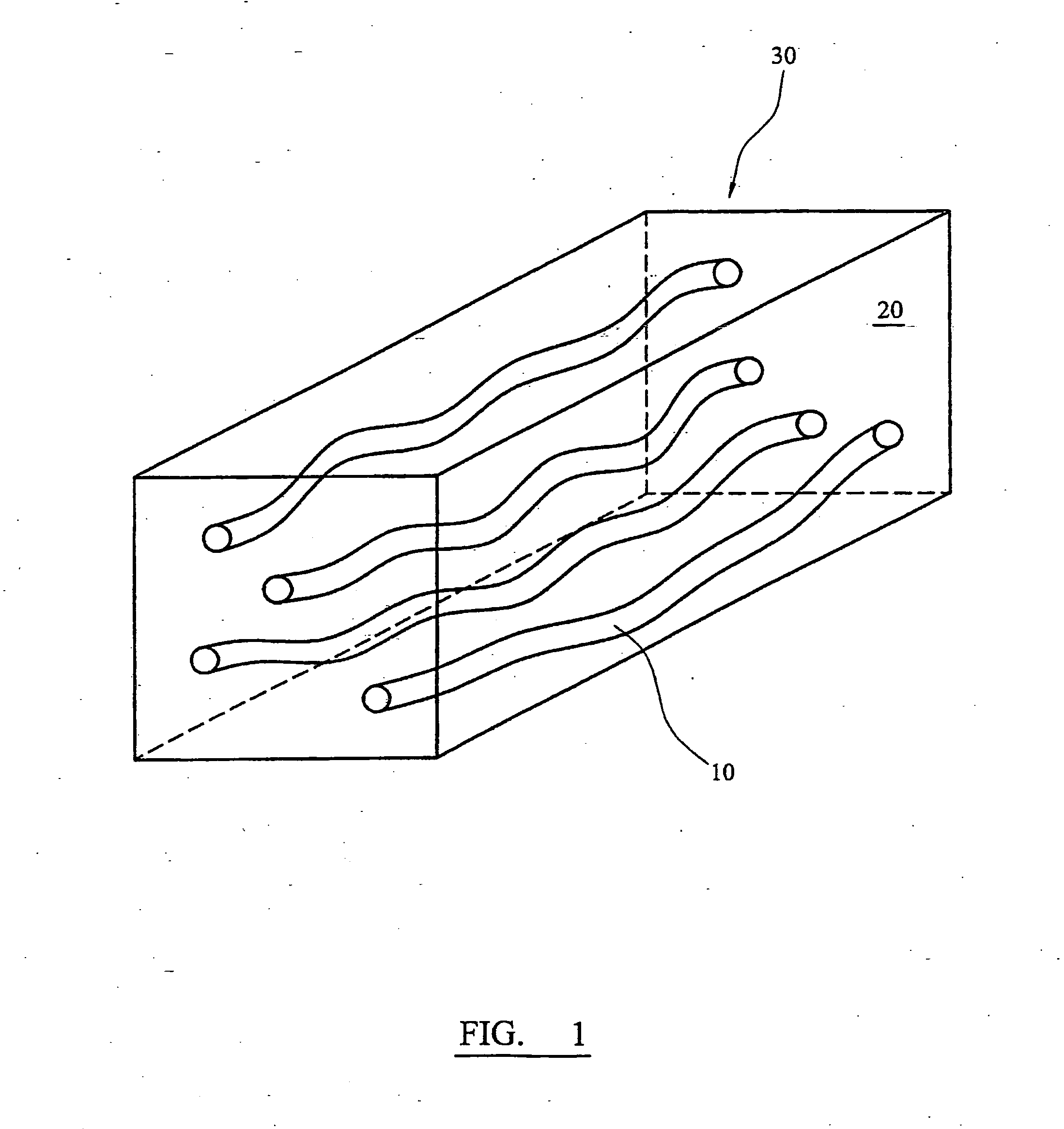

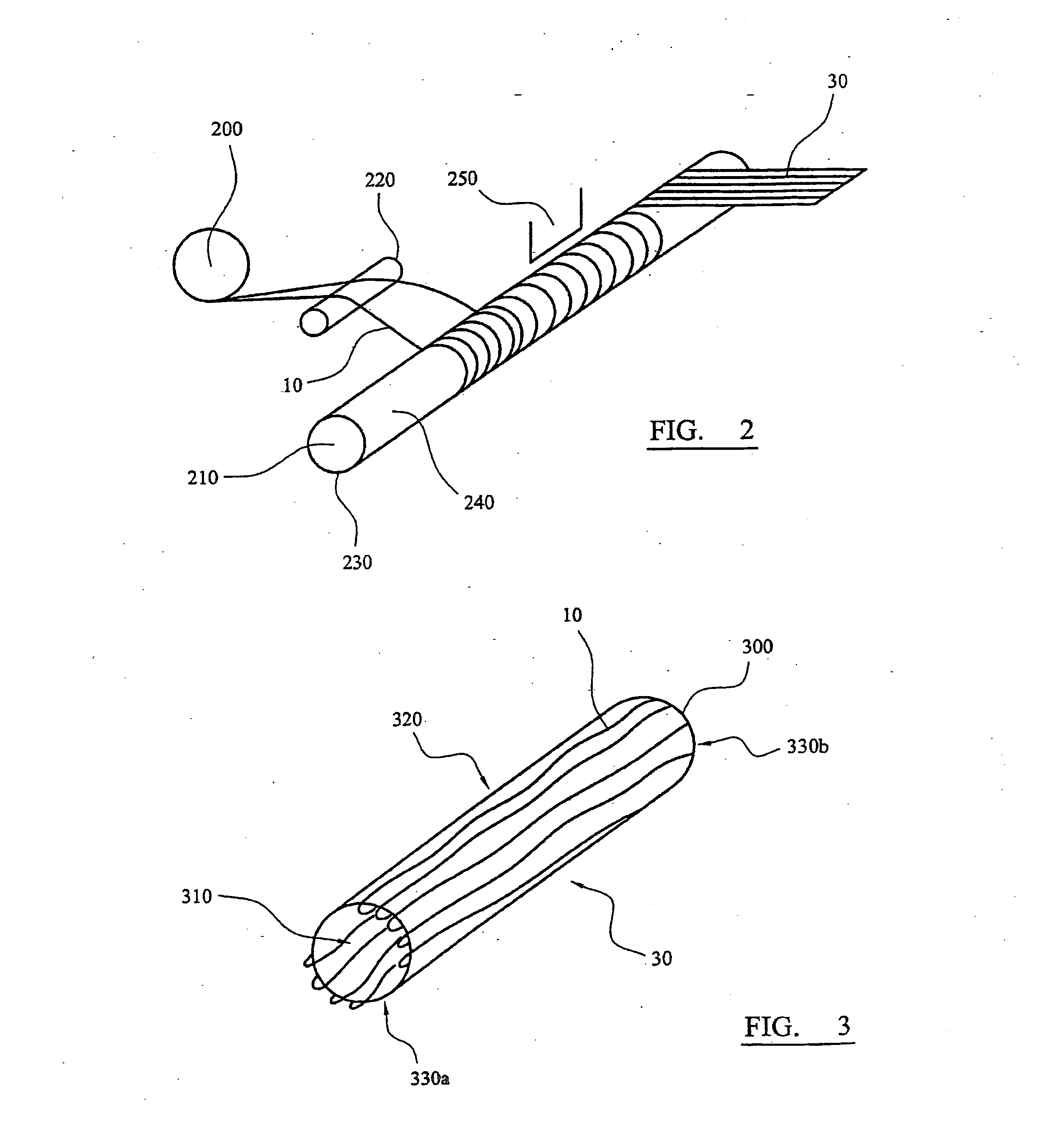

[0039] Antheraea pernyii silk filaments prepared from degummed silk cocoons were obtained from a commercial supplier. The carded silk from the sepin was smoothed into flat sheets and gently tensioned to pull the silk filaments parallel. Keeping the silk tensioned they were wound on to cylindrical formers 0.25 mm to 30 mm in diameter. The largest cylinders were made of glass and had a substantially smooth surface. The Smallest cylinders 0.25 mm were prepared by coating a thin stiff wire in low melting point wax. Cylindrical formers with intermediate diameters were made from low melting point wax. The silk filaments were generally laid circumferentially on the largest formers but were laid in a helical fashion on the smaller cylindrical formers.

[0040] Care was taken to ensure a uniform dense lay of filaments was achieved on the cylindrical formers. The silk filaments at the ends of the thin cylindrical ...

example 2

Demonstration of RGD Putative Integrin Binding Sites on Antheraea spp Heavy Chain Fibroins and their Location Adjacent to Turns.

[0043] The published sequences of silk proteins were searched on the TrBMBL and SwissPROT data bases for the well established cell binding sequence RGD and the putative cell binding sites PPSRN and KNEED. The sequence triplet RGD is of considerable interest as it forms part of the mechanism used in multicellular organisms to stick many types of cells to the connective tissue framework of the