Magnetic sealing guide rail system and powder laying system suitable for powder sintering equipment

A technology of sintering equipment and guide rail system, applied in the field of 3D printing, can solve the problems affecting the accuracy of parts, high surface finish, low coil spring life, etc., and achieve the effect of overcoming motion defects, good application prospects, and smooth transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

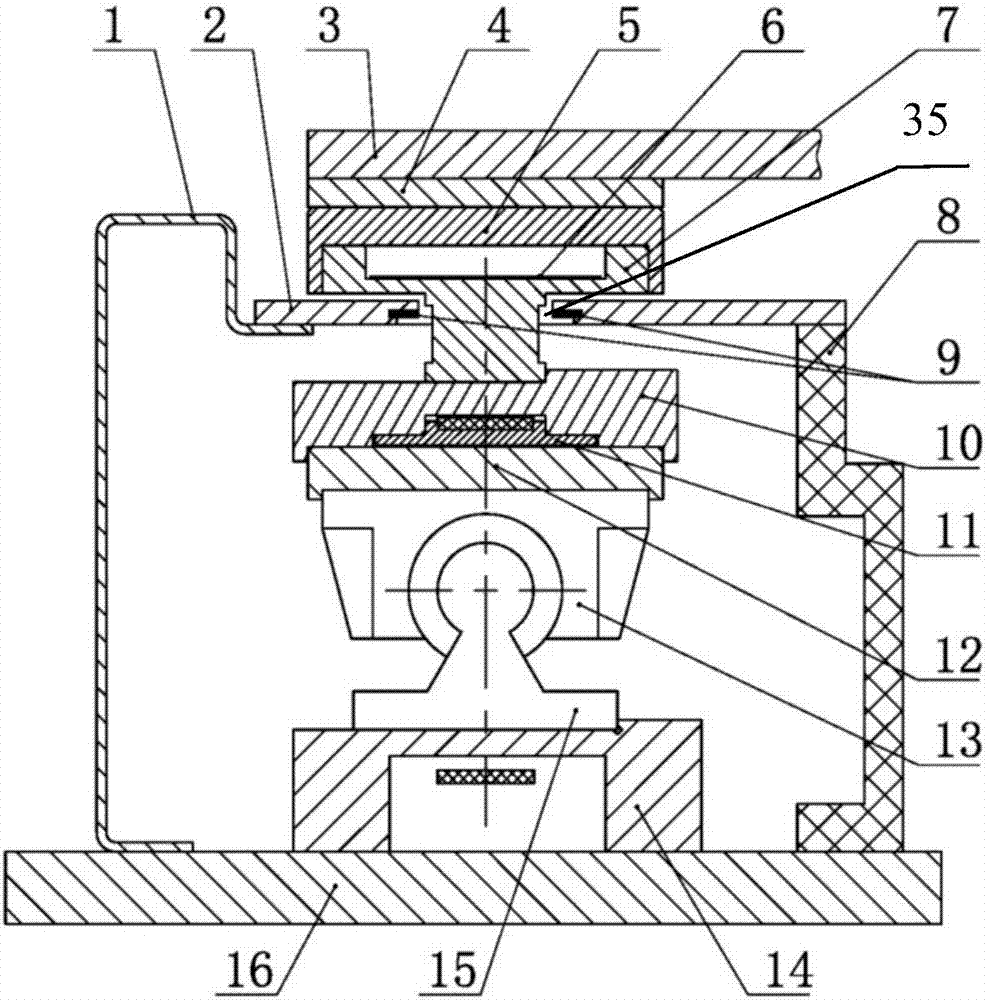

[0040] like Figure 1~Figure 5 As shown, a magnetic seal rail system suitable for powder sintering equipment, which is connected to the rail 15, includes side protection plates 1 and inner protection plates 8 on both sides of the rail 15, and a magnet-inlaid aluminum cover on the top of the rail 15. 2. T-shaped guide bridge 7, guide rail cover 5, sliding assembly, and transmission assembly. A groove body 35 is opened in the middle of the magnetic-inlaid aluminum cover plate 2, and permanent magnets 9 are arranged on both sides of the groove body 35. The groove body 35 of the magnetic aluminum cover plate 2 is covered with a stainless iron sheet 6 with a width greater than its groove width, and the length of the stainless iron sheet 6 is greater than that of the groove body 35 of the magnetic aluminum cover plate 2. Length; one end of the stainless iron sheet 6 is fixed on the front end or the rear end of the magnetic aluminum cover plate 2 with an iron sheet briquetting block ...