body. The RGD triplet on the silk-like connective tissue protein fibronectin binds specifically to integrins. Integrins are a class of cell adhesion molecules. They are found intercalated into the lipid bilayer of the cell membrane with the fibronectin binding (RGD recognition) site protruding into the extracellular space. Thus the RGD recognition site of integrins is available-to bind cells to the connective tissue-framework via RGD triplets on fibronectin molecules....

example 3

[0050] Tensile Data on Antheraea Pernyi Cyanoacrylate Composite

TABLE 1Tensile test data (n = 6) for wet strips of composite material containinga high density of well-oriented Antheraea pernyii filaments set in acyanoacrylate matrix. The strips (50 mm gauge length, average width10.5 mm and thickness 0.4 mm) were strainedparallel to the filament orientationUTS(Mpa)Strain to failureEnergy / kg (JKg)Modulus (Mpa)Average:310.15019001000SD8.0800.016590227

[0051] For comparison, the ultimate tensile stress of a typical-low alloy steel is in the region of 830 Mpa and a modulus of 200 Mpa but steel has a density of approximately 6 times that of the silk composite thus weight for weight this steel is less than 4 times as strong as the silk composite. The tensile data for the silk composite are comparable with that of that of two synthetic implantable materials (table 2).

TABLE 2Tensile data for wild silk cyanoacrylate composite comparedwith two synthetic implantable materials.Poly εA. pernyi ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com