Embodiment 2

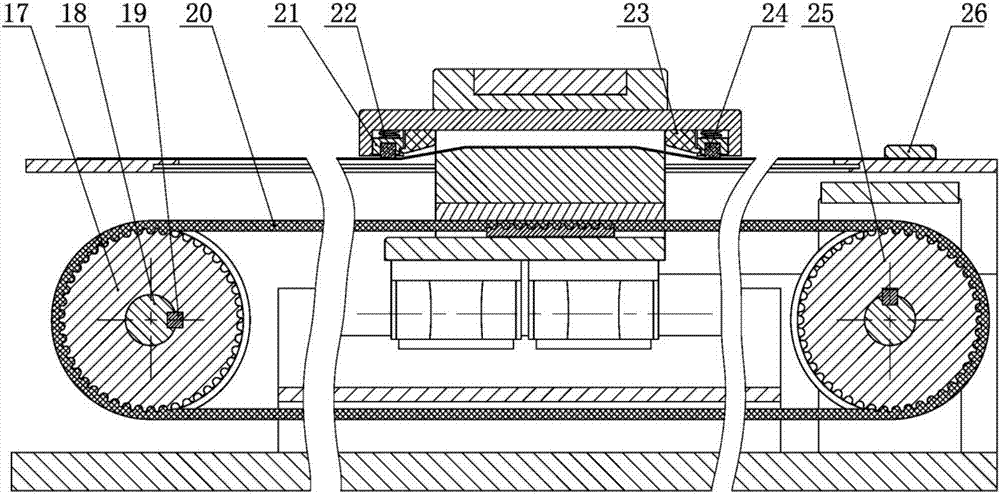

[0056] On the basis of Example 1, such as Figure 6 As shown, the pulley support assembly 25 includes two supports 27, a top cover 32, a synchronous pulley 31, a wheel shaft 29 with two ends smaller than the middle, and a bearing 30; the top cover 32 covers the two supports 27 Above, the synchronous pulley 31 is located between the two supports 27; the axle 29 is provided with a keyway, and the axle 29 is connected with the synchronous pulley 31 through the key 33 arranged in the keyway, so as to rotate together; The two ends of the axle 29 are respectively connected with the two supports 27 through bearings 30 .

[0057] like Figure 6 As shown, the support 27 is provided with a wheel shaft 29 mounting holes, and the outer side of the wheel shaft 29 mounting holes is provided with an end cover 28; the two ends of the wheel shaft 29 are fixedly connected with the inner ring side of the bearing 30, and the bearing 30 The side of the inner ring of the bearing 30 fits with the ...

Embodiment 3

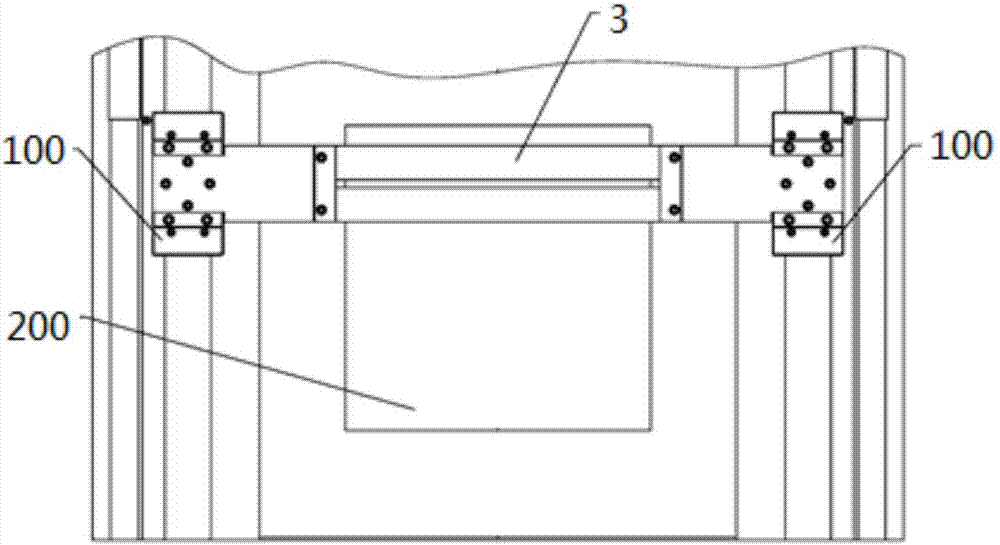

[0060] A powder spreading system for powder sintering equipment, such as figure 1 and Figure 7 As shown, it includes rails 15 on both sides, a magnetic sealing rail system 100 on the rails 15, and a powder spreading device 3. The magnetic sealing rail system 100 adopts the magnetic Sealed guide rail system; both ends of the powder spreading device 3 are connected to the magnetic seal guide rail system 100 on both sides of the track, the equipment working cylinder 200 is located in the middle between the two sides of the track 15, and the powder spreading device 3 is located in the equipment working cylinder 200; the magnetic seal guide rail system 100 moves on the track 15, driving the powder spreading device 3 to reciprocate above the equipment working cylinder 200.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com